Press cutting type corn threshing machine

A corn thresher and cutter technology, applied in the field of agricultural equipment, can solve problems such as poor threshing, and achieve the effect of easy manual operation and solving the difficulty of peeling corn cobs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

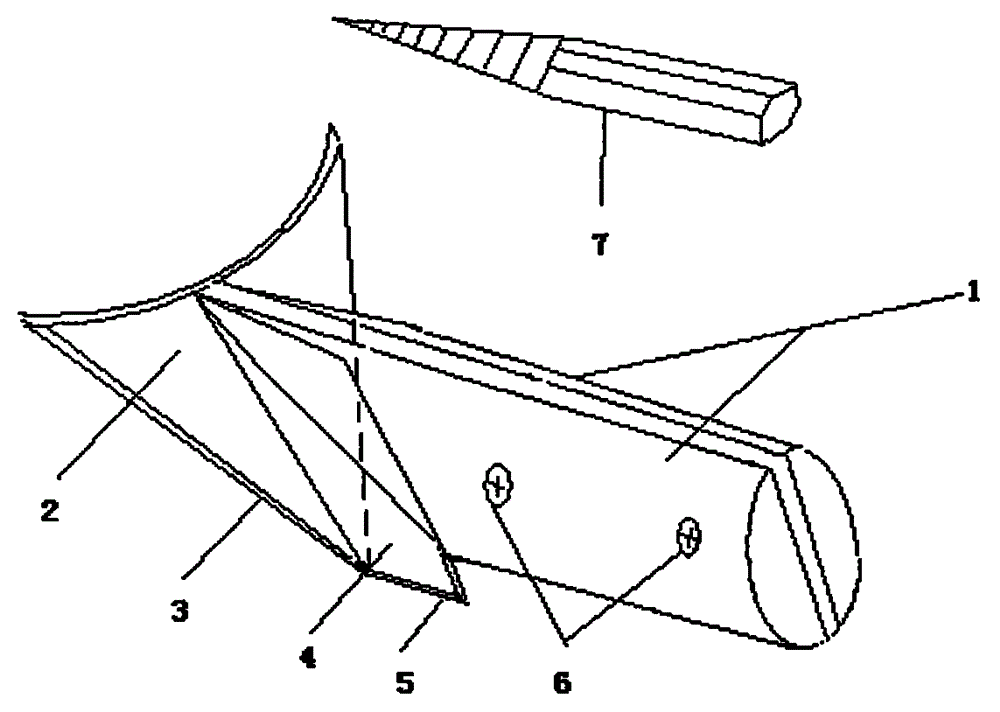

[0013] figure 1 In the press-cut corn thresher, the V-shaped side of the triangular cutter 2 is made into a V-shaped knife edge 3, and the convex arc of the triangular cutter 2 is connected to a 7-shaped blade 4 in the middle, and the triangular cutter 2 is made into a V-shaped cut. It is beneficial to squeeze and thresh the corn cob, and it can be made into an arc shape that can be close to the core of the cob, and the threshing is clean. The 7-shaped blade 4 is connected to the middle of the convex arc of the triangular cutter 2, and the 7-shaped blade 4 is formed with a knife-edge 5, and the 7-shaped blade 4 drills two holes, the handle 1 is installed, fixed with the bolt 6, and the knife-edge 5 is used as a guide Triangular cutter 2 press cut. Described fixed rod 7 is as fixing corn on the cob utensil, and part is shaped on screw thread, is beneficial to sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com