Side blown furnace

A side-blown furnace and hearth technology, which is used in the field of non-ferrous metal smelting combustion equipment and side-blown furnaces, can solve the problems of damage to the side-blown furnace, failure to meet the heating requirements, low efficiency and other problems, and achieve high energy utilization and temperature. The effect of uniform distribution and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The detailed structure of the present invention will be further described below in conjunction with the drawings and specific embodiments.

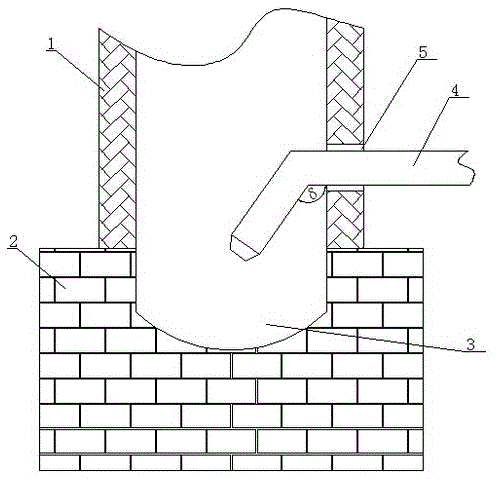

[0015] Such as figure 1 , figure 2 , image 3 Shown: a side-blown furnace, which includes a water jacket 1, a furnace body 2, a hearth 3 and a furnace burner 4; the cross-section of the furnace body 2 is rectangular, the hearth 3 is stacked with refractory materials, and the furnace bottom is Inverted arch shape, the upper furnace body of the hearth 3 is surrounded by a water jacket 1 and a heating port 5 is provided on the water jacket; the oven burner 4 passes through the heating port 5 of the water jacket 1 and enters the upper part of the hearth 3.

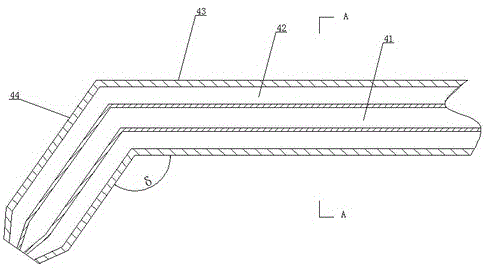

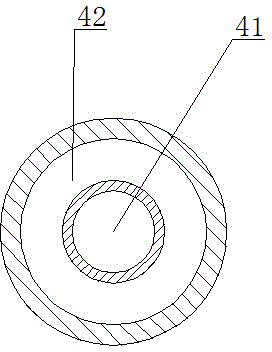

[0016] The oven burner 4 includes a first air inlet duct 41 and a second air inlet duct 42, and the second air inlet duct 42 is located inside the first air inlet duct 41.

[0017] The first air inlet duct 41 and the second air inlet duct 42 are composed of a burner oblique section 44 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com