Patents

Literature

46results about "Flue gas duct system" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

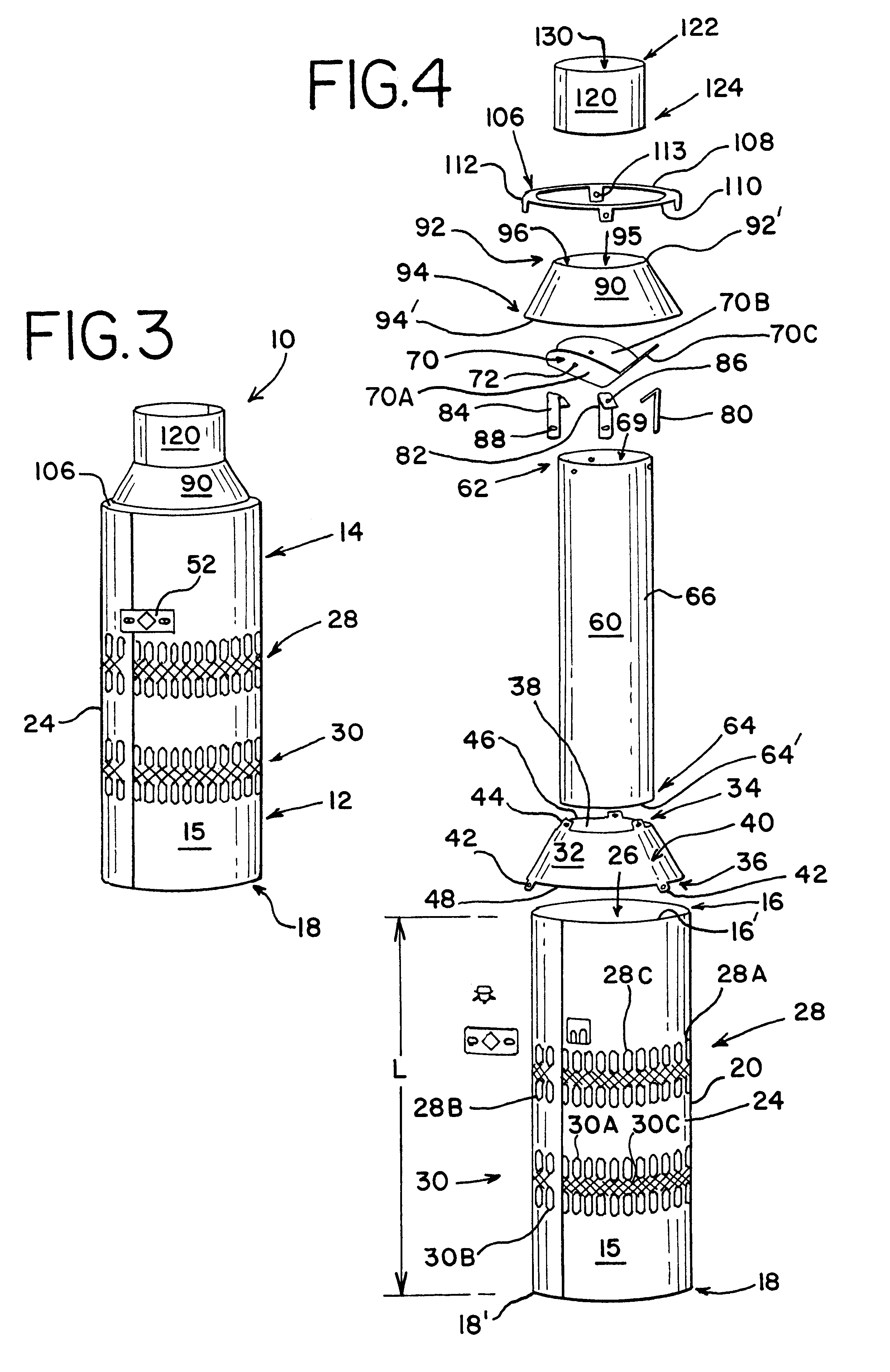

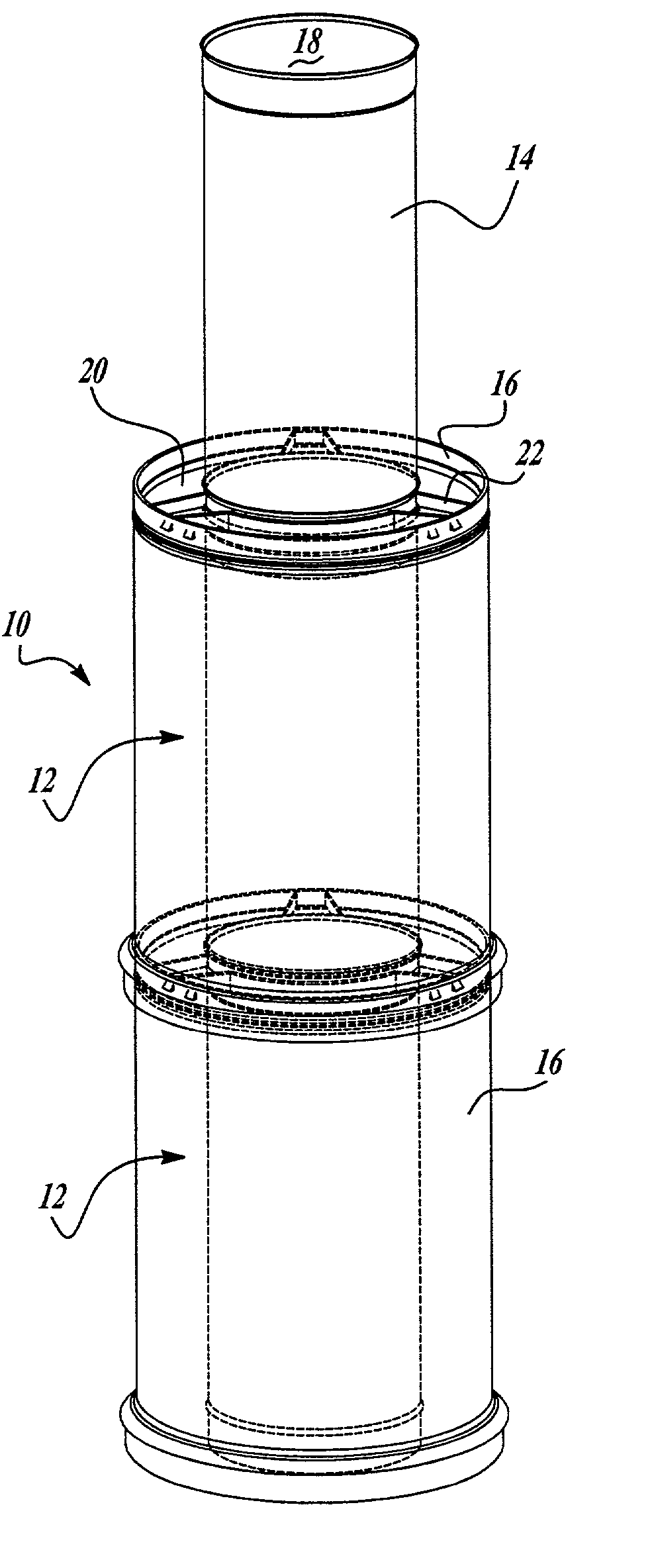

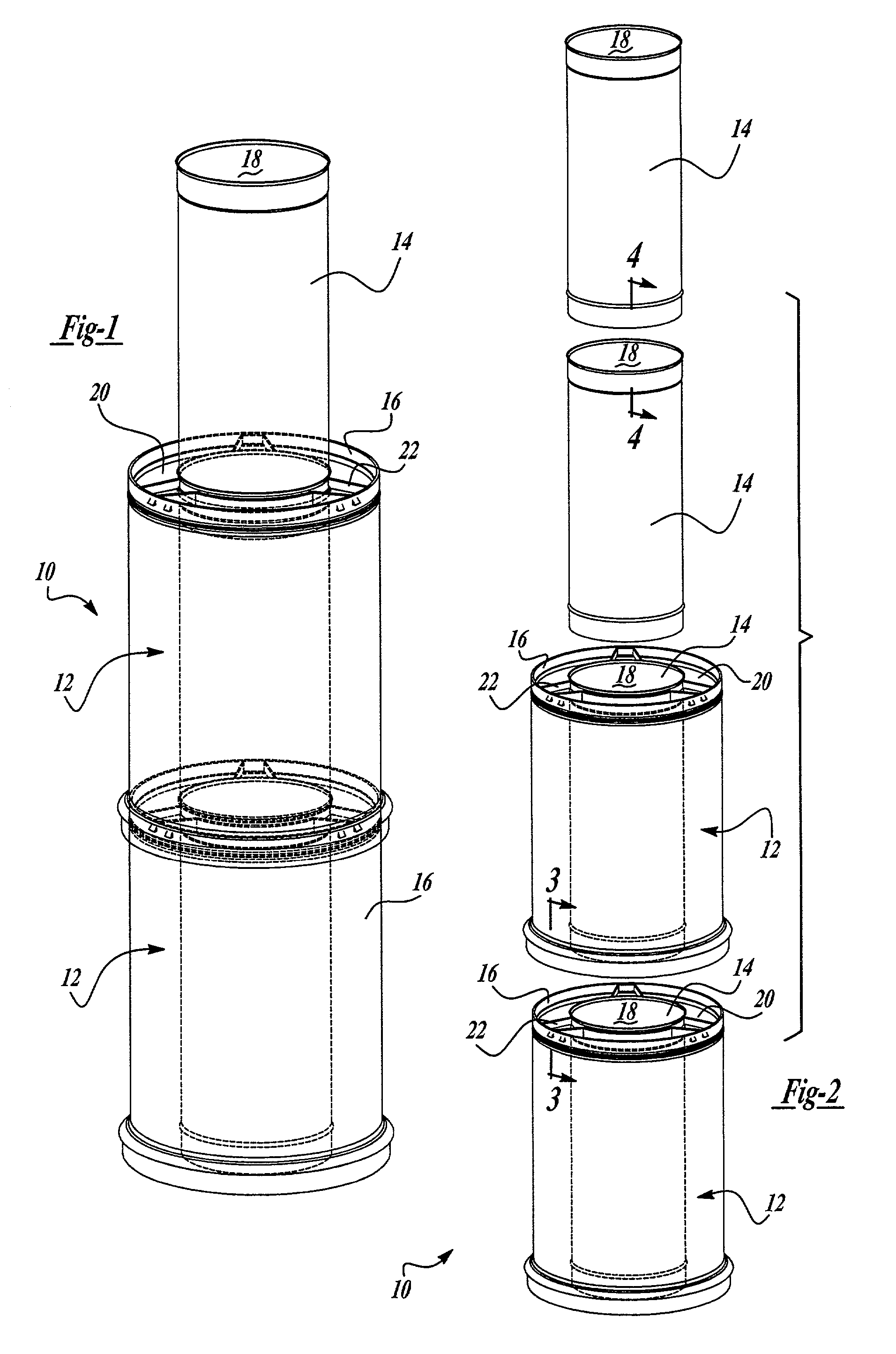

Direct venting vent pipe

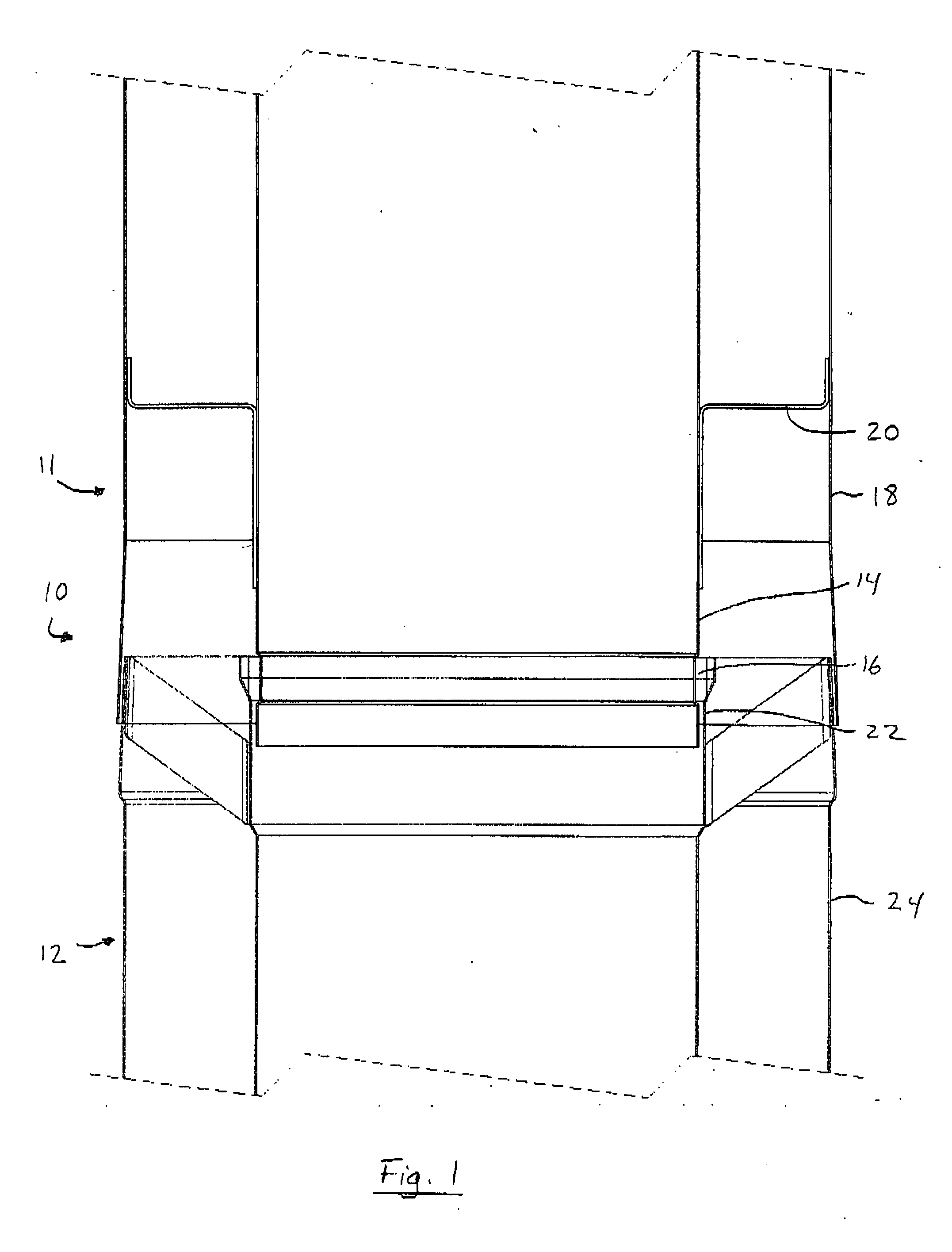

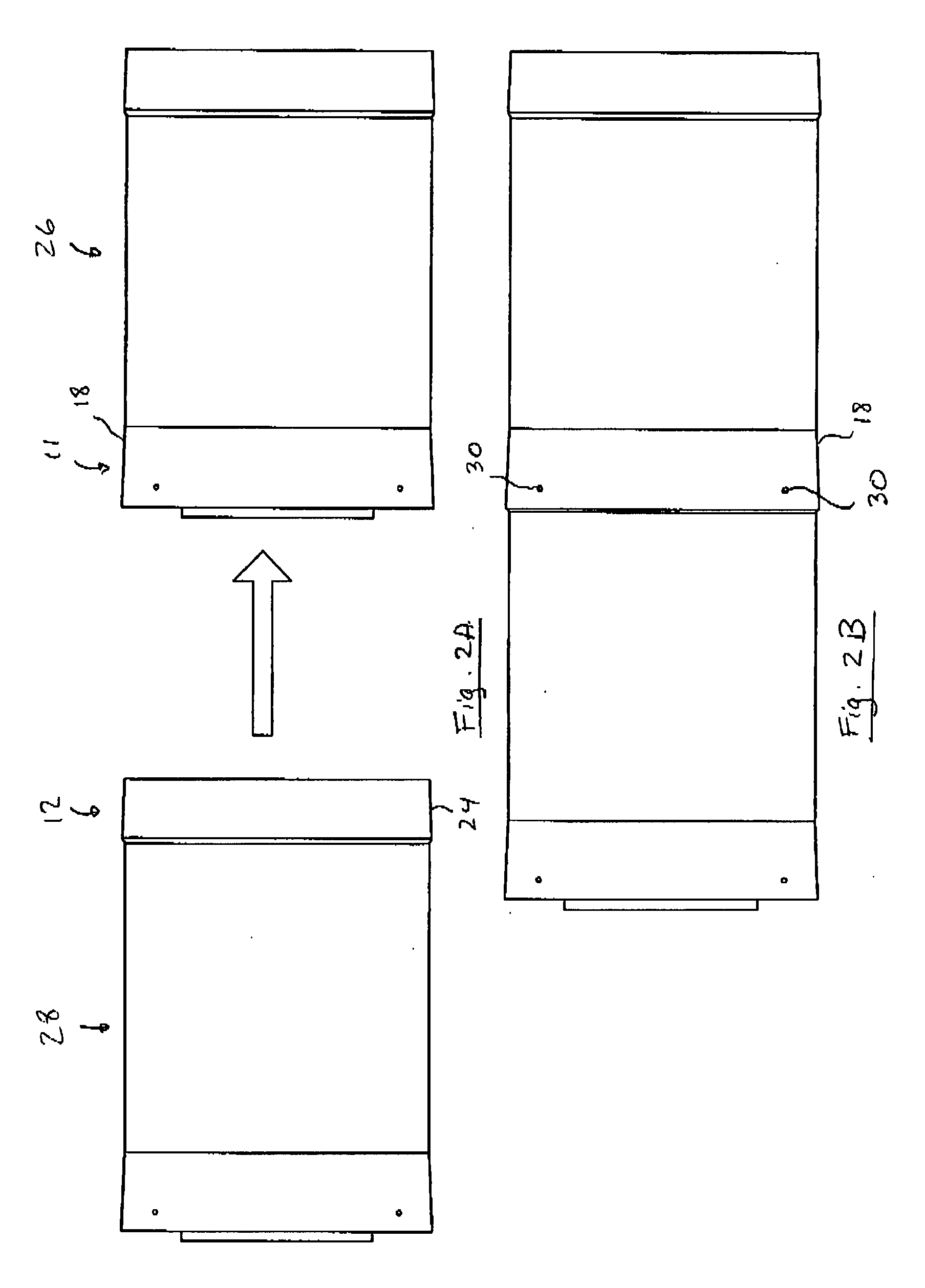

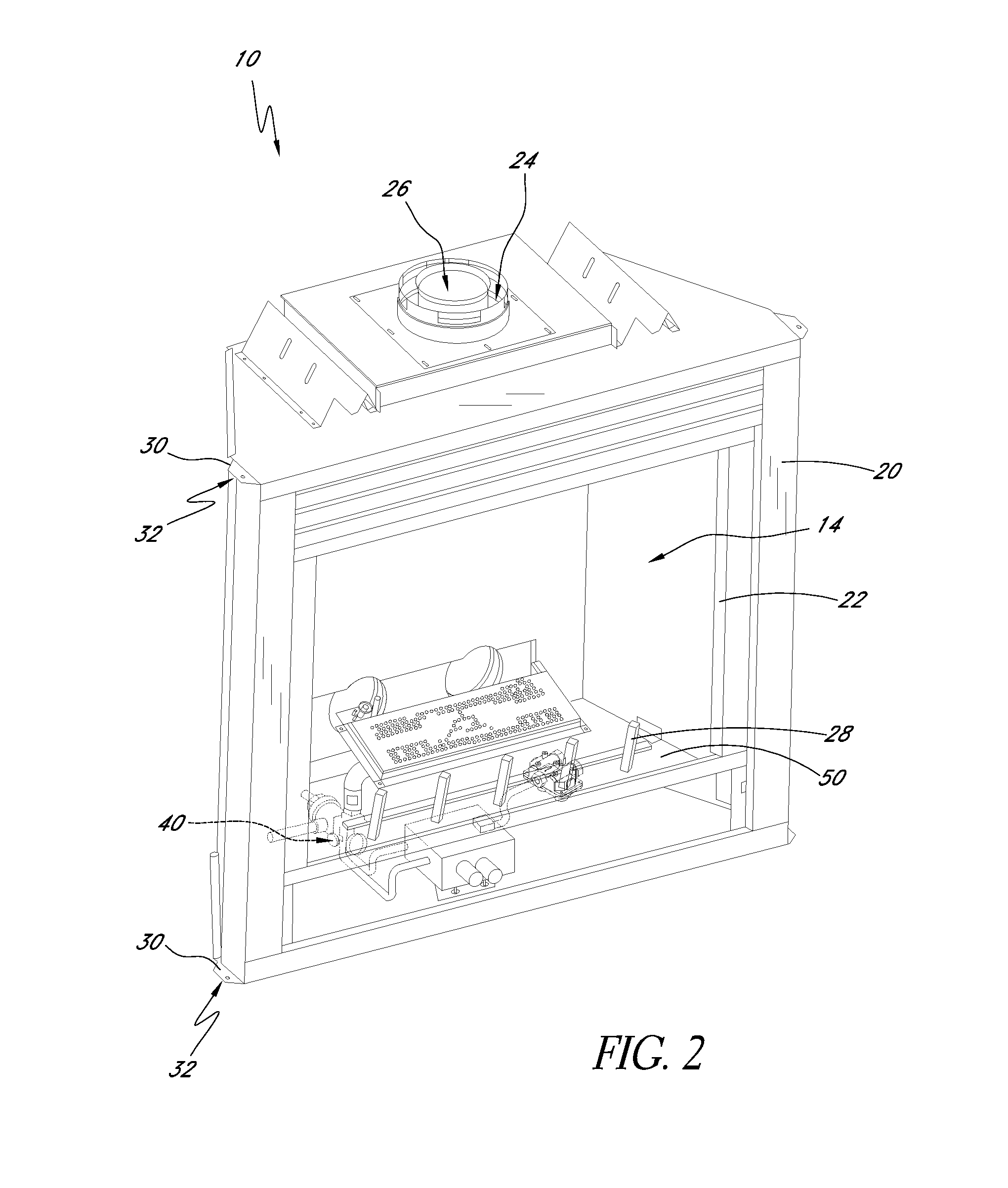

InactiveUS6634352B2Facilitate run of unrestricted lengthEfficient combustionPipe supportsDomestic stoves or rangesDirect combustionDouble wall

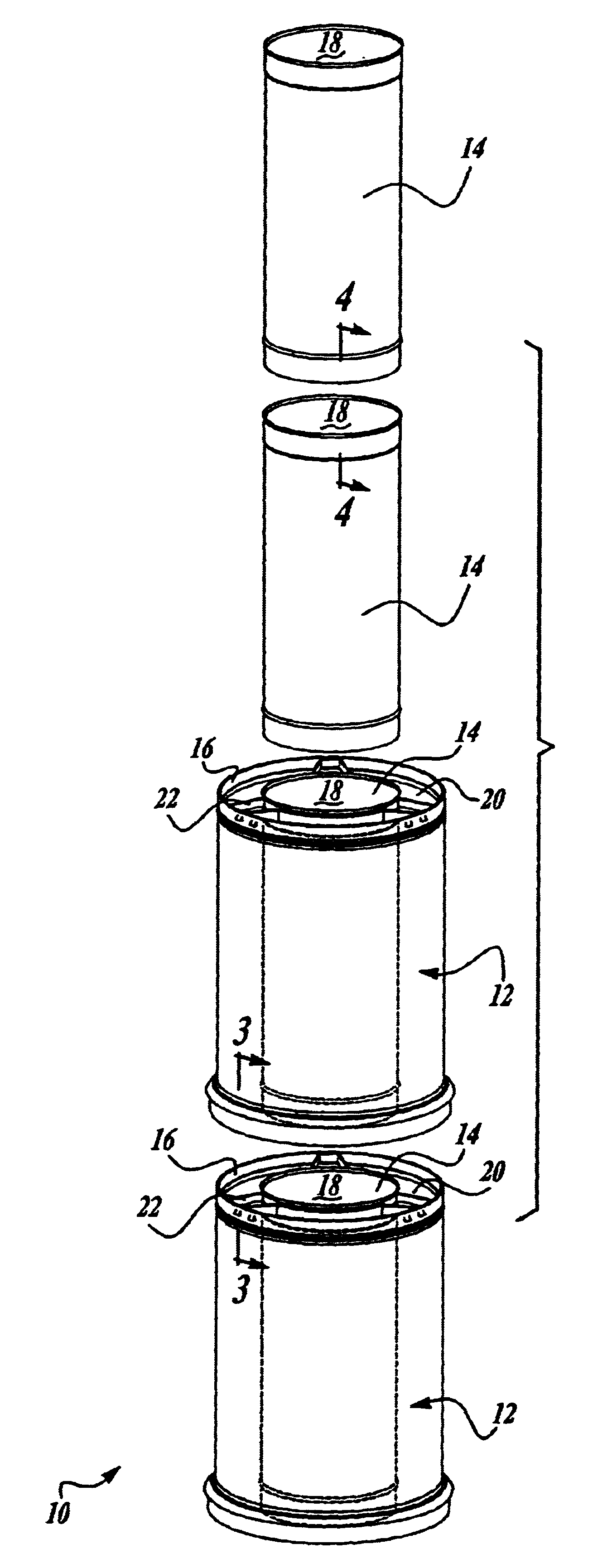

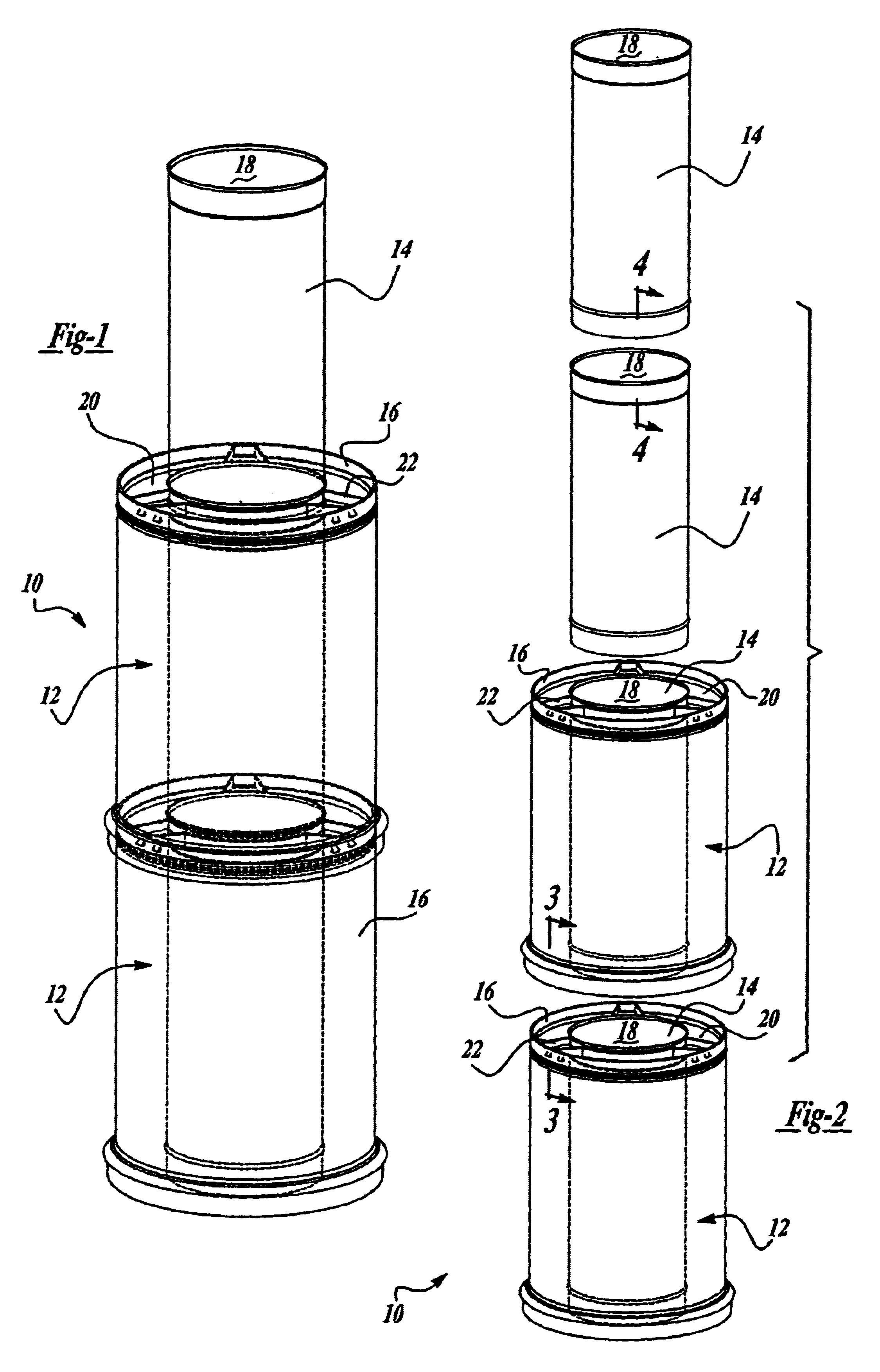

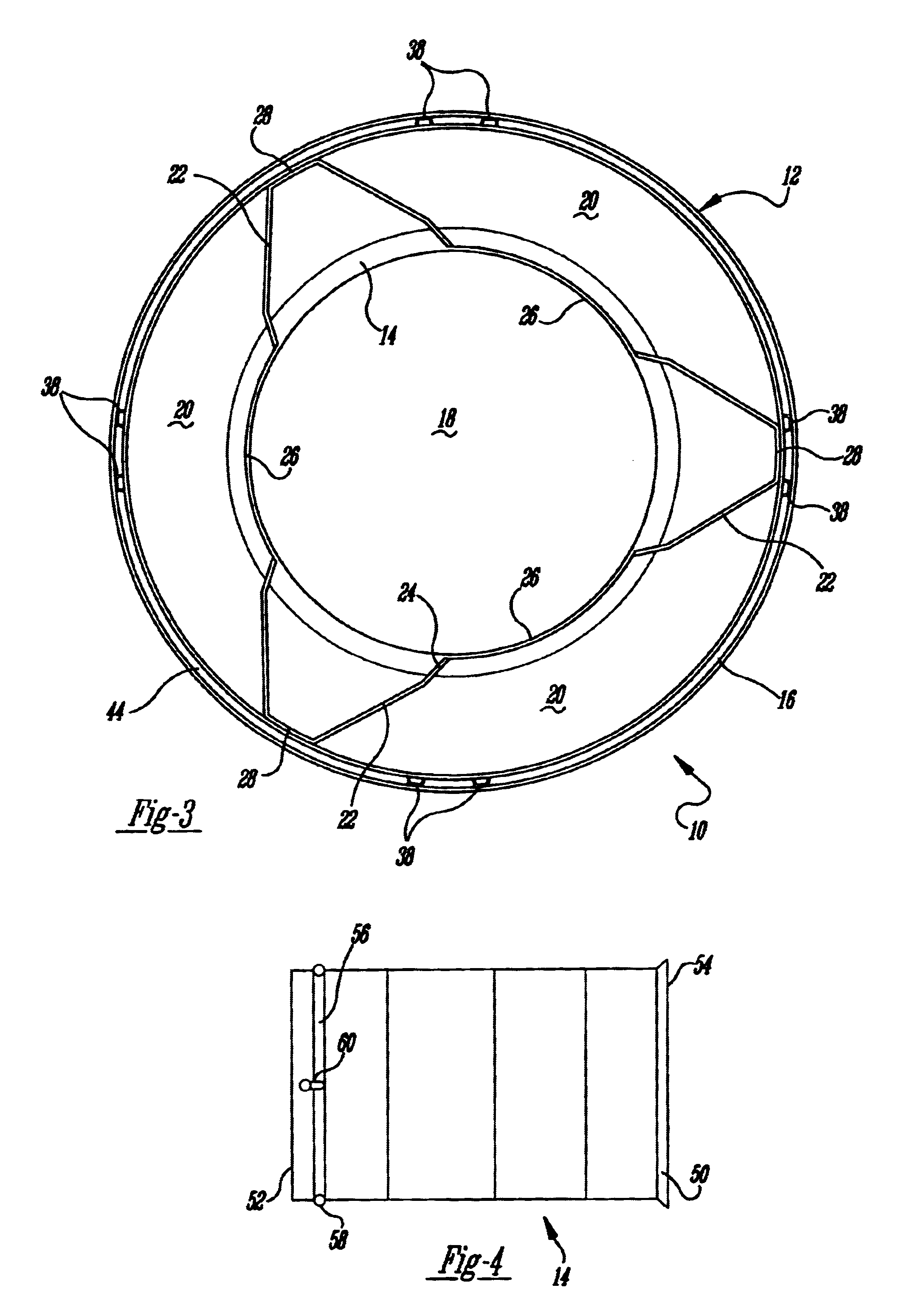

A venting system for a direct vent fireplace or other direct vent appliance to direct combustion gases to an exterior area. The direct venting vent pipe facilitates unrestricted lengths of pipe installations. The vent pipe has a double wall construction forming an interior axial passageway and a coaxial outer passageway. The double walls are spaced apart by an insert to maintain coaxial spacing. Sections of the vent pipe are lockingly connected to prevent separation and ensure sealing connection between the pipe sections. Elastic seal members are utilized between the matingly connected sections and a mechanical lock assembly prevents separation.

Owner:CARDINAL IP HLDG LLC

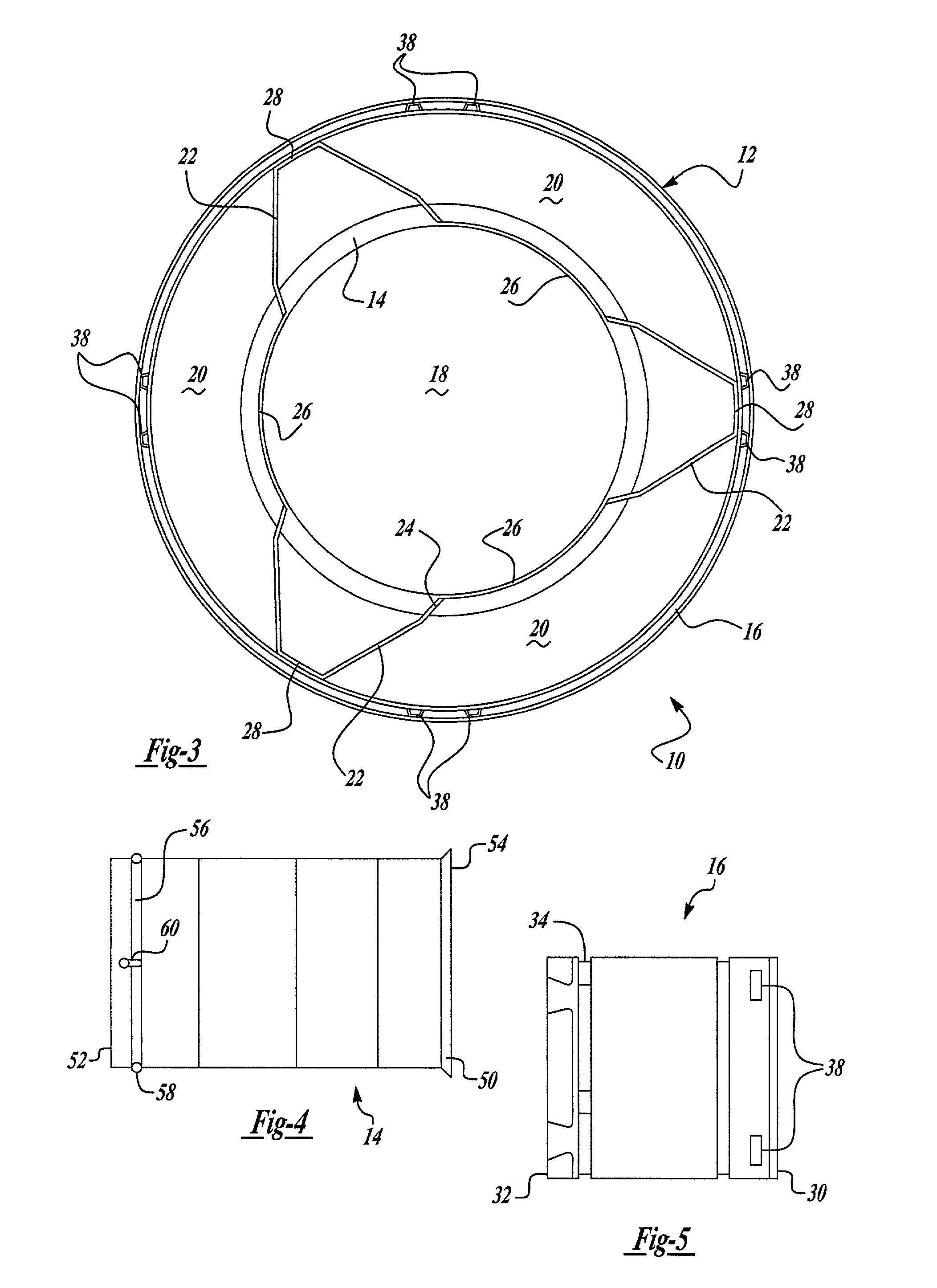

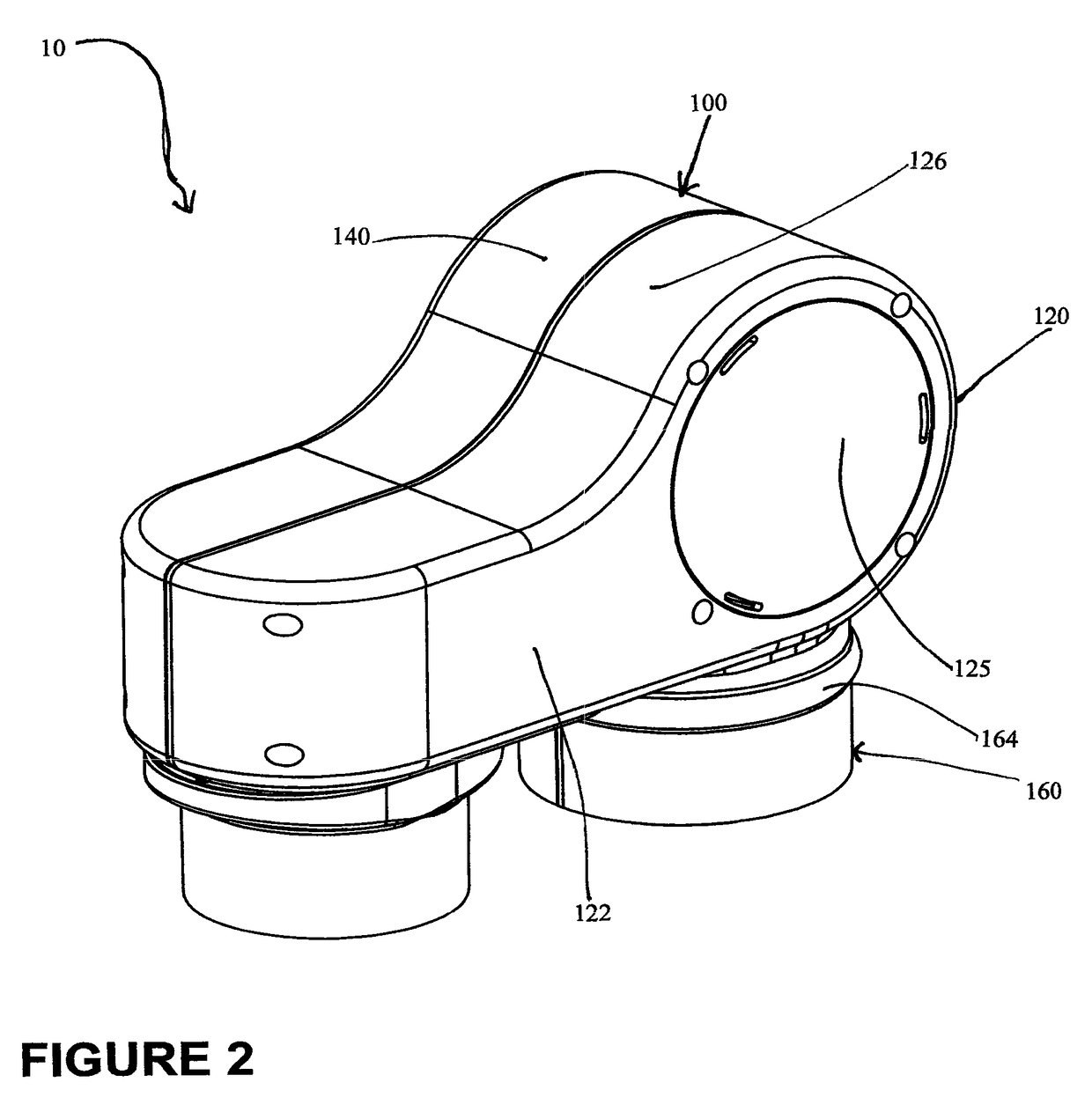

Coupling for direct venting system

InactiveUS20070221195A1More freedomReduce hole sizeDomestic stoves or rangesFlue gas duct systemVentilation tubeCoupling

A pipe coupling for components of a venting system comprising a male pipe member on an end of a first component and a female pipe member on a corresponding end of a second component. The male pipe member comprises an inner flue pipe having a compressible gasket surrounding the inner flue pipe proximate an external end of the inner flue pipe, an external venting pipe surrounding the inner flue pipe and brackets linking the inner flue pipe to the external venting pipe. The female pipe member receives the male pipe member and comprises an inner flue sleeve being sized larger than the outer diameter of the flue pipe at an outer end of the sleeve. The inner flue sleeve remains in circumferential contact with the compressible gasket when the male pipe member is inserted into the female pipe member.

