Transverse milling type tree mover

A milling type tree digging machine technology, applied in forestry, application, agriculture, etc., can solve the problems of low transplant survival rate, rising transplant cost, high labor intensity, etc., and achieve the effect of improving transplant efficiency, simple structure and reliable work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with accompanying drawing.

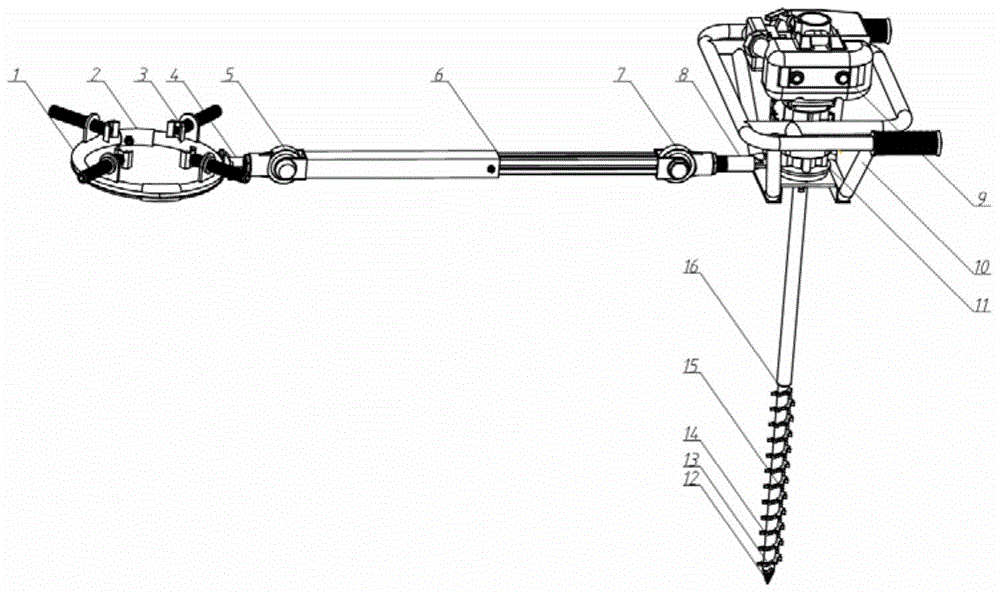

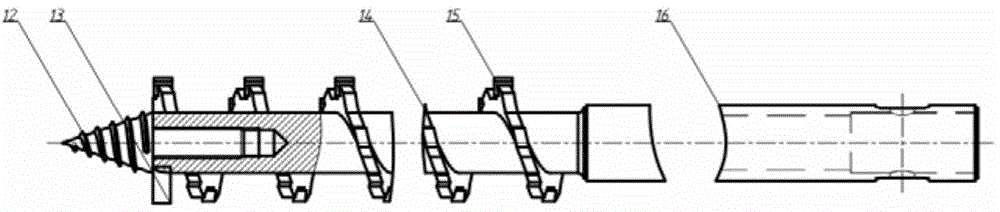

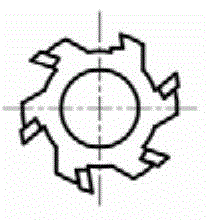

[0017] Such as figure 1 Shown, the horizontal milling type tree excavator of the present invention comprises helical milling rod, rotating bracket, speed reducer 11, handle 10, gasoline engine 9. Among them, the helical milling rod and the output shaft of the reducer are connected by threads and bolts. The positioning of the helical milling rod is realized by the conical helical positioning tip, the longitudinal drilling is realized by the carbide blade, and the horizontal milling is realized by the helical carbide tooth. The soil is lifted by the spiral surface; the rotating bracket is installed at the bottom of the reducer through the mounting plate, the tree trunk is fixed by the thread locking mechanism, the circular rotation around the trunk is realized by the rotating track and the rotating mechanism, and the horizontal movement is realized by the telescopic mechanism...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com