Mounting fixture of cement roadbed guardrail

A technology for installing fixtures and roadbeds, applied in the field of fixtures, can solve the problems of difficulty in accurately controlling the discharge position, time-consuming and laborious construction, and self-heavy weight.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

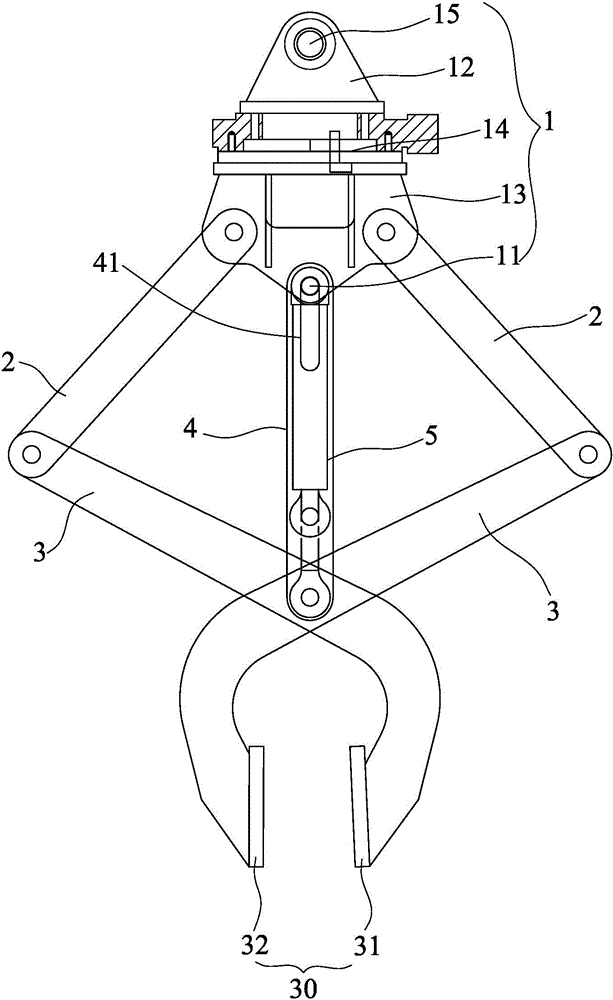

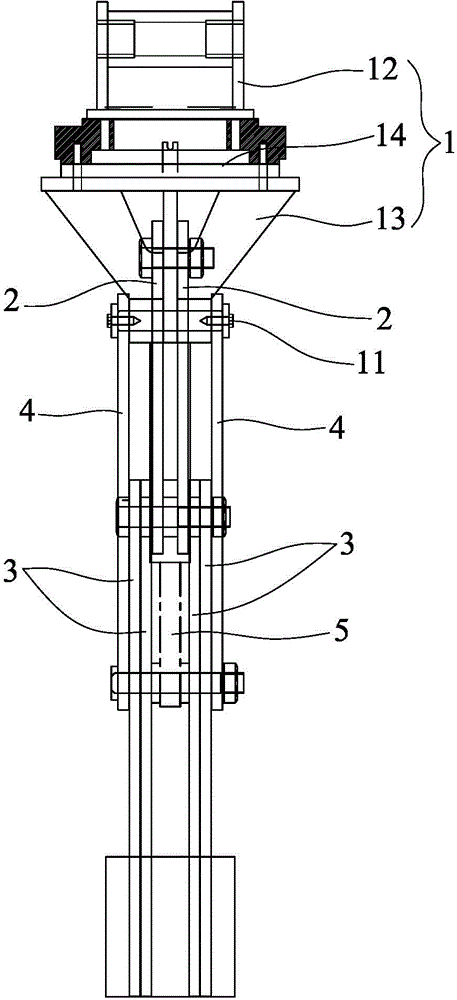

[0015] Such as figure 1 and figure 2 As shown, the installation fixture of a cement roadbed guardrail disclosed by the present invention is composed of a suspension head 1 , an upper arm 2 , a lower arm 3 , a limiting plate 4 and an oil cylinder 5 .

[0016] The left side of the lower end of the suspension head 1 is pivotally connected with the upper end of the left upper arm 2 , and the right side of the lower end of the suspension head 1 is pivotally connected with the upper end of the right upper arm 2 .

[0017] The lower end of the left upper arm 2 is pivotally connected with the upper end of the left lower arm 3 , and the lower end of the right upper arm 2 is pivotally connected with the upper end of the right lower arm 3 .

[0018] Middle positions of the left lower arm 3 and the right lower arm 3 are pivotally connected together to form a pivot point. The lower ends of the left lower arm 3 and the right lower arm 3 are relatively bent to form a clamping portion 30, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com