Owner:ICC COMPAGNIE DES CHEMINEES IND

Heating apparatus with fan

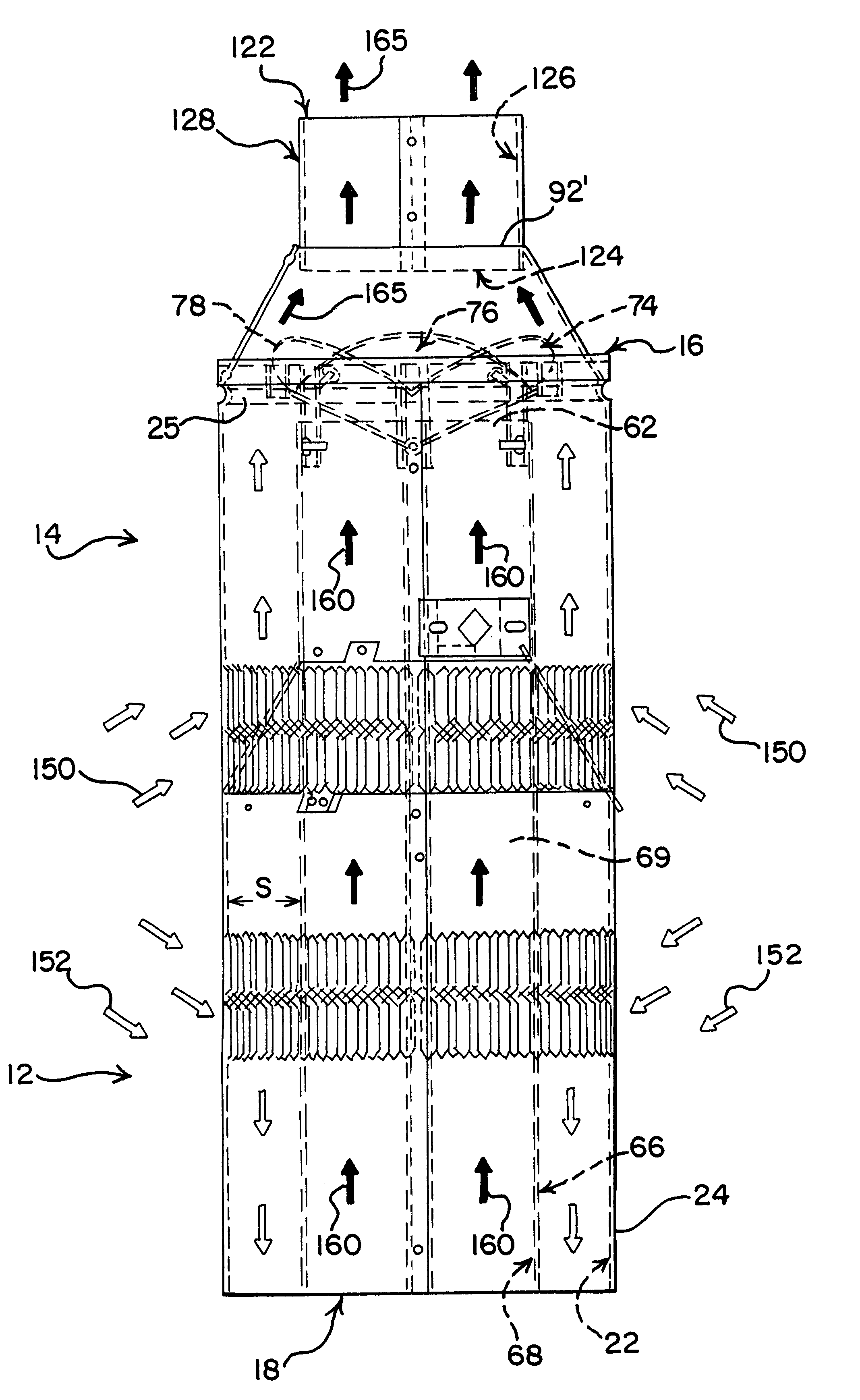

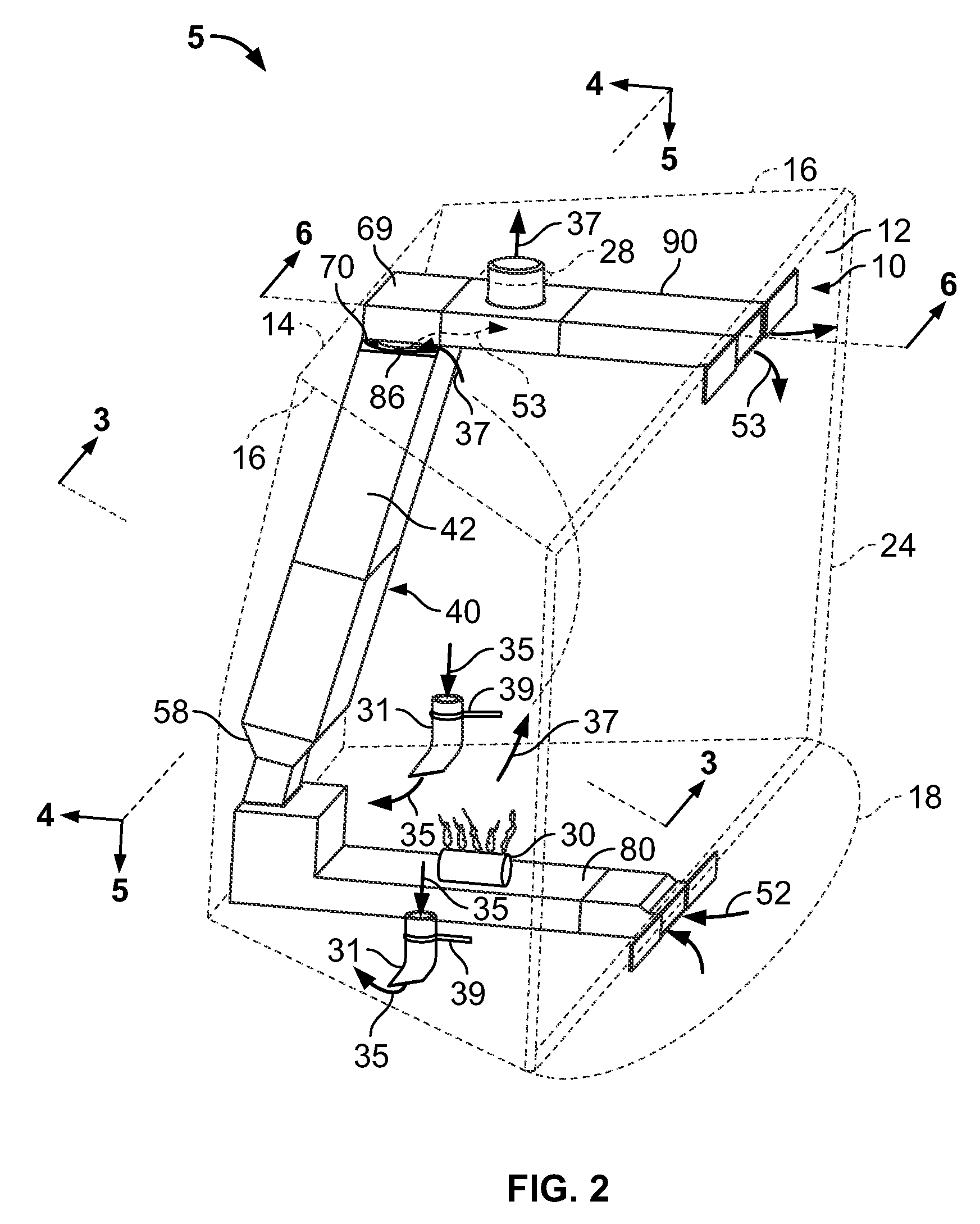

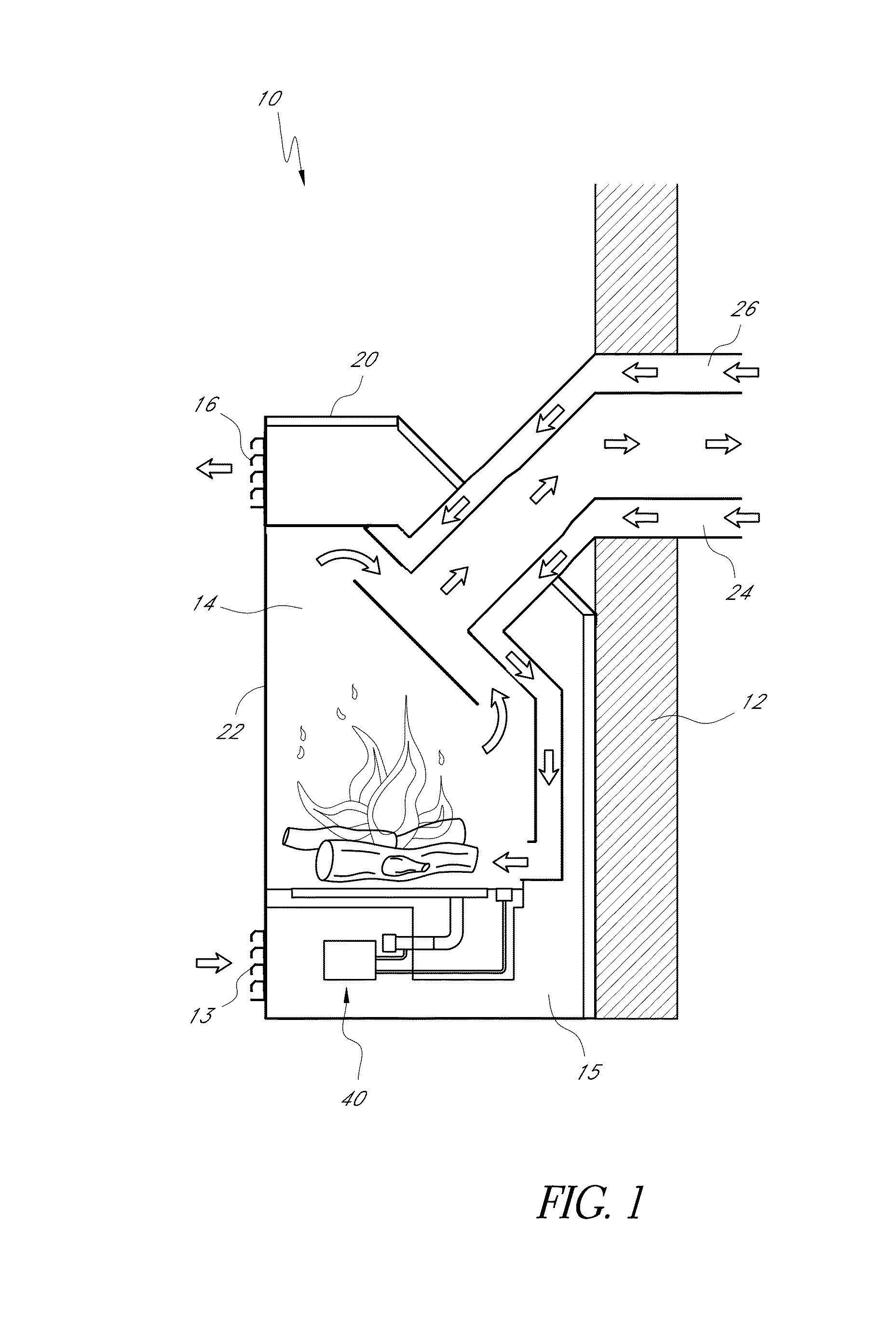

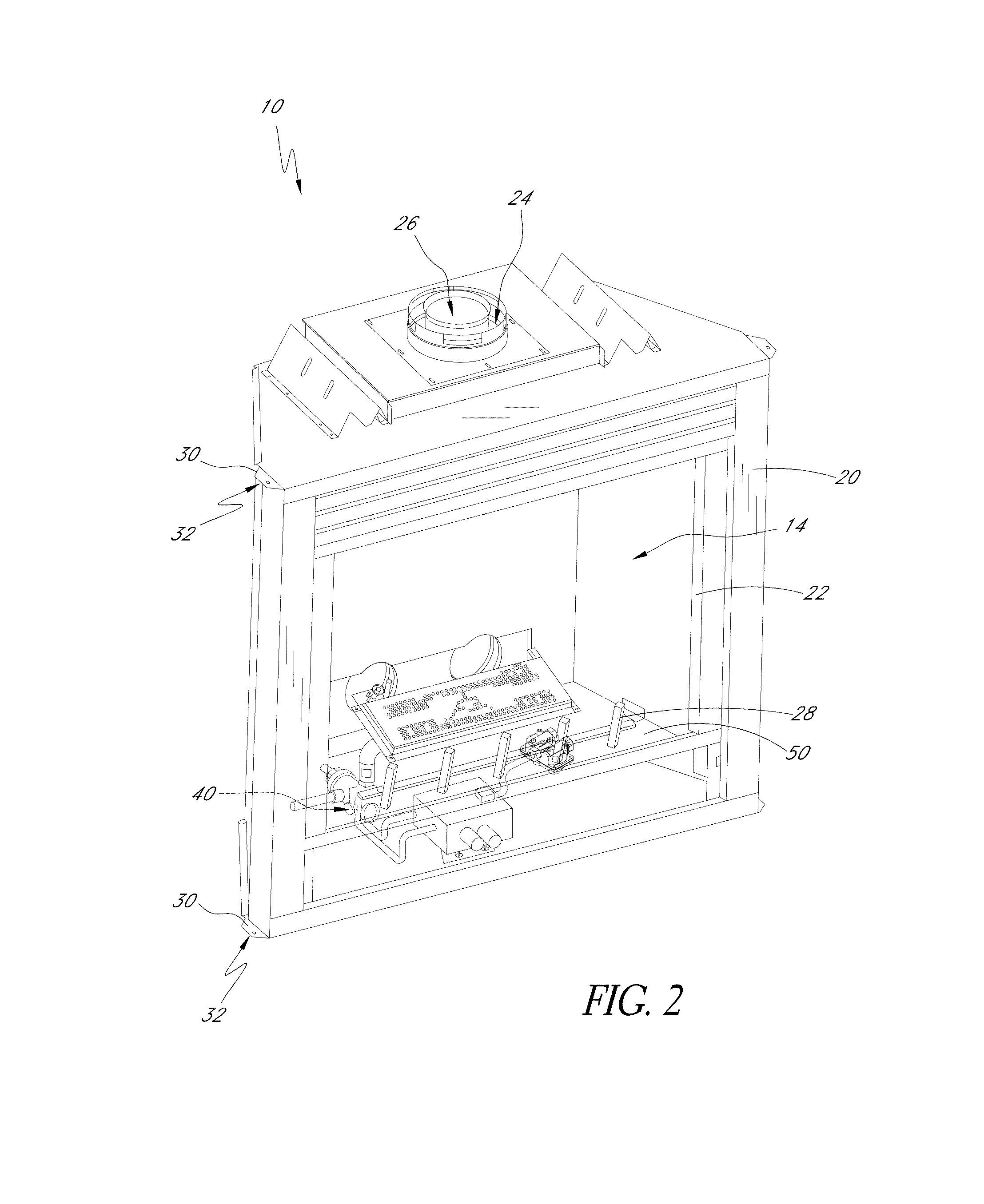

InactiveUS20120031392A1Reduced temperature external surfaceLiquid heating fuelCombustion-air/flue-gas circulation for stovesInterior spaceCombustion chamber

Owner:DENG DAVID

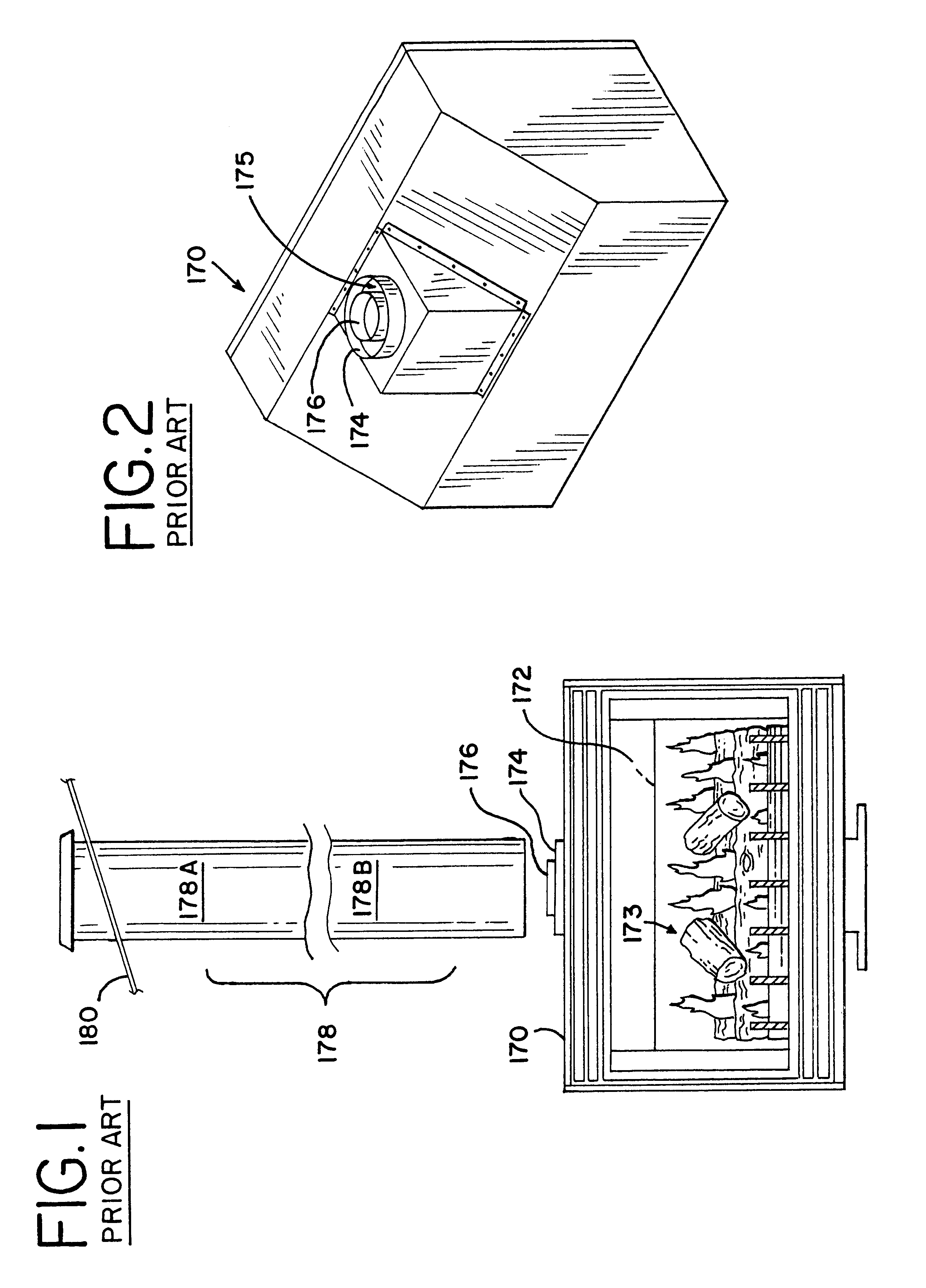

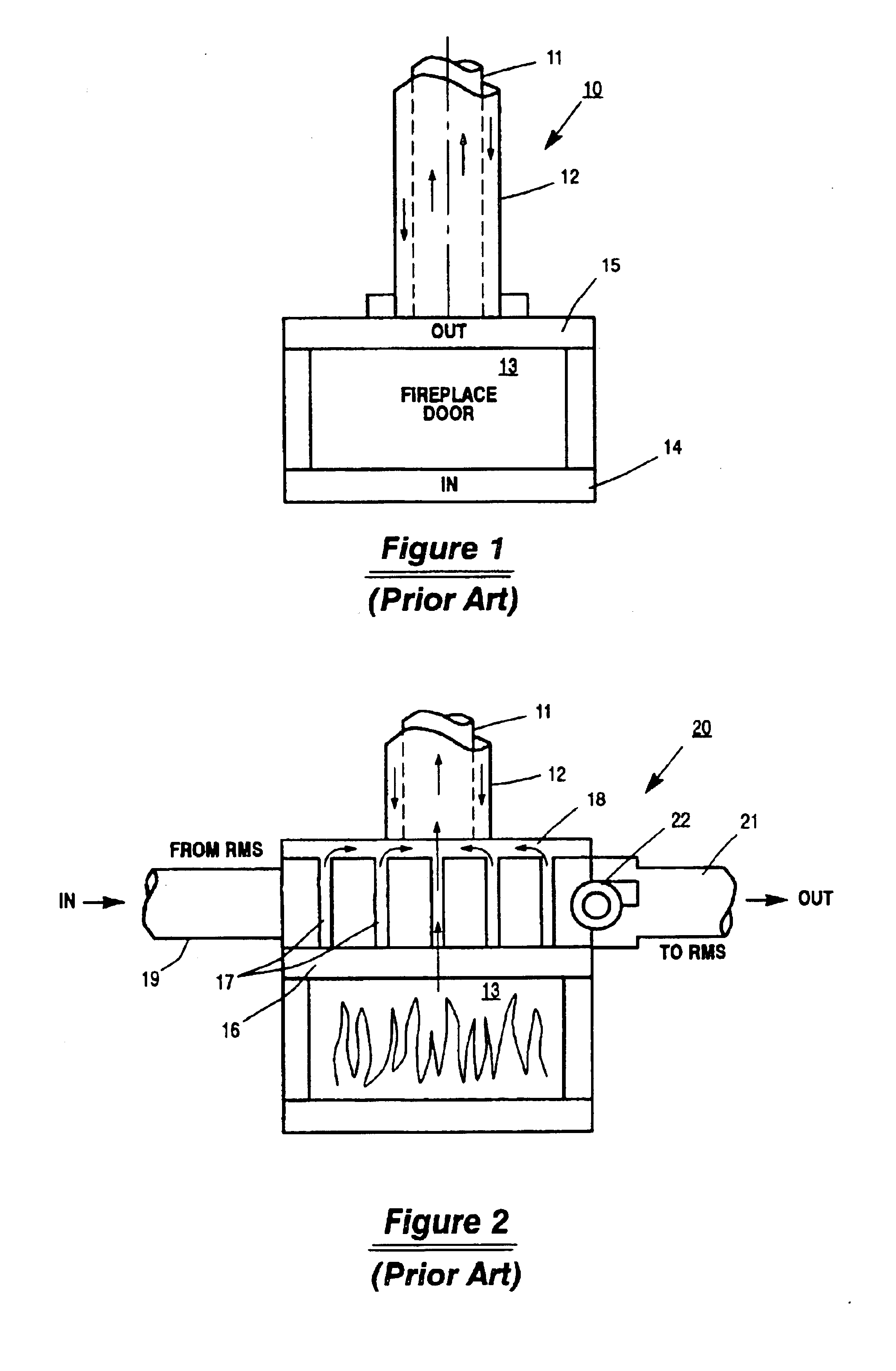

Drafthood adapter assembly particularly for stoves and fireplaces

A drafthood assembly for inclusion within a vent stack for a direct venting stove or fireplace, converting the direct venting stove or fireplace for use with a natural venting flue. The assembly includes an air intake section for feeding ambient room air into the combustion chamber and an exhaust gas section for feeding ambient room air into the products of combustion that are exhausted from the combustion chamber in order to cool the exhaust gas products so that a B-vent type flue can be used to carry the exhaust gas products out of the dwelling.

