Height adjusting mechanisms for air suspensions of automobile

An air suspension and height adjustment technology, which is applied to suspensions, elastic suspensions, vehicle components, etc., can solve the problems of difficulty in adjusting the height of the left and right suspensions, affecting the debugging effect and production efficiency, and insensitive suspension response. , to achieve the effect of the frame jumping response is sensitive, the effective length is simple and accurate, and the adjustment is simple and accurate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings.

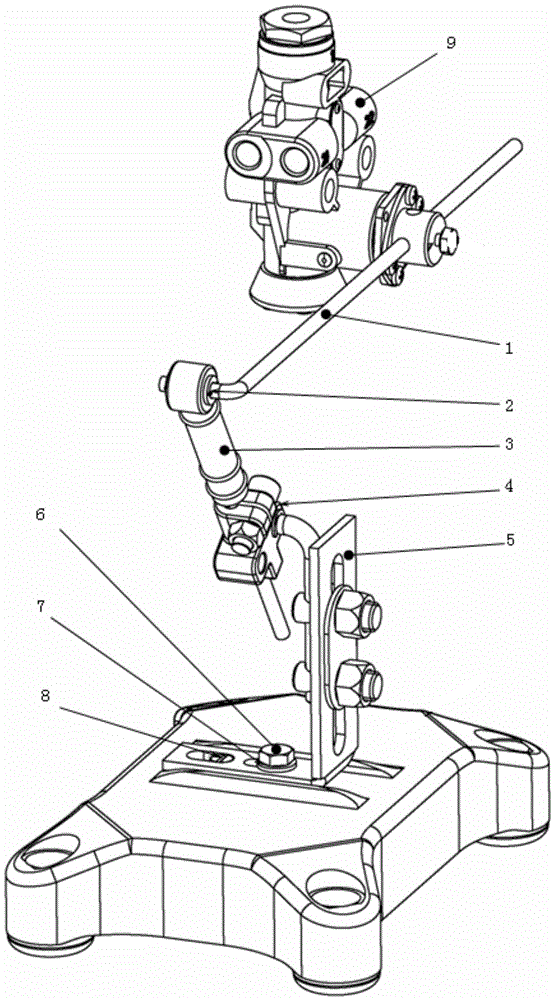

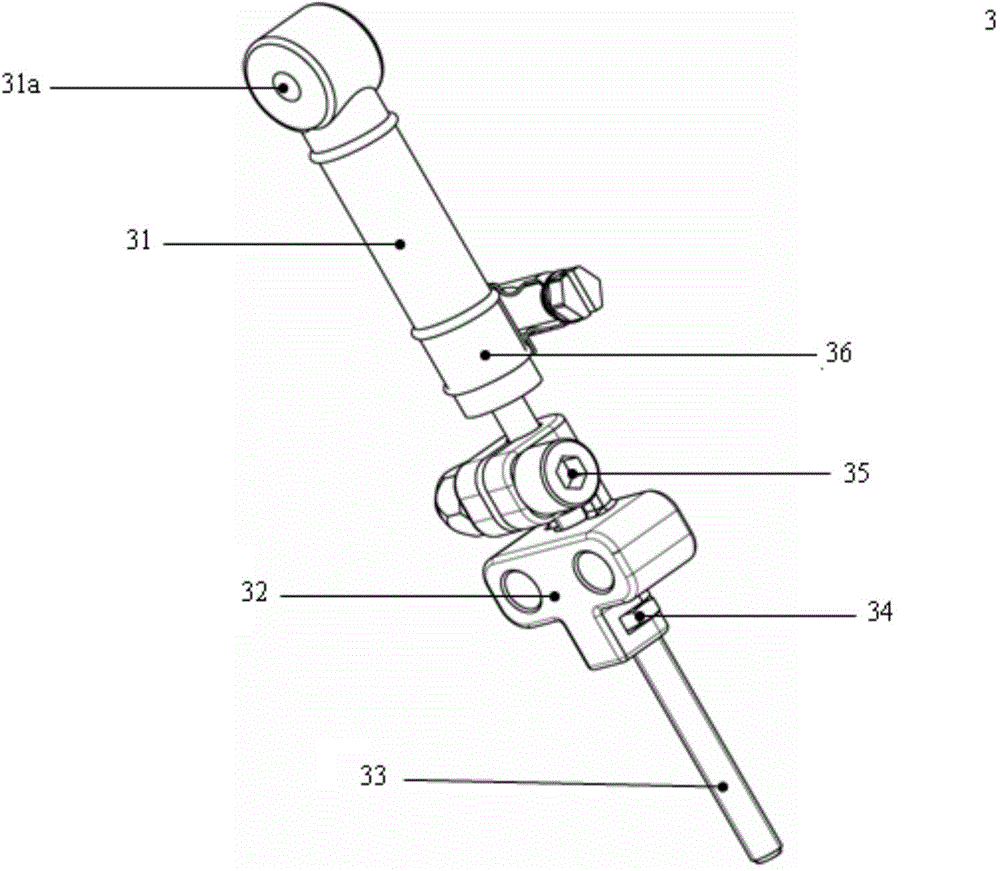

[0024] Such as figure 1 As shown, the height adjustment mechanism of this kind of mechanical automobile air suspension is arranged symmetrically