A speed-limited pulse nozzle for well washing

A speed-limited, pulse-type technology, which is applied in the direction of flushing wellbore, wellbore/well components, earthwork drilling and production, etc., can solve the problems affecting the efficiency of well washing, the lack of types of nozzles, and the effect of controlling the speed to be studied.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

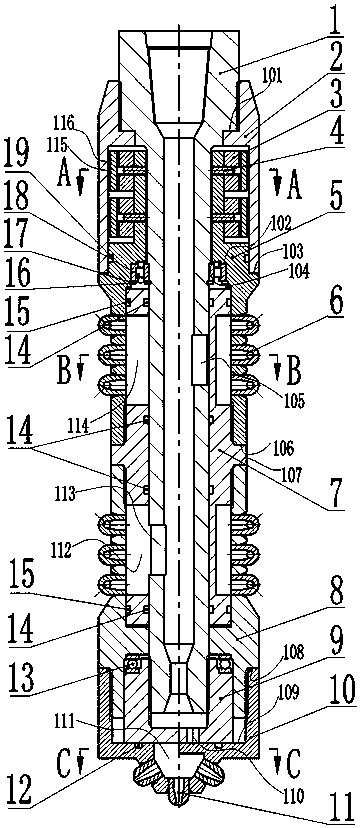

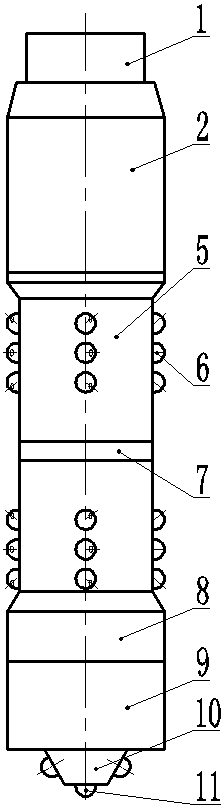

[0018] Embodiment 1: Taking the 160mm type pulse nozzle with limited rotation speed for well washing as an example, it will be further described in detail.

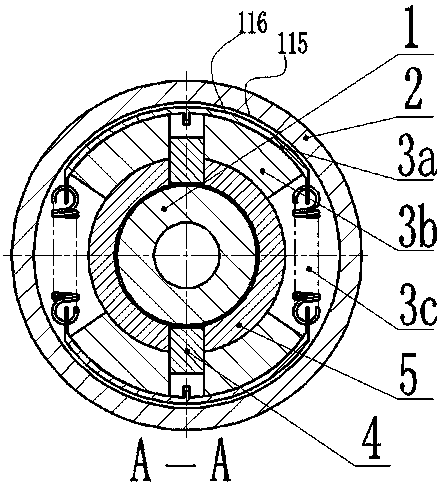

[0019] refer to figure 1. The 160mm type limited-speed pulse nozzle for well cleaning is a kind of oil and gas well that is applied to the casing of the above size and above. It is installed on the joint at the bottom of the downhole string during well cleaning operations. The nozzle can effectively control the rotation speed within a certain range and generate pulsed jet flow, remove sand bridges, rust, paraffin and other attachments on the well pipe wall, and realize normal and efficient well washing operations. Mainly consists of central tube 1, end cover 2, friction wheel assembly 3, pin 4, upper joint 5, nozzle A6, middle joint 7, lower joint 8, seat 9, bottom joint 10, nozzle B11, O-shaped rubber sealing ring A12, thrust ball bearing 13, O-type rubber seal ring B14, O-type rubber seal ring C15, shaft circlip 16, h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com