Owner:MONESSEN HEARTH SYST

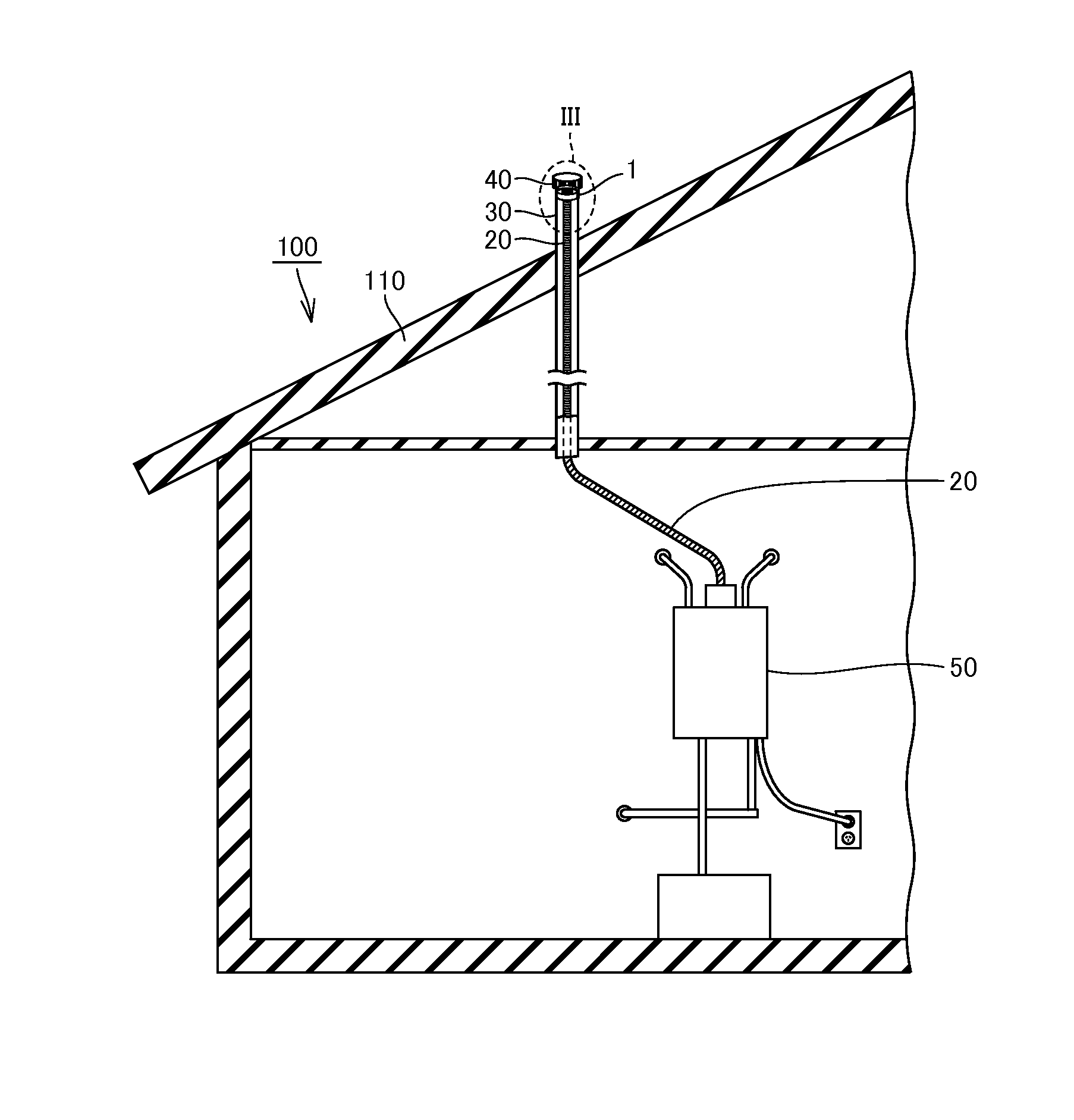

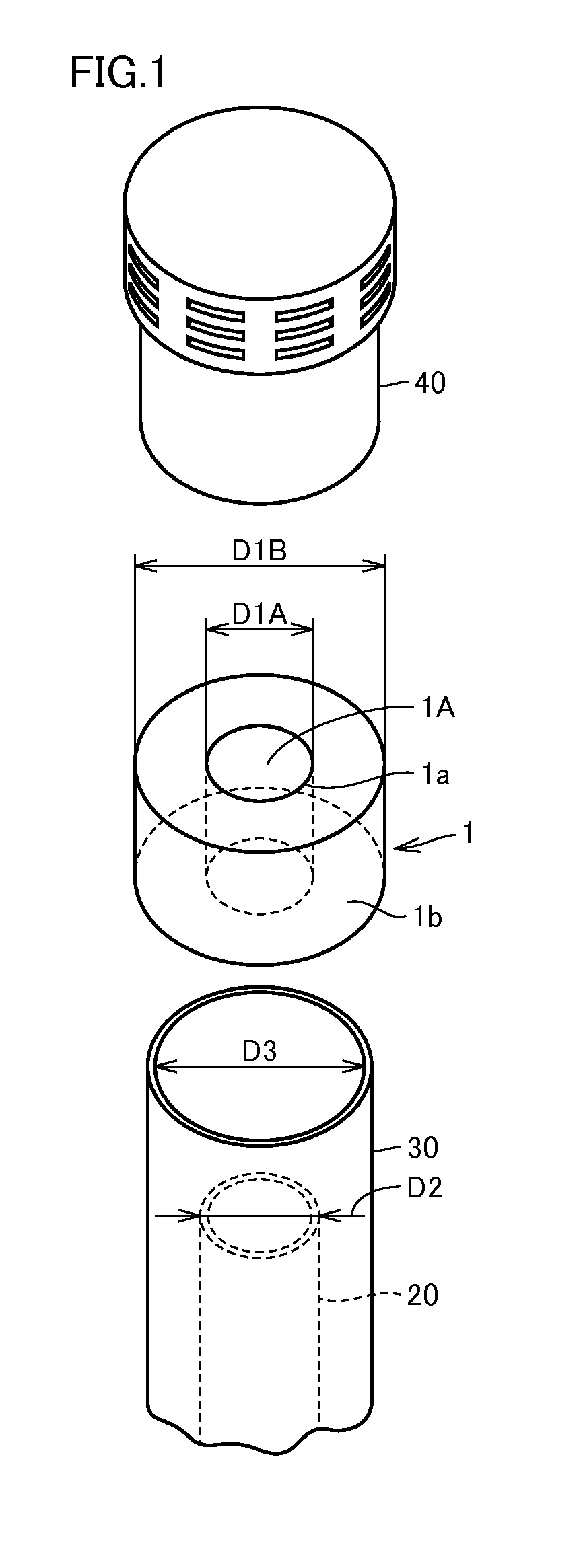

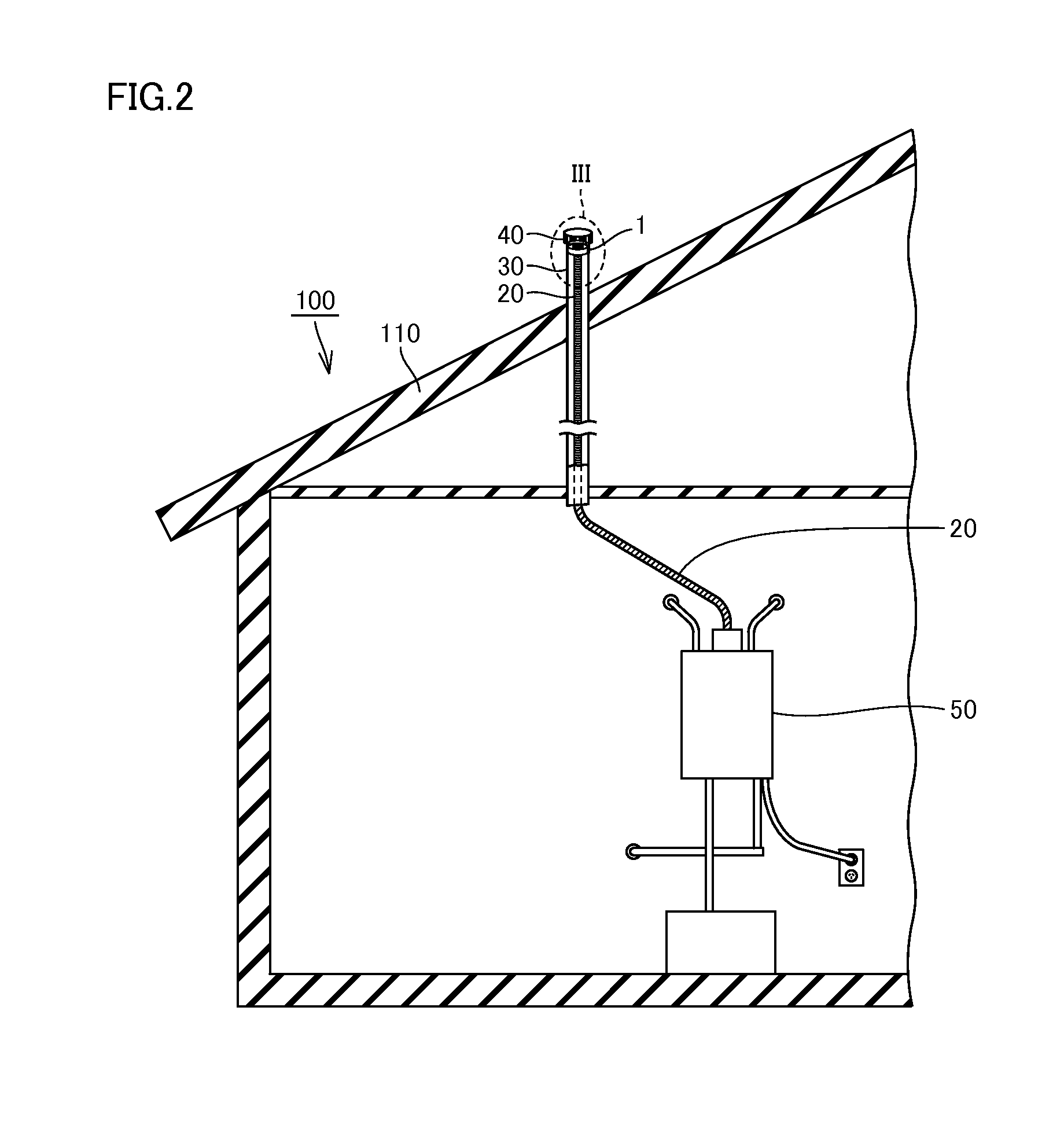

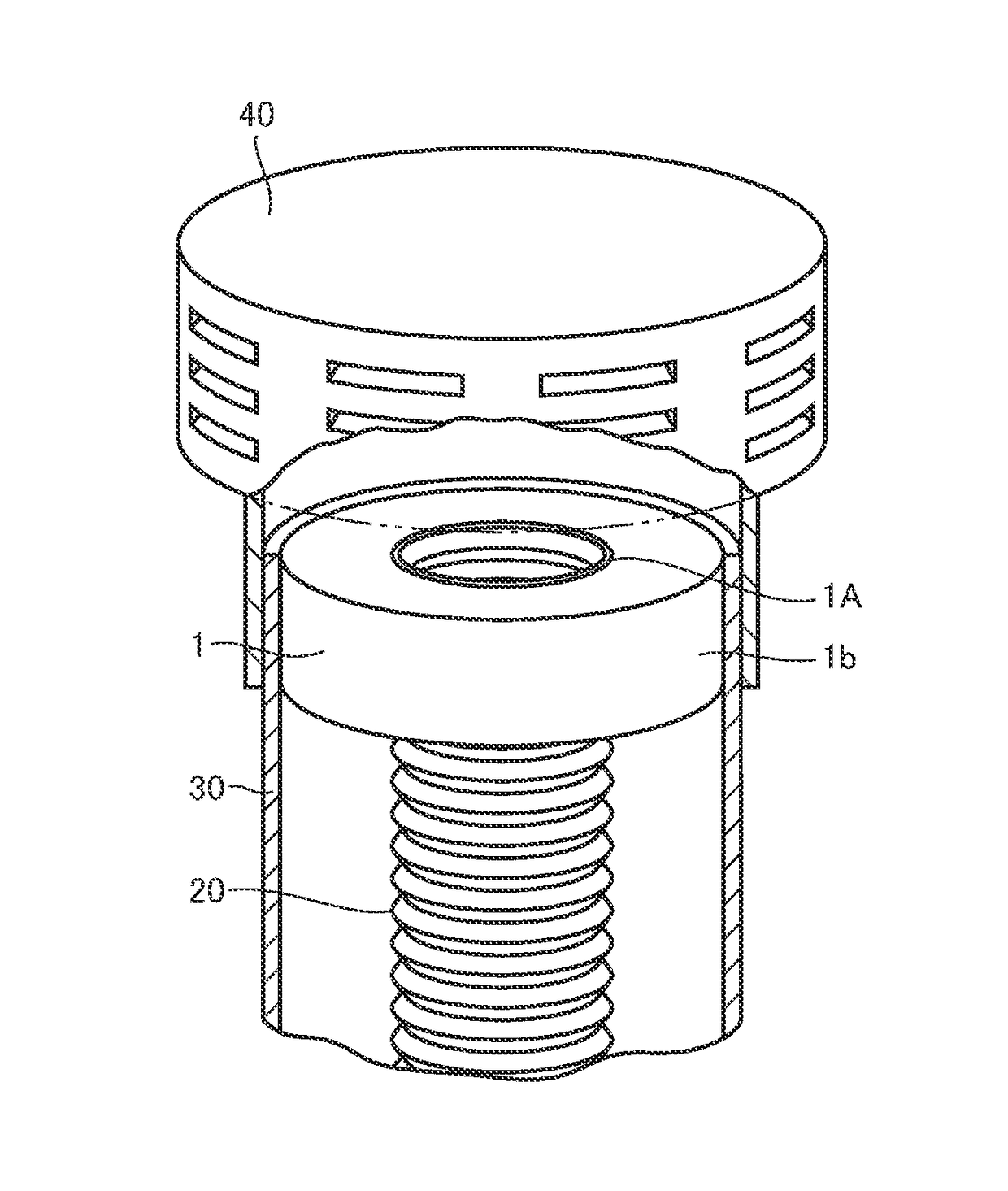

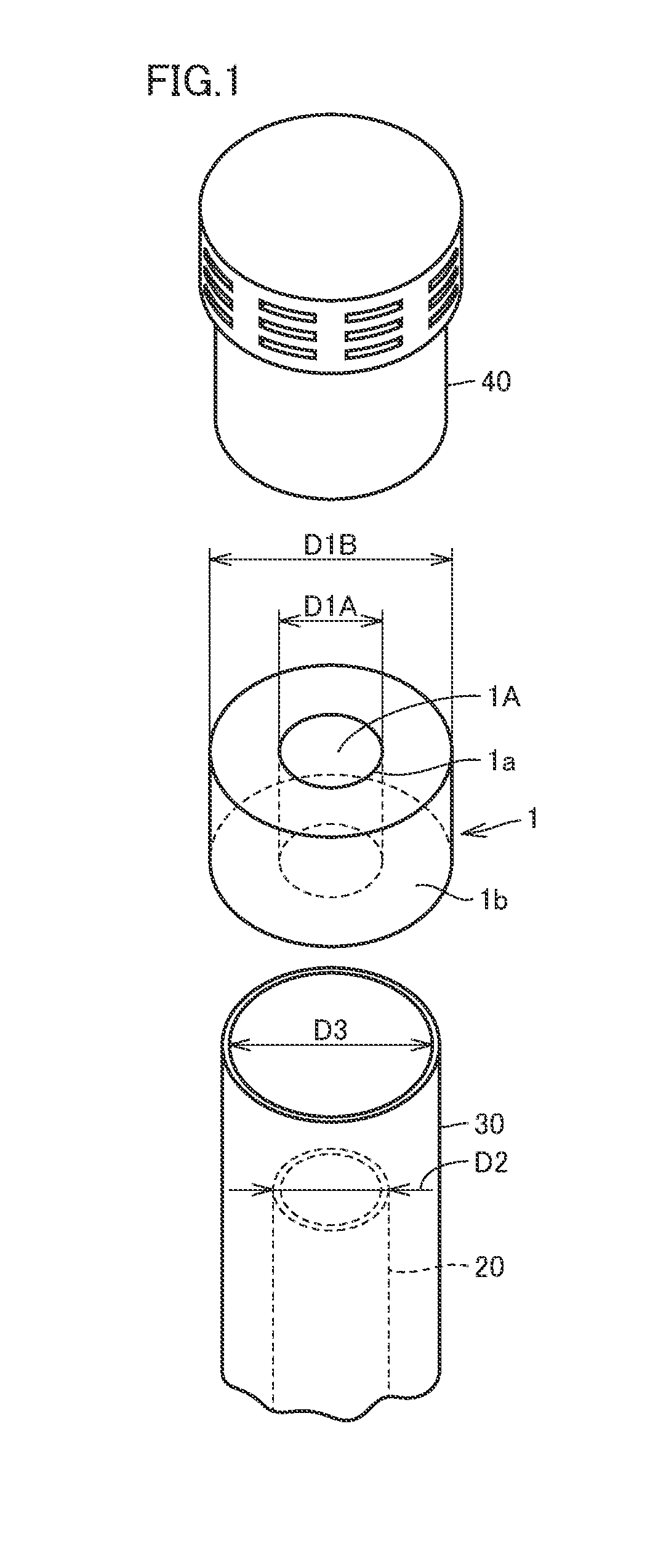

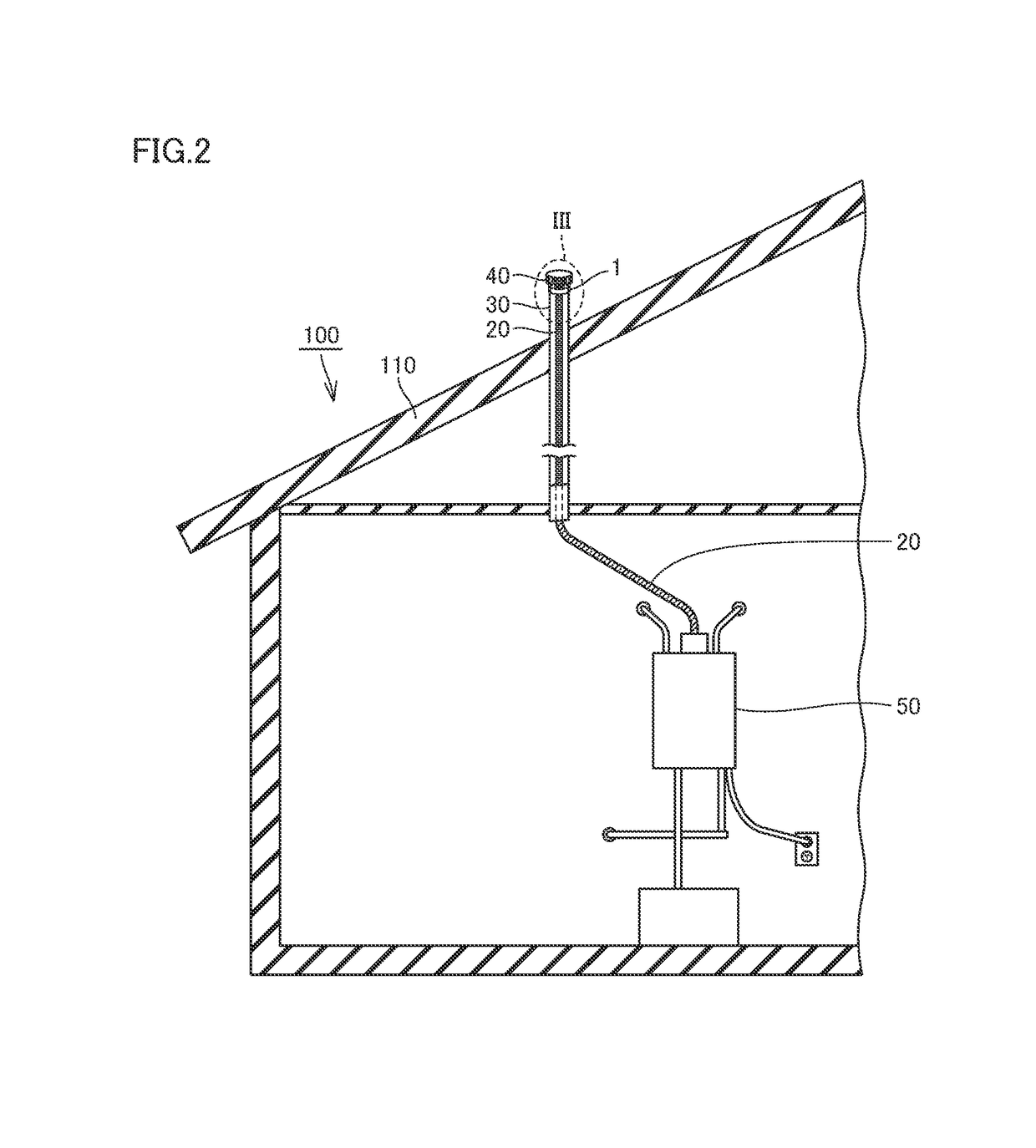

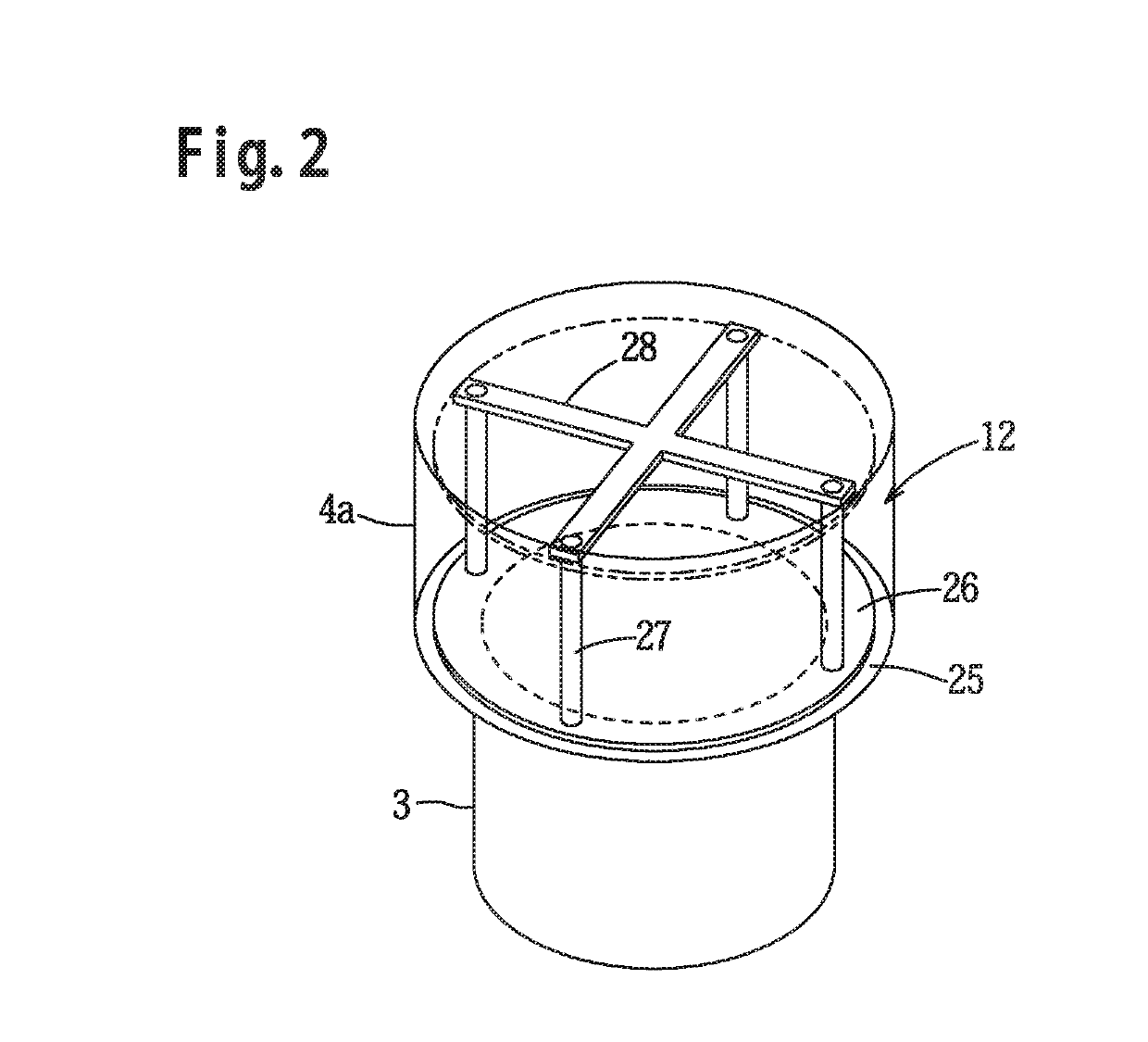

Exhaust adapter, exhaust structure for water heater, and method for installing exhaust adapter

ActiveUS20150056903A1Easy and cheap to performPipe supportsFluid pressure sealed jointsPulp and paper industryExhaust pipe

An exhaust adapter secures an exhaust tube relative to an exhaust pipe. The exhaust adapter is formed to have an annular shape enclosing a through hole, and is mounted on the outer peripheral surface of the exhaust tube and on the inner peripheral surface of the exhaust pipe by inserting the exhaust tube into the through hole. When the exhaust adapter is being fitted on the outer peripheral surface of the exhaust tube, the inner peripheral surface of the exhaust adapter presses the outer peripheral surface of the exhaust tube, and when the exhaust adapter is being fitted on the inner peripheral surface of the exhaust pipe, the outer peripheral surface of the exhaust adapter presses the inner peripheral surface of the exhaust pipe.

Owner:NORITZ CORP

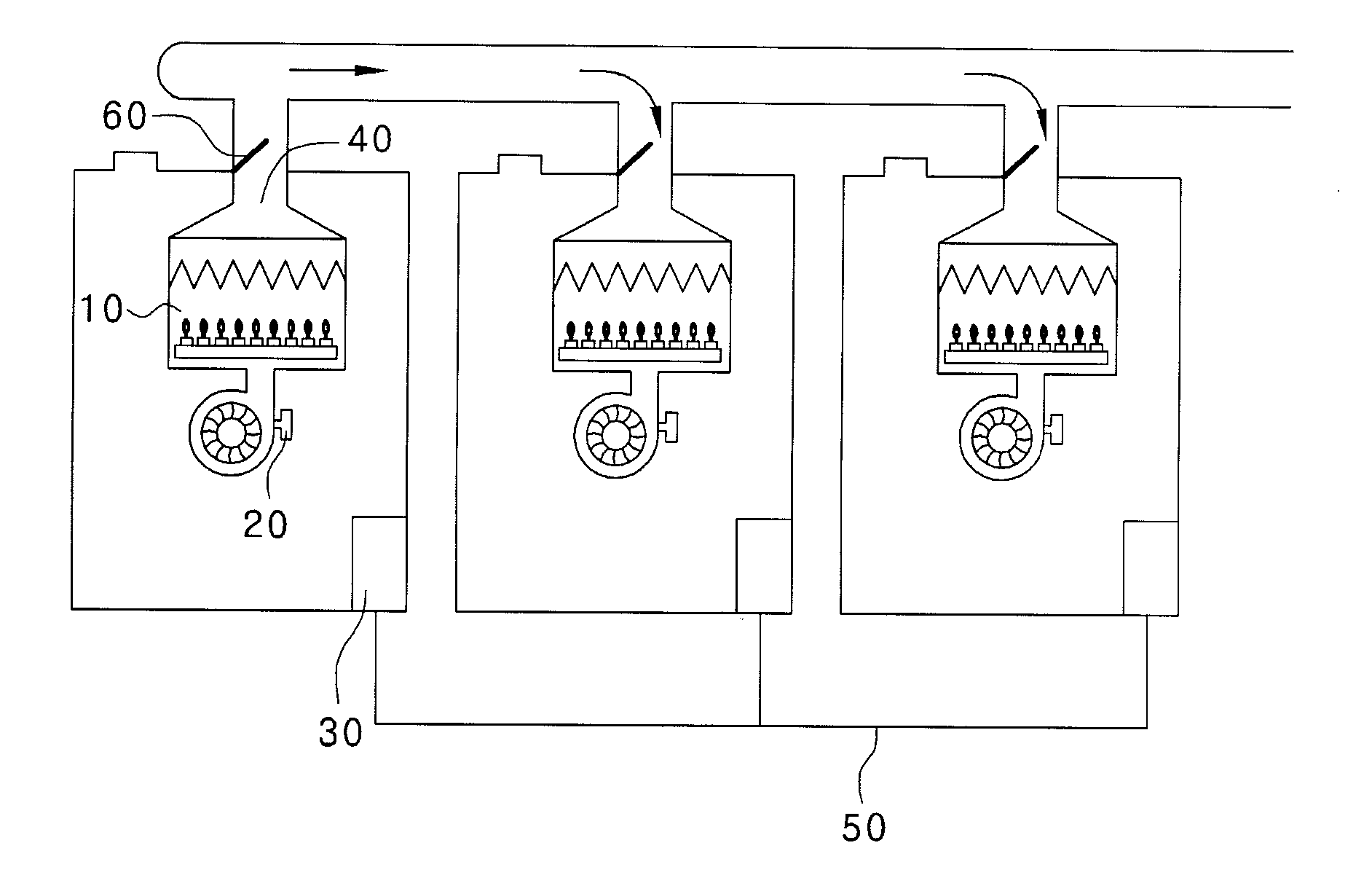

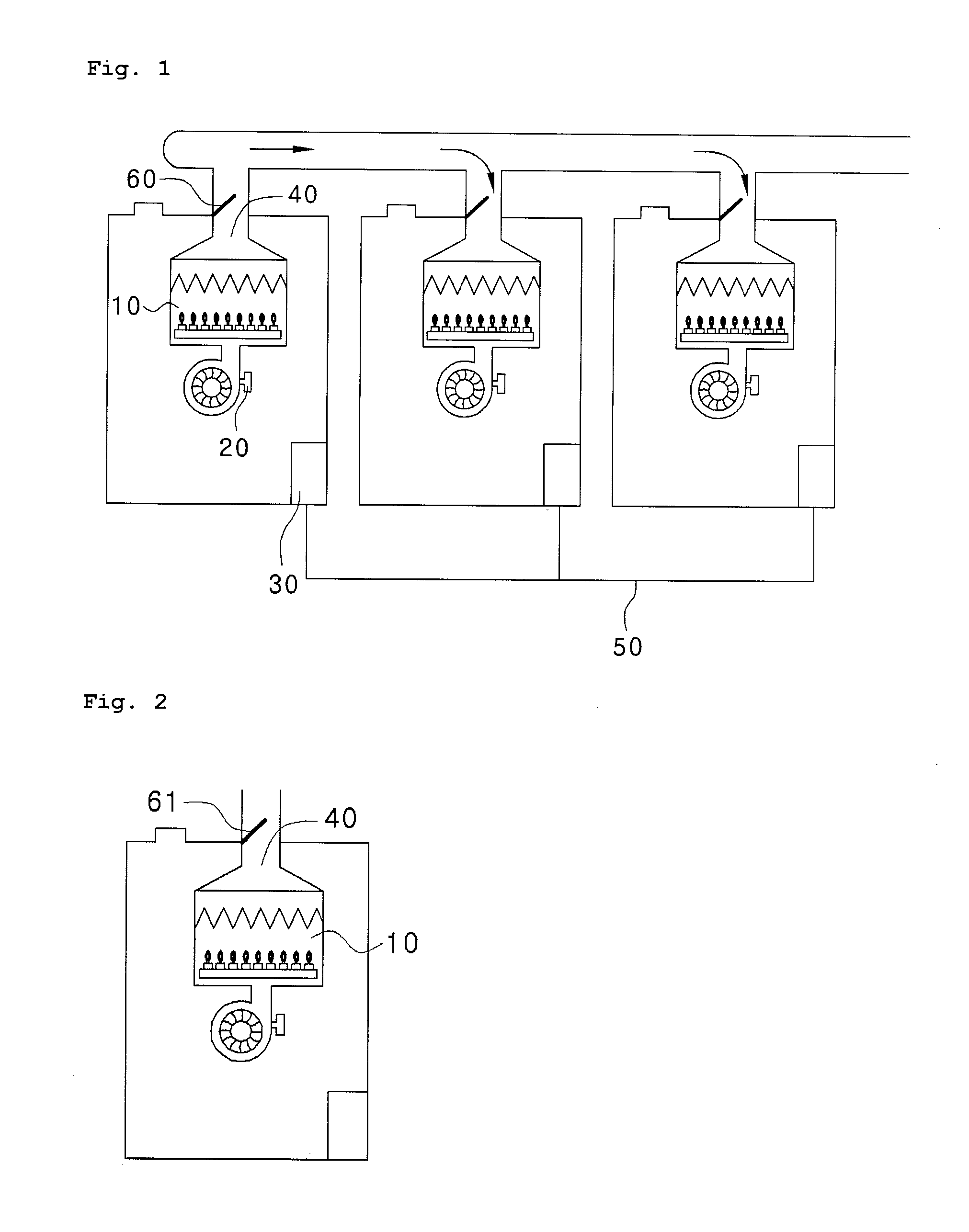

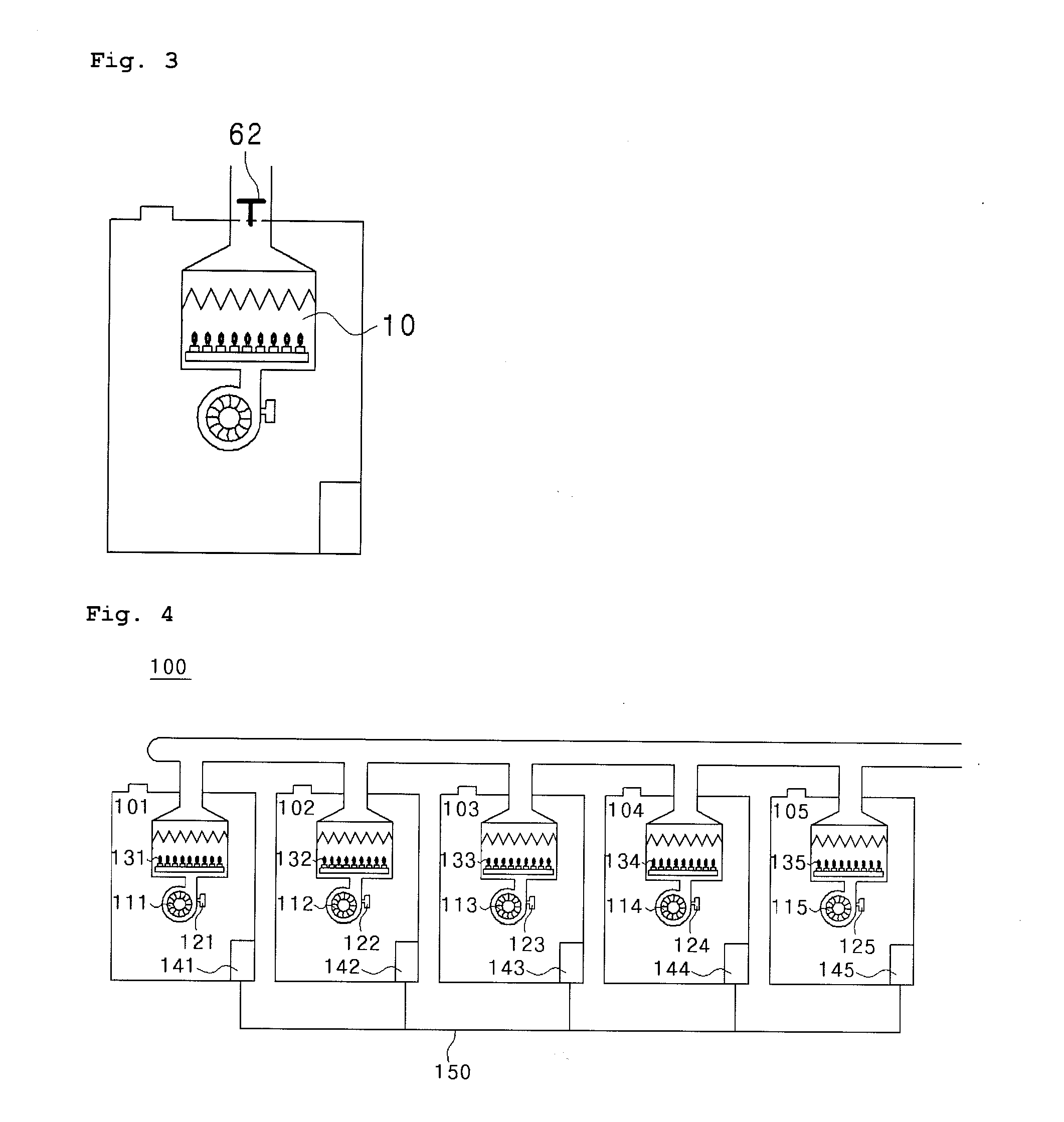

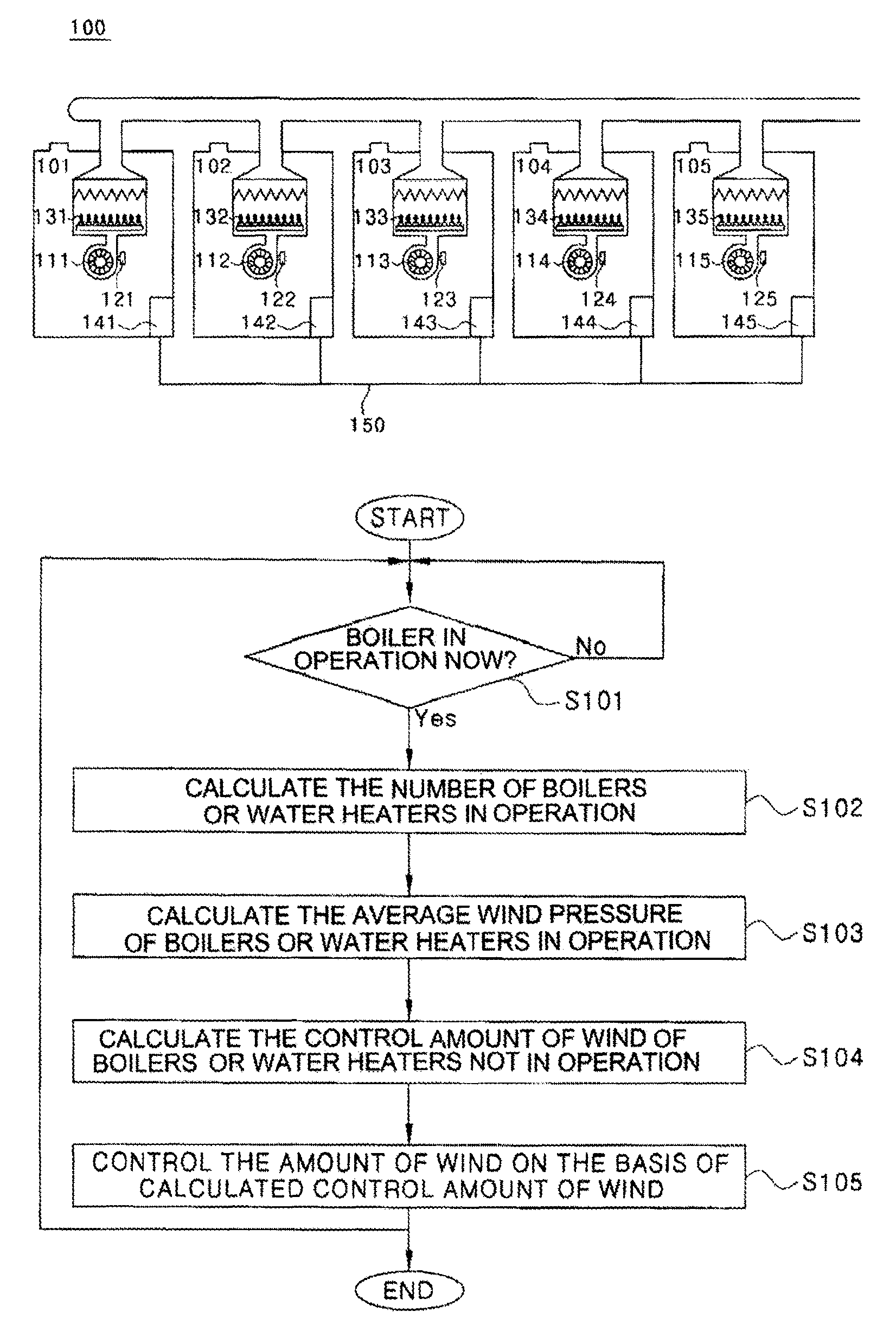

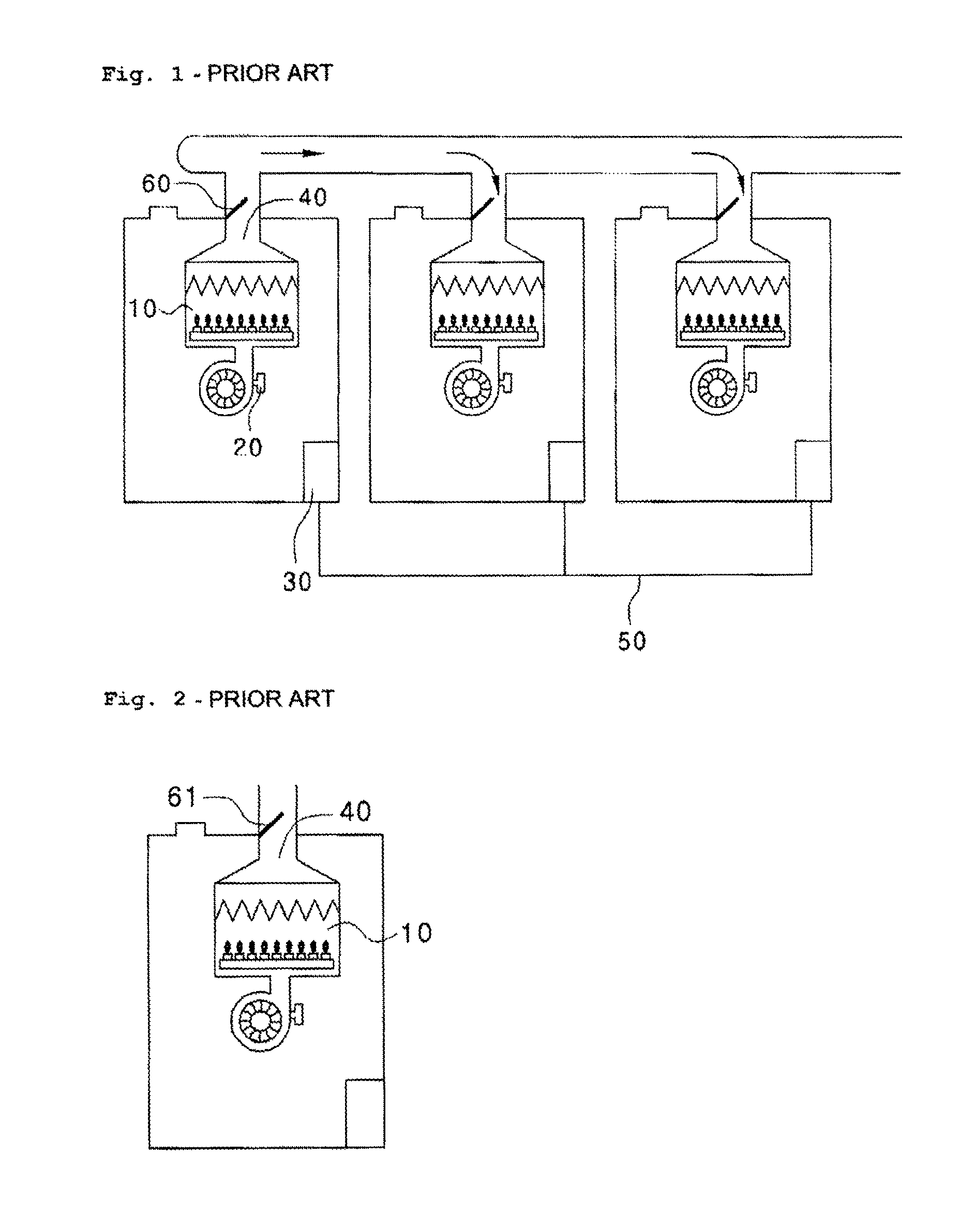

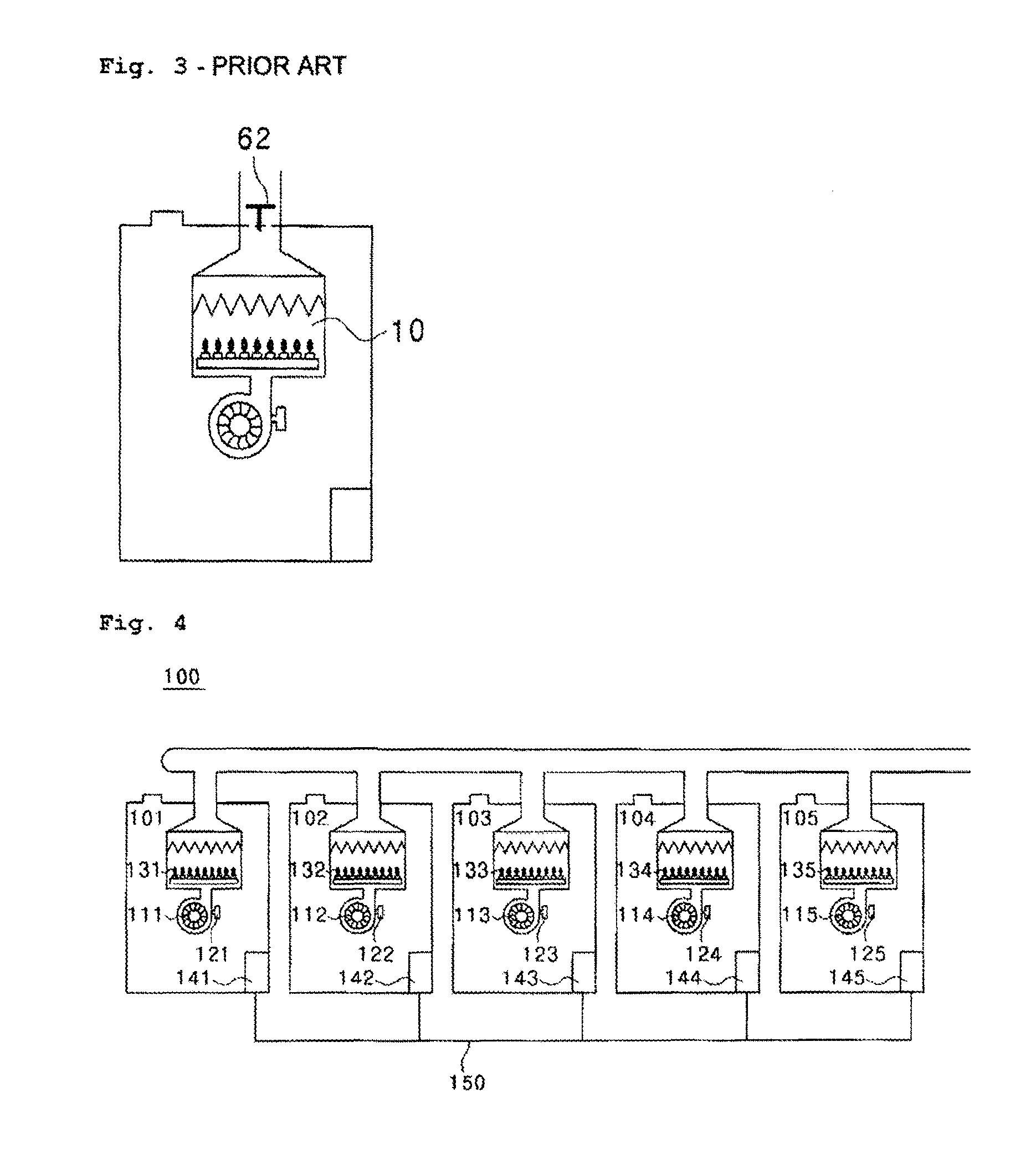

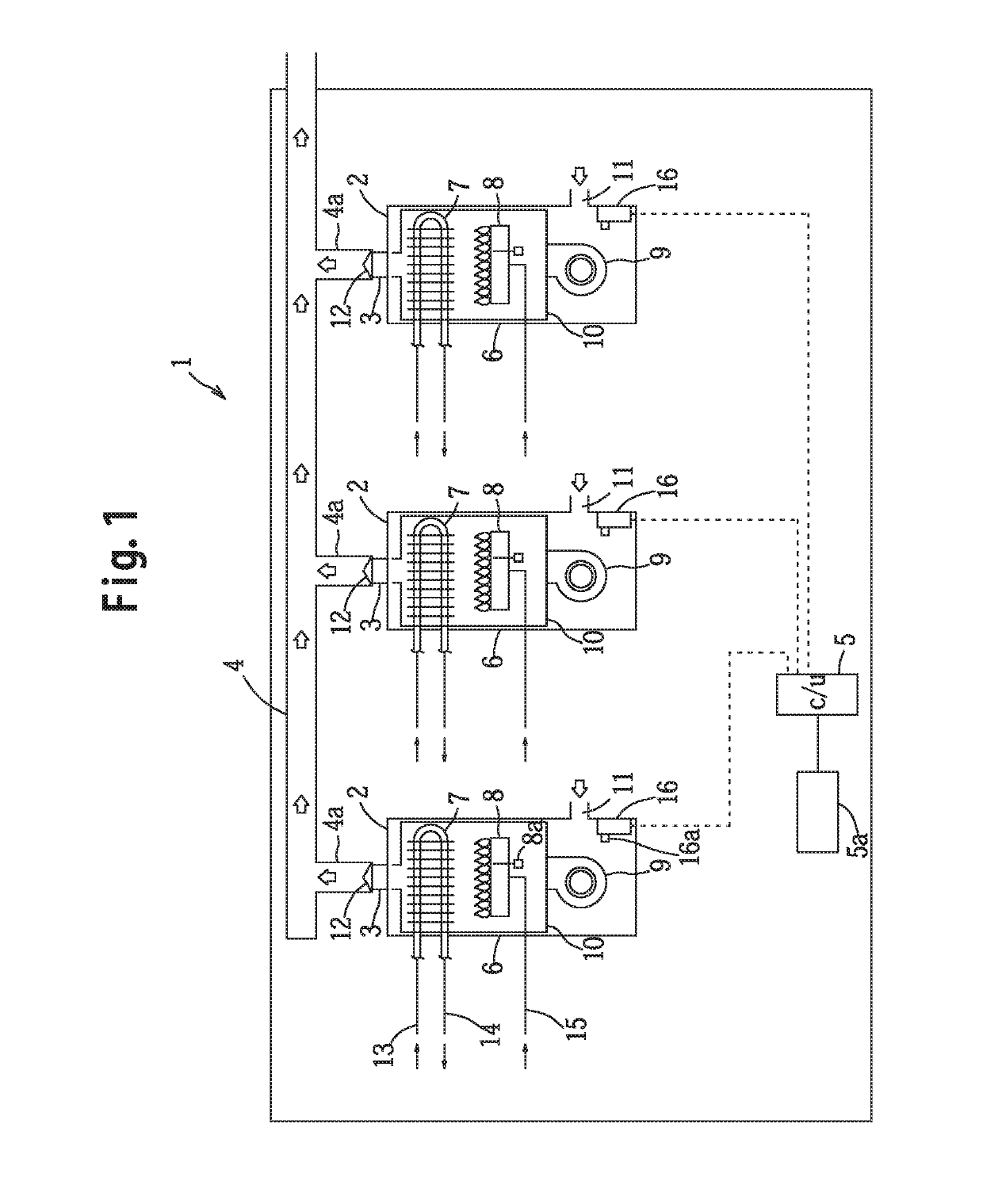

Multi-boiler and control method thereof for preventing back flow of exhaust gas

ActiveUS20100330512A1Maintenance savingIncrease costMechanical apparatusSpace heating and ventilation detailsCombustion chamberAir volume

The present invention relates to a control method of preventing backflow of exhaust gas of a multiboiler that is composed of a plurality of boilers connected in a line, each of which includes a wind pressure sensor measuring wind pressure of air flowing into a combustion chamber and a controller controlling the number of revolutions of a fan supplying air into the combustion chamber on the basis of the wind pressure measured by the wind pressure sensor, and in which any one of the controllers is set as a master controller and the other controllers are set as slave controllers and the master controller and the slave controllers are connected by a communication line to communicate with each other, and the control method includes: measuring wind pressures of air flowing into the combustion chambers using the wind pressure sensors in the controller of boilers that are in operation; and calculating the average wind pressure of the boilers that are in operation in response to information about the wind pressures measured by the controllers of the boilers that are in operation, using the master controller, determining the control amount of wind of the fans of boilers that are not in operation on the basis of the average wind pressure, and then operating the fan of the boilers that are not in operation on the basis of the determined results. According to the method, it is possible to provide a multi-boiler or a multi-water heater that does not generate additional cost for installing the dampers are not needed and does not substantially breakdown due even though it is used for a long period of time, thereby saving cost for maintenance.

Owner:KYUNGDONG NAVIEN

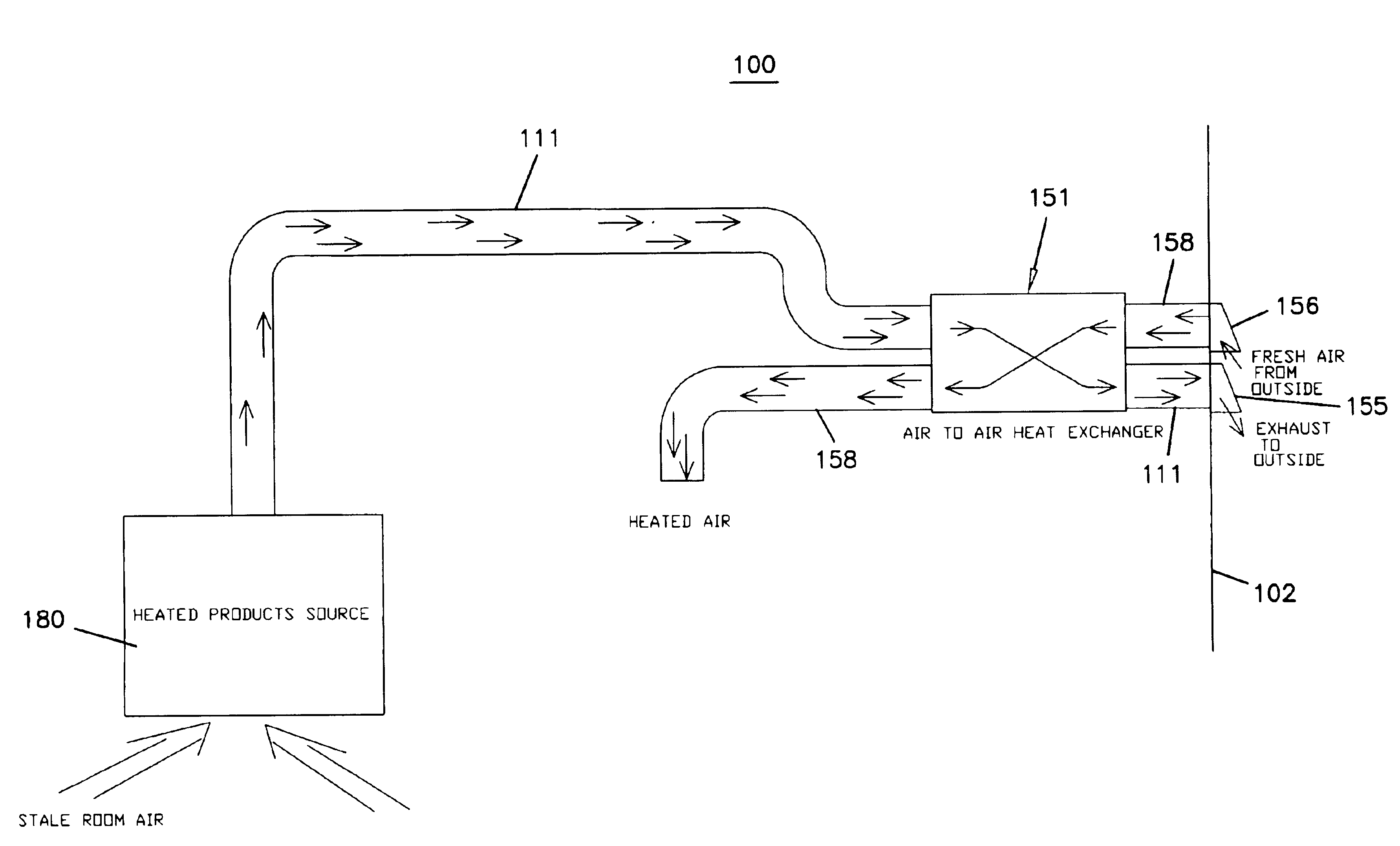

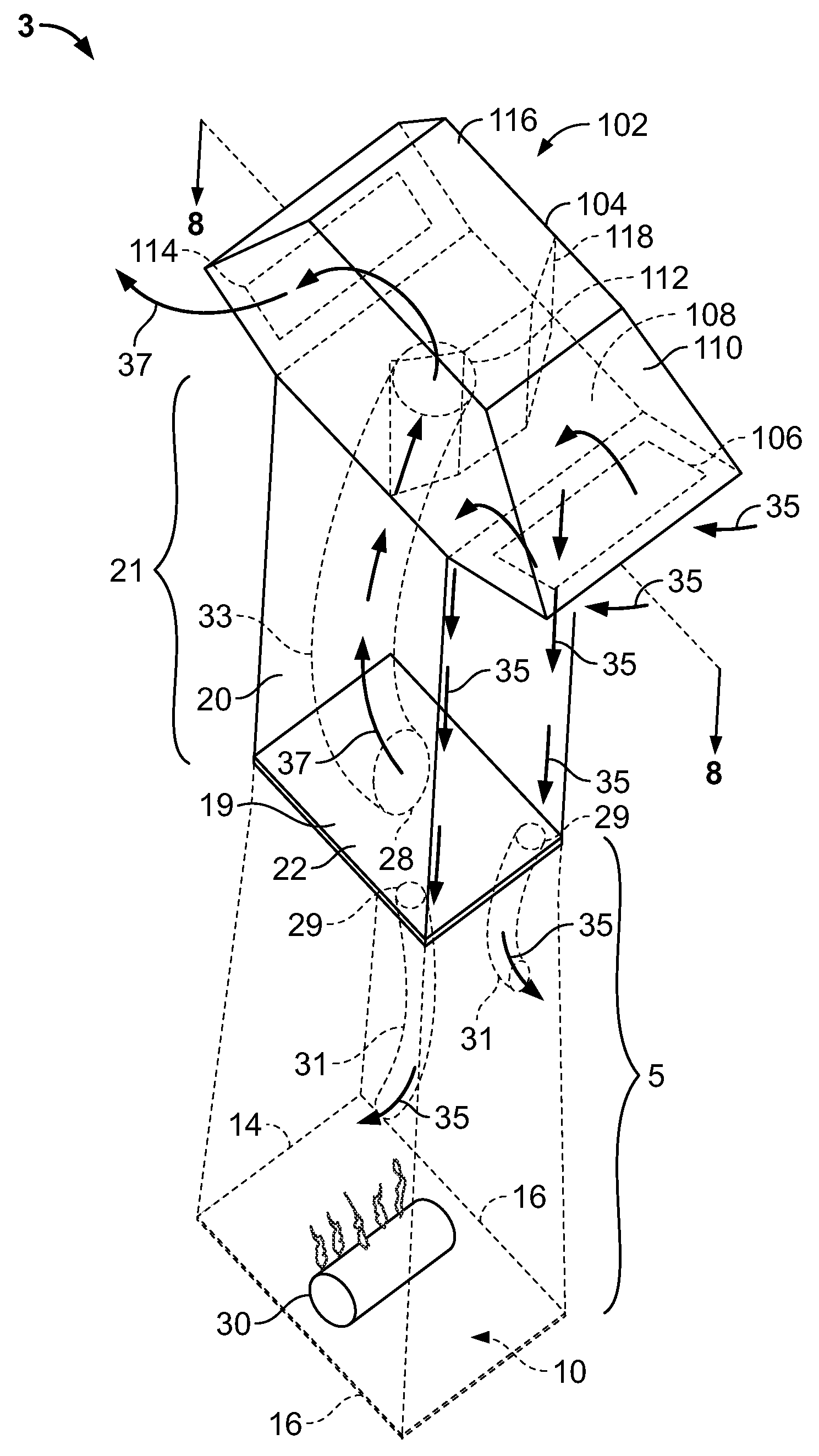

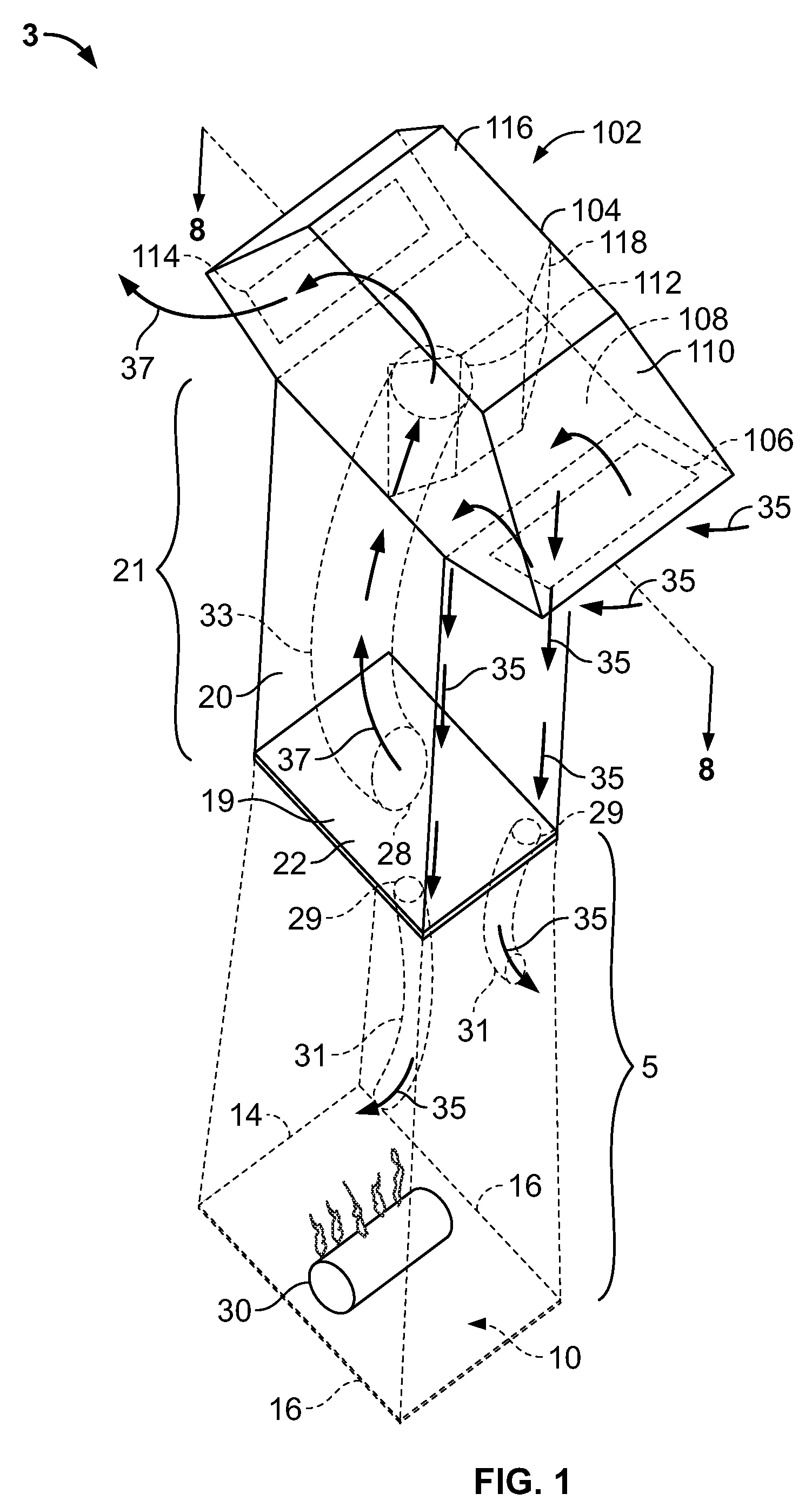

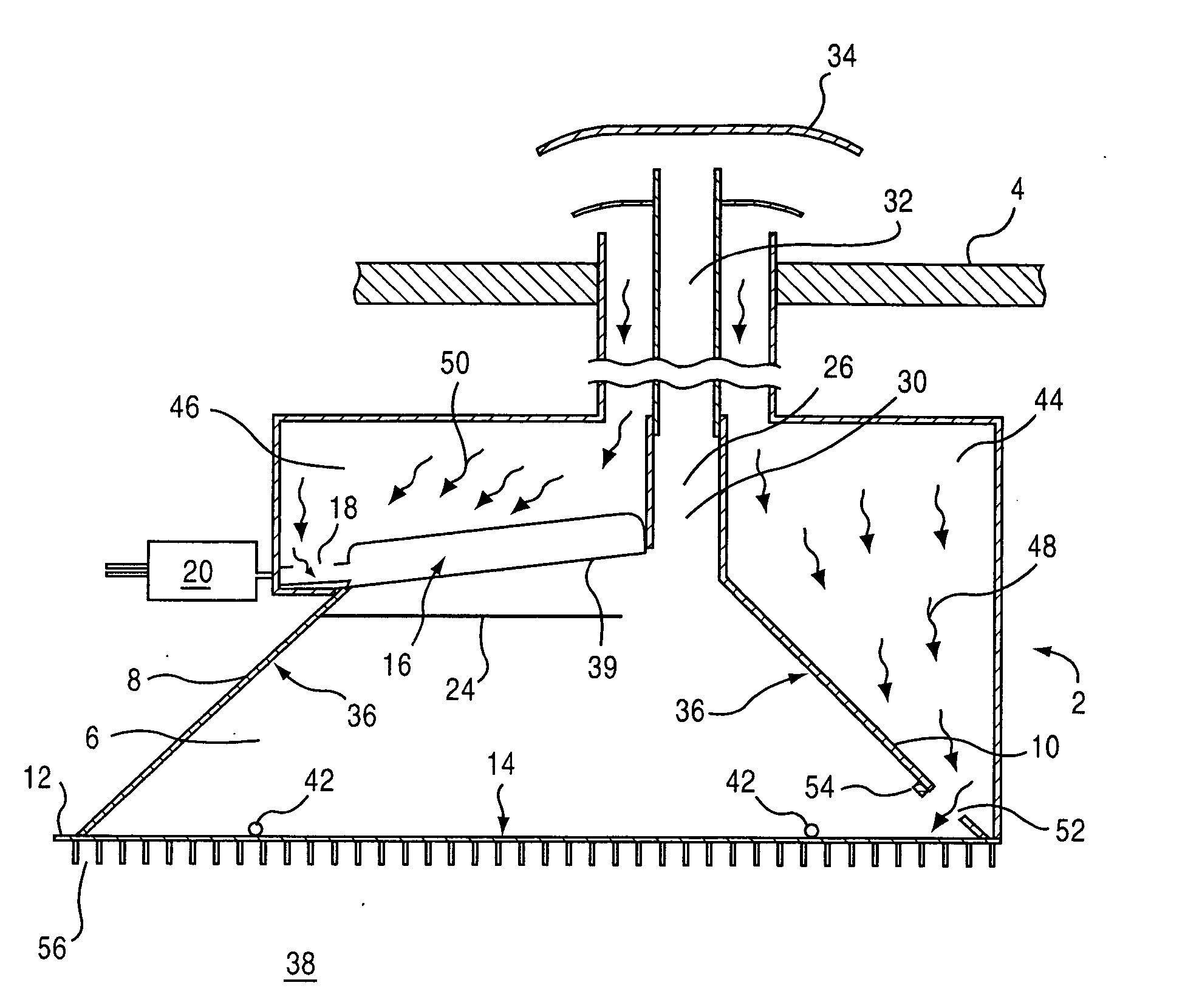

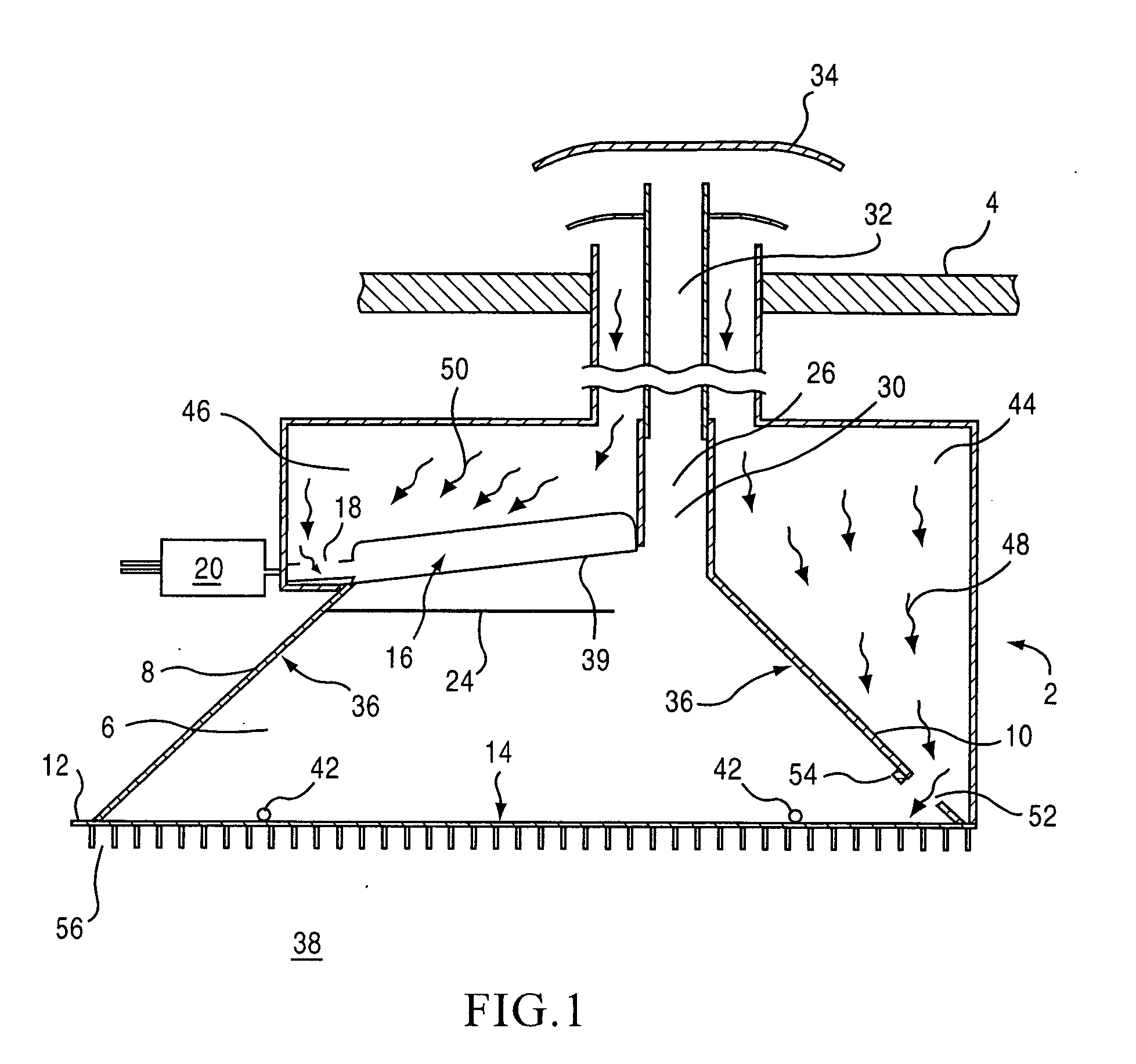

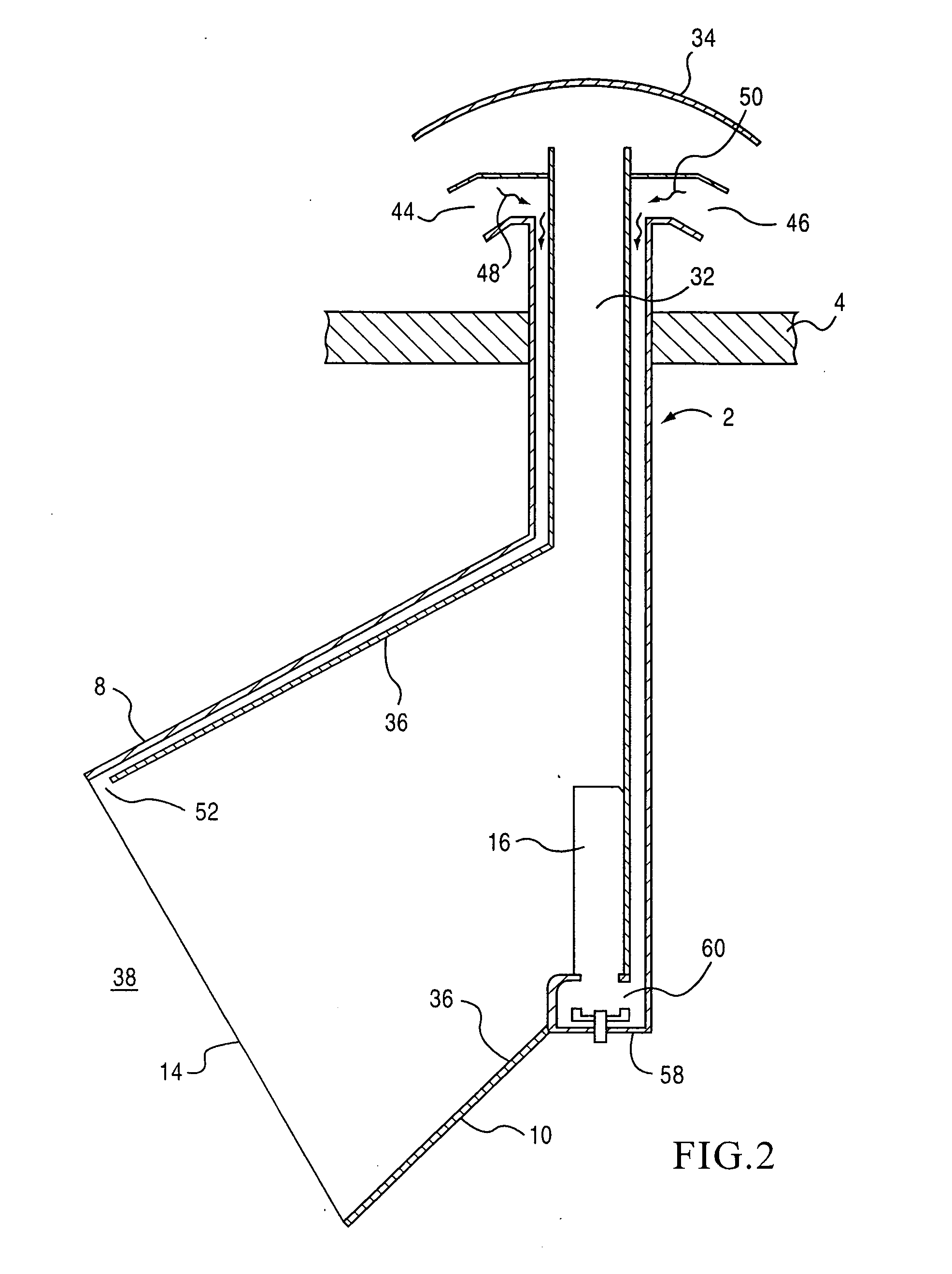

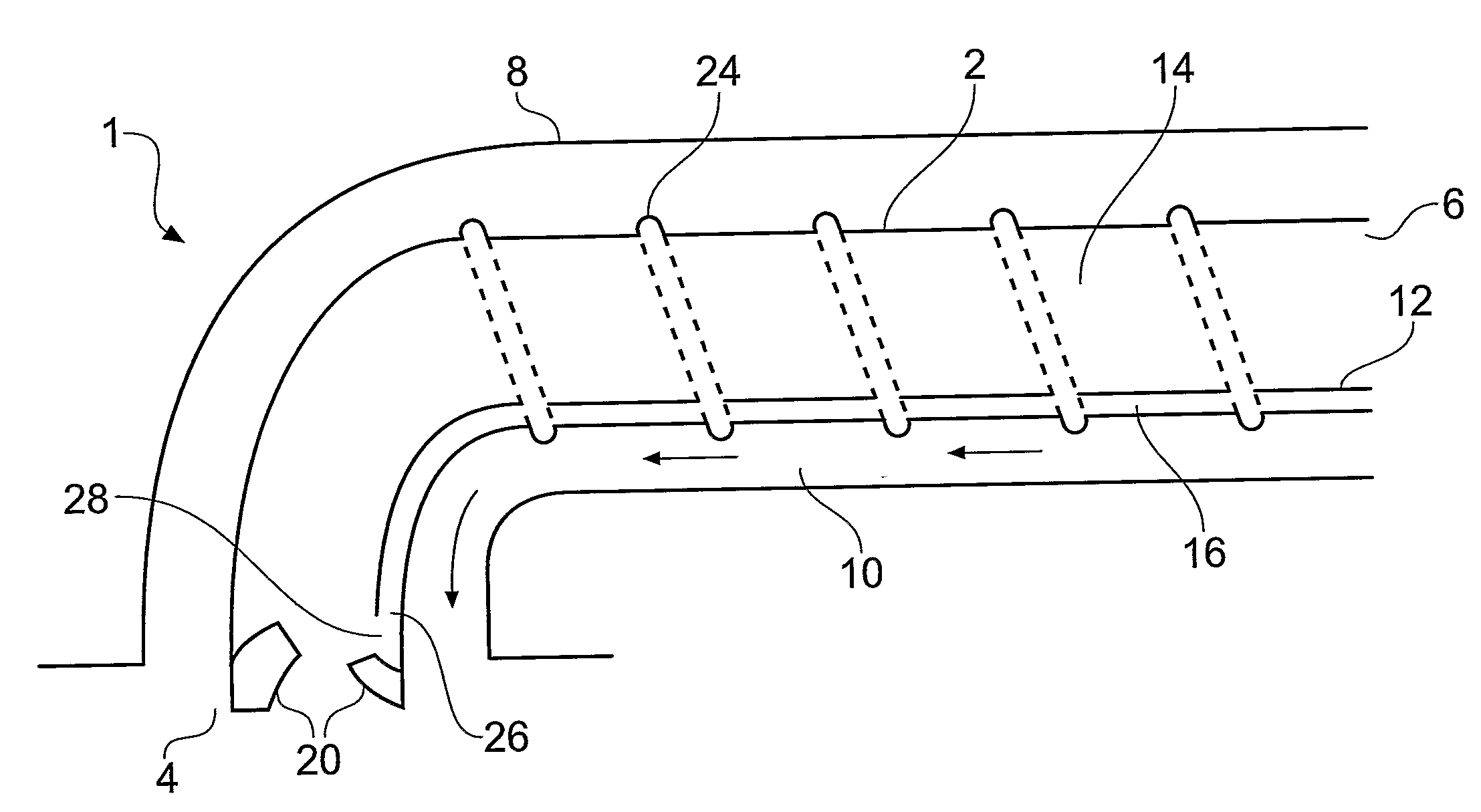

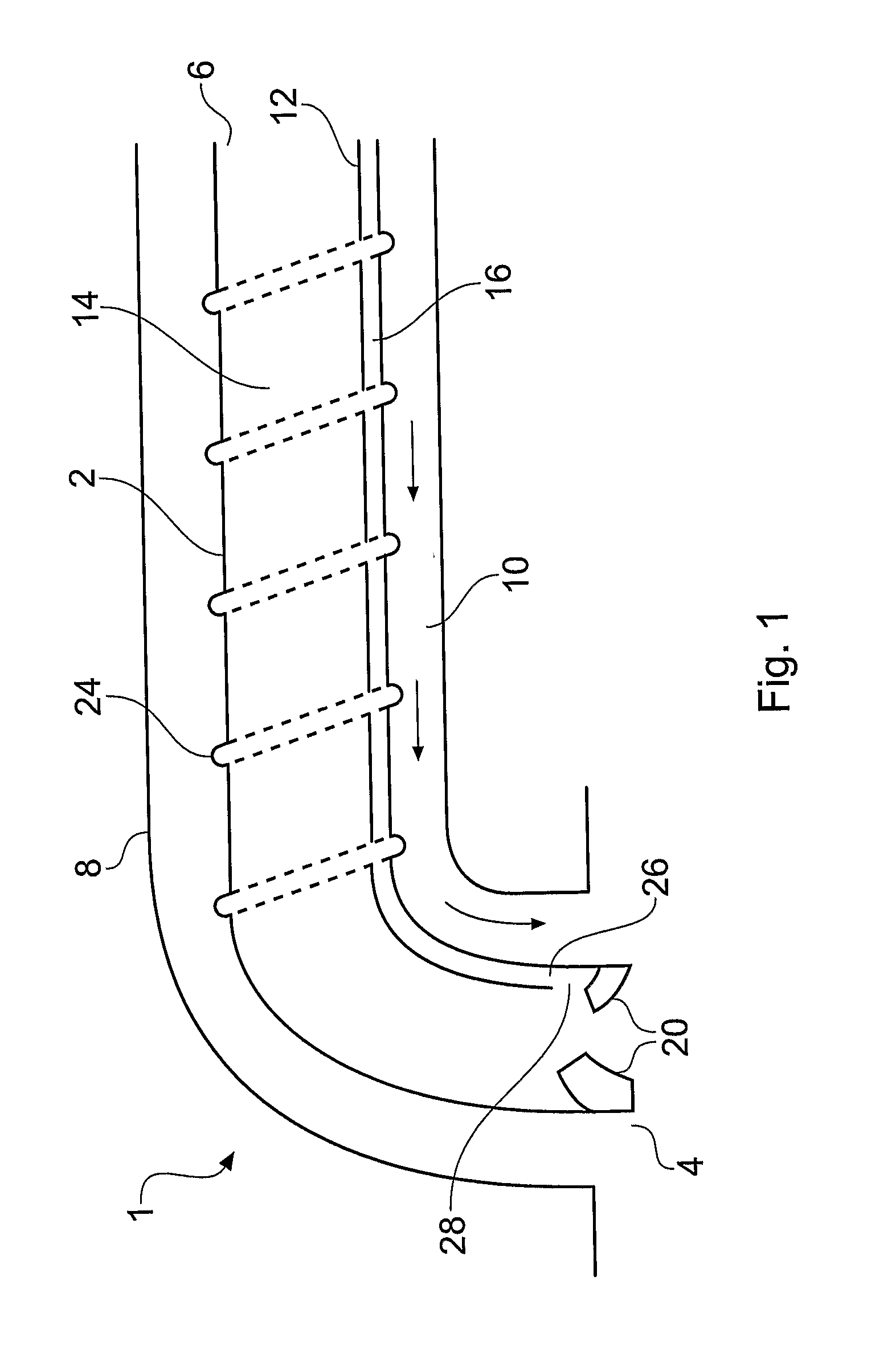

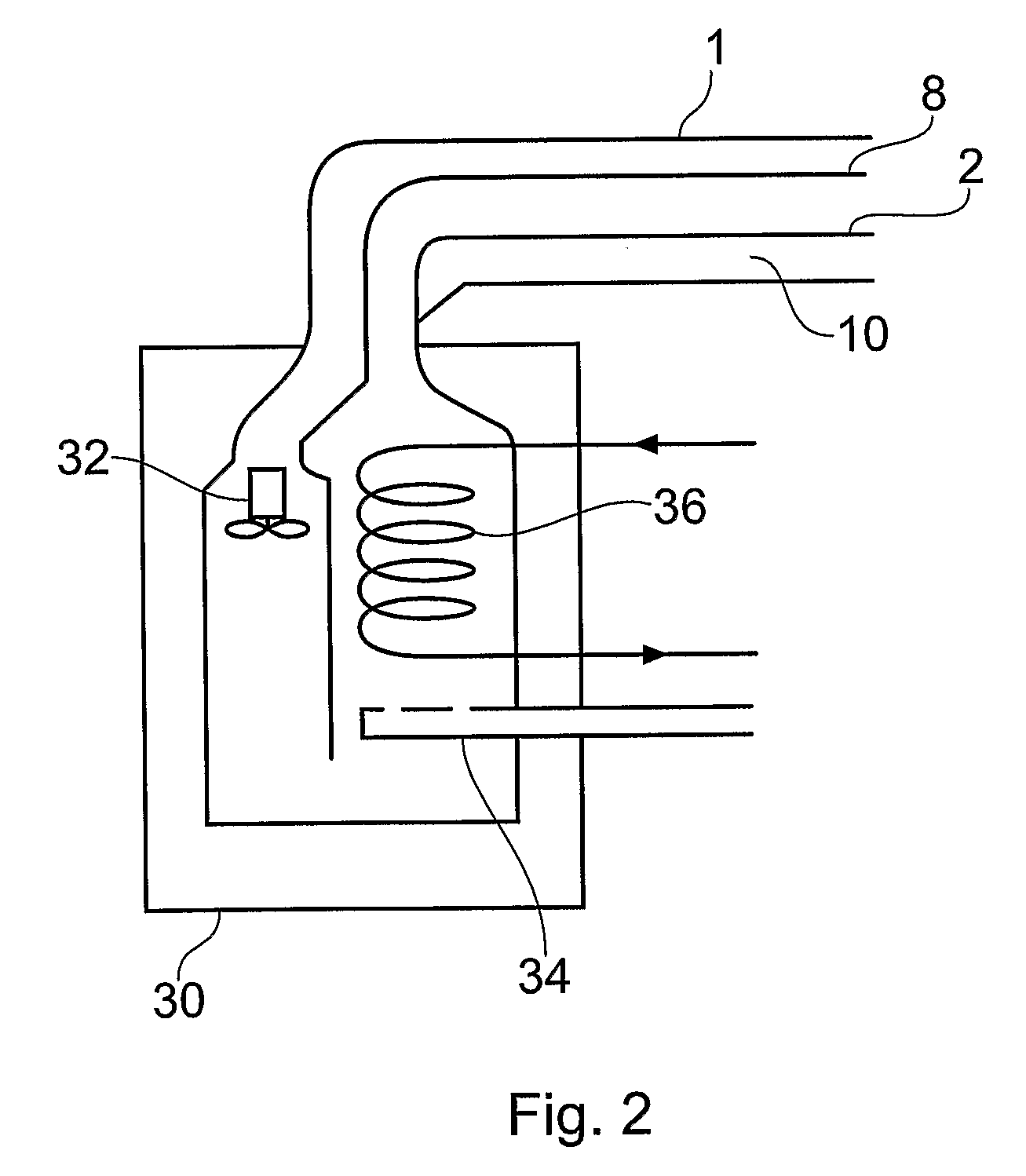

Heat exchange system

A heat exchange system and method for heating outside air provided to a structure are disclosed. The system uses and recovers heat from waste products that are being exhausted from the structure. A heated products source generates heated waste products as a result of combustion. An exhaust duct passes the heated waste products through a heat exchanger before exhaustion from the structure. An intake duct that supplies fresh outside air to the structure also passes through the heat exchanger. The heat exchanger couples the exhaust duct and the intake duct and transfers otherwise unused heat from the waste products to the outside air to increase the overall efficiency of the heated product source.

Owner:HNI TECH INC

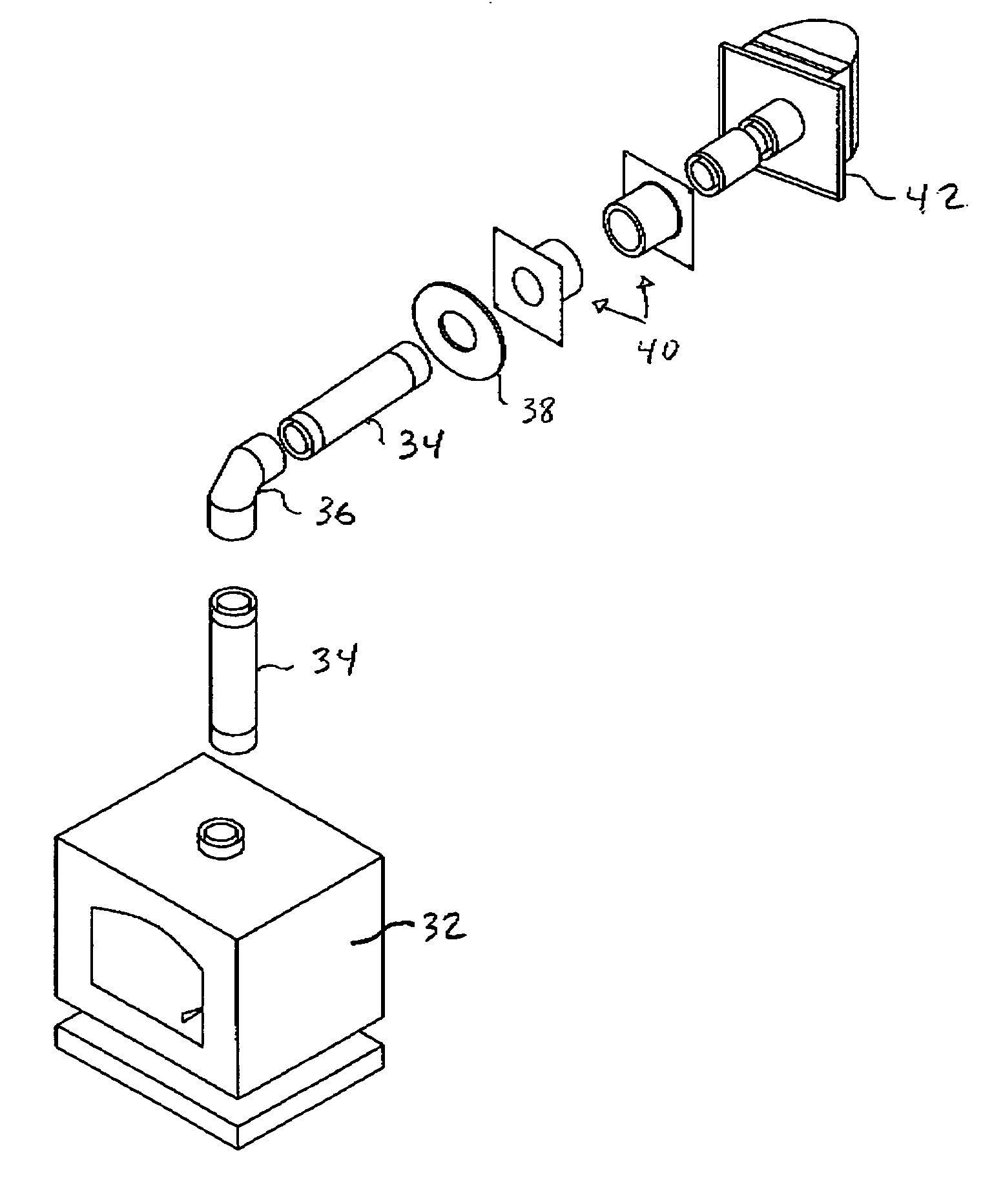

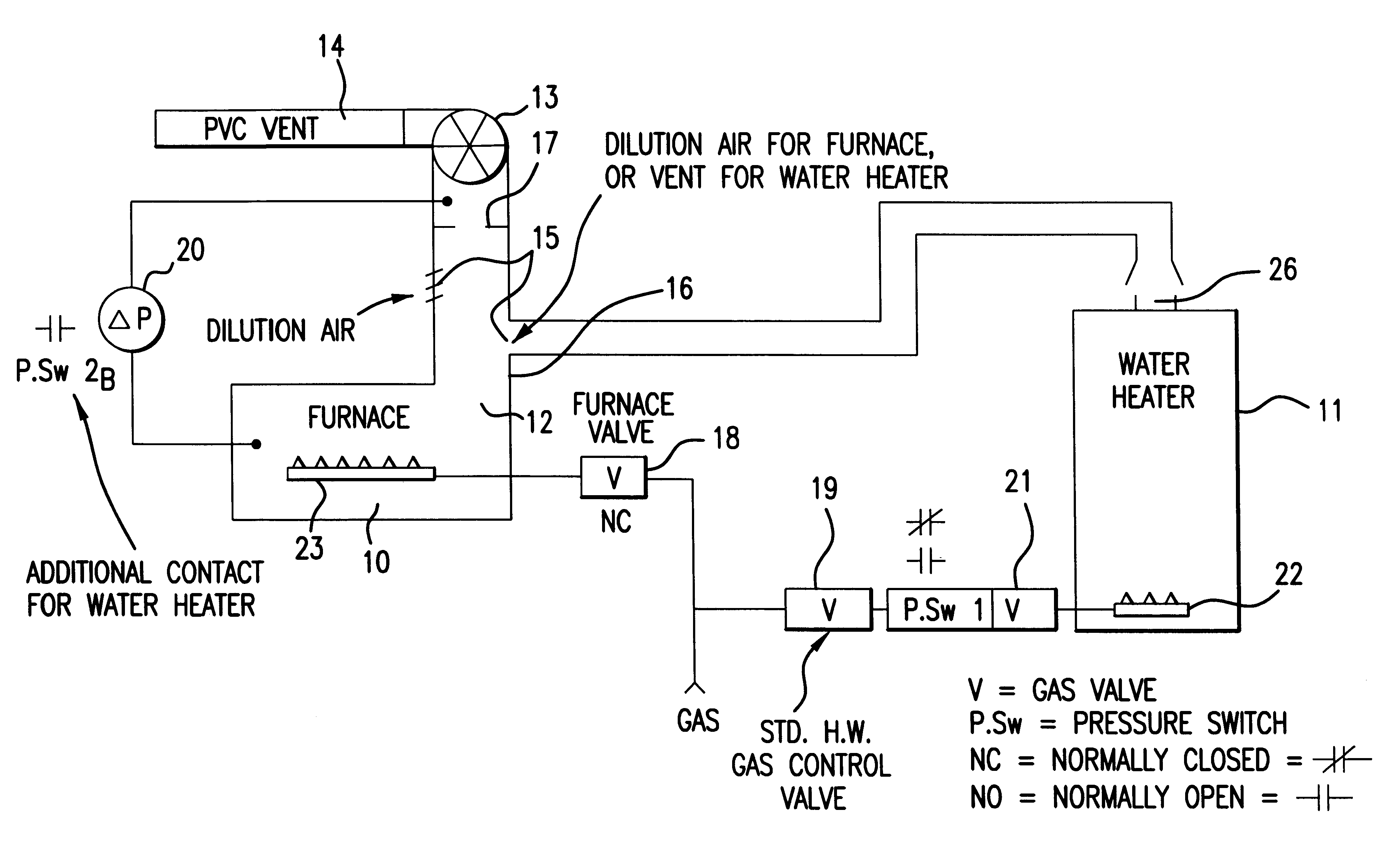

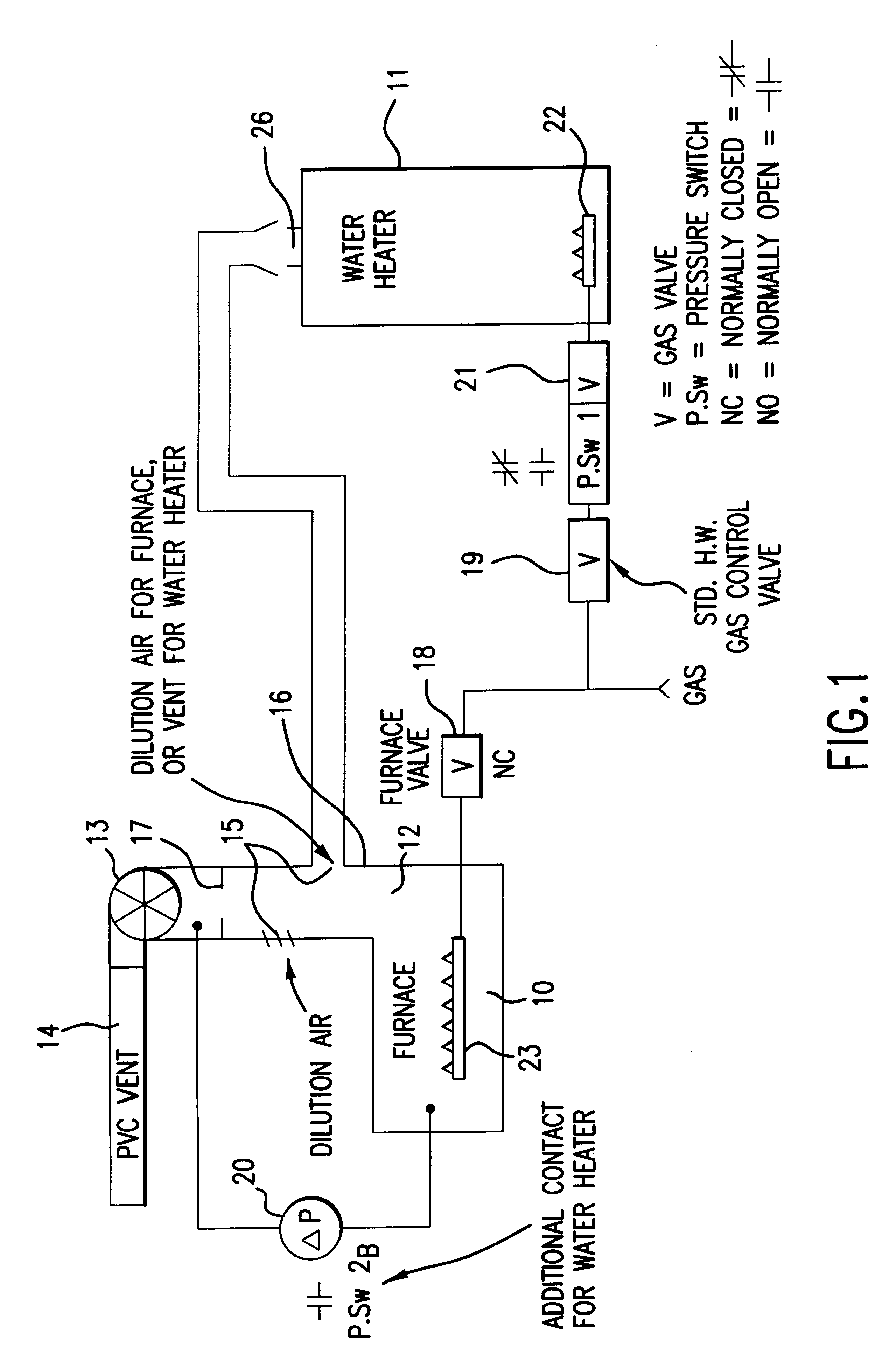

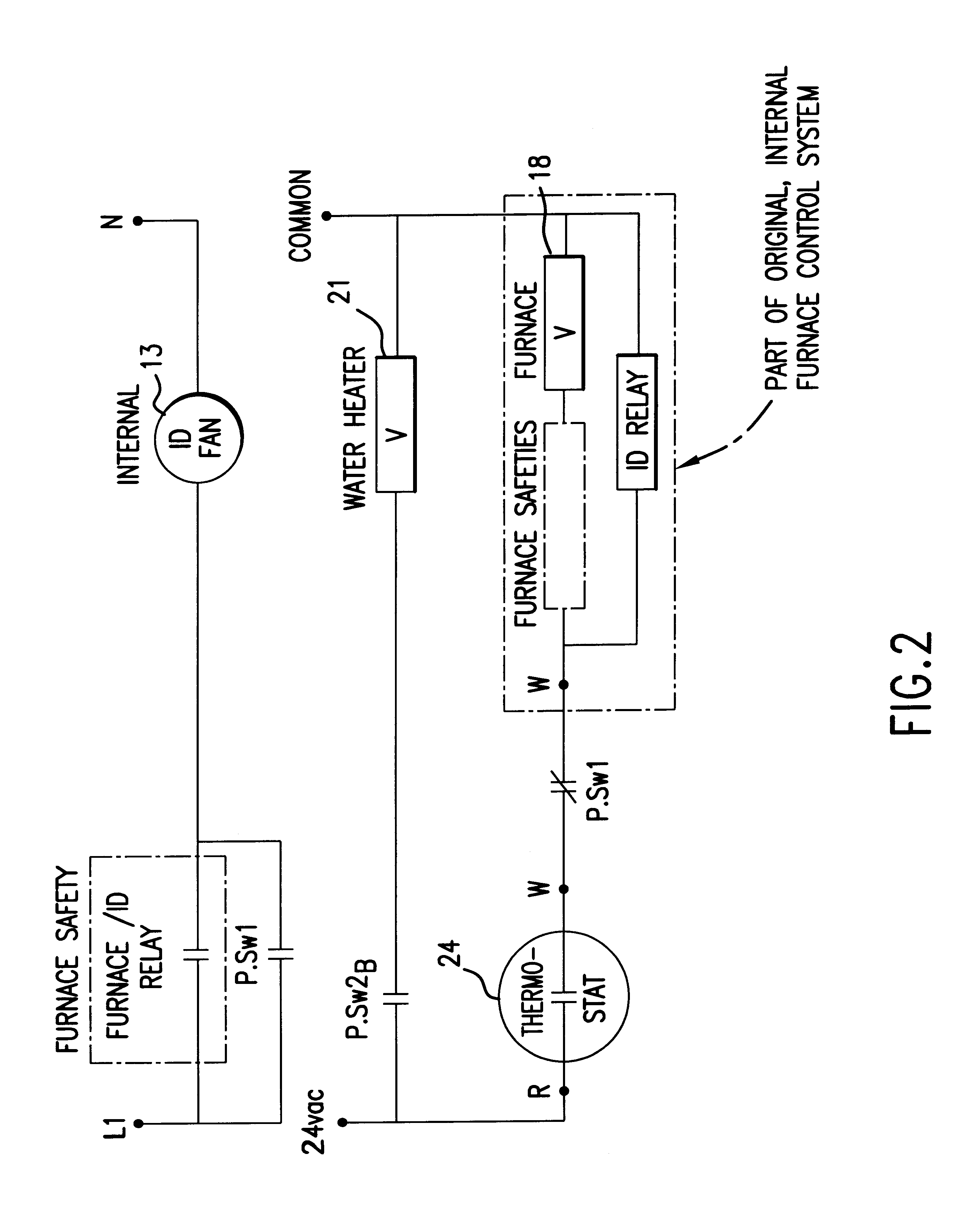

Common venting of water heater and induced draft furnace

A common, side-wall, Category III or Category IV-vented gaseous fuel-fired furnace and gaseous fuel-fired water heater system having a gaseous fuel-fired furnace having a furnace combustion products exhaust, a gaseous fuel-fired water heater having a water heater combustion products exhaust, and a Category III or Category IV vent in communication with the furnace combustion products exhaust and the water heater combustion products exhaust for venting of the combustion products from the furnace and water heater.

Owner:GAS TECH INST

Direct venting vent pipe

InactiveUS20020092518A1Efficient combustionEnsure sealing performancePipe supportsDomestic stoves or rangesDirect combustionDouble wall

A venting system for a direct vent fireplace or other direct vent appliance to direct combustion gases to an exterior area. The direct venting vent pipe facilitates unrestricted lengths of pipe installations. The vent pipe has a double wall construction forming an interior axial passageway and a coaxial outer passageway. The double walls are spaced apart by an insert to maintain coaxial spacing. Sections of the vent pipe are lockingly connected to prevent separation and ensure sealing connection between the pipe sections. Elastic seal members are utilized between the matingly connected sections and a mechanical lock assembly prevents separation

Owner:CARDINAL IP HLDG LLC

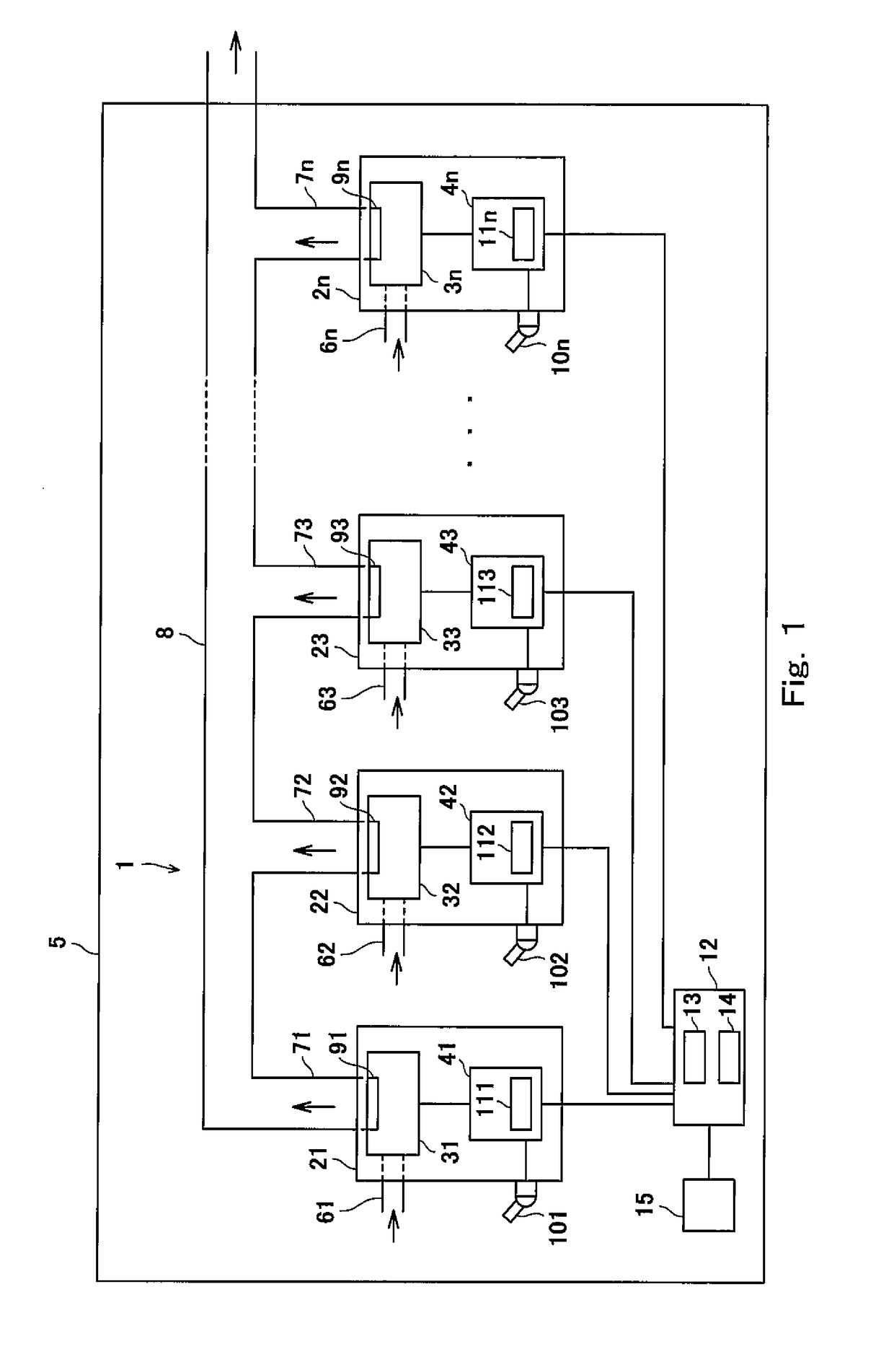

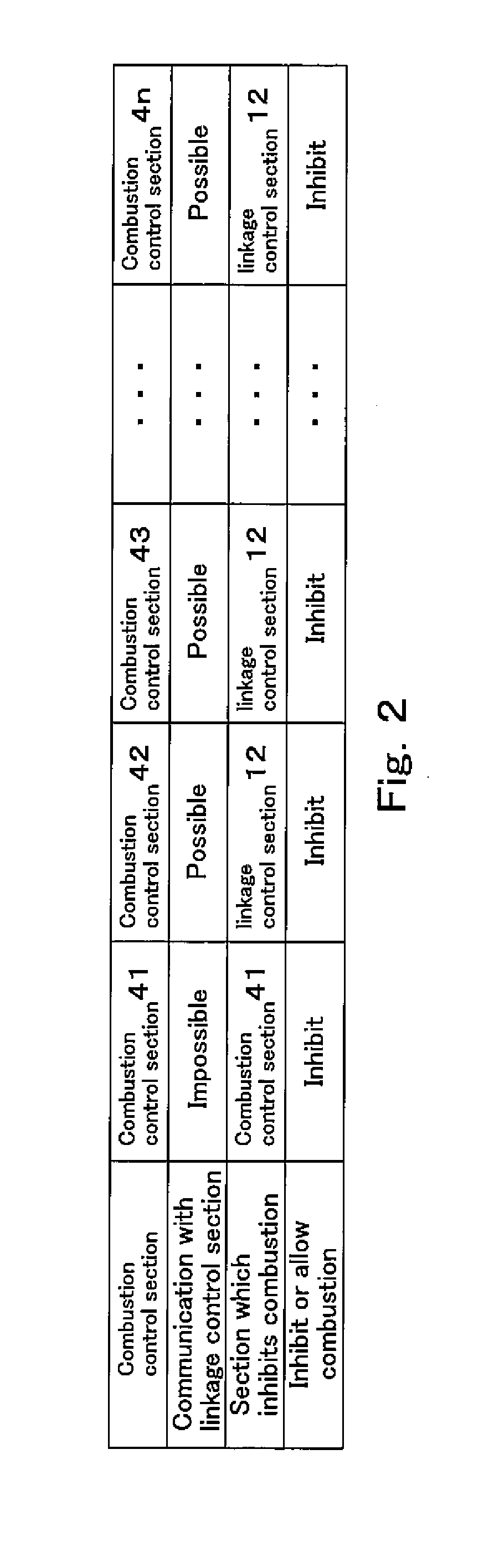

Multi-boiler and control method thereof for preventing back flow of exhaust gas

ActiveUS8235707B2Prevent backflowAdditional costMechanical apparatusDomestic stoves or rangesCombustion chamberMaster controller

The present invention relates to a control method of preventing backflow of exhaust gas into combustion chambers of boilers or water heaters that are not in operation for a multiboiler comprising a plurality of boilers or water heaters connected in line, each of which including a wind pressure sensor measuring wind pressure of air flowing into a combustion chamber and a controller controlling a fan supplying air into the combustion chamber on the basis of the wind pressure measured by the wind pressure sensor. The control method includes measuring wind pressures using the wind pressure sensors in the operating boilers and calculating an average wind pressure, using any controller as a master controller to determine a control amount of wind of the fans of non-operational boilers based on the average wind pressure, and operating the fans of the non-operational boilers on the basis of the control amount of wind.

Owner:KYUNGDONG NAVIEN

Partitioned chimney cap and fireplace venting system

InactiveUS20080160894A1Reduce noise levelOperation efficiency can be improvedDomestic stoves or rangesFlue gas duct systemCombustion chamberEngineering

A fireplace chimney cap includes a body having first and second apertures in fluid communication defining a first cavity therebetween. The first cavity is configured and disposed to receive combustion air through the first aperture, then through the second aperture for delivery to a fireplace combustion chamber. The body has third and fourth apertures in fluid communication defining a second cavity therebetween. The second cavity is configured and disposed to receive combustion gases from the fireplace combustion chamber through the third aperture, then through the fourth aperture for exhausting exterior of the body. The first and second cavities are fluidly separated from each other. The first and fourth apertures are configured and disposed to provide a pitot effect to more readily draw both combustion air into the first cavity and combustion gases into the second cavity in response to the first aperture disposed upwind and fourth aperture position disposed downwind.

Owner:EBERHARDT H ALFRED

Sealed combustion gas-fired infrared heater

A gas fired infrared heater is provided that includes a burner, a combustion chamber, a cooling air passage for supplying cooling air to the combustion chamber, a combustion air passage for supplying combustion air to the burner; and an outlet passage allowing combustion product gases to exit the combustion chamber. The cooling air passage is separate from the combustion air passage. The cooling air passage and the combustion air passage both draw from the same pressure zone into which combustion products exit.

Owner:EICHENLAUB JOHN E

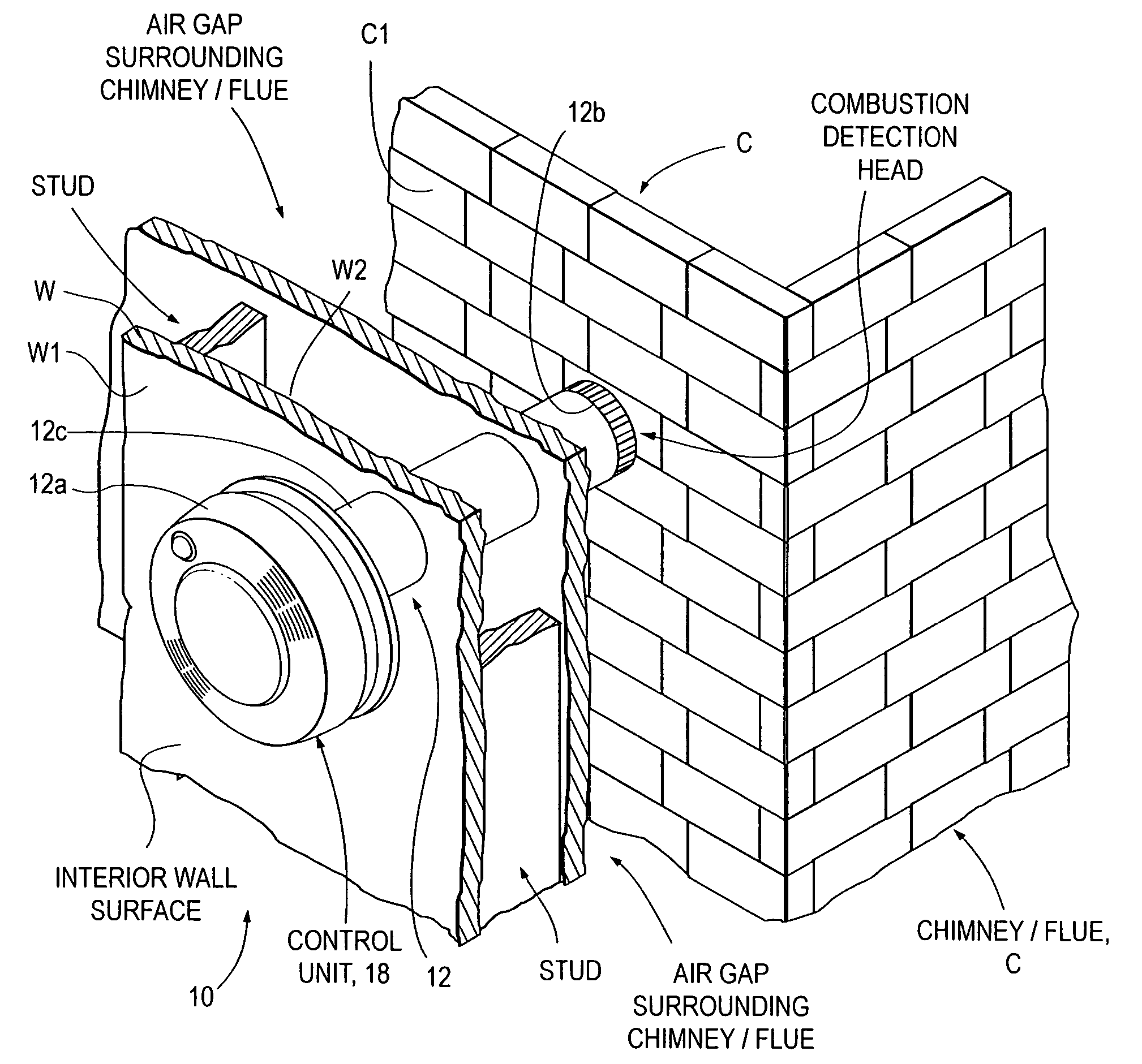

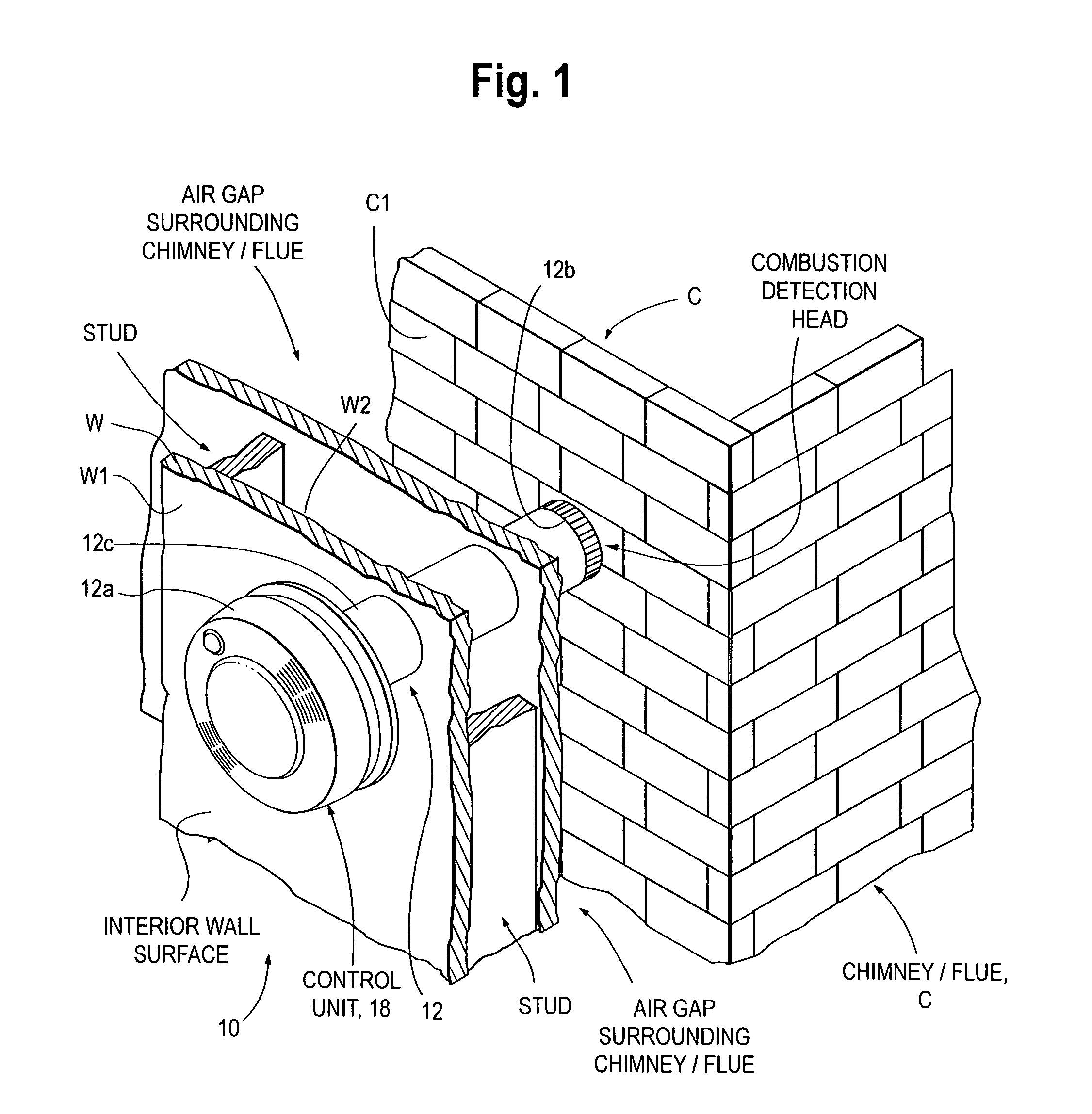

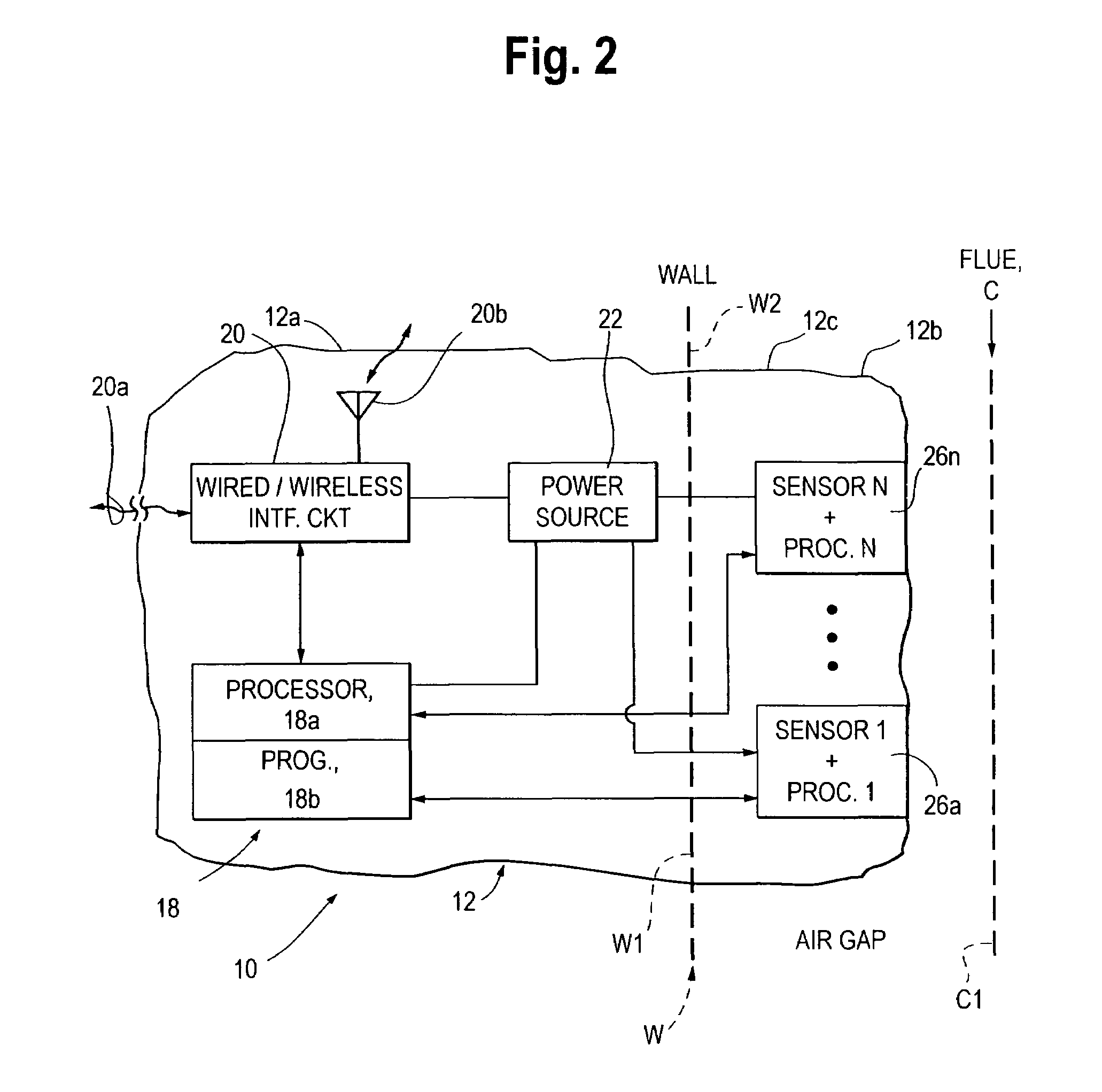

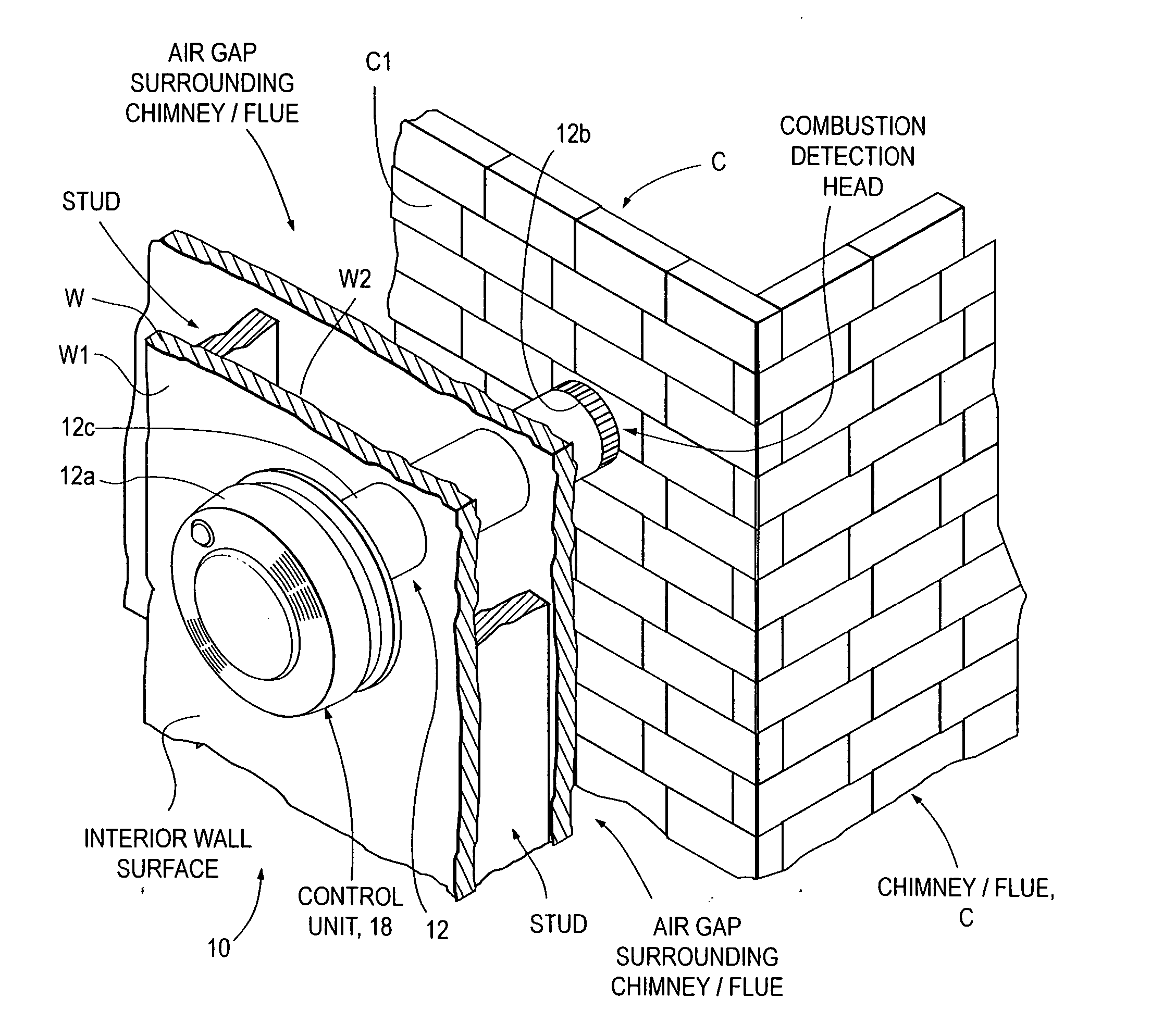

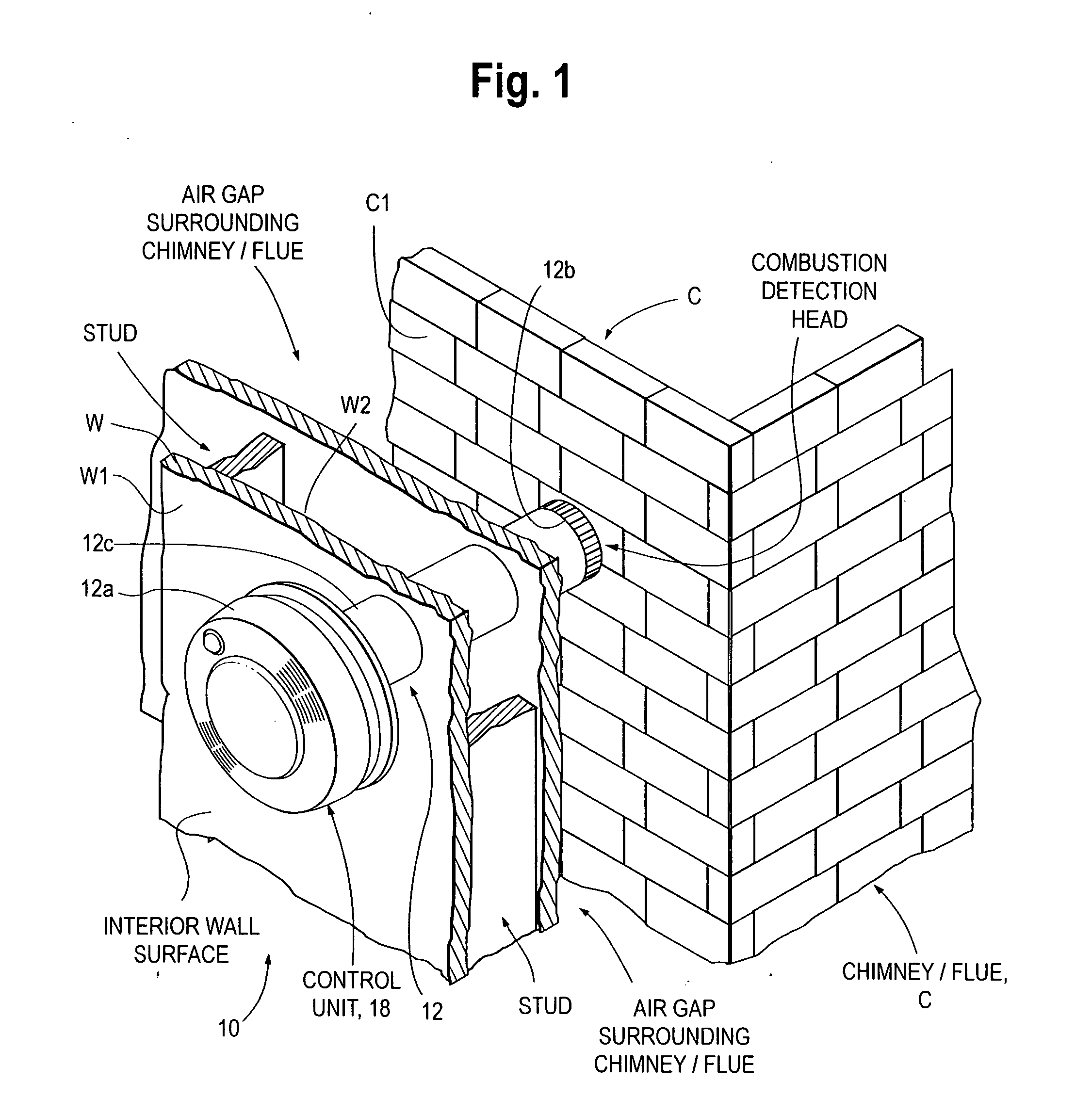

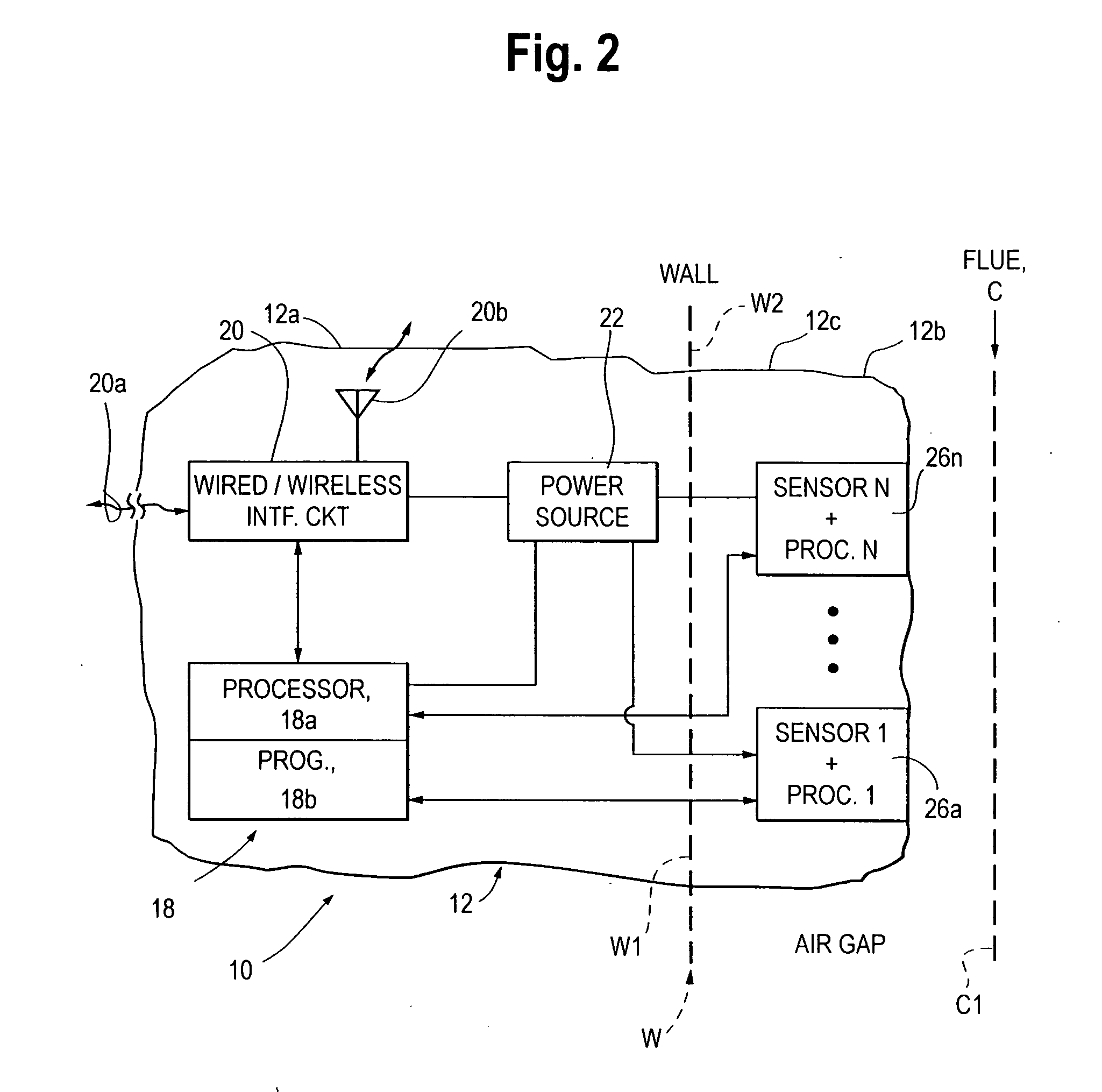

Through a wall combustion detector

A detector of combustion products in air gaps adjacent to chimneys or flues has an air gap detection unit coupled to a displaced control unit. The control unit can be located adjacent to a proximal, exposed, surface of a wall. When so installed, the detection unit is located in an air space adjacent to the chimney or flue. The assembly can be removed for cleaning or maintenance.

Owner:HONEYWELL INT INC

Exhaust adapter, exhaust structure for water heater, and method for installing exhaust adapter

ActiveUS20170130960A1Easy and cheap to performFluid heatersPipe supportsPulp and paper industryExhaust pipe

An exhaust adapter secures an exhaust tube relative to an exhaust pipe. The exhaust adapter is formed to have an annular shape enclosing a through hole, and is mounted on the outer peripheral surface of the exhaust tube and on the inner peripheral surface of the exhaust pipe by inserting the exhaust tube into the through hole. When the exhaust adapter is being fitted on the outer peripheral surface of the exhaust tube, the inner peripheral surface of the exhaust adapter presses the outer peripheral surface of the exhaust tube, and when the exhaust adapter is being fitted on the inner peripheral surface of the exhaust pipe, the outer peripheral surface of the exhaust adapter presses the inner peripheral surface of the exhaust pipe.

Owner:NORITZ CORP

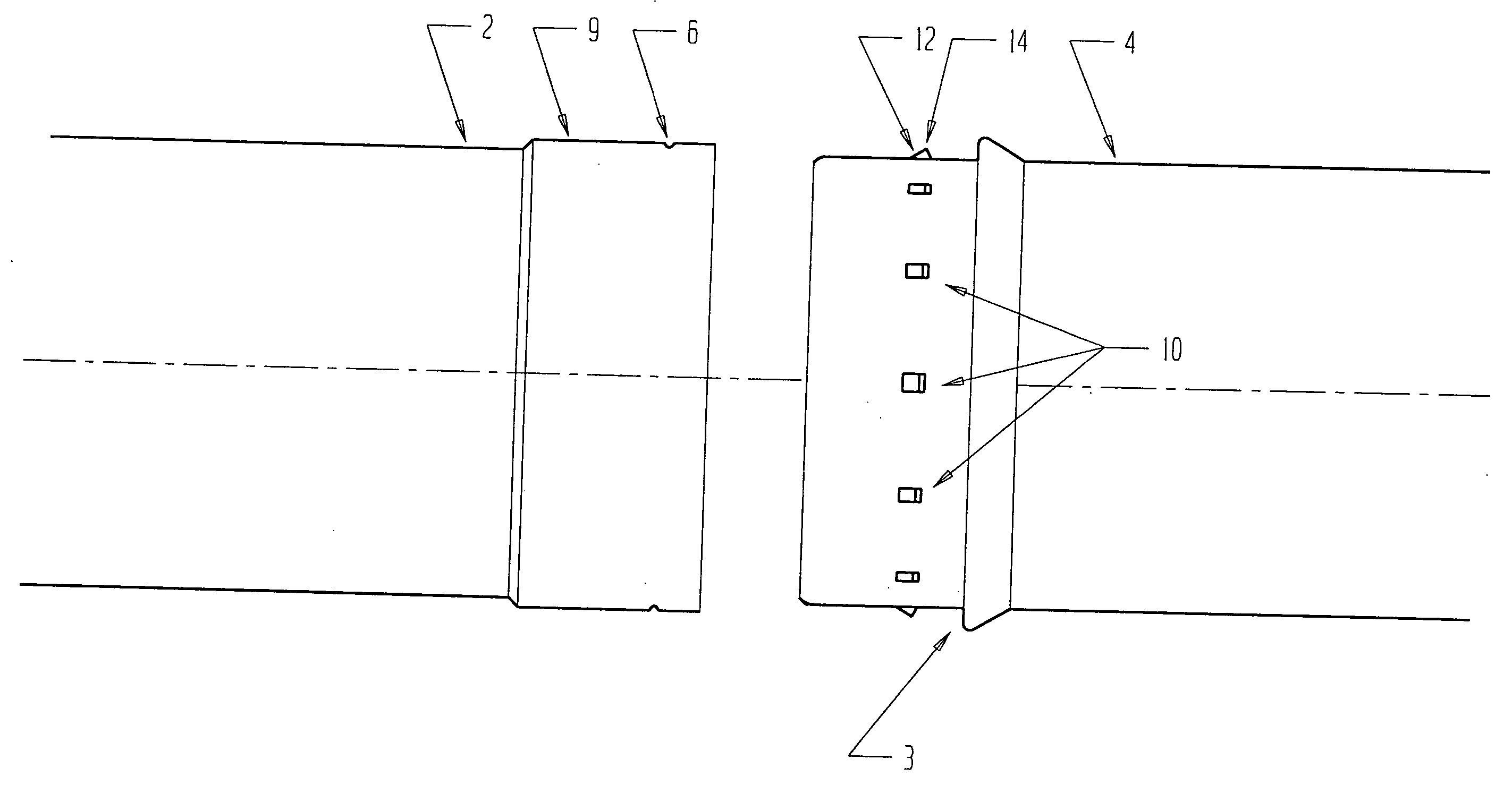

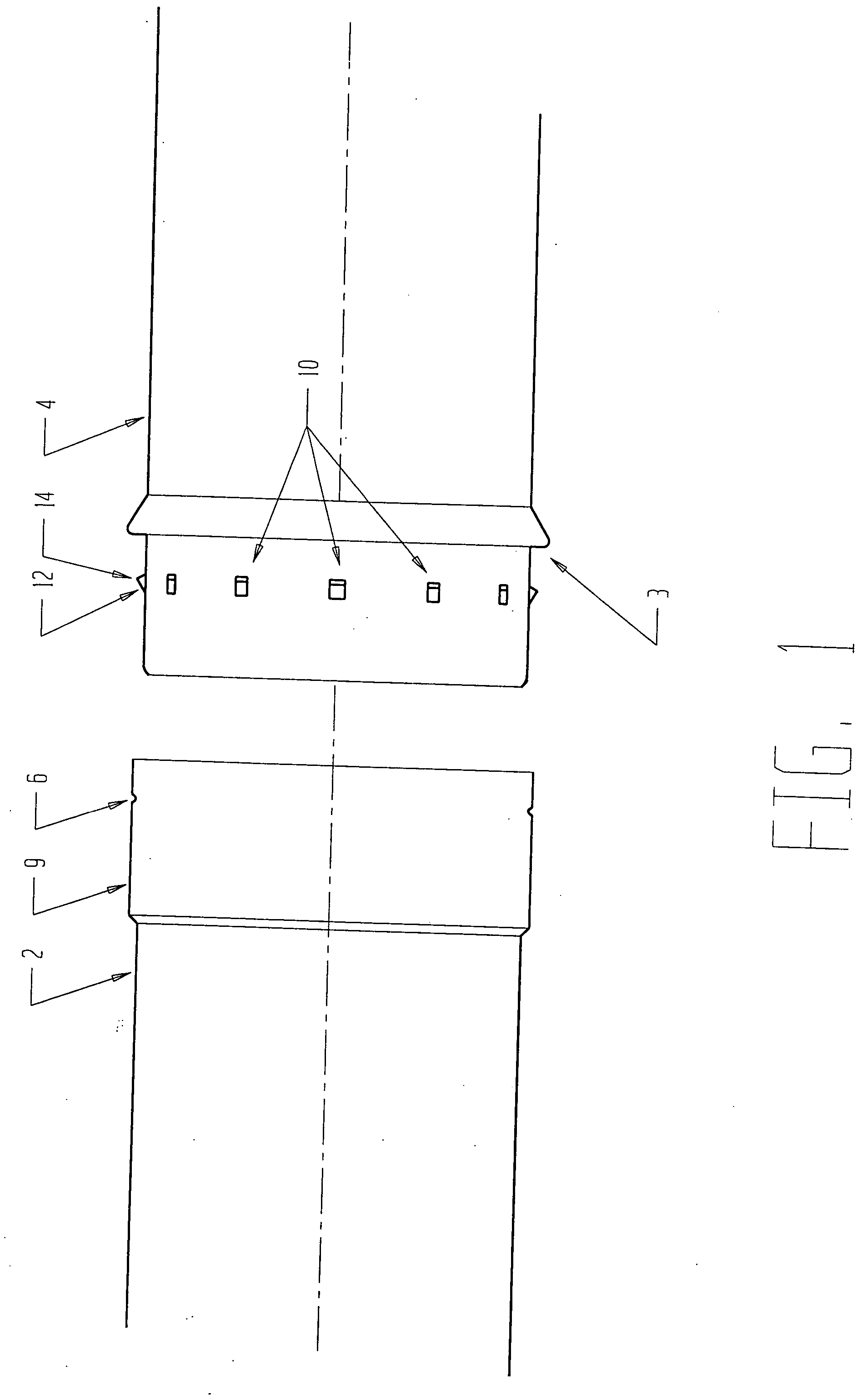

Positive pipe interlock

A system and method is taught of positively joining to pipes, such as stovepipe or conduit. A first pipe is made with an indentation about the perimeter of one end, into which a second pipe is fitted snugly. The second pipe has a plurality of protrusions about the perimeter near the end to be inserted into the first pipe. The protrusions are shaped so as to allow passage past the indentation in the first pipe during insertion of the second pipe, while resisting disassembly by withdrawing the second pipe.