along the two sides of the longitudinal beam of the vehicle frame, and each mechanism includes: a height valve 9 fixed on the longitudinal beam of the vehicle frame, a yaw rod 1 , vertical bar assembly 3, lower bracket assembly 5 and bridge tube pressing plate.

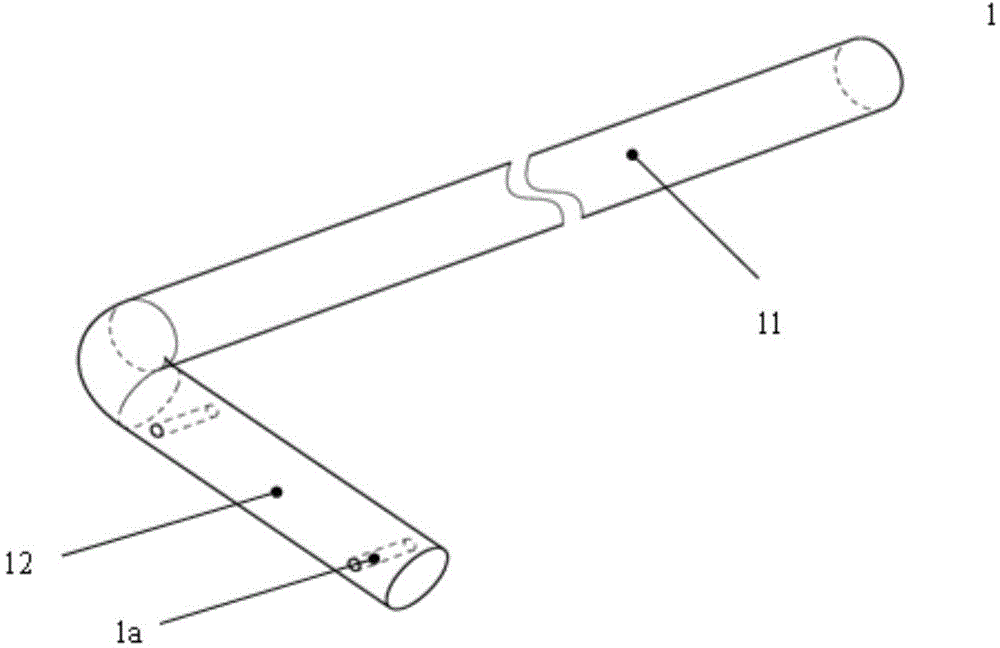

[0025] combine figure 1 with figure 2 As shown, the yaw rod 1 is composed of a bent end 12 (that is, a short rod end) and a long rod end 11. The long rod end passes through the swing shaft hole of the height valve 9. The bent end faces the frame rail and is folded. Two fixing through holes 1a are provided on the bent end, and after the bent end passes through the hinge sleeve 31 in the vertical rod assembly, cotter pins 2 are respectively arranged in the fixing th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap