System and method for overhead line fault location and monitoring

A technology for fault location and overhead lines, applied in fault locations, information technology support systems, and electrical measurement, can solve problems such as unsafe communication, low accuracy, time-consuming and labor-intensive equipment and methods, and achieve safety and fault resolution. The detection is accurate and reliable, and the effect of overcoming inaccuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The specific implementation of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the implementation examples described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

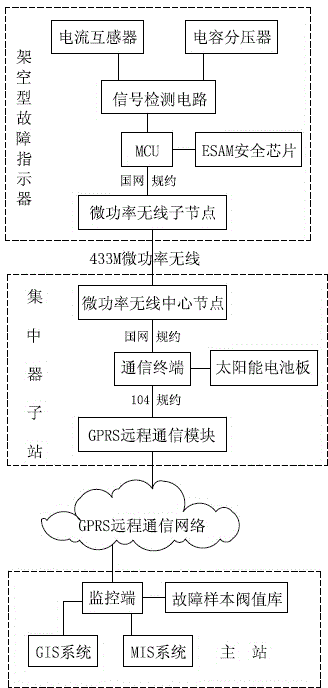

[0037] Such as figure 1 The overhead line fault location monitoring system shown includes a fault indicator, a concentrator substation and a main station.

[0038] The fault indicator includes MCU, current transformer, capacitive voltage divider, signal detection circuit, ESAM safety chip and micro-power wireless sub-node.

[0039] Overhead Line Fault Indicators utilize the principle of CT (Current Transformer) to measure line current. When the overhead line fault indicator is hung on the wire, the primary current will flow through the current sensor of the overhead line fault indicator, and the current sensor will generate a CT secondary signal, which is filte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com