Method of fabricating solar cells with p-doped cdte layers of reduced thickness

A technology of solar cells and doped layers, applied in the direction of final product manufacturing, sustainable manufacturing/processing, circuits, etc., can solve problems such as limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

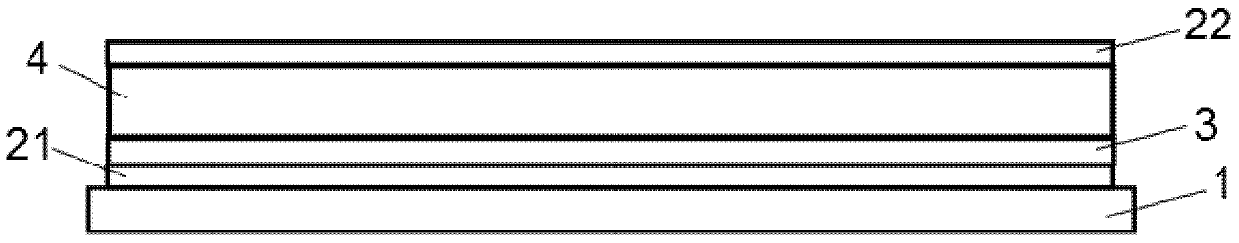

[0042] In the following, the method according to the invention is explained in a first exemplary embodiment showing the production of a solar cell in a layer structure, without any limitation being meant for said embodiment.

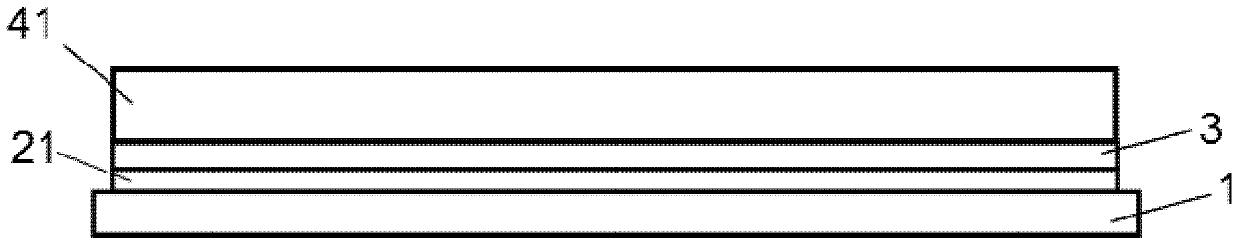

[0043] as in Figure 2a As shown in , the front contact (21) and the CdS layer (3) have been applied on the transparent substrate (1) by means of methods according to the prior art. As a front contact ( 21 ), a 450 nm thick transparent bilayer [fluorine-doped tin oxide (350 nm) as conductive layer and tin oxide (100 nm) as high-resistance buffer layer] was applied (as TCO). The CdS layer (3) reaches a thickness of 90nm and is deposited using the CSS technique. On it, a first CdTe layer ( 41 ) according to the invention is deposited with a thickness of 1.6 μm. The deposition process was carried out as a CSS process at a substrate temperature of 530°C, resulting in large grains of the deposited layer.

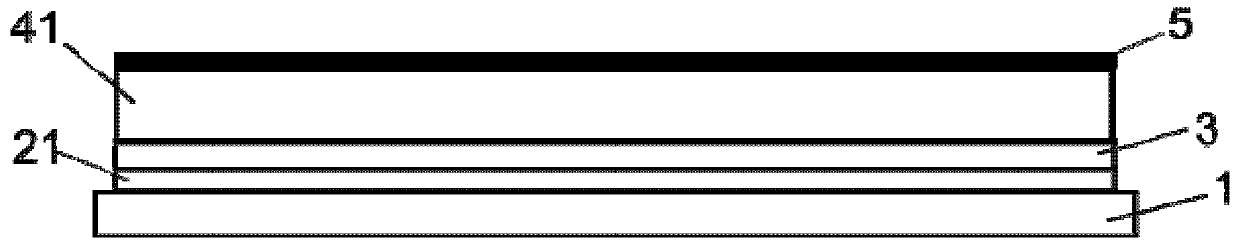

[0044] Figure 2b A sacrificial doped layer (5) a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com