Owner:FLEXMASTER CANADA

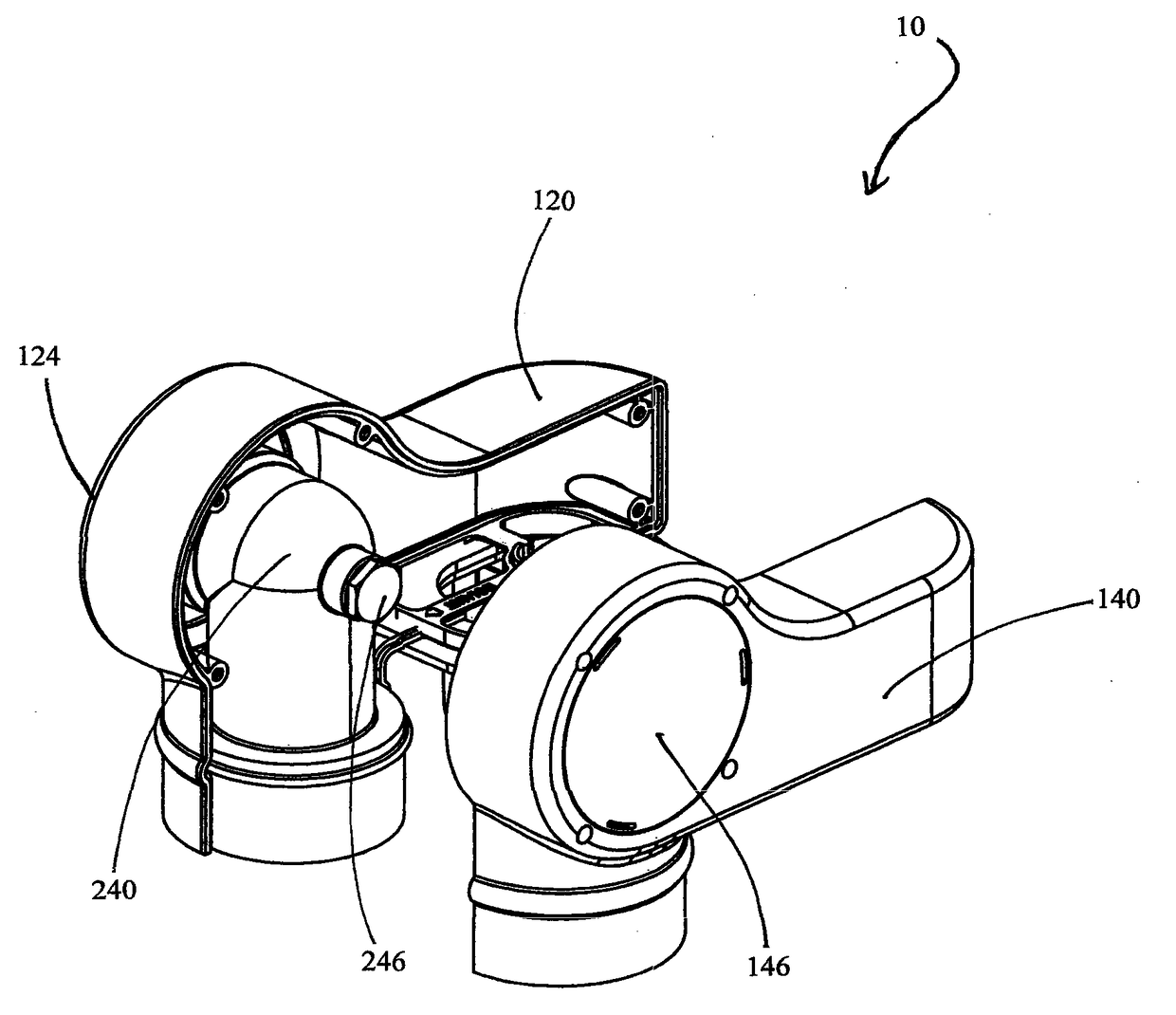

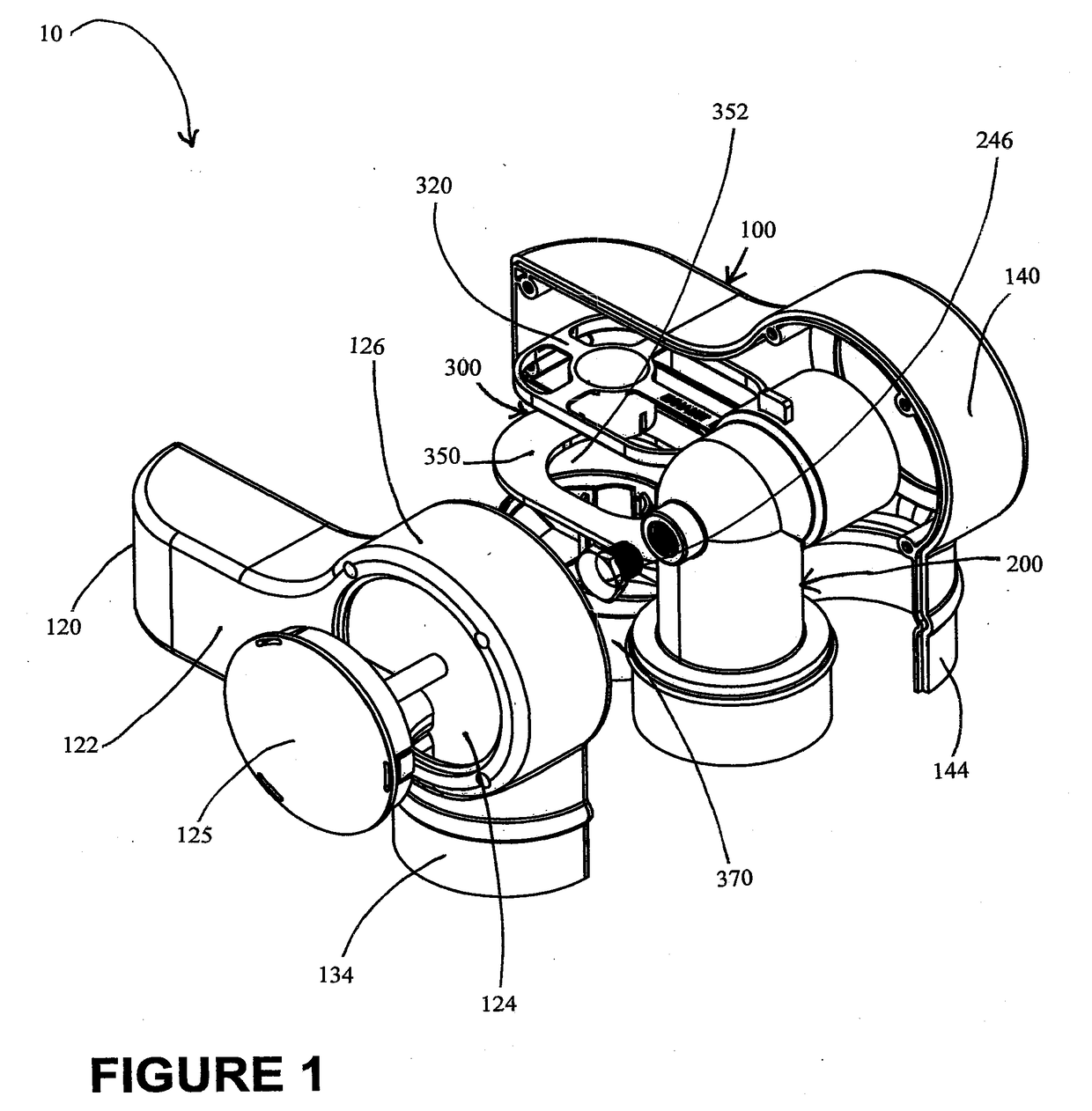

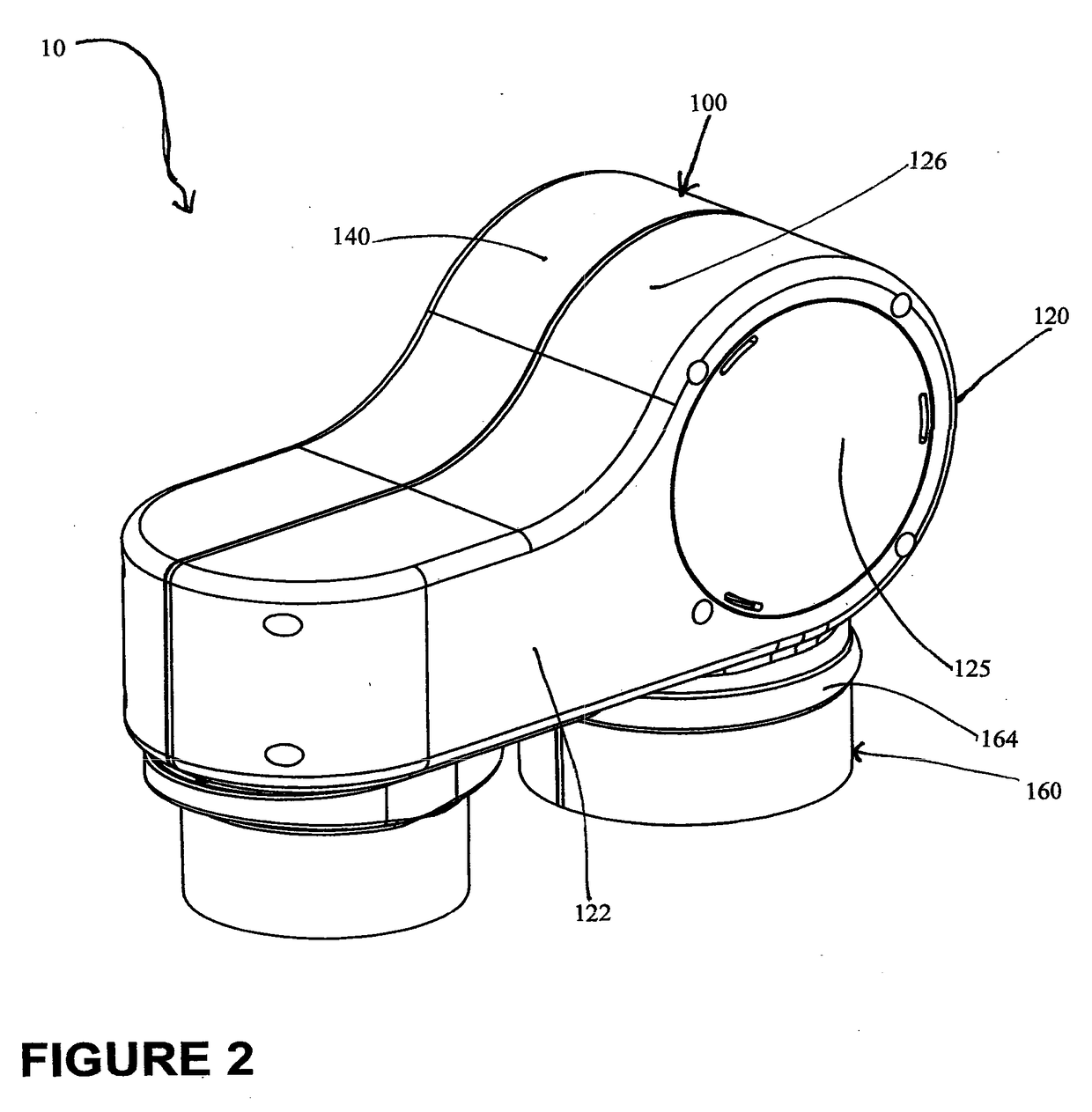

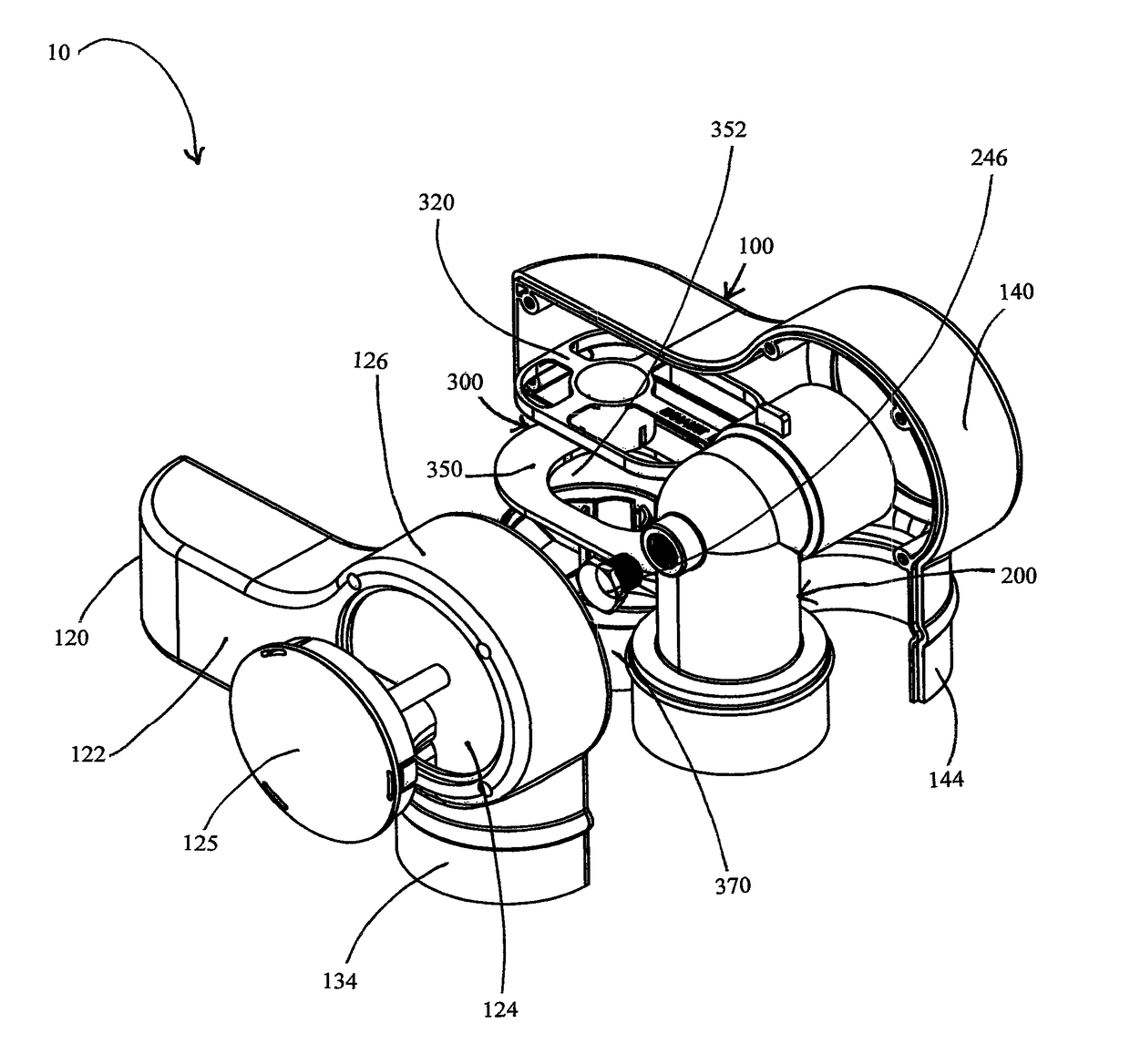

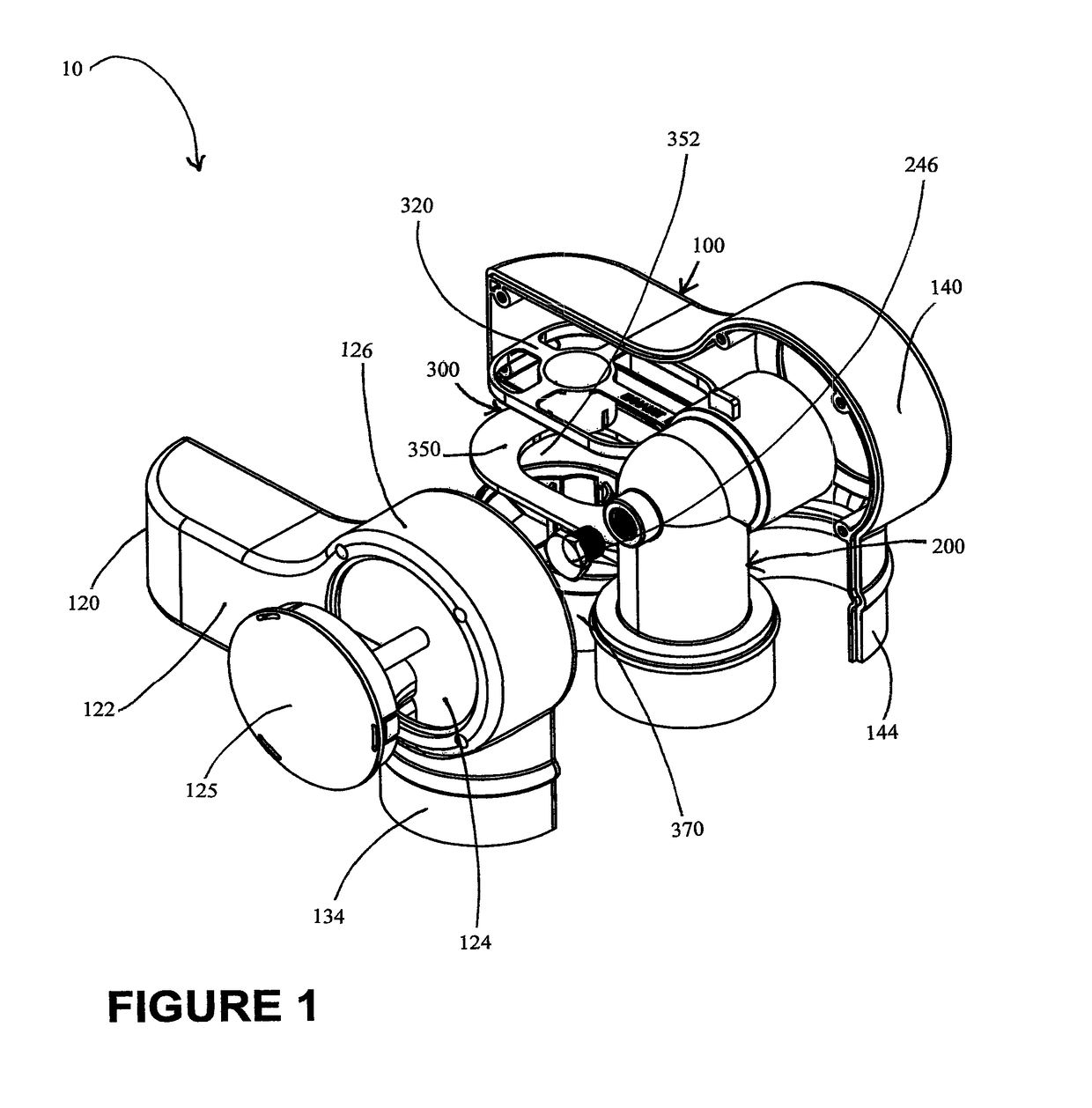

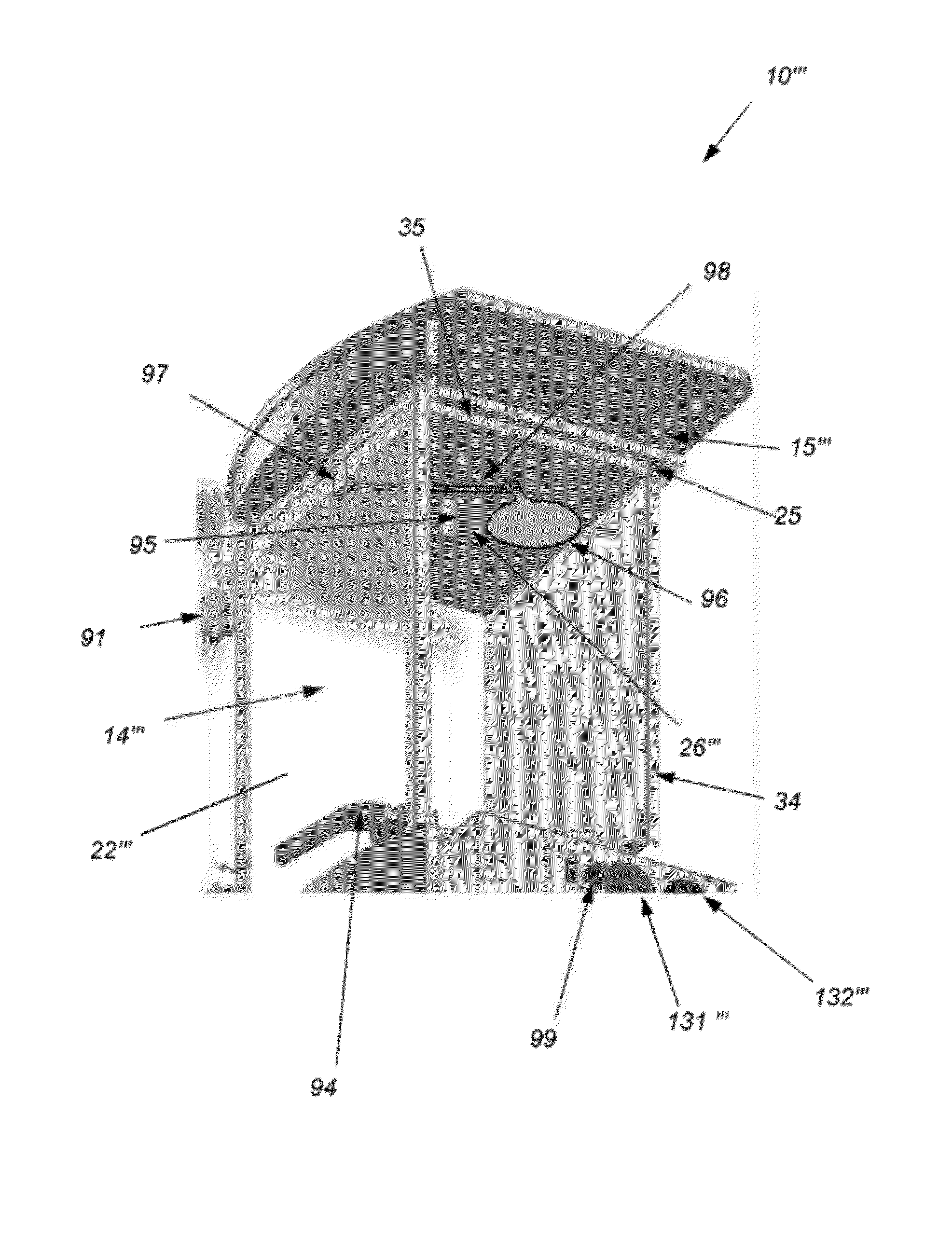

Water Heater Venting Assembly

ActiveUS20170356646A1Overcomes shortcomingPermit adjustmentFlue gas duct systemWater heatersCombustionMechanical engineering

In a preferred embodiment, there is provided a water heater venting assembly for directing a combustion air and a flue gas between an outdoor atmosphere and a water heater, and which includes a generally hollow housing defining a combustion air aperture, a flue gas exhaust conduit disposed in the housing, and an adjustable inlet duct coupling assembly having a retention member for placement in the housing proximal to the aperture, a gasket for placement around an outer periphery of the aperture and a combustion air supply member. The retention member is for retaining the supply member in fluid sealing engagement with the gasket to effect fluid communication between the aperture and the supply member, and is sized to permit slidable movement of the supply member relative to the gasket.

Owner:IPEX TECH

Through a wall combustion detector

A detector of combustion products in air gaps adjacent to chimneys or flues has an air gap detection unit coupled to a displaced control unit. The control unit can be located adjacent to a proximal, exposed, surface of a wall. When so installed, the detection unit is located in an air space adjacent to the chimney or flue. The assembly can be removed for cleaning or maintenance.

Owner:HONEYWELL INT INC

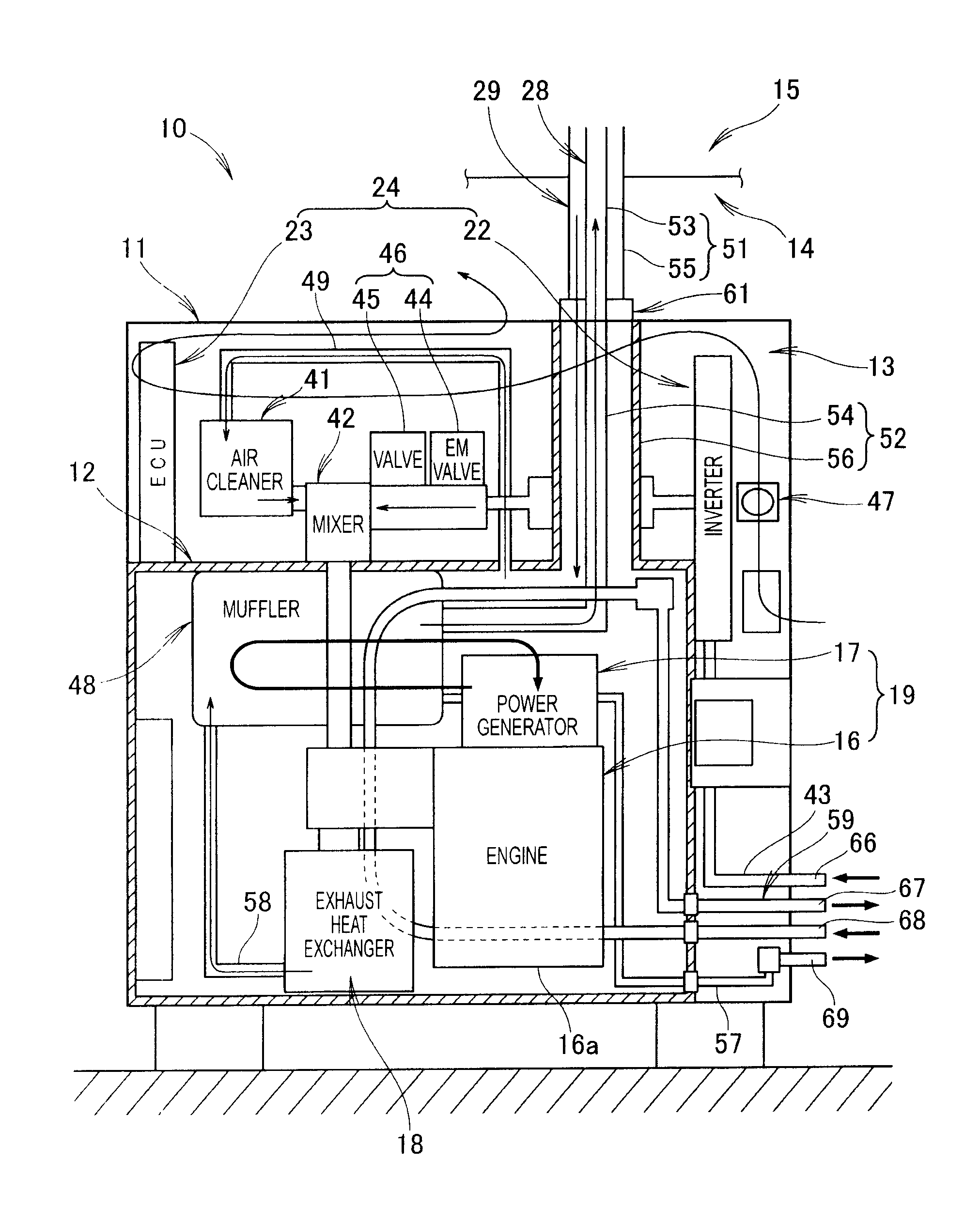

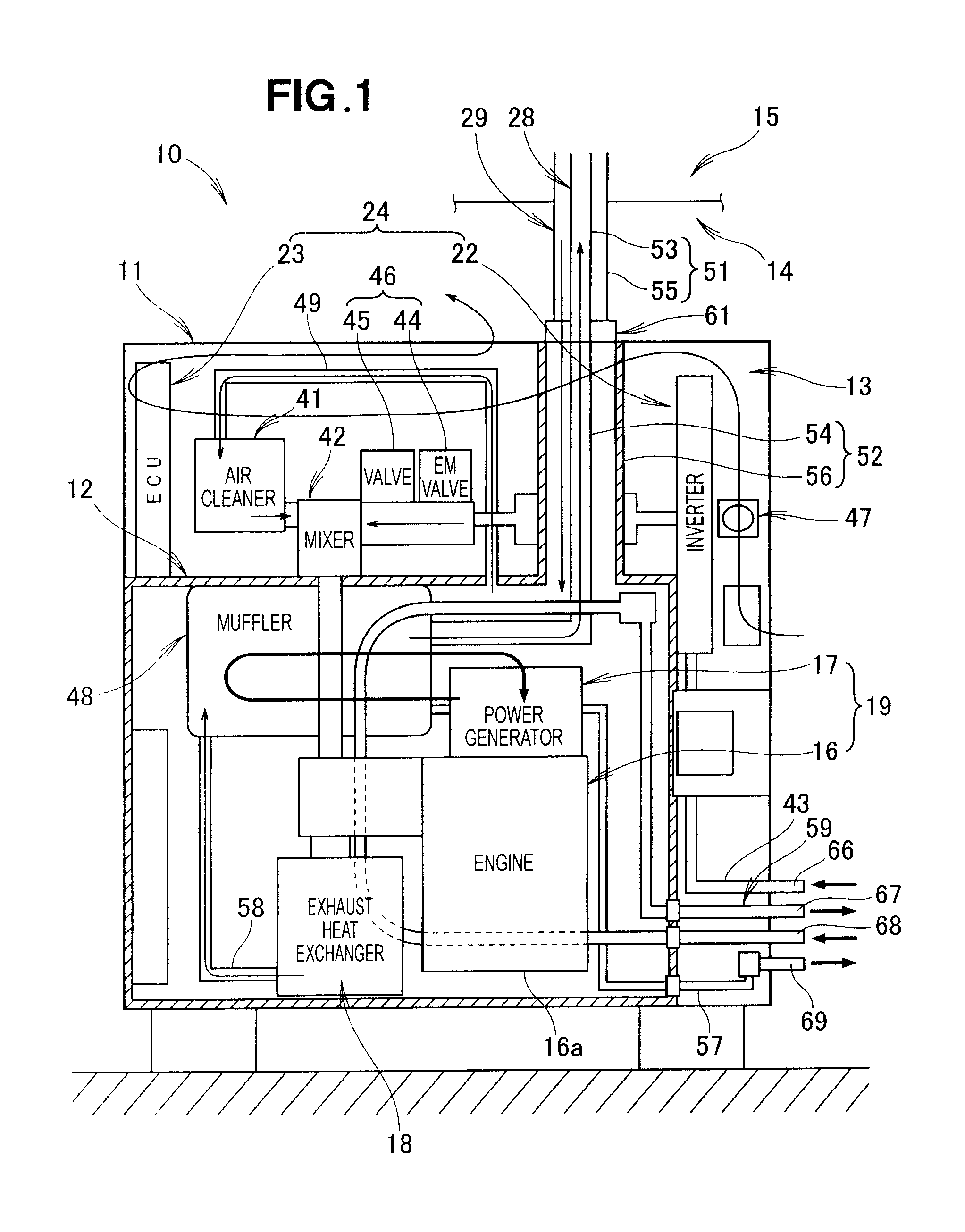

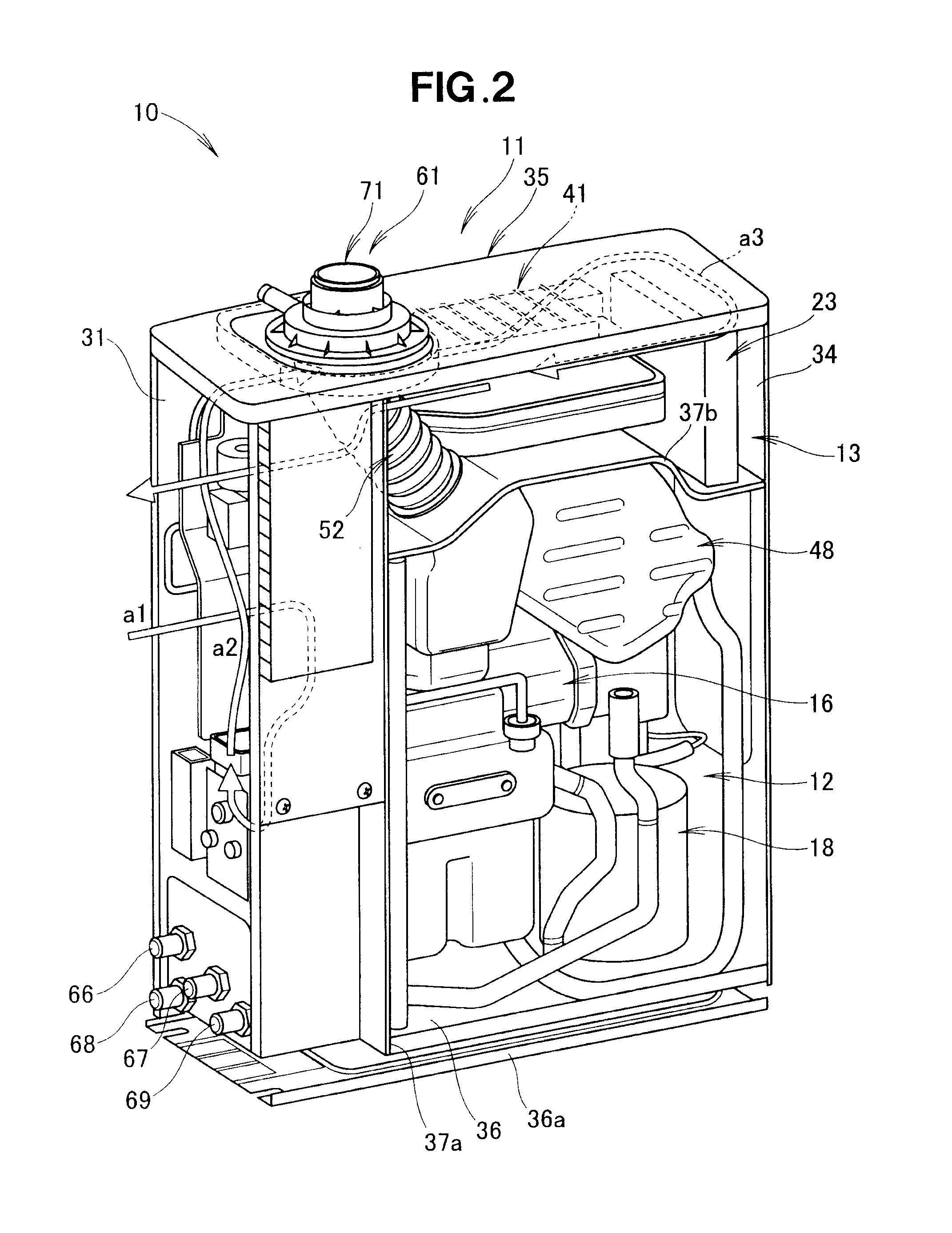

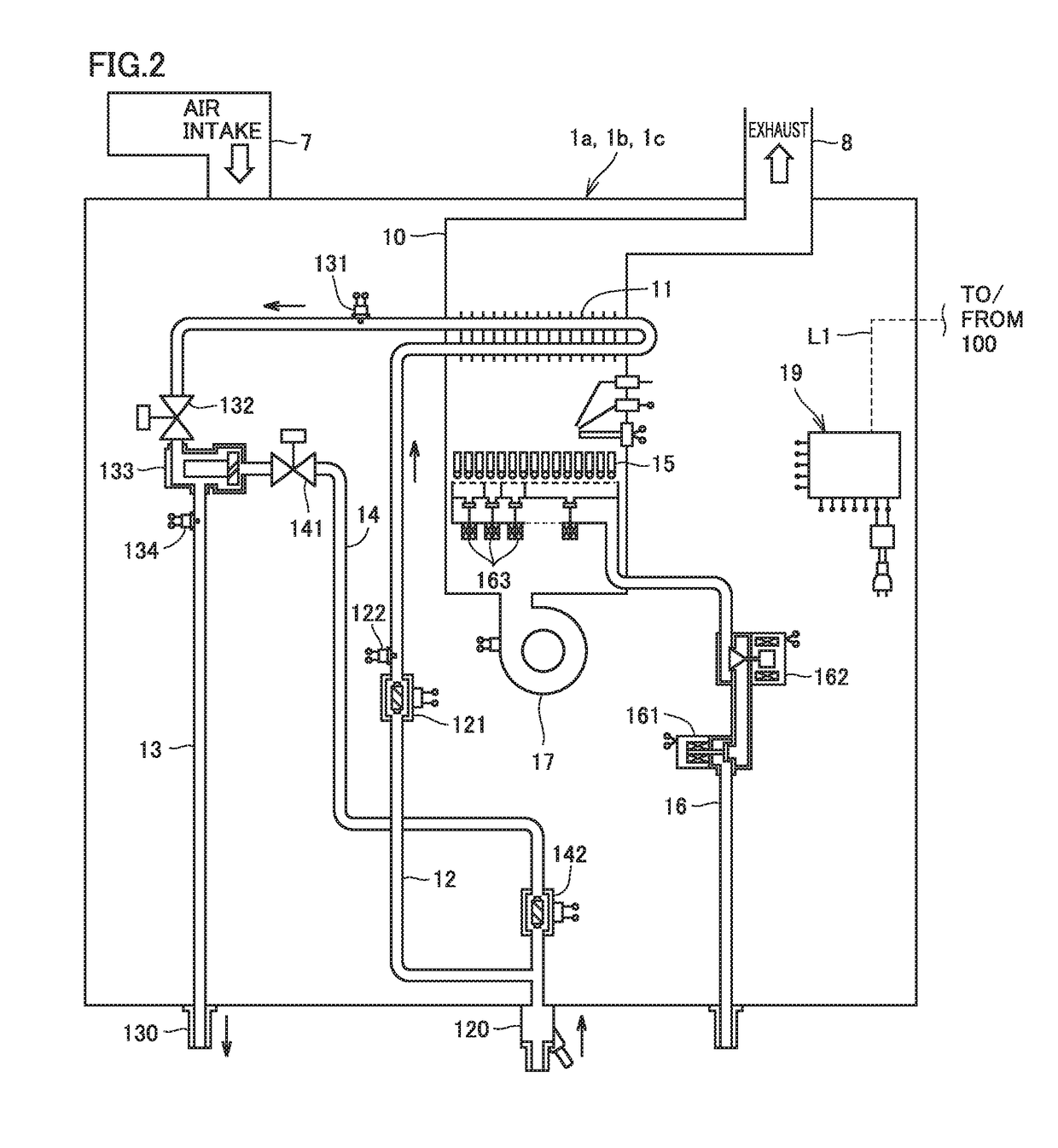

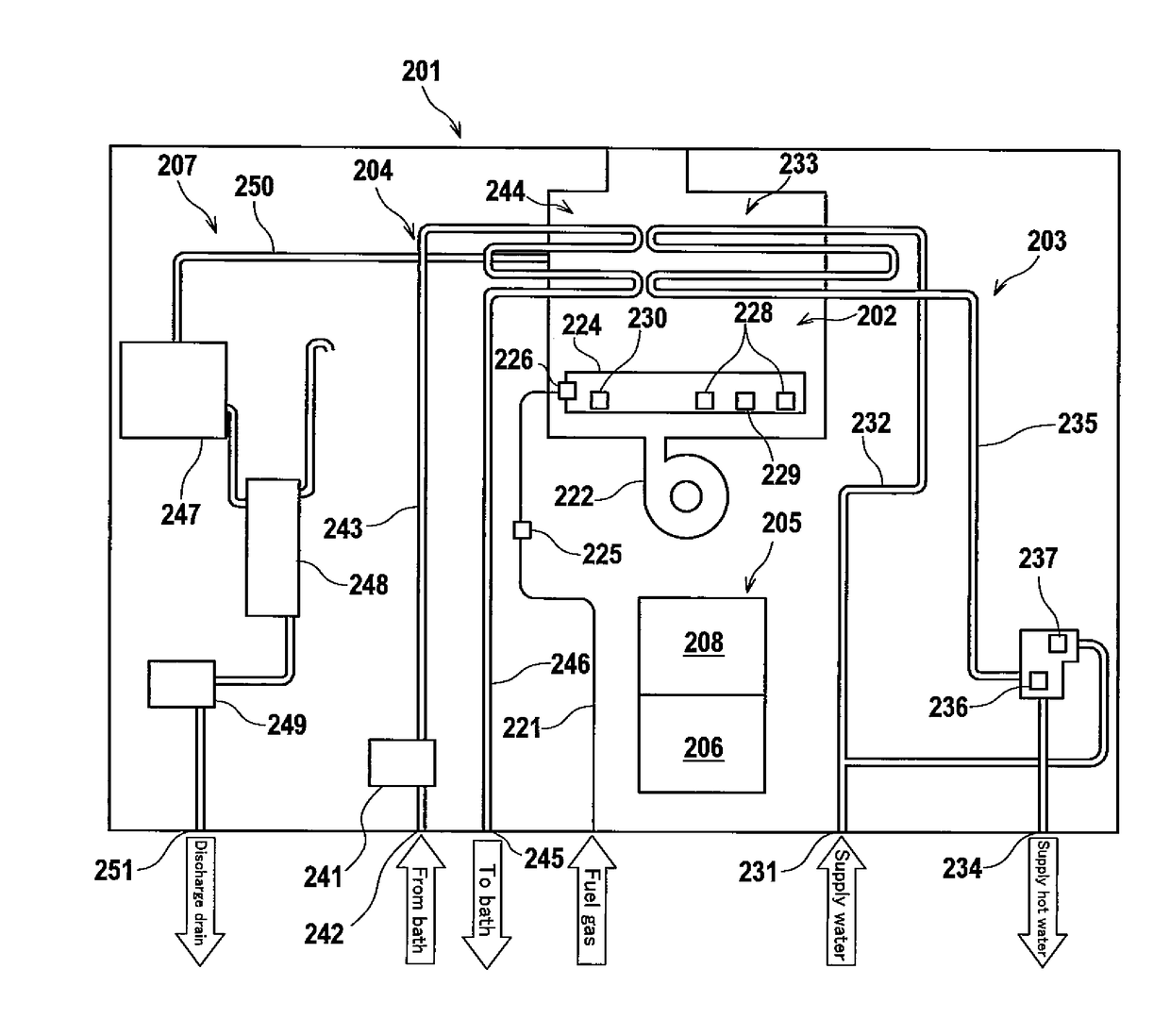

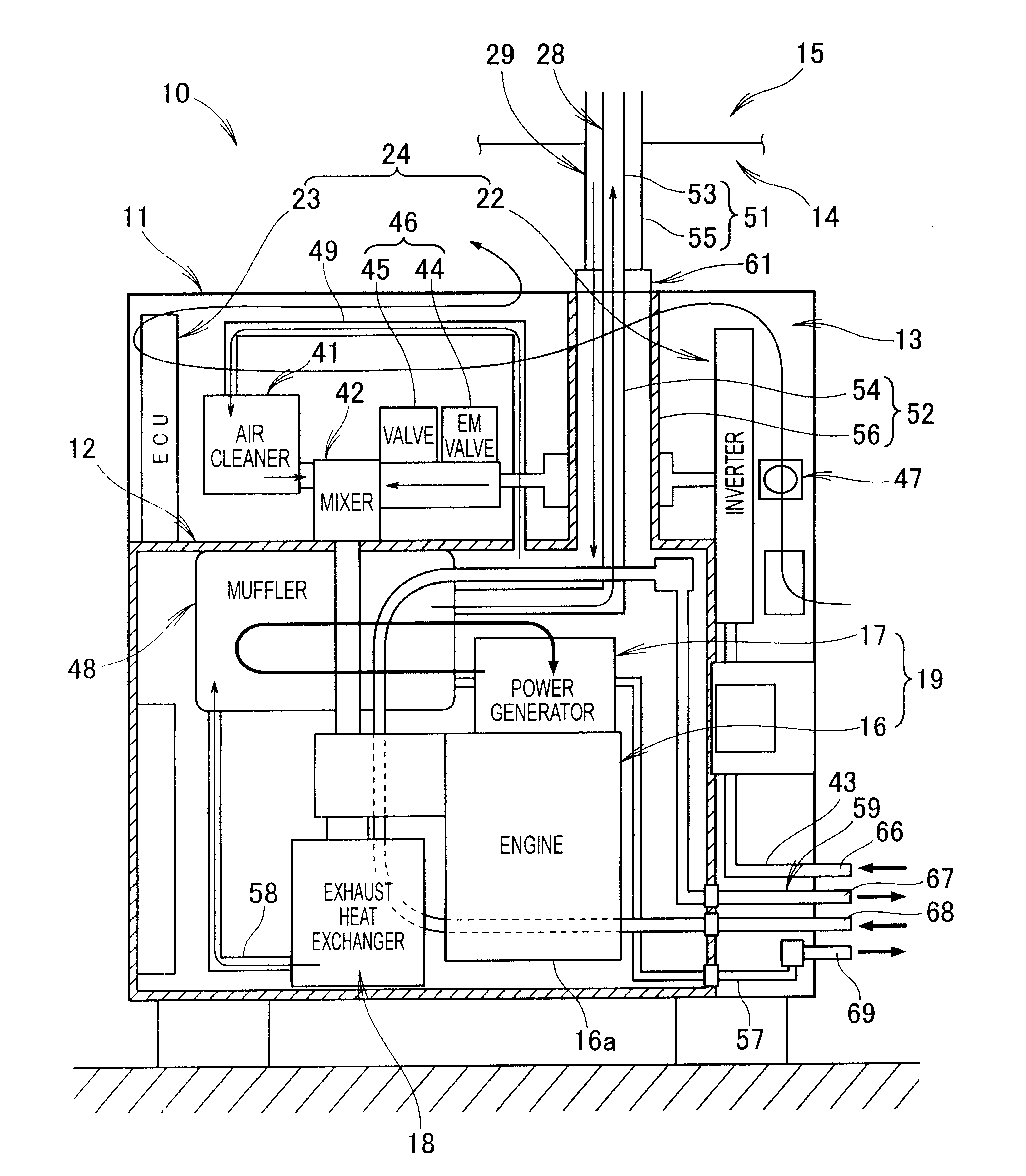

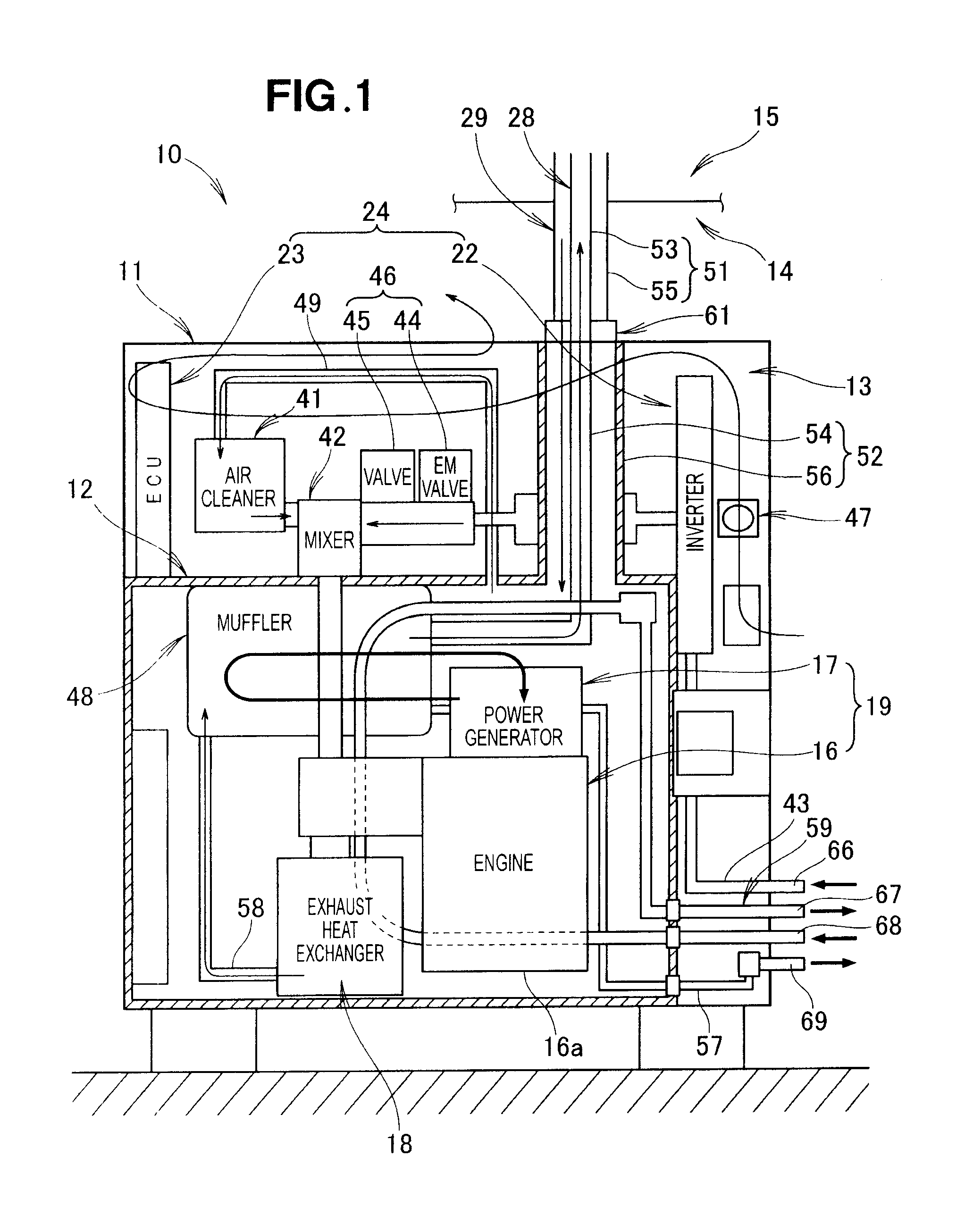

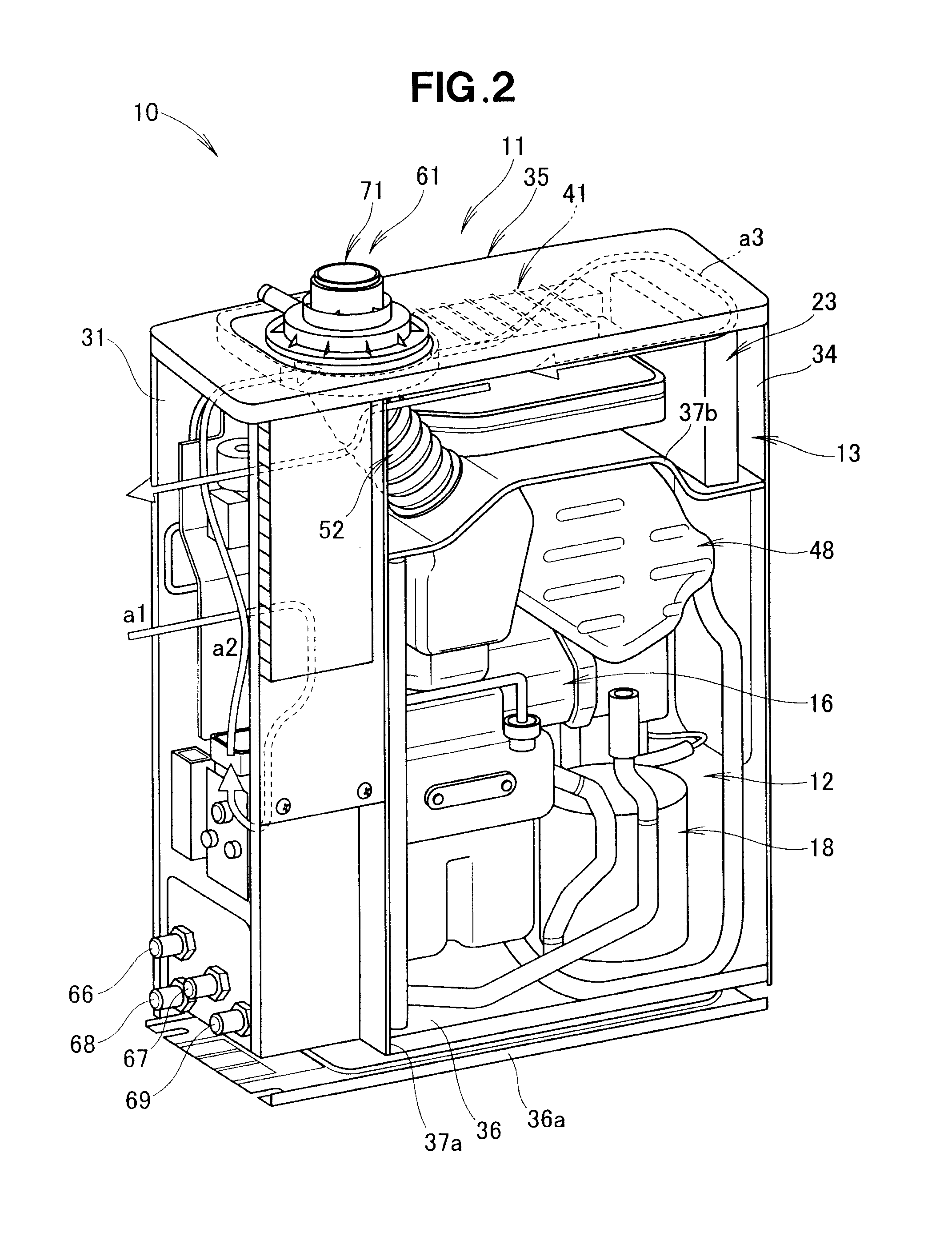

Cogeneration apparatus

ActiveUS8552574B2Improve cooling effectInternal combustion piston enginesFlue gas duct systemCogenerationAir cleaners

A cogeneration apparatus for indoor installation includes: an airtight chamber provided within a housing, at least a power generator and an engine being accommodated within the airtight chamber; an intake duct connected to the airtight chamber for introducing air from outside the housing into the airtight chamber; and an exhaust duct connected to the engine for discharging exhaust gas of the engine. The air introduced through the intake duct cools the interior of the airtight chamber and is also sucked in to an air cleaner of the engine, and the exhaust gas of the engine is discharged directly to outside the airtight chamber through the exhaust duct.

Owner:HONDA MOTOR CO LTD

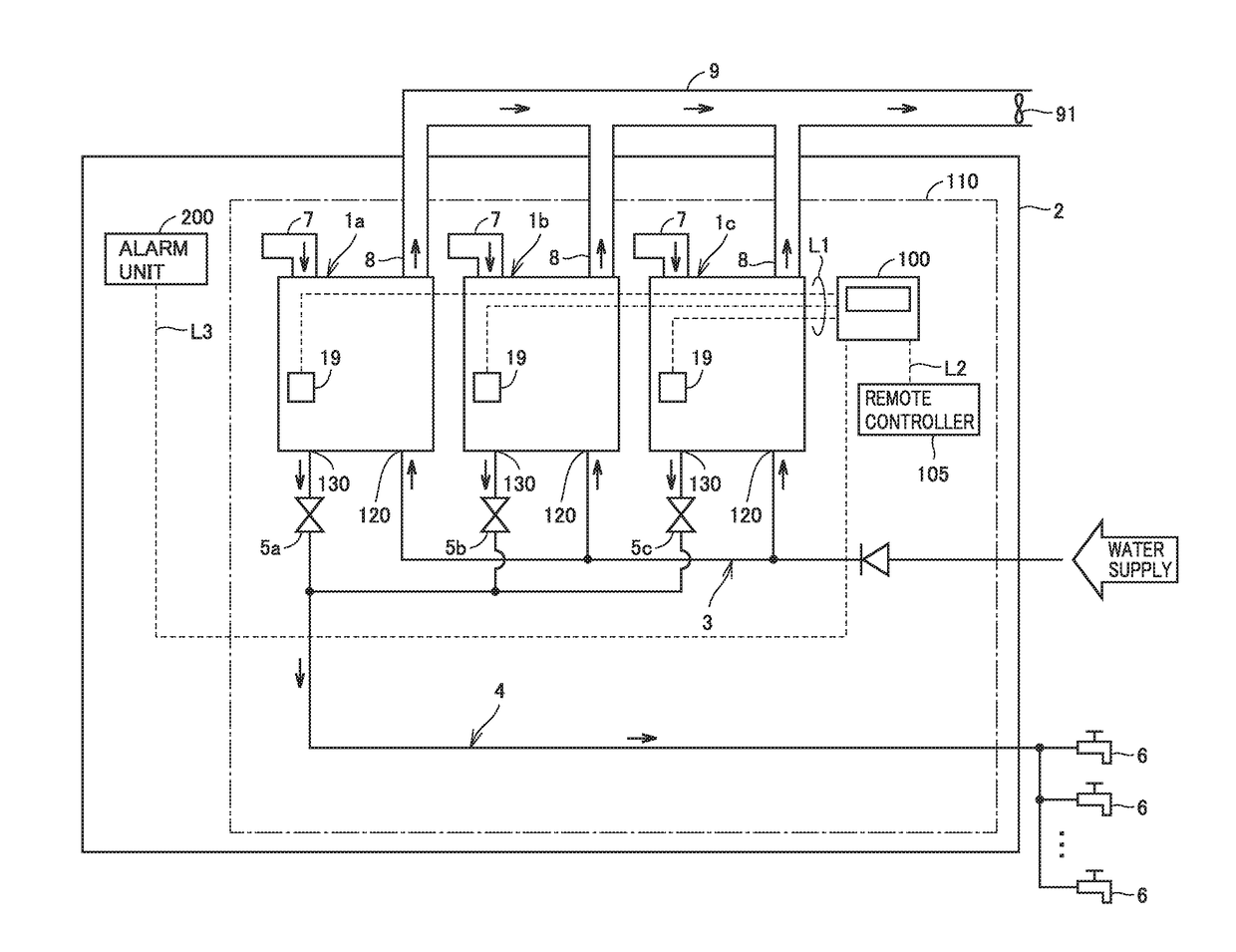

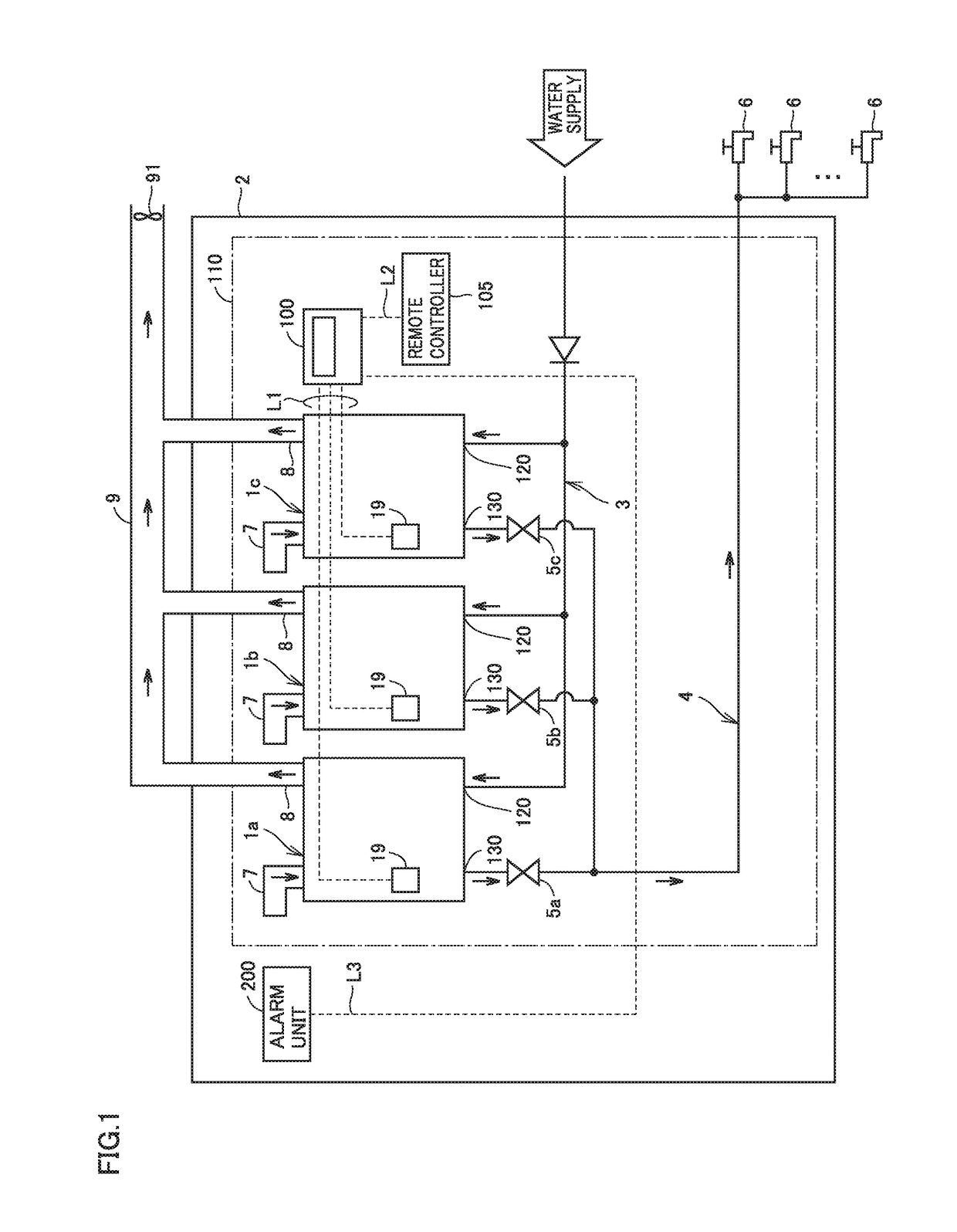

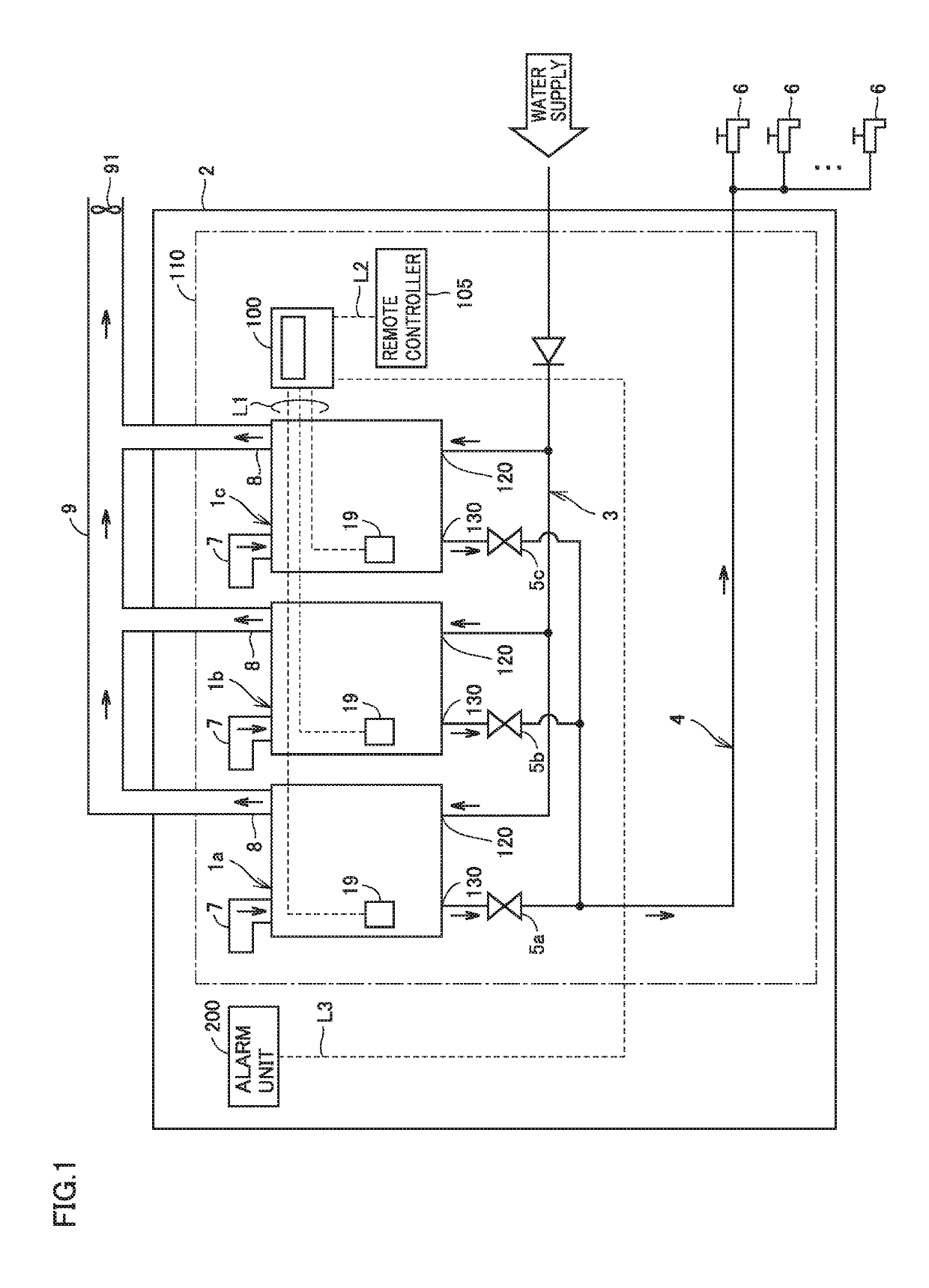

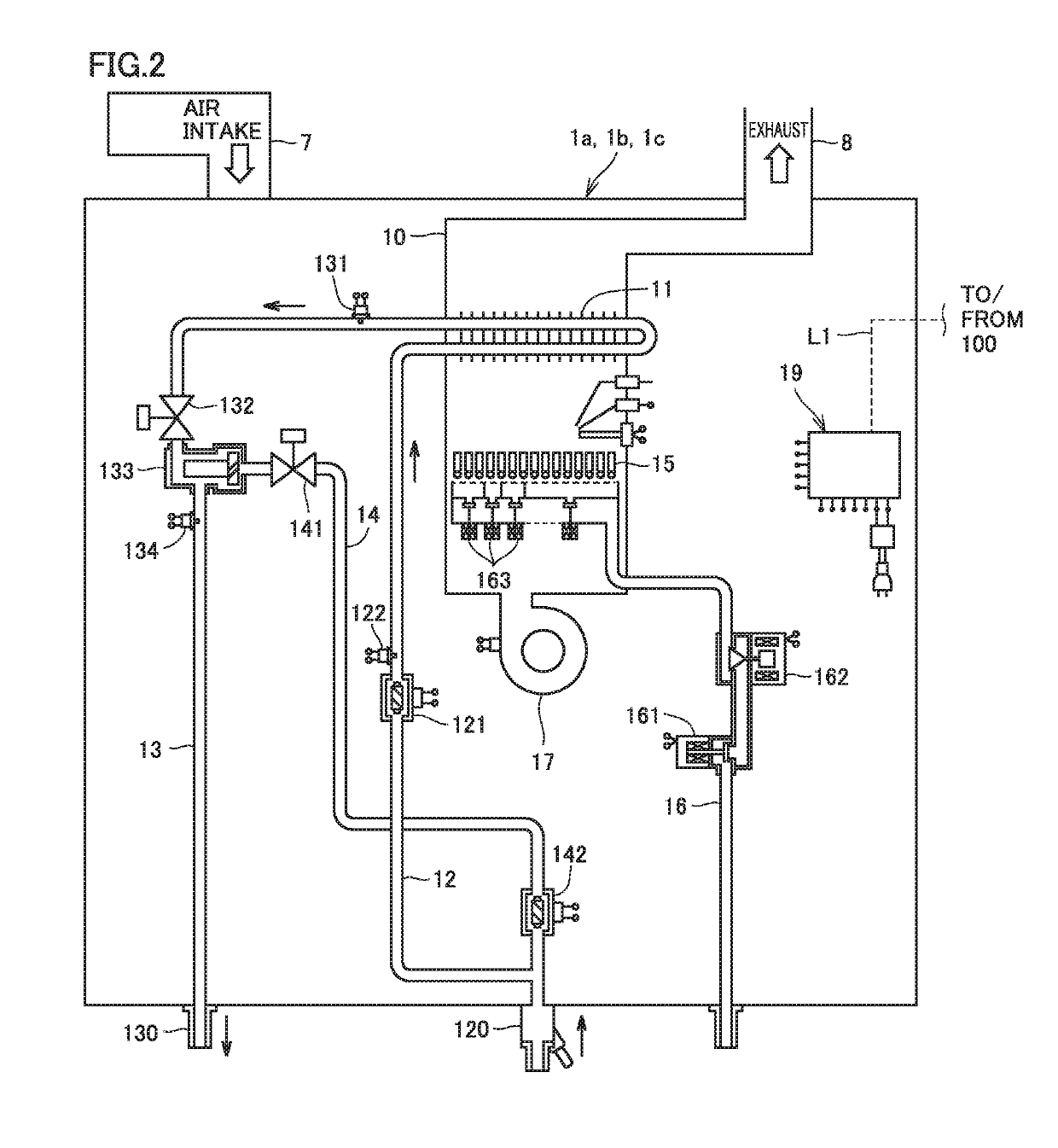

Water heating system

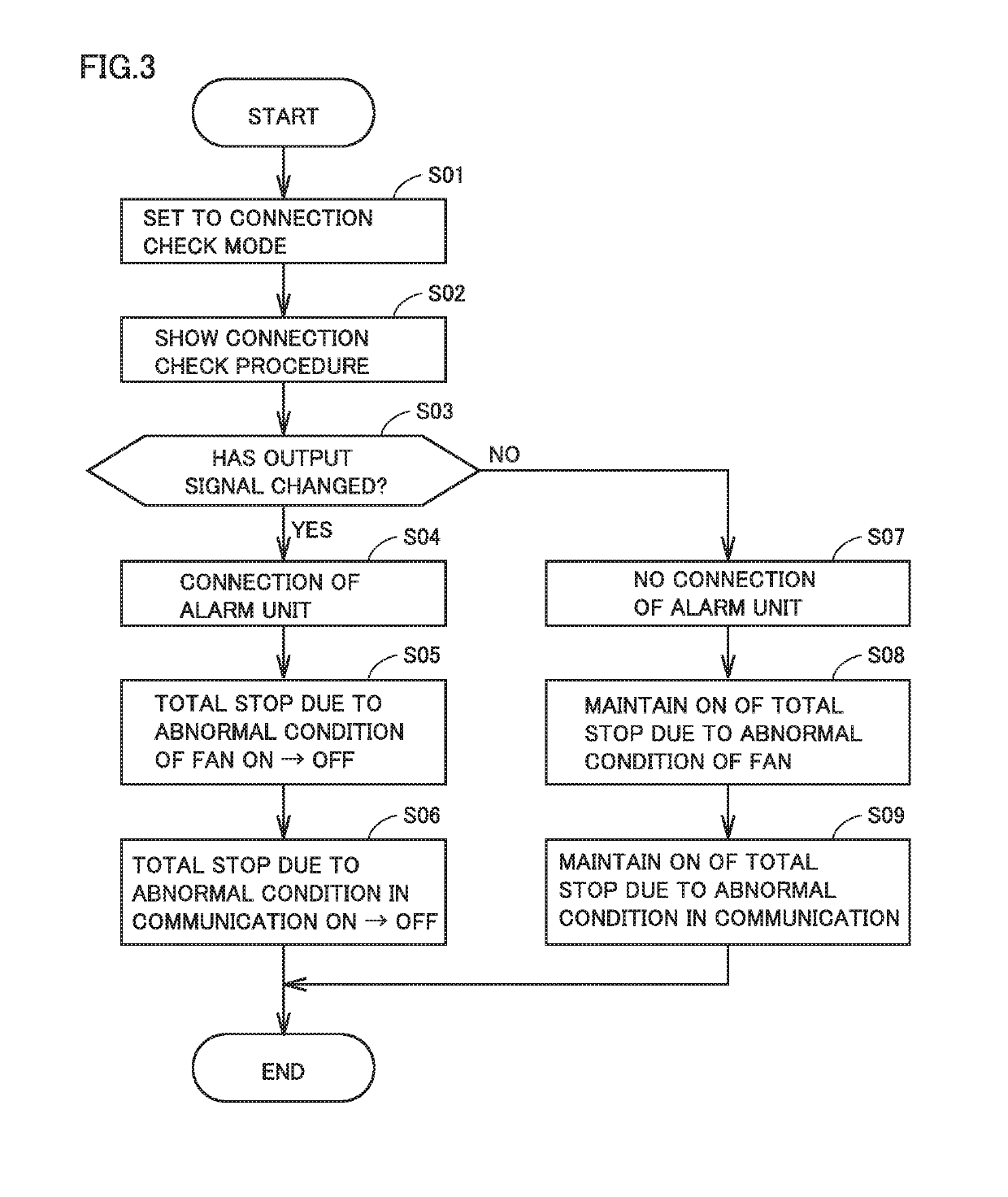

ActiveUS20180112891A1Guaranteed uptimeLong operationFluid heatersFlue gas duct systemEngineeringBackflow

A controller is configured to set total stop in which operations of all of a plurality of water heaters are stopped when an abnormal condition of a fan or an abnormal condition in communication is sensed in any of the plurality of water heaters while at least one of the plurality of water heaters is operating. The controller is further configured not to set total stop when an abnormal condition of the fan or an abnormal condition in communication is sensed in at least one of the plurality of water heaters while a sensing element for sensing a backflow of an exhaust from an exhaust path assembly is connected to the controller.

Owner:NORITZ CORP

Flue, and a Boiler Including Such a Flue

ActiveUS20090272340A1Reduce moisturePrevent re-evaporationFlue gas duct systemEnergy efficient heating/coolingFlue gasProcess engineering

Owner:CANETIS HLDG LTD

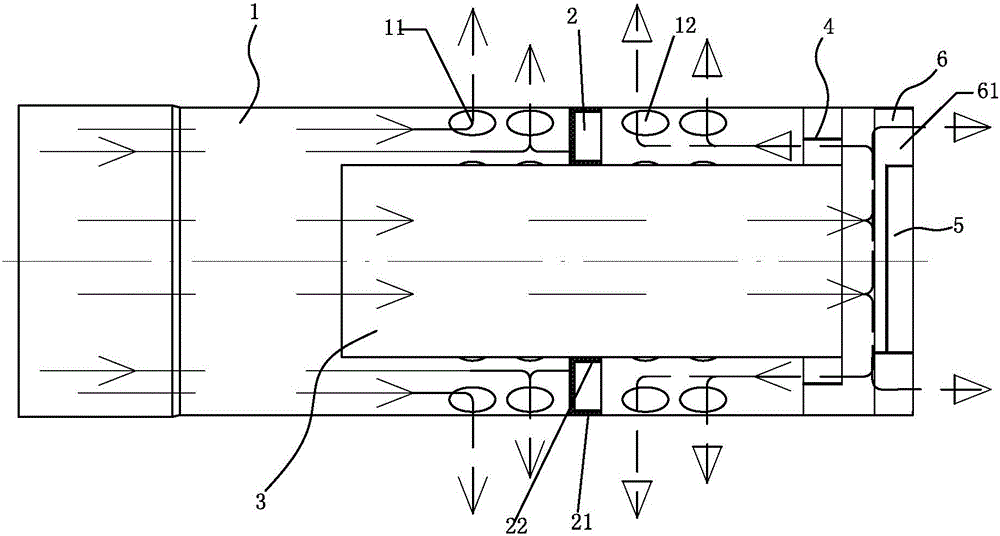

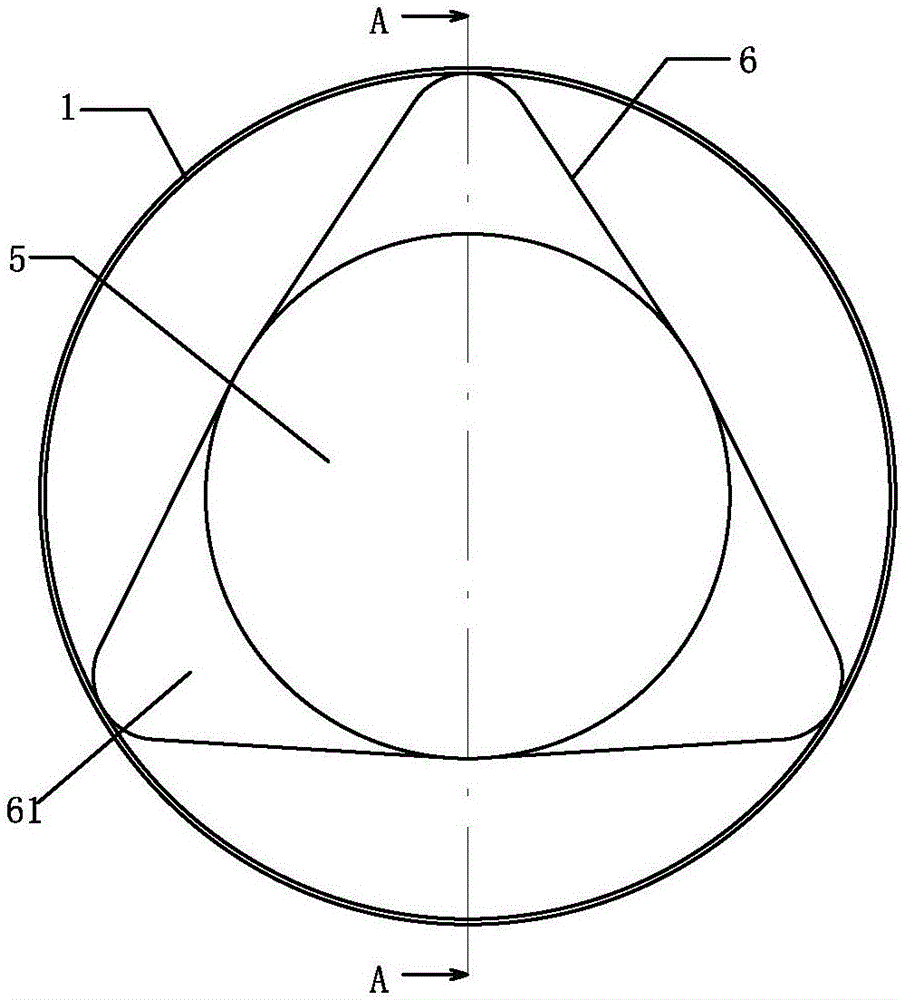

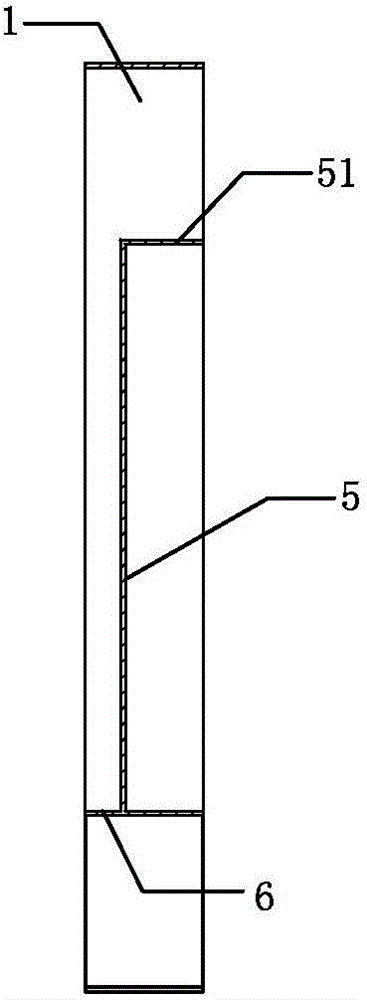

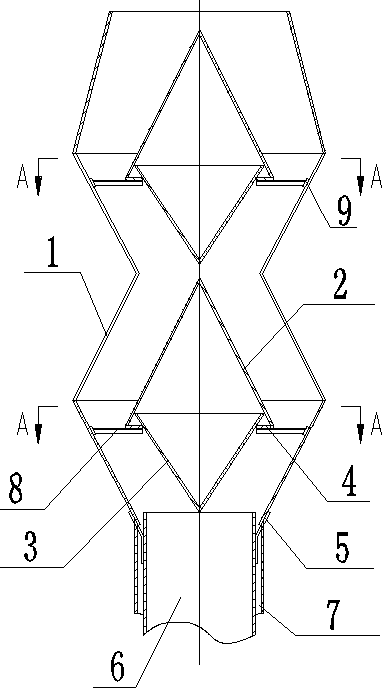

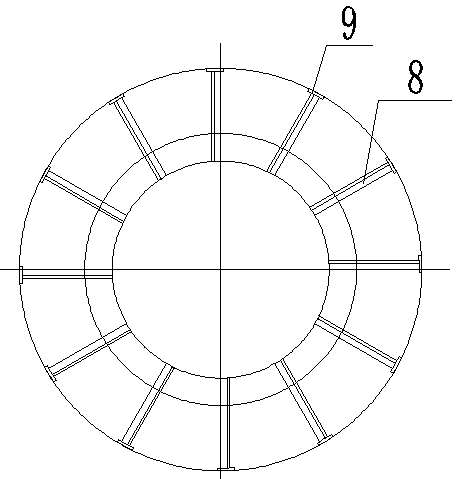

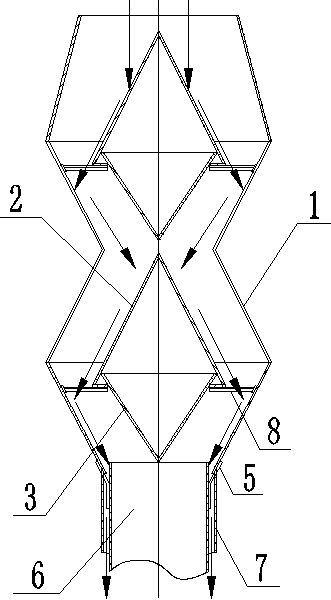

Anti-puffing smoke exhausting device

ActiveCN106839438AEliminate potential safety hazardsFluid heatersFlue gas duct systemEngineeringExhaust pipe

The invention provides an anti-puffing smoke exhausting device. The device comprisesa main smoke exhausting pipe, apartition board with a center hole, a center pipe, atopboard and atopboard support, oneend of the center pipe passes through the center hole of the partition board and is fixedly connected, the partition board is located in the middle of the center pipe; the center pipe and the partition boardare arranged in the main smoke exhausting pipe, the partition boardis fixedly connected with the main smoke exhaust pipe betweenan inner main smoke exhaust hole and an outer main smoke exhaust hole; the top board component is arrangedin an air outlet end of the main smoke exhausting pipe, an air guide gap is arranged between the top board andthe air outlet end of the center pipe, the top board support of the top board component is connectedwith the main smoke exhaust pipe on the inner side. As a result of the adoption of such astructure, the device has a variety of smoke discharging directions, the deviceis not under the influence of wind direction, and is anti-puffing, safe and reliable, and the potential of safety risk is eliminated.

Owner:阿诗丹顿燃具有限公司

Combustion device and combustion device system including combustion device

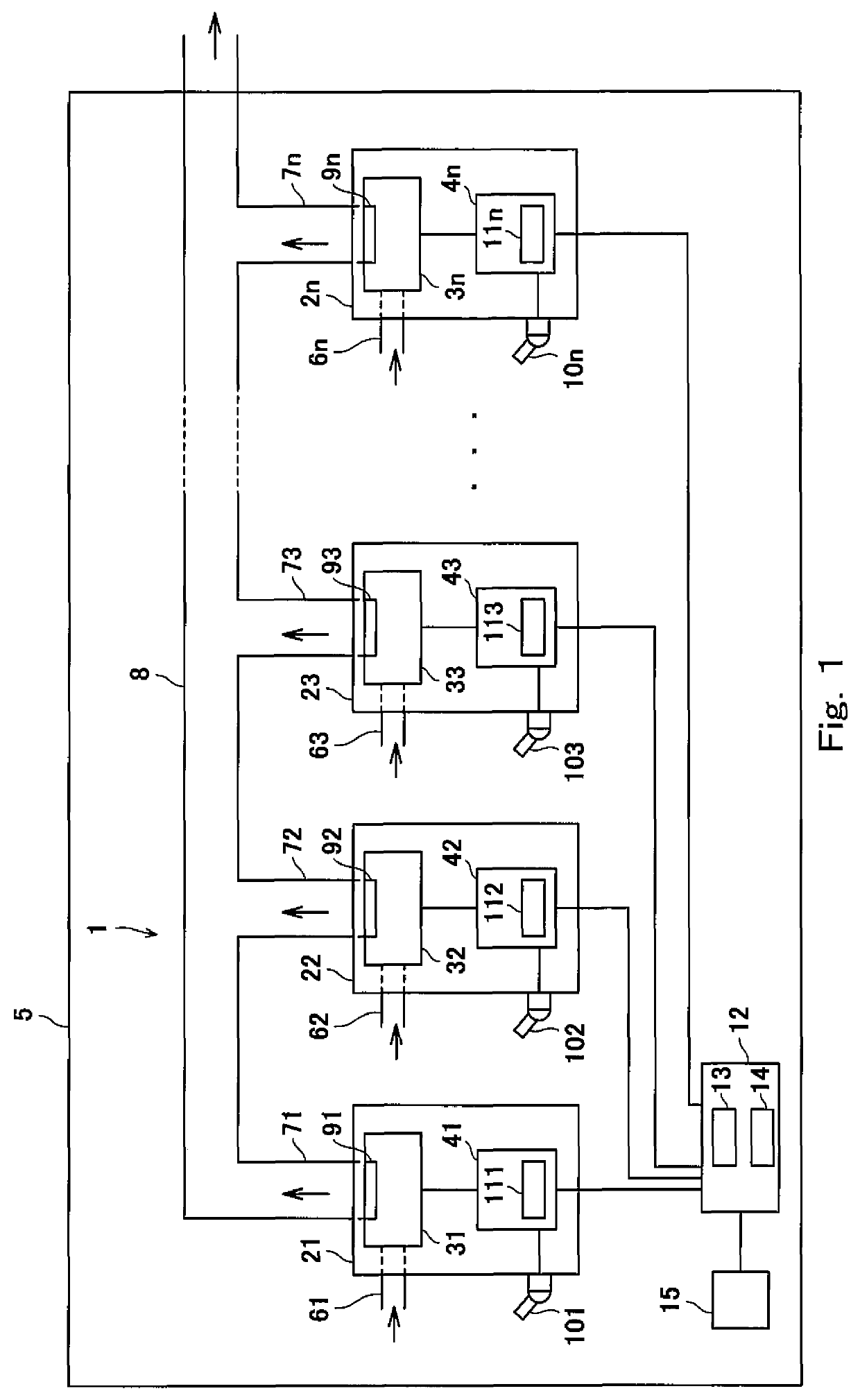

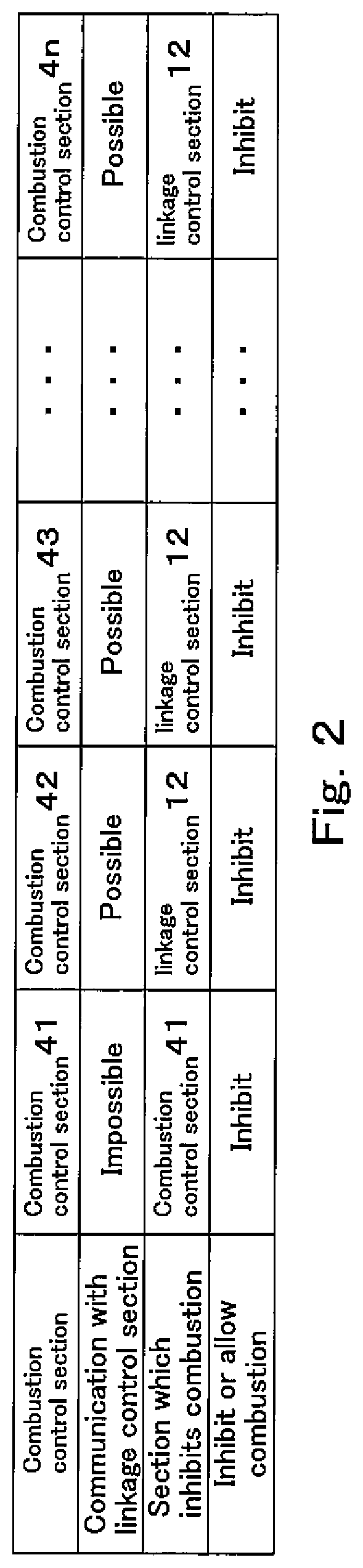

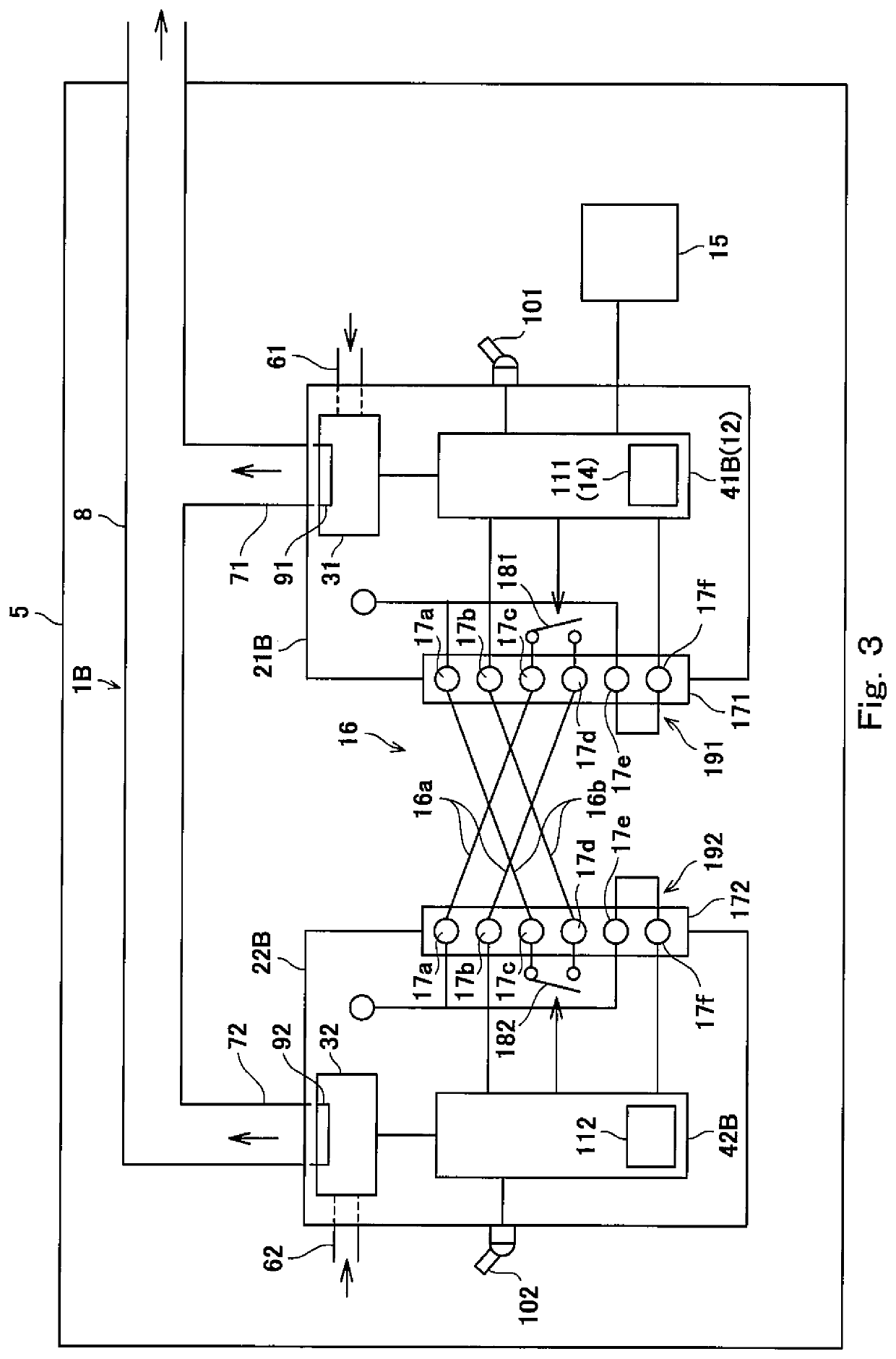

ActiveUS20180112890A1Ensure correct executionAvoid burnsHeating fuelFlue gas duct systemCombustionMechanical engineering

A combustion device includes a combustion control section which controls combustion in the combustion device; a setting section operated to set information indicating whether or not a plurality of combustion devices are in a common vent discharge state; and a memory section which stores therein connection configurations with the other combustion control sections to which the combustion control section is communicatively connected, and the combustion control section determines whether or not the combustion control section can communicate with a linkage control section or the other combustion control sections, and inhibits combustion in the combustion device to which the combustion control section belongs, in a case where the combustion control section determines that the combustion control section cannot communicate with the linkage control section or at least one of the other combustion control sections and the common vent discharge state is set by the setting section.

Owner:NORITZ CORP

Water heater venting assembly

ActiveUS10088156B2Overcomes shortcomingPermit adjustmentFlue gas duct systemWater heatersCombustionFlue gas

In a preferred embodiment, there is provided a water heater venting assembly for directing a combustion air and a flue gas between an outdoor atmosphere and a water heater, and which includes a generally hollow housing defining a combustion air aperture, a flue gas exhaust conduit disposed in the housing, and an adjustable inlet duct coupling assembly having a retention member for placement in the housing proximal to the aperture, a gasket for placement around an outer periphery of the aperture and a combustion air supply member. The retention member is for retaining the supply member in fluid sealing engagement with the gasket to effect fluid communication between the aperture and the supply member, and is sized to permit slidable movement of the supply member relative to the gasket.

Owner:IPEX TECH

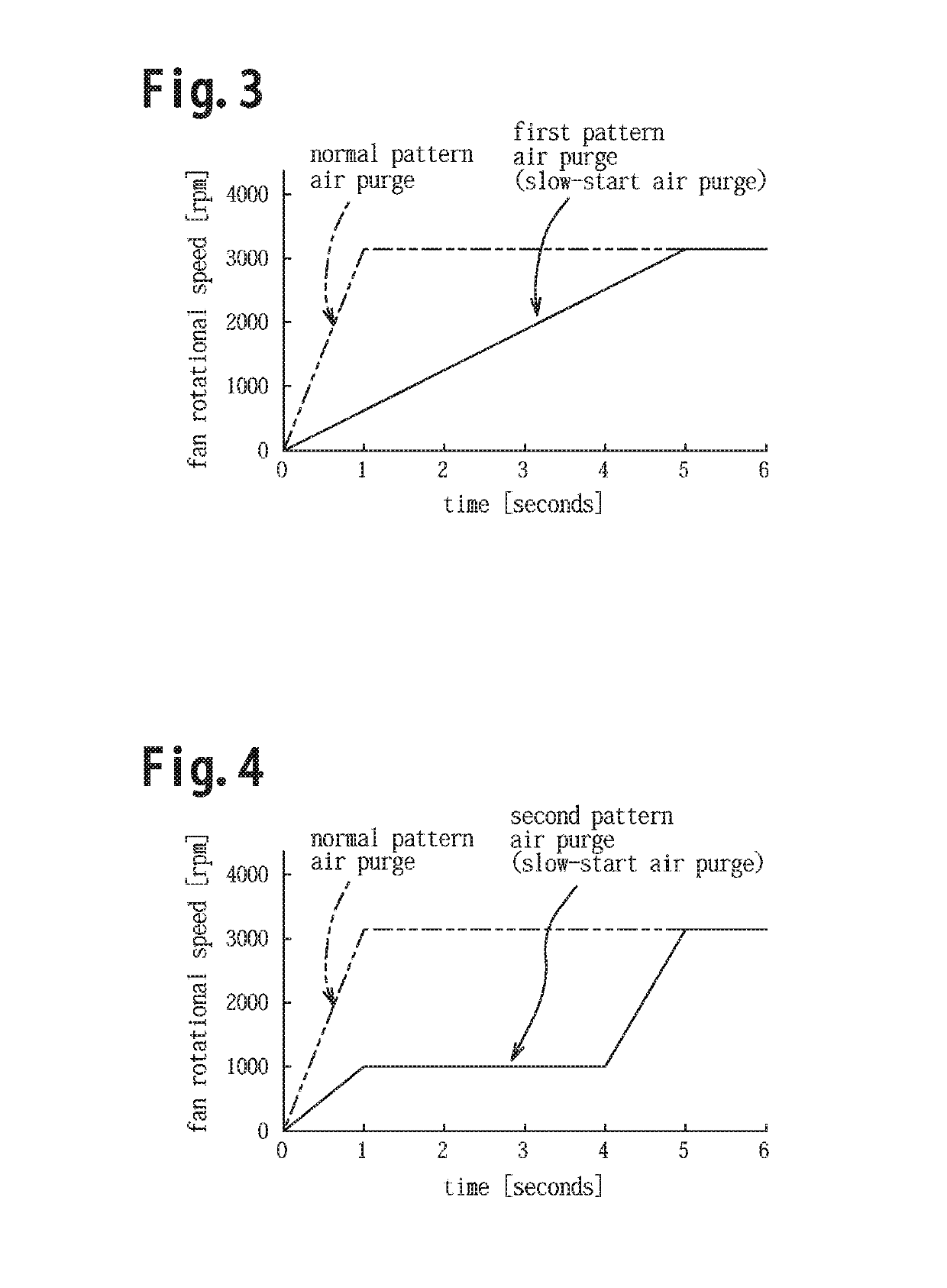

Combustion device

ActiveUS20190093888A1Suppress rapid openingAvoid noiseAir supply regulationFlue gas duct systemCombustorSlow-start

The combustion device includes: a burner; an igniter; a fuel supply unit that supplies fuel to the burner; a blower fan that supplies air for combustion; an exhaust port that discharges combustion exhaust; a device control unit that, before ignition of fuel supplied to the burner by operation of the igniter, performs air purge of the burner at a predetermined air blowing amount by driving the blower fan; and a setting means that is set when a check valve for preventing back flow of exhaust is connected to the exhaust port. When the setting means is set to indicate that the check valve is connected, the device control unit controls the operation of the blower fan so that slow-start air purge is performed in which the time interval from the start of air purge until the predetermined air blowing amount is reached becomes longer, than in the case in which no such check valve is connected.

Owner:NORITZ CORP

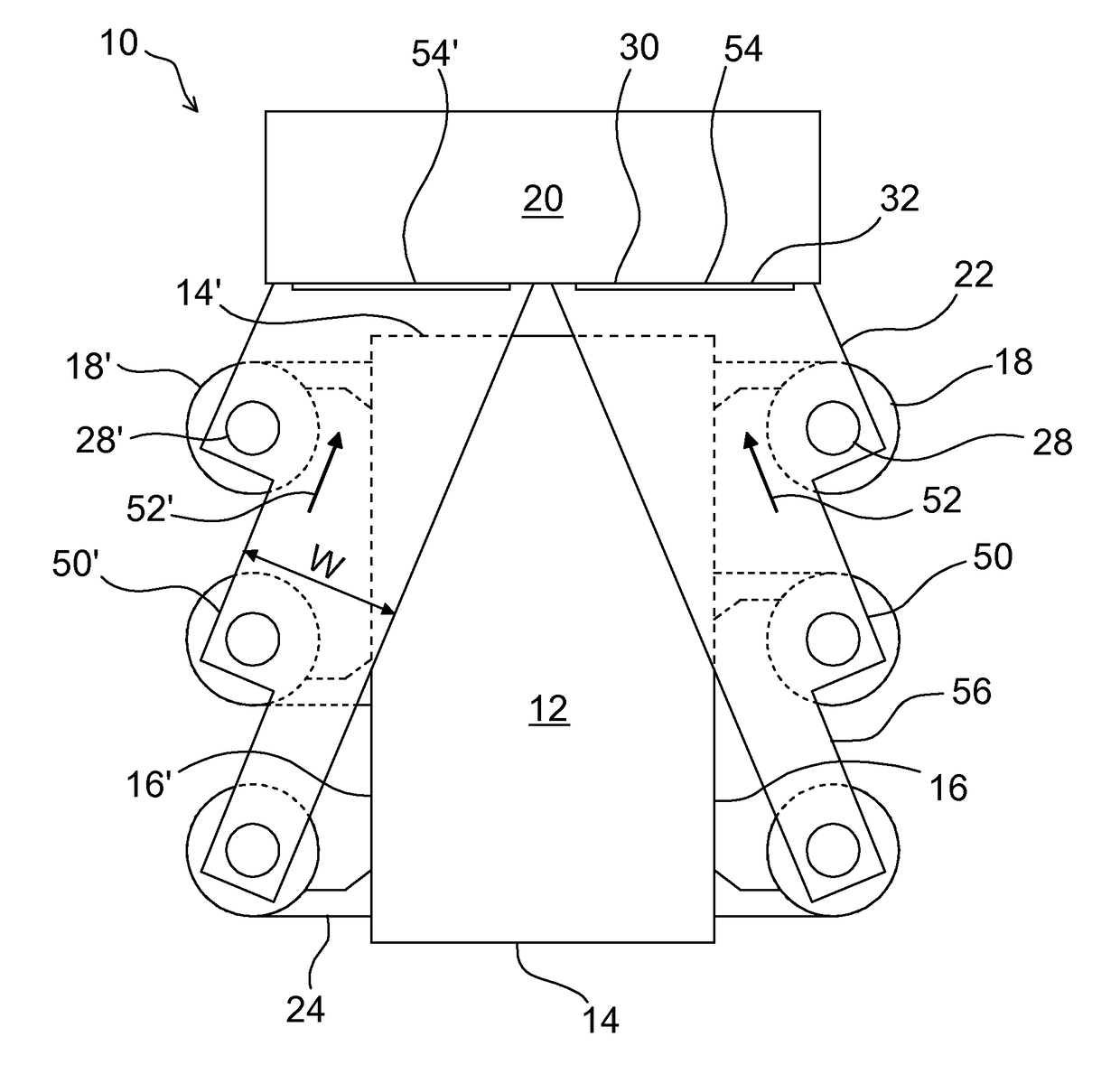

Waterproof and dust-settling air exhausting device

ActiveCN106196120ADoes not affect the exhaust effectReduce pollutionFlue gas duct systemChimneysEngineeringExhaust pipe

The invention relates to the technical field of environmental protection equipment, in particular to a waterproof and dust-settling air exhausting device. The waterproof and dust-settling air exhausting device comprises a shell, a guide structure, an air exhausting pipe and a drainage pipe, wherein the guide structure comprises an inversed upper conical barrel, a lower conical barrel and a lining plate and is connected with the shell through a connecting plate and a base plate; the lower part of the shell is welded with the air exhausting pipe through reinforcing ribs; the shell is further connected with a flow guide pipe through reinforcing ribs; and the shape of the shell is matched with that of the guide structure. The waterproof and dust-settling air exhausting device is used at the tail of an air exhausting pipe, not only can be waterproof, but also collect dust in tail gas on the premise of not affecting the air exhausting effect, and pollution is reduced. When the device is designed, running situations of a system and components in smoke should be considered, and therefore, different materials such as common materials, anti-corrosion materials or high-temperature-resistant materials and the like can be used according to the different situations.

Owner:NANJING C HOPE ENVIRONMENTAL SCI & TECH

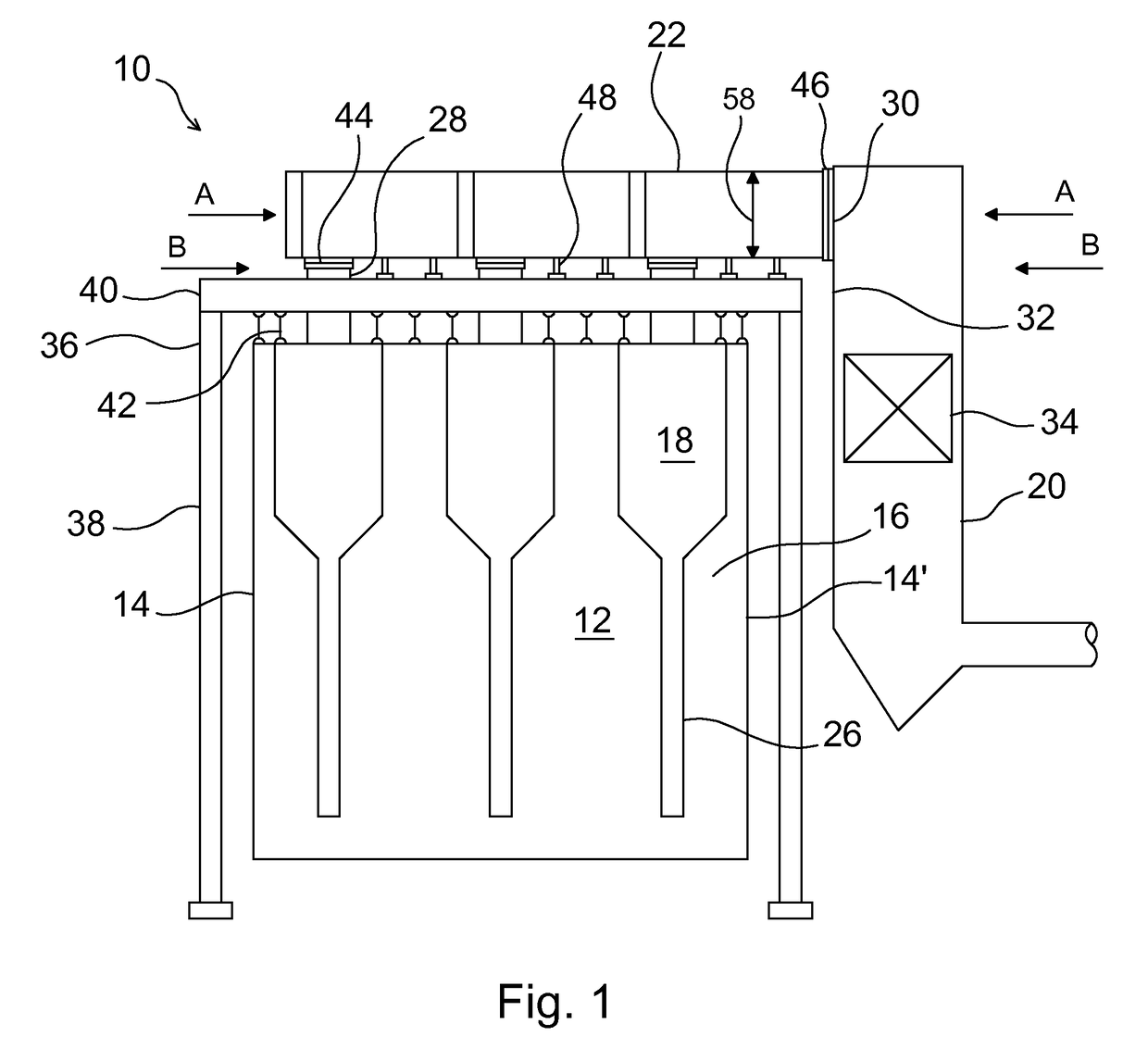

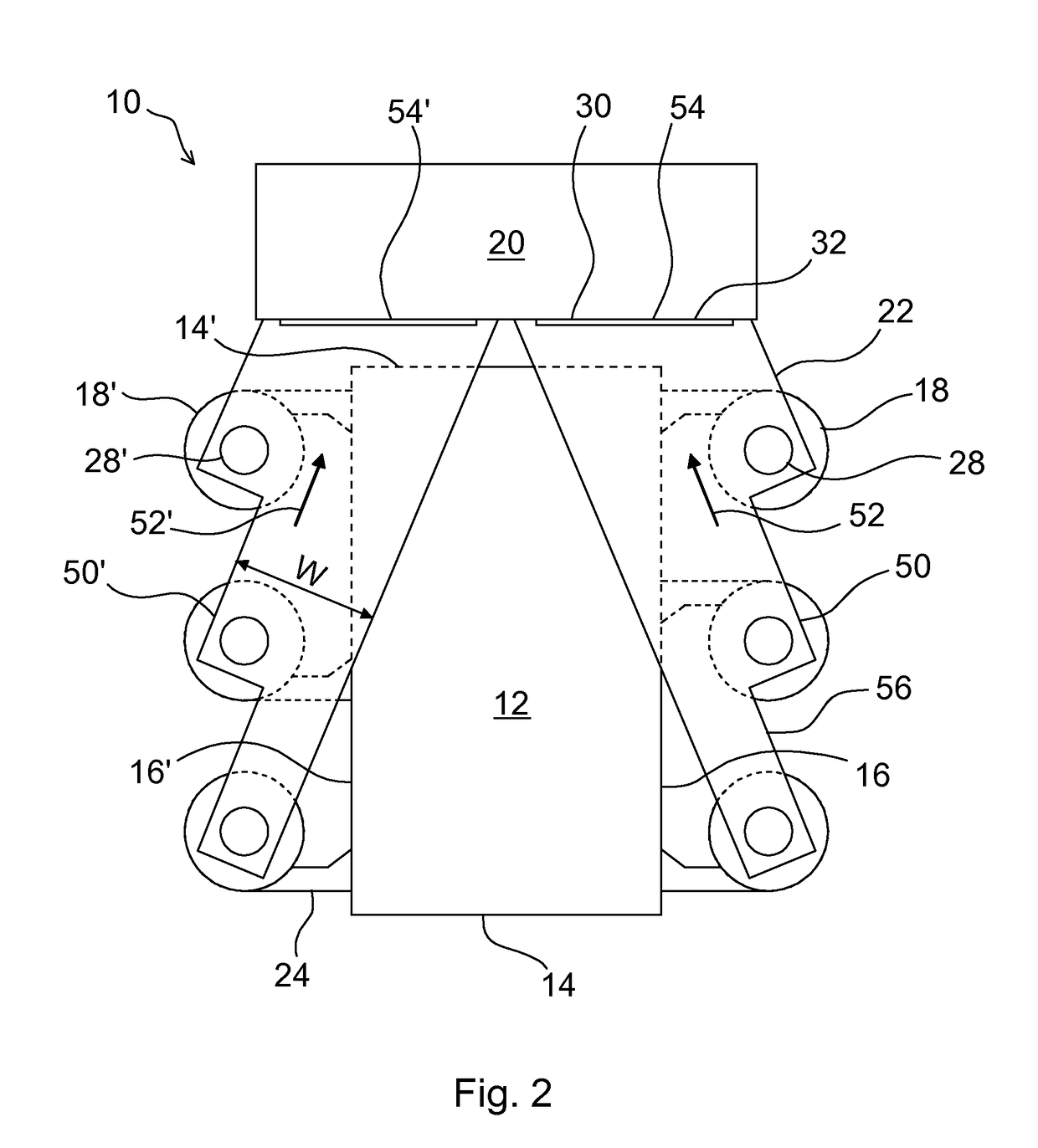

Circulating fluidized bed boiler and a method of assembling a circulating fluidized bed boiler

ActiveUS20180187884A1Erosion minimizationIncrease the cross-sectional areaFluidized bed combustionFlue gas duct systemCombustionFlue gas

Owner:SUMITOMO SHI FW ENERGIA OY

Water heating system

Owner:NORITZ CORP

Combustion device and combustion device system including combustion device

ActiveUS10539338B2Extension of timeHeating fuelFlue gas duct systemThermodynamicsProcess engineering

A combustion device includes a combustion control section which controls combustion in the combustion device; a setting section operated to set information indicating whether or not a plurality of combustion devices are in a common vent discharge state; and a memory section which stores therein connection configurations with the other combustion control sections to which the combustion control section is communicatively connected, and the combustion control section determines whether or not the combustion control section can communicate with a linkage control section or the other combustion control sections, and inhibits combustion in the combustion device to which the combustion control section belongs, in a case where the combustion control section determines that the combustion control section cannot communicate with the linkage control section or at least one of the other combustion control sections and the common vent discharge state is set by the setting section.

Owner:NORITZ CORP

Cogeneration apparatus

ActiveUS20120193911A1Improve cooling effectInternal combustion piston enginesFlue gas duct systemCogenerationExhaust fumes

A cogeneration apparatus for indoor installation includes: an airtight chamber provided within a housing, at least a power generator and an engine being accommodated within the airtight chamber; an intake duct connected to the airtight chamber for introducing air from outside the housing into the airtight chamber; and an exhaust duct connected to the engine for discharging exhaust gas of the engine. The air introduced through the intake duct cools the interior of the airtight chamber and is also sucked in to an air cleaner of the engine, and the exhaust gas of the engine is discharged directly to outside the airtight chamber through the exhaust duct.

Owner:HONDA MOTOR CO LTD

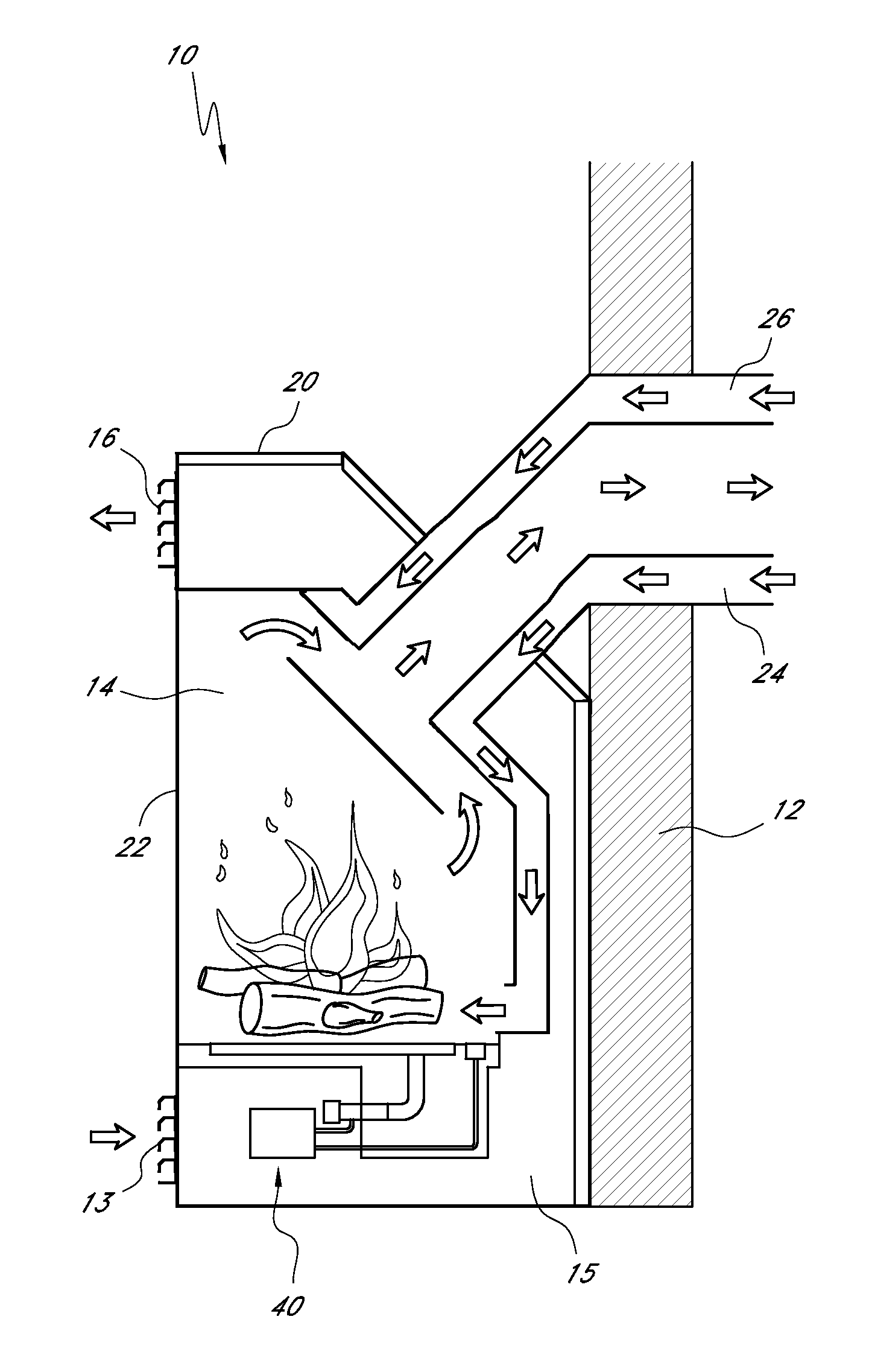

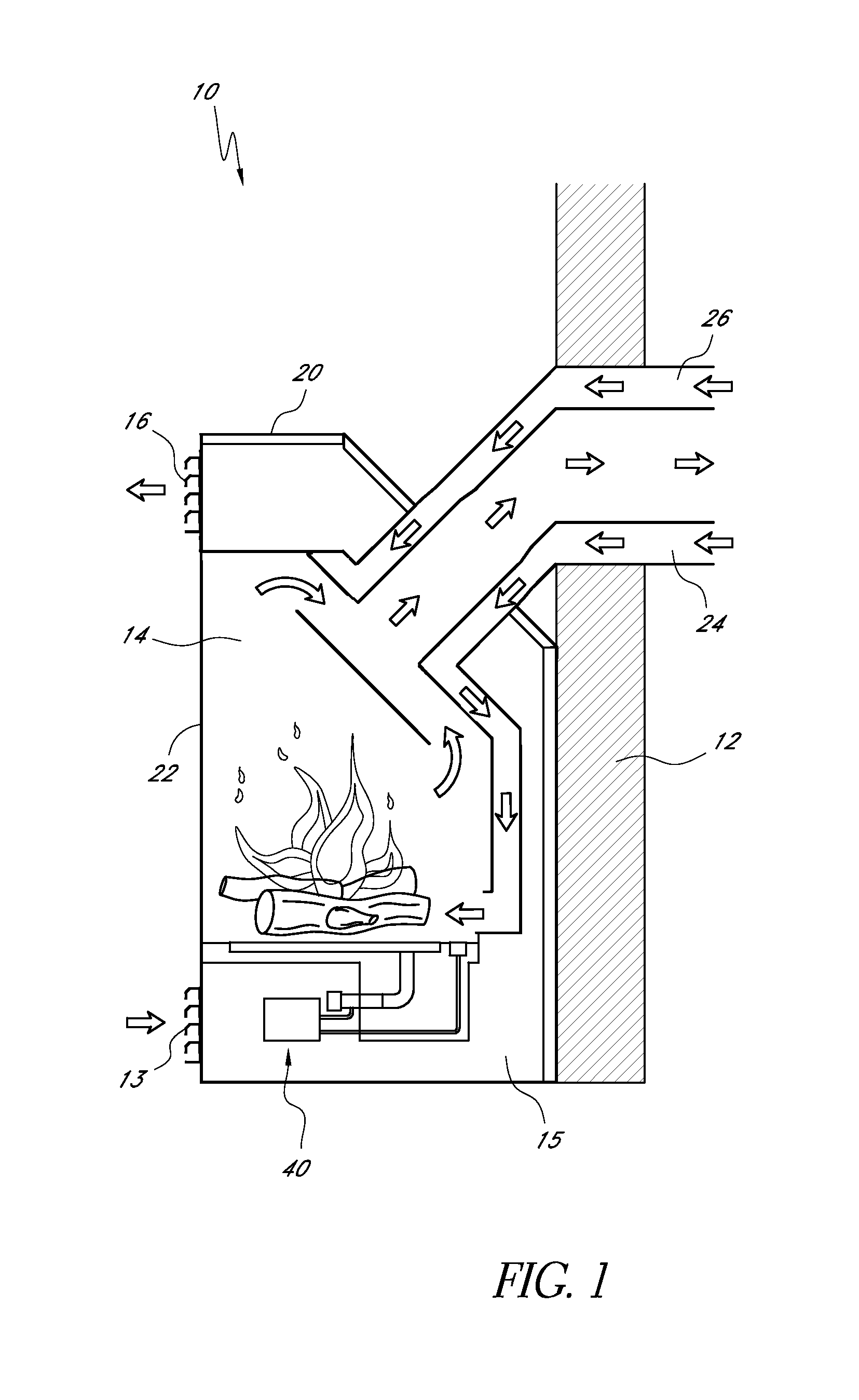

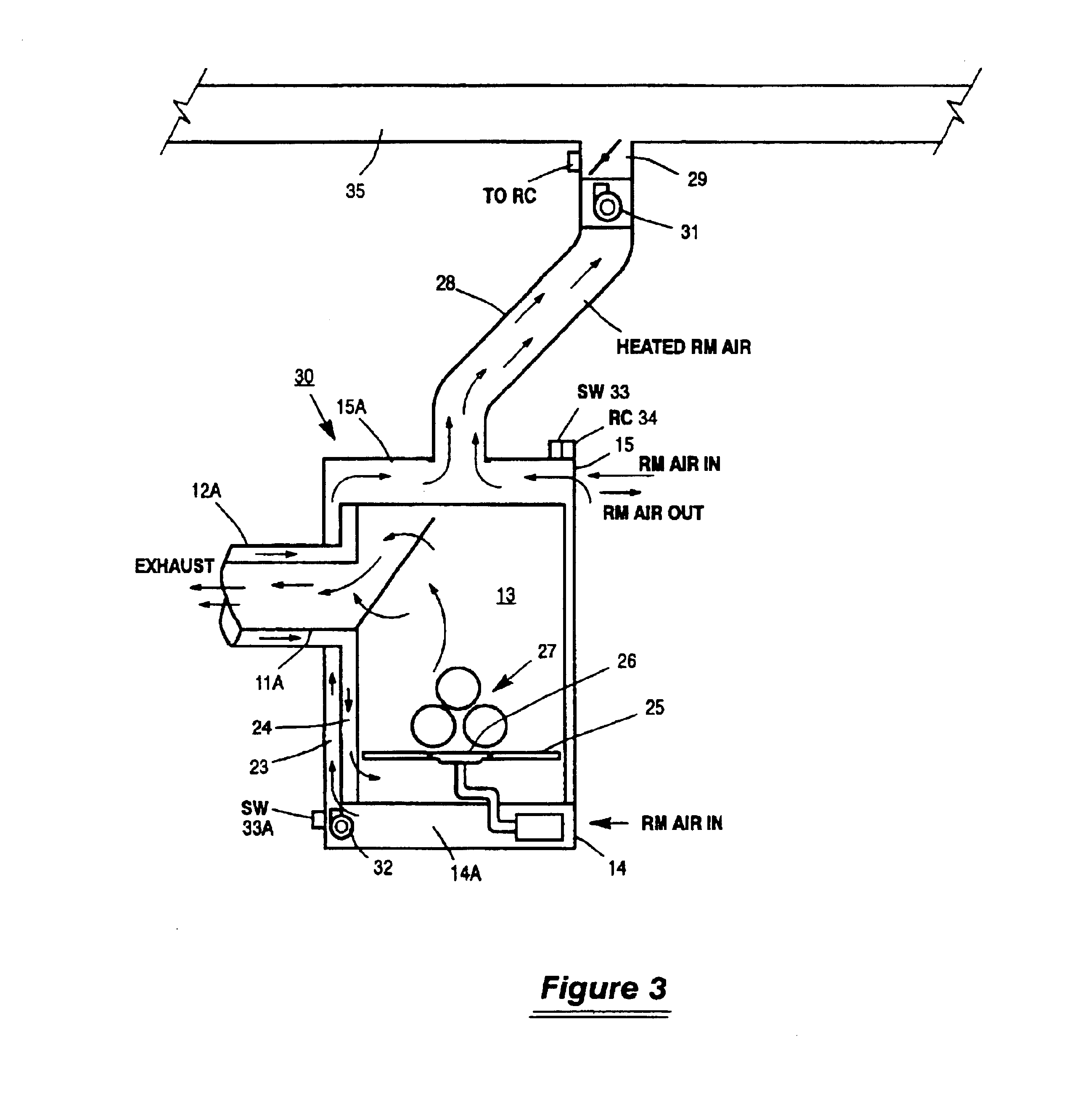

Heating apparatus with fan

A heating apparatus can have a sealed combustion chamber, a burner, and various air channels to direct air into the sealed combustion chamber and to provide heated air to the desired area or environment such as an interior room. A channel can direct a flow of air along a face of the sealed combustion chamber to cool the face. The channel can be within or outside of the sealed combustion chamber. Alternatively, or in addition, the heating apparatus can be capable of operating as a direct vent device or as a vent free device.

Owner:DENG DAVID

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com