Device for testing underground space spallation strength and application thereof

A technology of underground space and testing equipment, applied in the direction of measuring equipment, strength characteristics, instruments, etc., can solve the stress situation that cannot accurately reflect the damage of spalling, and there is no testing method and device that considers the strength of spalling. Accurately obtain spalling strength and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

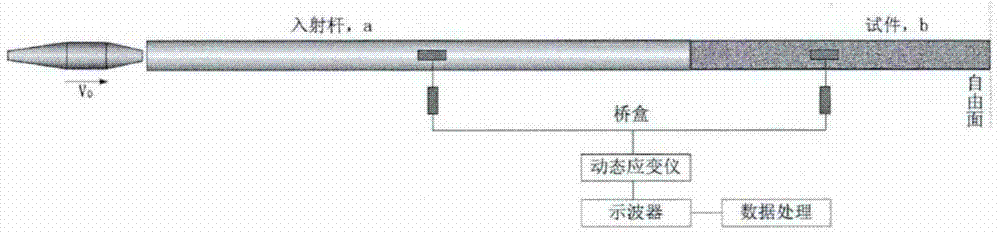

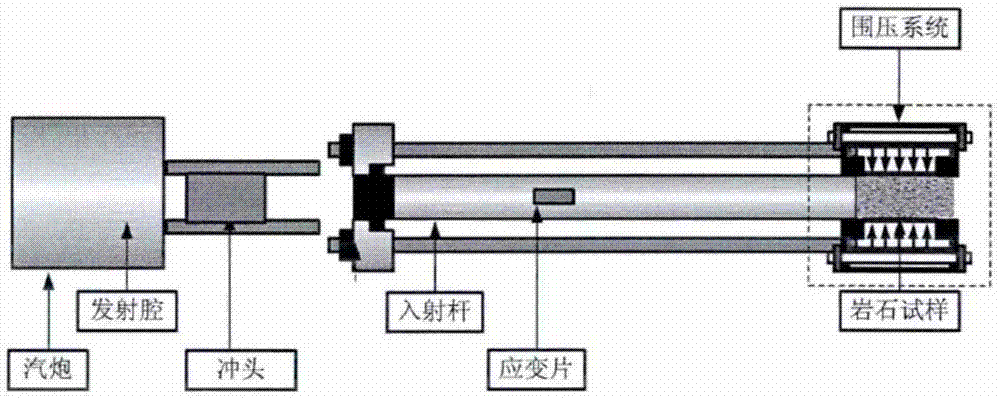

Method used

Image

Examples

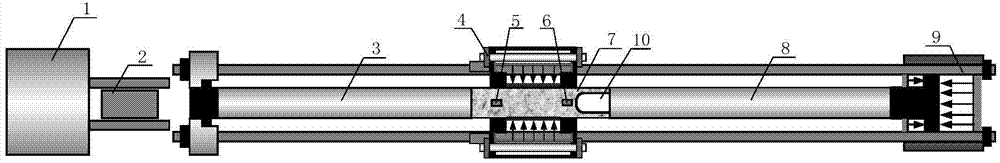

Embodiment 1

[0085] In this embodiment, the diameters of the incident rod, the sample, and the transmission rod are equal, wherein the size of the incident rod is Φ50×2000 mm, and the size of the transmission rod is Φ50×1500 mm;

[0086] step one

[0087] Measure sample density ρ=2740kg / m 3 Finally, according to the designed size, it is processed into a cylindrical sample 7; the end of one end of the sample 7 is provided with a U-shaped groove; the length of the sample 7 is 20cm; the two ends of the cylindrical sample 7 and the test piece The surface of the sample is polished flat and smooth so that the unevenness is less than 0.02mm, so as to reduce the distortion and dispersion effect generated by the stress wave in the process of propagating inside the sample 7; the size of the U-shaped groove is , and the width B of the notch is 3cm , the groove depth H is 6cm;

[0088] step two

[0089] Air gun 1, punch 2, incident rod 3, confining pressure providing device 4, first set of strain g...

Embodiment 2

[0110] In this embodiment, the diameters of the incident rod, the sample, and the transmission rod are equal, wherein the size of the incident rod is Φ50×2000 mm, and the size of the projection rod is Φ50×1500 mm;

[0111] Step A

[0112] After measuring the rock density ρ=2740, according to the designed size, it is processed into a cylindrical sample 7; the end of one end of the sample 7 is provided with a U-shaped groove; the length of the sample 7 is 20cm; The two ends of sample 7 and the surface of the sample are ground flat and smooth so that the unevenness is less than 0.02 mm, so as to reduce the distortion and dispersion effect produced by the stress wave in the process of propagating inside the sample 7; the size of the U-shaped groove is, The slot width B is 3cm, and the slot depth H is 6cm;

[0113] Step B

[0114] Air gun 1, punch 2, incident rod 3, confining pressure providing device 4, first set of strain gauges 5, second set of strain gauges 6, transmission ro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com