Flue gas desulfurization device

A desulfurization device and flue gas technology, applied to the separation of dispersed particles, chemical instruments and methods, separation methods, etc., can solve problems such as complex structure, unsatisfactory desulfurization effect, and high manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with accompanying drawing:

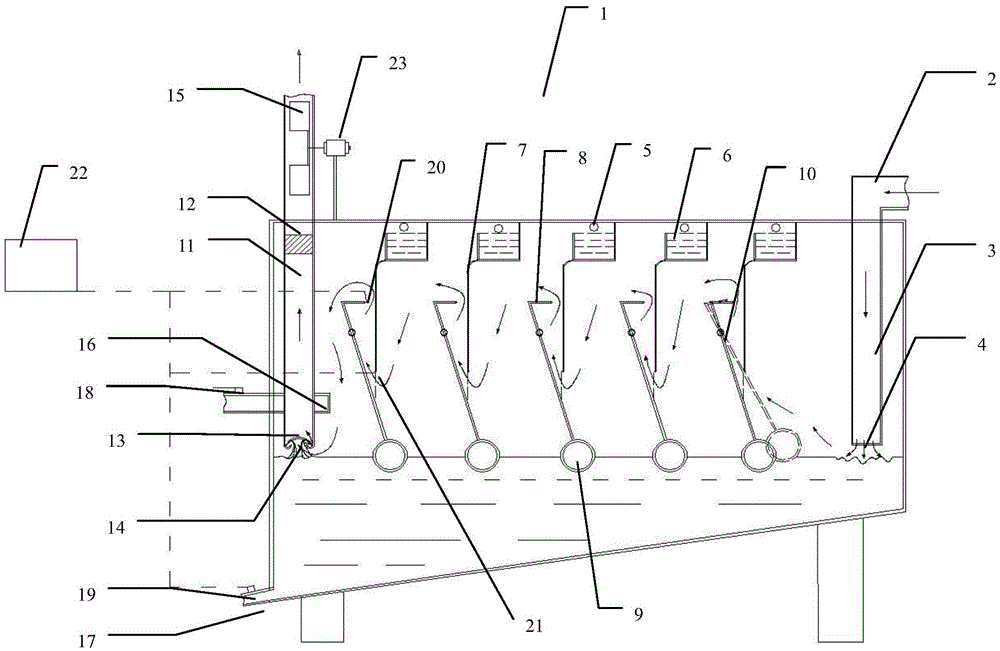

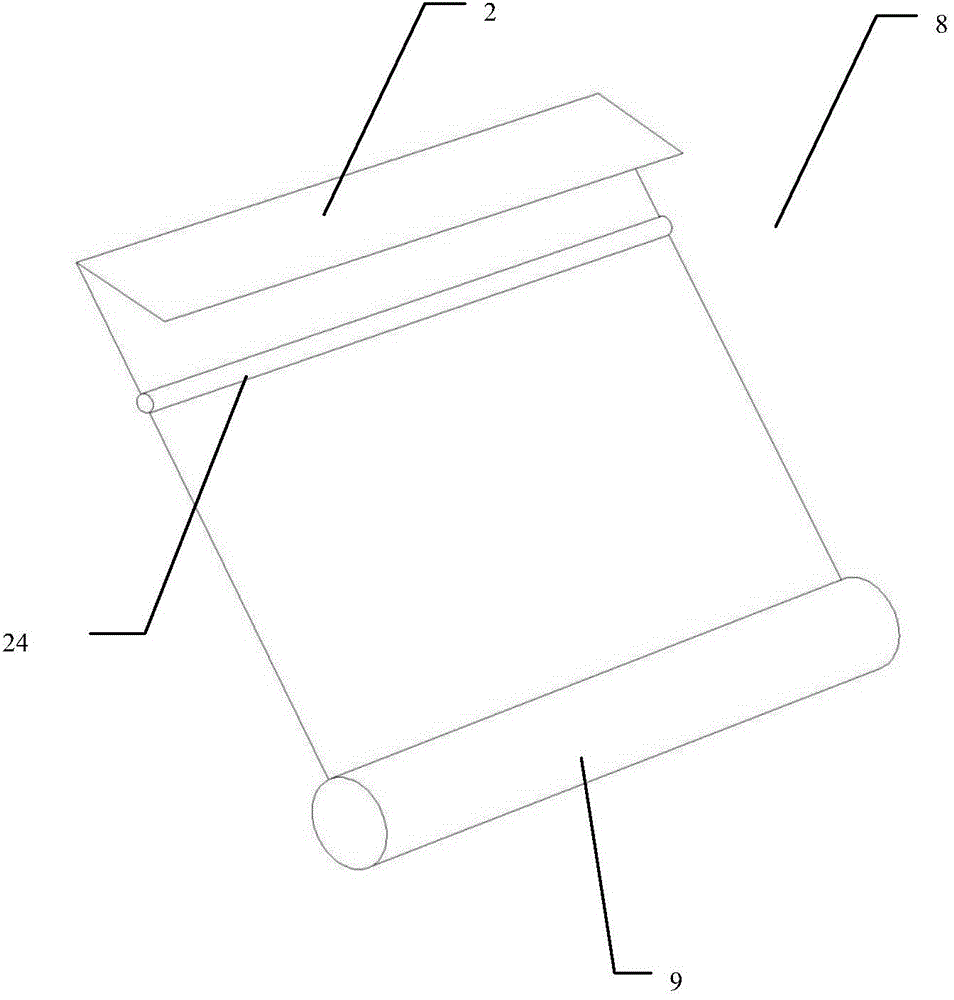

[0019] like figure 1 As shown, the flue gas desulfurization device of the present invention includes a housing 1, an air inlet pipe 3, an air outlet pipe 11, an overflow tank 6, an overflow plate 7, a liquid replenishment pipe 5, a rotating partition 8, a buoy 9, a rotating beam 10, an inlet Liquid pipe 16, liquid outlet pipe 17, liquid inlet pipe control valve 18, liquid outlet pipe control valve 19, rotating partition contact 20, overflow plate contact 21, demister 12, fan blade 15, motor 23, control Device 22. Wherein the air intake pipe 3 enters from the upper end of one side of the housing 1, the air intake pipe 3 extends downwards, the air intake pipe outlet 4 at the lower end of the air intake pipe 3 is close to the liquid surface, the absorption liquid is a sodium hydroxide solution, and multiple overflows are arranged above the housing. A launder 6 and a pluralit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com