Power assembly lubricating device, power assembly lubricating method and power assembly lubrication control system

A powertrain and lubricating device technology, applied in the field of vehicle lubrication, can solve the problem that the lubricating device cannot meet the vehicle's passability lubrication performance at the same time, and achieve the effects of improving passability, good lubrication effect, and large ground clearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

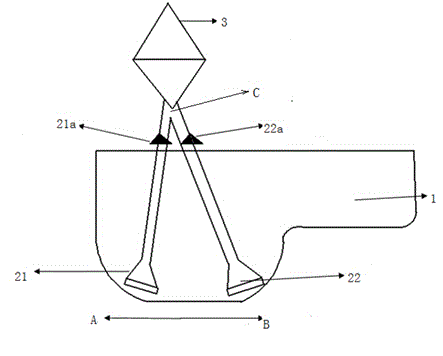

[0078] Such as figure 1 As shown, this embodiment provides a powertrain lubricating device, including an oil pan 1, two filter collectors 2 installed in the oil pan 1, a valve for controlling the on-off of the filter collector 2, and a valve for driving the collector The filter absorbs the power unit 3 of lubricating oil in the oil pan 1 , the oil filter 4 used to filter the lubricating oil before entering the powertrain, and several oil pipelines 5 .

[0079] Among them, the two filter collectors include near the rear ( figure 1 Shown by the arrow A in the middle), the first set filter 21 set, and near the front of the car ( figure 1 The second filter collector 22 is set as indicated by the middle arrow B), and the valves include a first valve 21a for controlling the opening and closing of the first filter collecting filter 21 and a second valve 22a for controlling the opening and closing of the second filter collecting filter 22 .

[0080] Since there are two filter col...

Embodiment 2

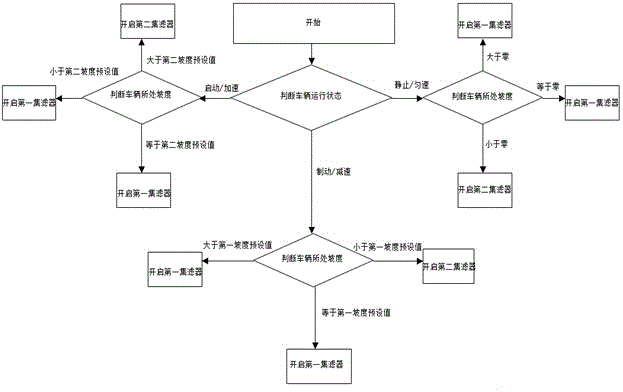

[0088] This embodiment provides a method for lubricating the powertrain of a vehicle using the lubricating device described in Embodiment 1, including:

[0089] Judging step, judging the tilt state of the liquid surface in the oil pan 1;

[0090] Execute the step of selecting and opening at least one collector filter whose liquid suction port is below the liquid level according to the tilt state of the liquid level.

[0091] Judging the inclination state of the liquid surface in the oil pan 1 through the judging step, and then selecting and opening at least one filter with a suction port below the liquid surface according to the inclination state of the liquid surface through the execution steps, so as to ensure various conditions of vehicle operation Under, for example, braking / deceleration, starting / accelerating, constant speed / stationary, uphill, downhill and flat road, the suction port of at least one filter 2 can always be located below the liquid level in the oil pan 1, ...

Embodiment 3

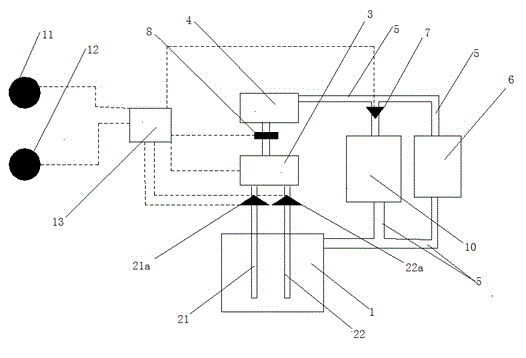

[0115] This embodiment provides a vehicle powertrain lubrication control system, which can be used in the lubrication method of Embodiment 2, including

[0116] a judging unit for judging the inclination state of the liquid surface in the oil pan 1; and

[0117] The execution unit is used for selectively opening at least one collector filter 2 whose liquid suction port is below the liquid level according to the tilt state of the liquid level.

[0118] The inclination state of the liquid surface in the oil pan 1 is judged by the judging unit, and then the execution unit is used to select and open at least one filter whose suction port is below the liquid surface according to the inclination state of the liquid surface, so as to ensure various conditions of vehicle operation Under, for example, braking / deceleration, starting / accelerating, constant speed / stationary, uphill, downhill and flat road, the suction port of at least one filter 2 can always be located below the liquid le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com