Multilayer waste gas purification device

A waste gas purification device and filter layer technology, which is applied in the direction of combined devices, chemical instruments and methods, and the separation of dispersed particles, can solve the problems of environmental damage, inability to effectively remove harmful substances in waste gas, etc., and achieve good purification effect and reasonable structural design , Ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

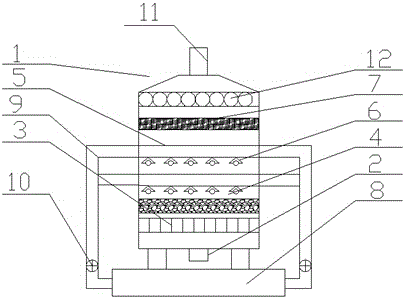

[0011] Such as figure 1 As shown, a multi-layer exhaust gas purification device includes a body 1, the body 1 includes an air inlet 2, an air outlet 11, a spray pipe 5 and a liquid storage tank 8, and the bottom of the body 1 is provided with an air inlet 2. A layer of airflow equalizing plate 3 is arranged inside the body 1; a first filter layer 4 is arranged above the airflow evenly dividing plate 3; a plurality of spray pipes 5 are arranged above the first filter layer 4; A second filter layer 7 is arranged above the spray pipe 5; a heating pipe 12 is arranged above the second filter layer 7; a liquid reservoir 8 is arranged below the body 1; The room is connected by a conduit 9; an air outlet 11 is provided above the body 1.

[0012] The second filter layer 7 is filled with granular activated carbon, so that harmful substances in the exhaust gas can be effectively filtered out, the exhaust gas can be fully purified, and the working efficiency is greatly improved.

[0013...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com