Multi-stop-point single-slide-way sliding groove structure

A technology of multiple stop points and stop grooves, which is applied in the field of multi-stop points and single slideway chute structure, can solve the problems of large pulling force of the microphone cable, difficulty in pulling, recovery, and repositioning of the microphone cable, etc. Achieve the effect of smooth pulling and recovery, increasing the effective pulling length and avoiding misoperation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

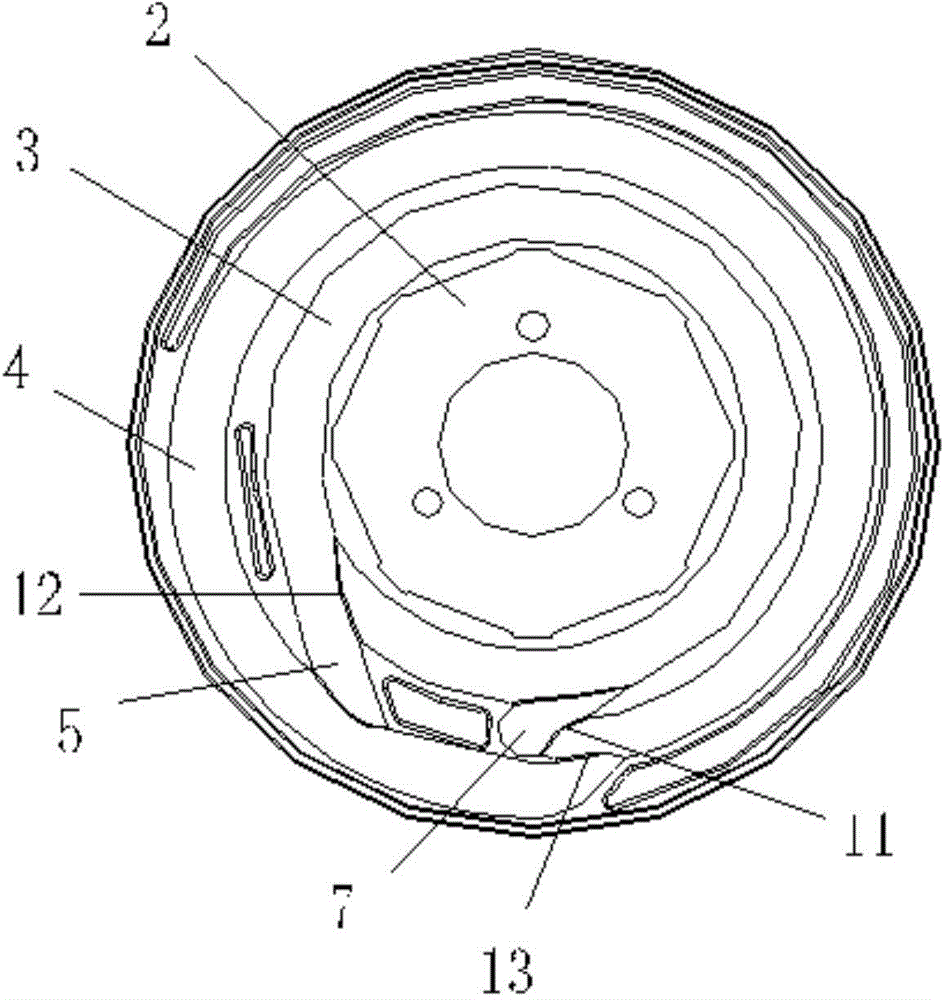

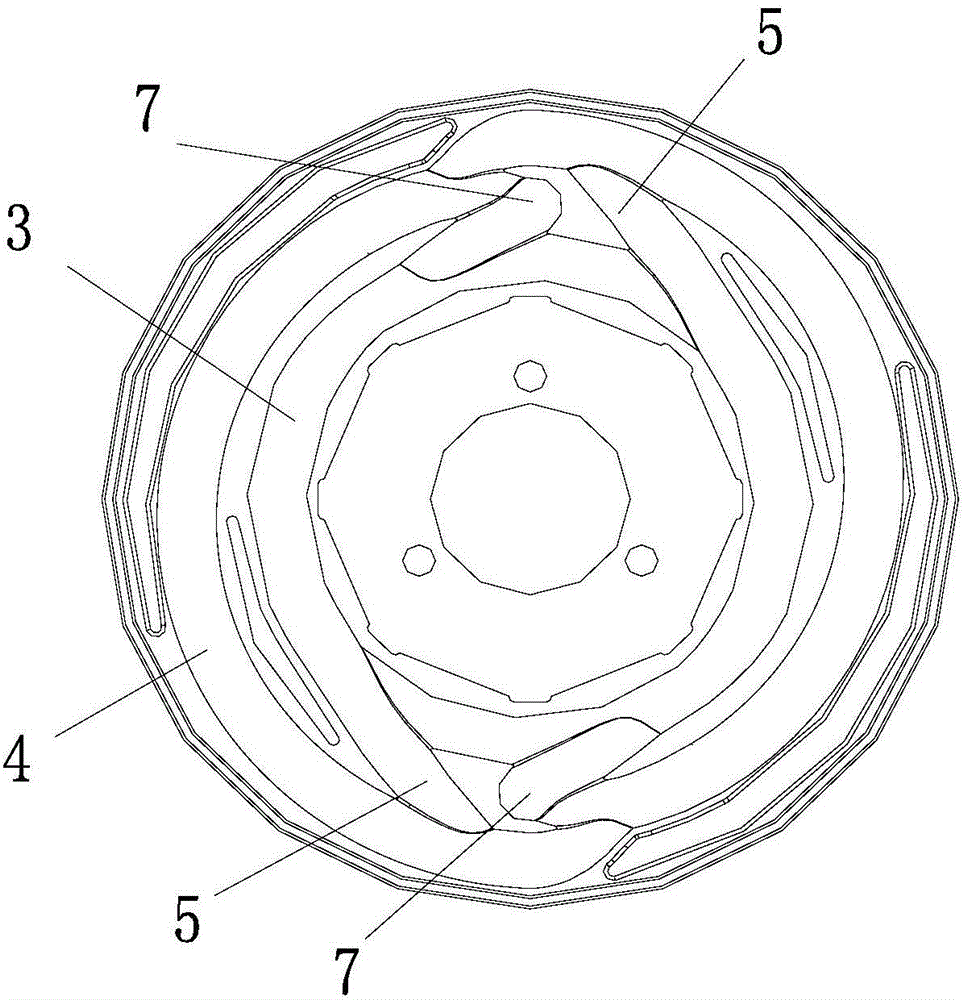

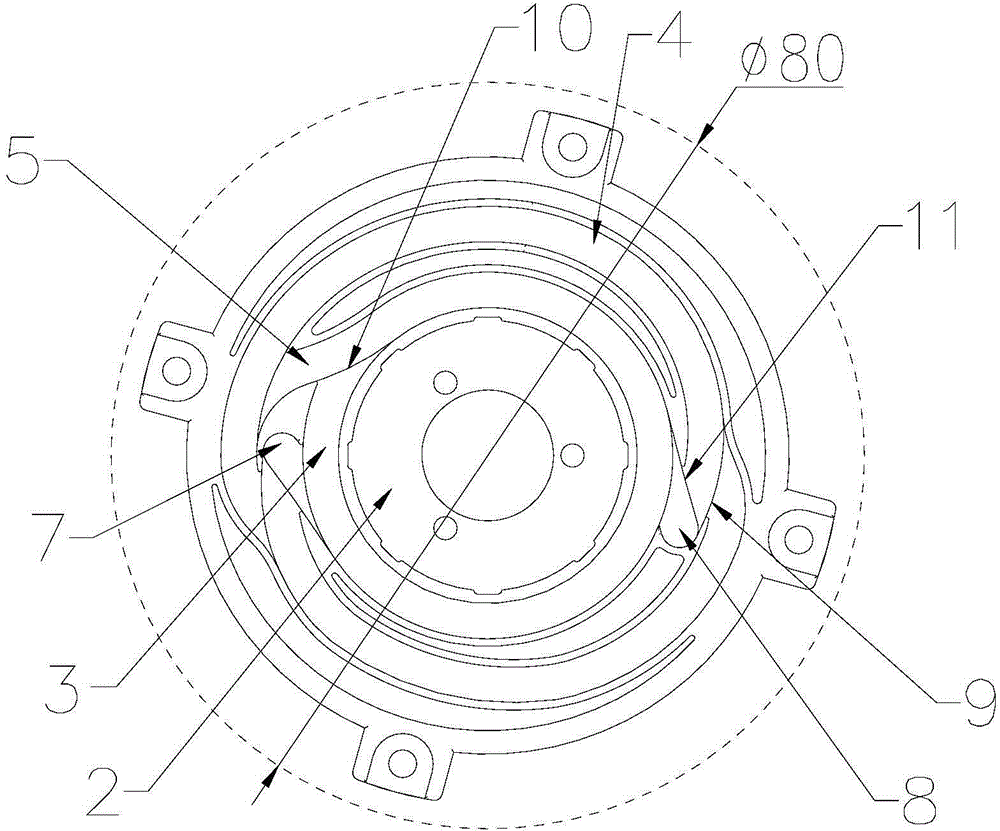

[0026] see image 3 , be provided with inner ring slideway 3 and outer ring slideway 4 on clockwork spring box 2, only be provided with a first step 10 in inner ring slideway 3, the side elevation of first step 10 and clockwork spring The pulling direction is opposite, and the inner ring slideway 3 adopts a slide out slideway 5 to connect with the outer ring slideway 4 at the side elevation of the first step 10, and the outer ring slideway 4 is provided with two second steps 9, each The side facade of the second step 9 is consistent with the tension direction of the mainspring spring, and the mainspring spring box 2 is also provided with two stop grooves between the inner ring slideway 3 and the outer ring slideway 4, namely the first stop groove. The first stop groove 7 and the second stop groove 8, the first stop groove 7 and the second stop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com