Sealed combustion gas-fired infrared heater

a gas-fired infrared heater and sealing technology, which is applied in the direction of gaseous heating fuel, combustion types, stoves or ranges, etc., can solve the problems of snuffing of flames, carbon monoxide formation, and combustion products that are not admixed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

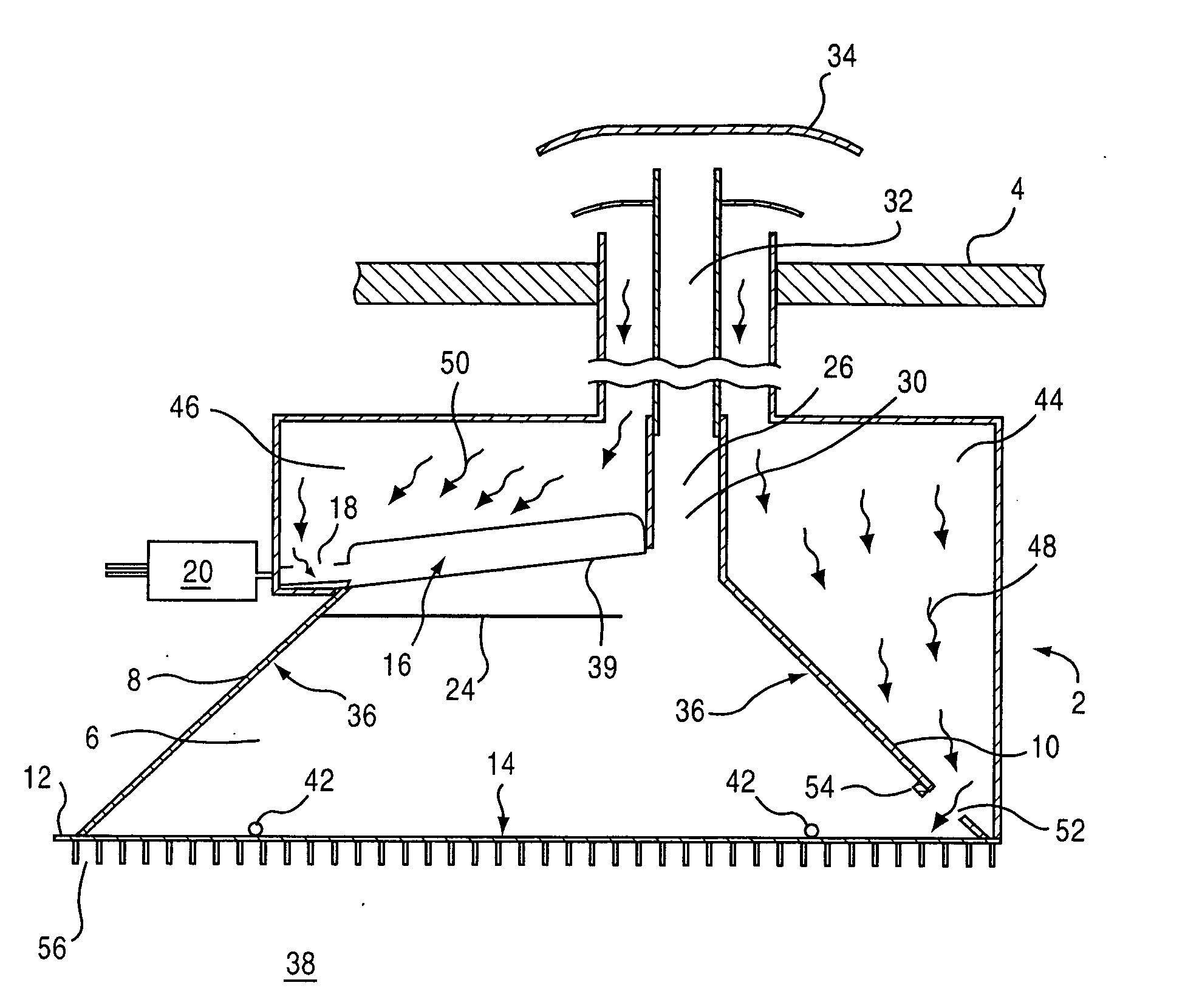

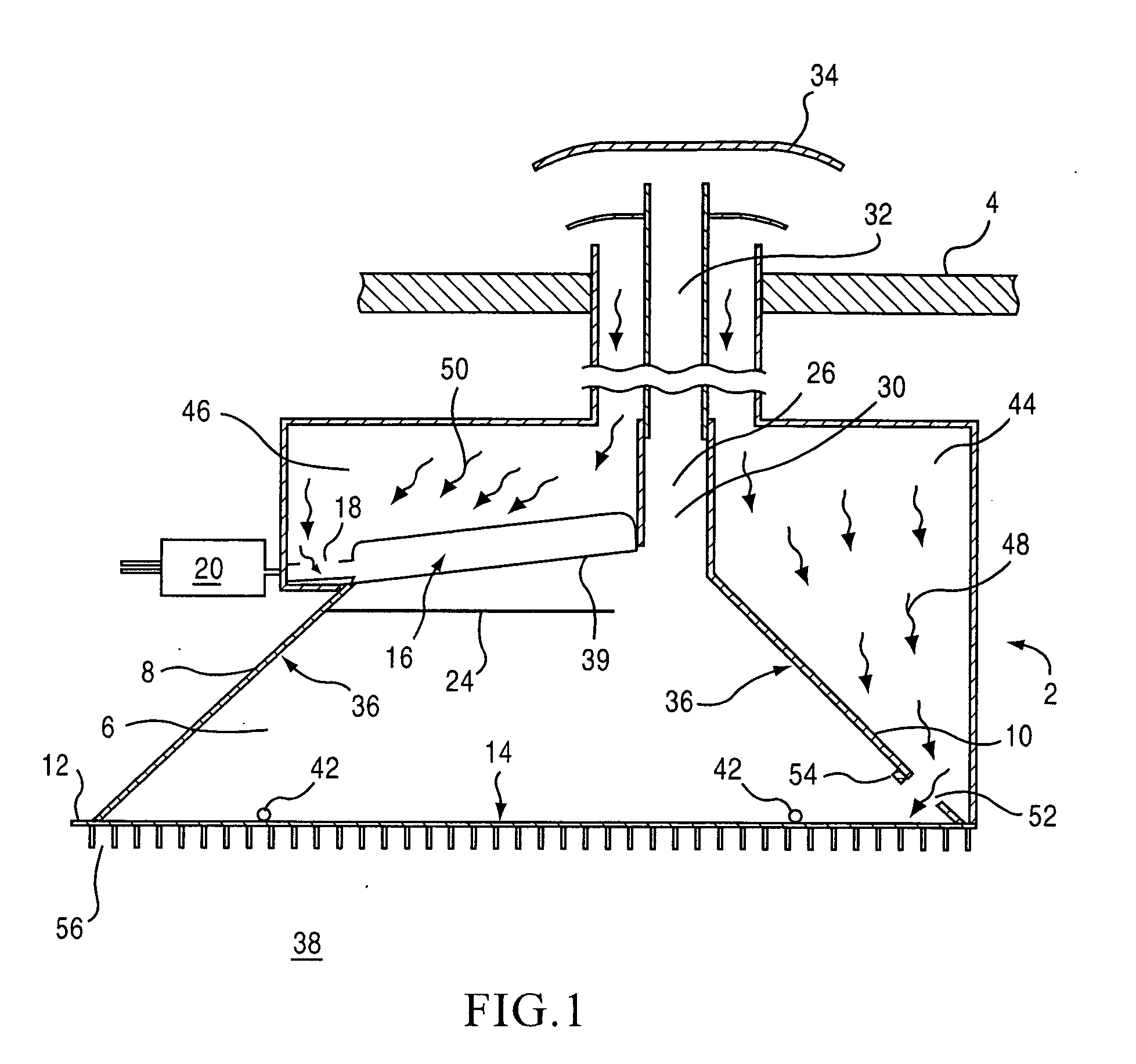

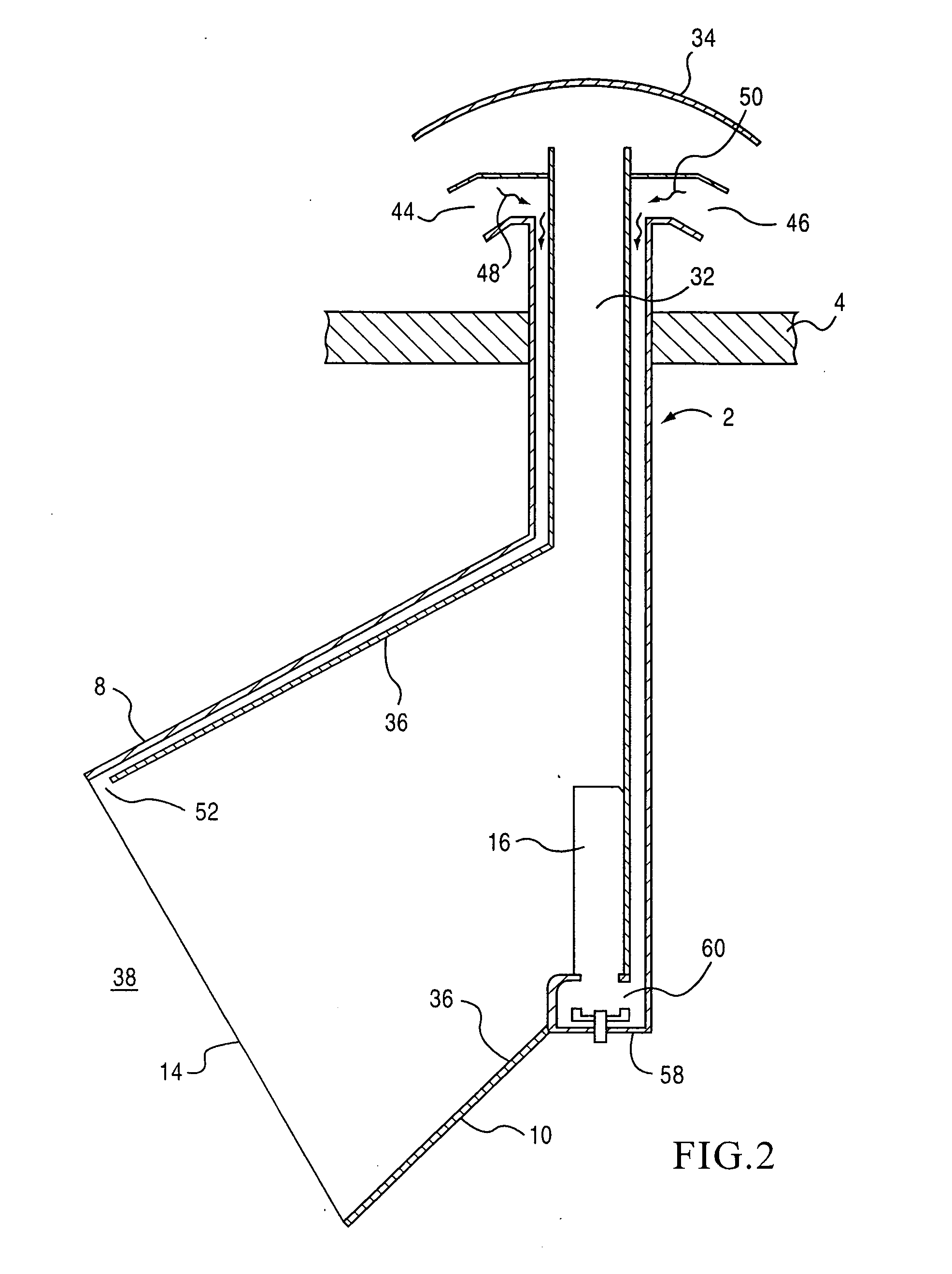

[0017] Embodiments of the present invention will be described hereinafter with reference to the accompanying drawings.

[0018] Referring to FIG. 1, the heater of the invention is designated by a reference numeral 2, and as shown in an exemplary position as being secured to a ceiling 4 of an enclosure to be heated (e.g., tent, bathroom, ice-fishing shanty, mobile home, etc.) A combustion chamber 6 is provided with generally upright side walls 8, 10, a front and rear wall (not shown) and a bottom wall 12, with a radiation-transmissive port therein. The port may extend between the side walls 8, 10 and the front and rear walls of the combustion chamber 6, although it may be desirable, in some instances, to have a smaller port. A sealing barrier 14 is located to close the port, and may be fastened by clamps, spline in groove, or the like (not shown) to the periphery of the front, rear, and side walls of the combustion chamber 6.

[0019] The sealing barrier 14 is desirably of a thin, flexib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com