A boiler flue gas waste heat recovery and utilization device

A flue gas waste heat and boiler technology, which is applied in the field of industrial boilers, can solve the problems of low preheating utilization rate and insufficient coal preheating, and achieves the effects of good filtering, improving service life and avoiding cumbersome operations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

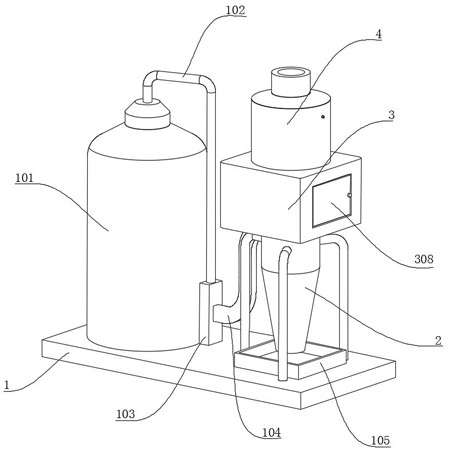

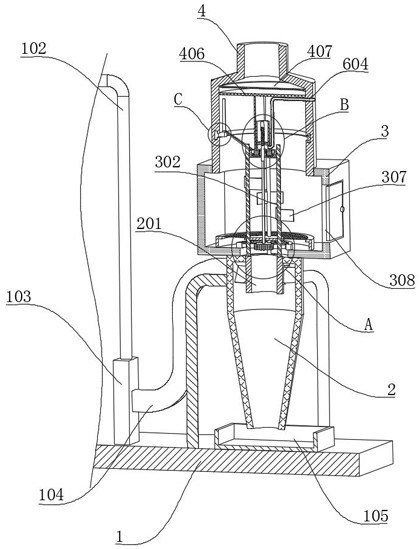

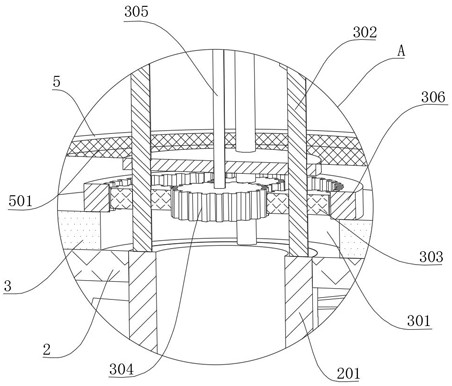

[0031] refer to Figure 1-9 , a boiler flue gas waste heat recovery and utilization device, including a base 1, the upper surface of the base 1 is fixedly connected with an ash removal tube 2 through a bracket, such as figure 1 and figure 2 As shown, the upper part of the ash removal tube 2 is cylindrical, and the lower part is a truncated cone, so that the flue gas with fly ash enters the ash removal bin 2, and the flue gas will rotate along the inner wall of the ash removal bin 2 from top to bottom , fly ash and other large particles of sundries, under the action of centrifugal force, cling to the inner wall of the ash removal tube 2 and fall down, while the flue gas after pre-dust removal will swirl upward along the center line of the ash removal tube 2 and pass through the rotating tube 201 to be discharged. into the preheating box 3, so that the flue gas is pretreated, and the fly ash in the flue gas is removed, so that the flue gas can directly contact with the coal, b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com