Clamping type rolling wheel for fire hose

A hose-type, fire-fighting hose technology, applied in the direction of pipe supports, pipes/pipe joints/pipes, mechanical equipment, etc., can solve the problems of constant dragging and inflexibility of fire hoses, and achieve simple structure and structure reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail with reference to the accompanying drawings and embodiments.

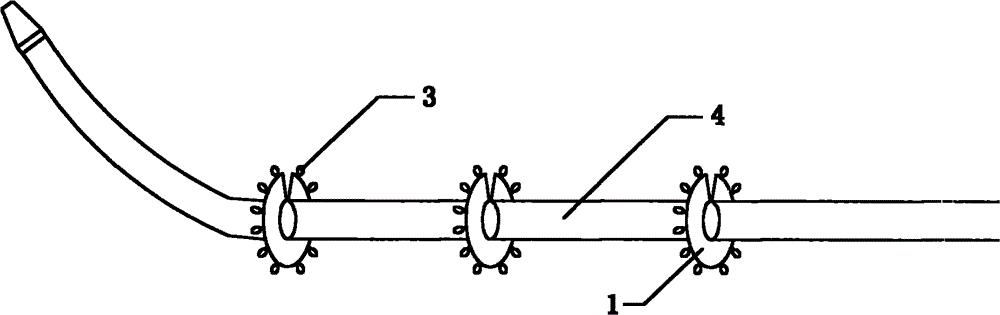

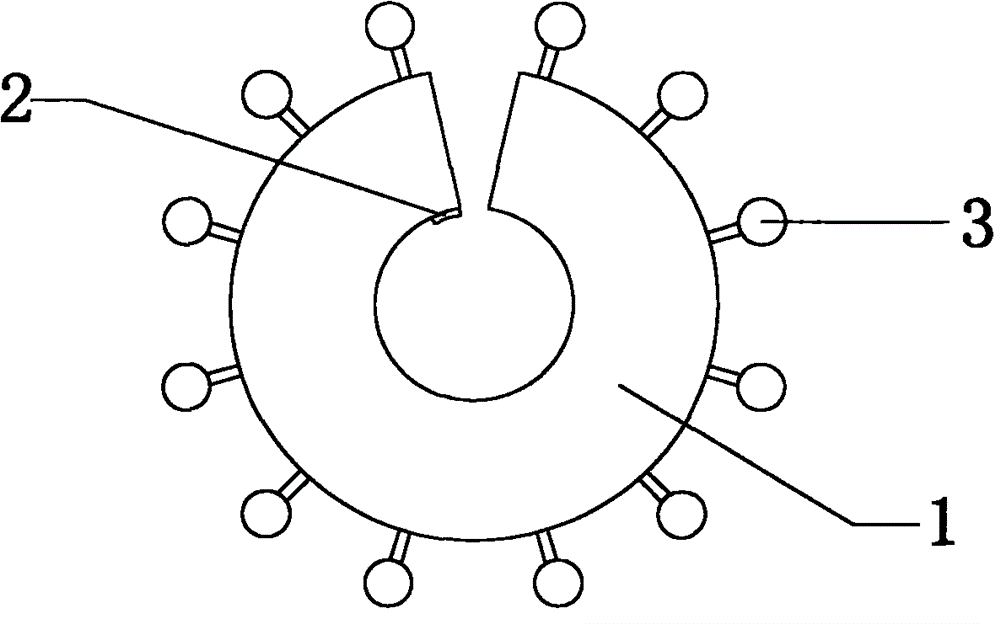

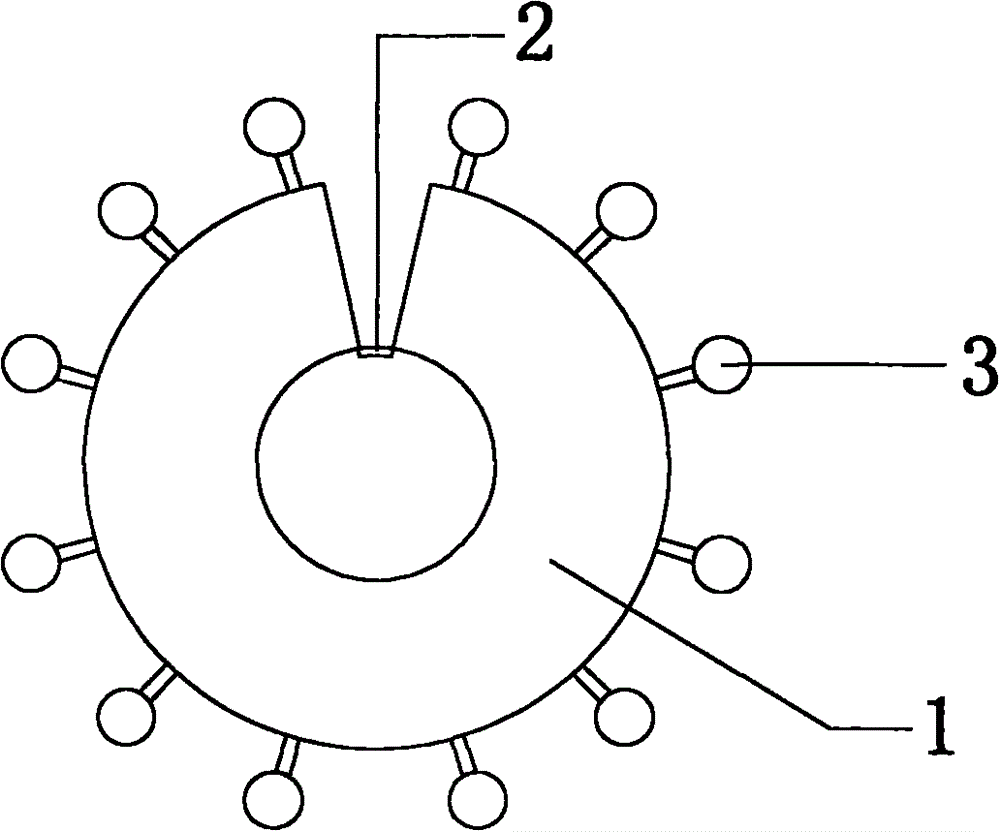

[0019] A cassette roller for a fire hose, comprising an annular slot 1, a sliding piece 2, a universal wheel 3, and a fire hose 4, the top of the inner ring of the annular slot 1 is provided with a sliding piece 2, and the outer Universal wheels 3 are uniformly arranged around the ring; the fire hose 4 runs through the inner ring of the annular card slot 1 .

[0020] The inner diameter of the annular clamping groove 1 is 5-8 centimeters, the outer diameter is 10-12 centimeters, and an opening is provided at the upper end.

[0021] The number of said universal wheels 3 is 8 to 12, which are evenly arranged around the periphery of the annular slot 1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com