Large-scale bi-dimensional fractured rock mass shearing seepage meter

A fractured rock mass, large-scale technology, applied in the direction of scientific instruments, permeability/surface area analysis, suspension and porous material analysis, etc., can solve the problem that it is difficult to simulate the seepage state of the real rock mass fracture network, and small-sized rock samples have great influence , large difference in fracture network, etc., to achieve the effect of overcoming small size defects, flexible loading control, and high experimental accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

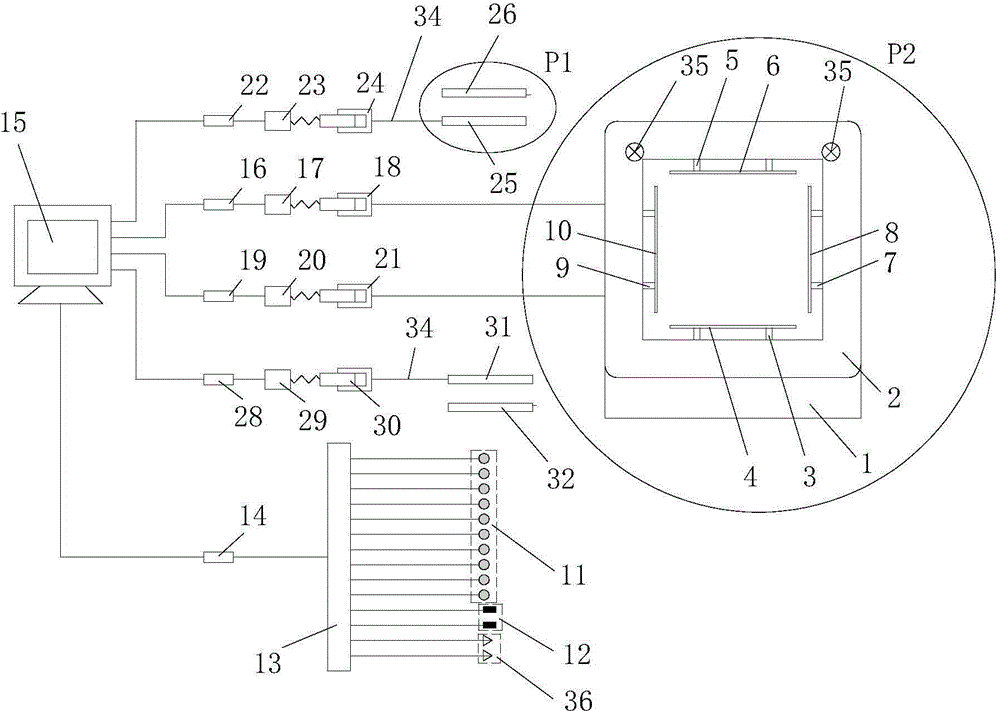

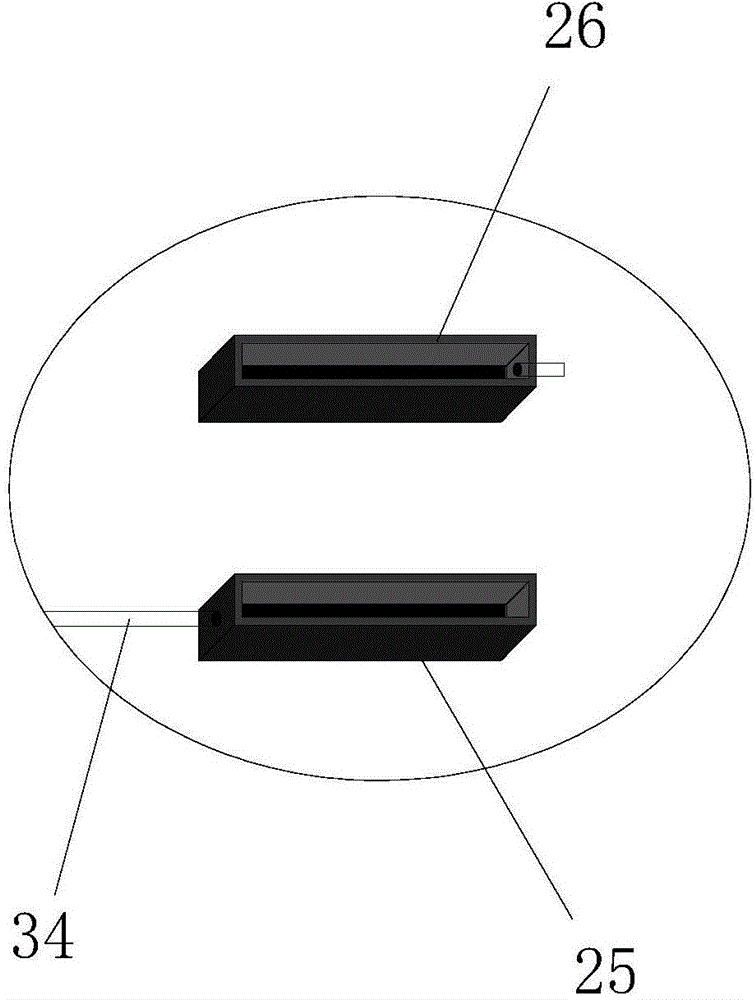

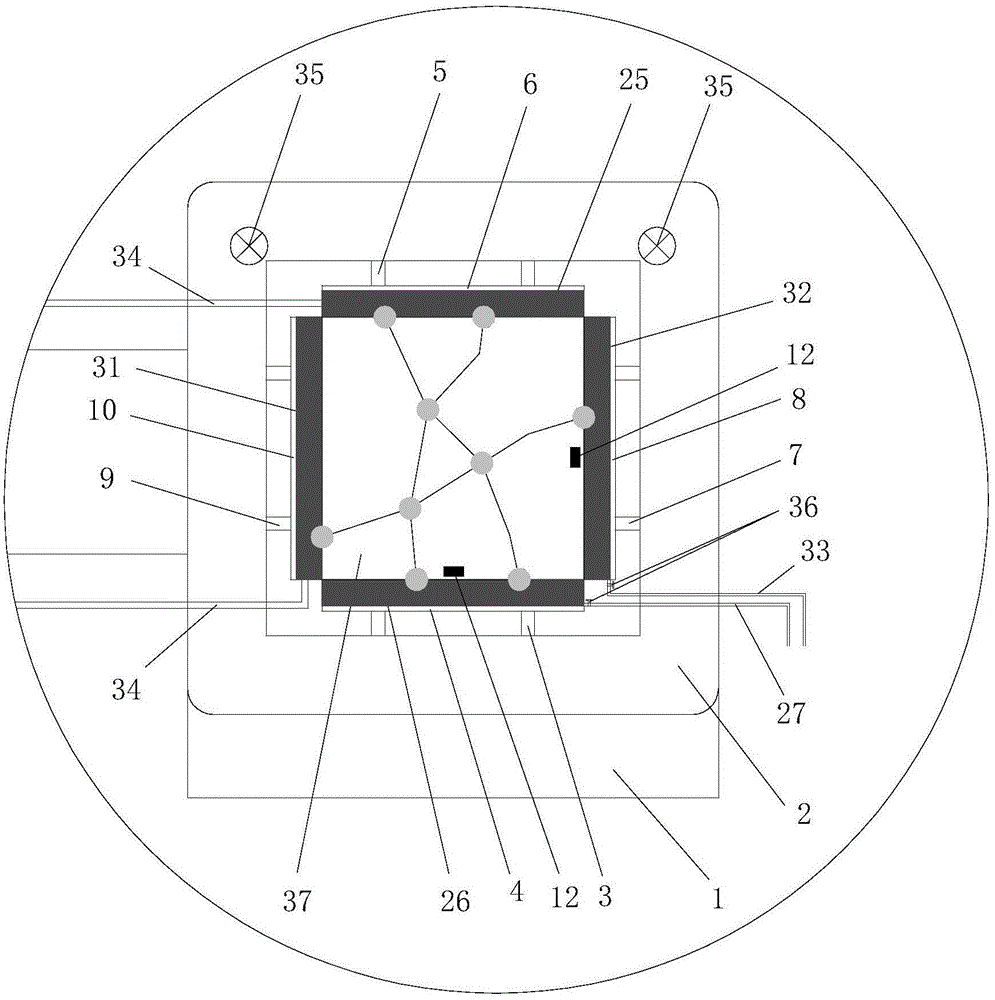

[0025] figure 1 It is a schematic diagram of the structure of the large-scale two-dimensional fractured rock mass shear seepage meter of the present invention; figure 2 for figure 1 The enlarged 3D schematic diagram of the P1 part in the middle; image 3 When doing the bidirectional loading multidirectional seepage experiment for the large-scale two-dimensional fractured rock mass shear seepage meter of the present invention figure 1 Schematic diagram of the installation in the P2 section.

[0026] like Figure 1-3 As shown, in this embodiment, the large-scale two-dimensional fractured rock mass shear seepage meter includes a workbench, a stress loading system, a seepage loading system and a data measurement control system, and the stress loading system includes a vertical stress loading system and a lateral stress loading system, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com