Processing apparatus for manufacturing antistatic shoes

A processing device and technology for anti-static shoes, which are applied in the direction of shoe-making machinery, footwear, heel pads, etc., can solve the problems of high cost and reduce cost, and achieve the effect of cost saving, convenient and fast processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

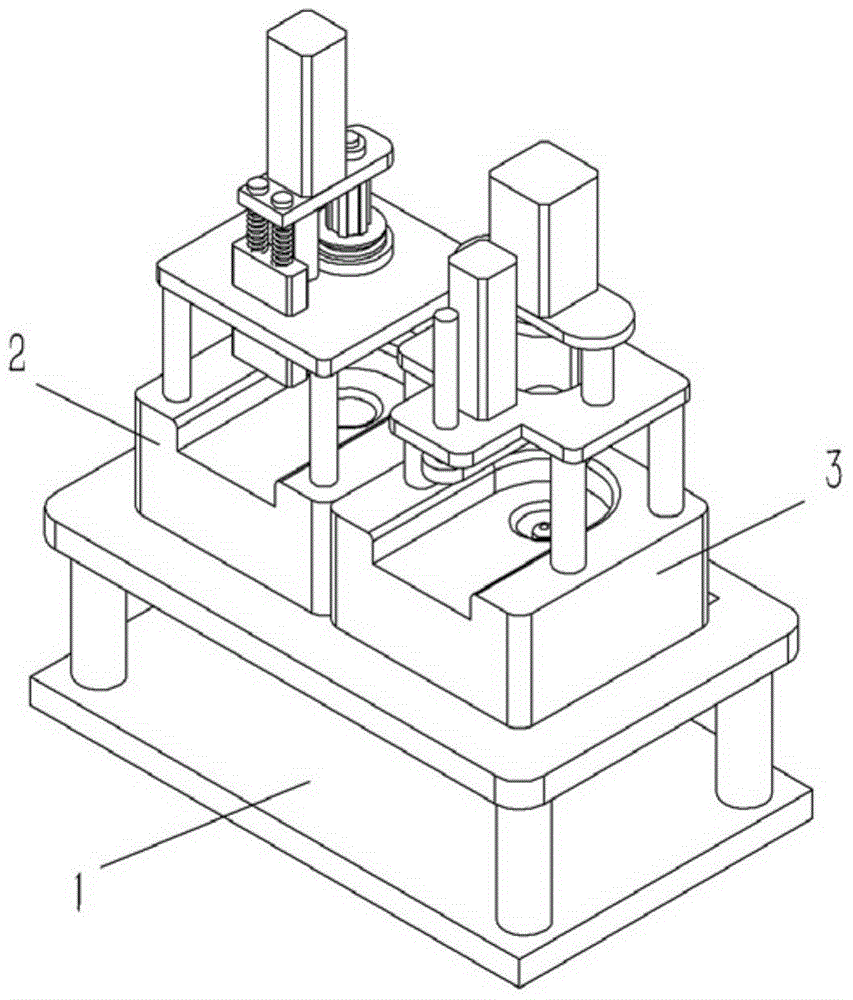

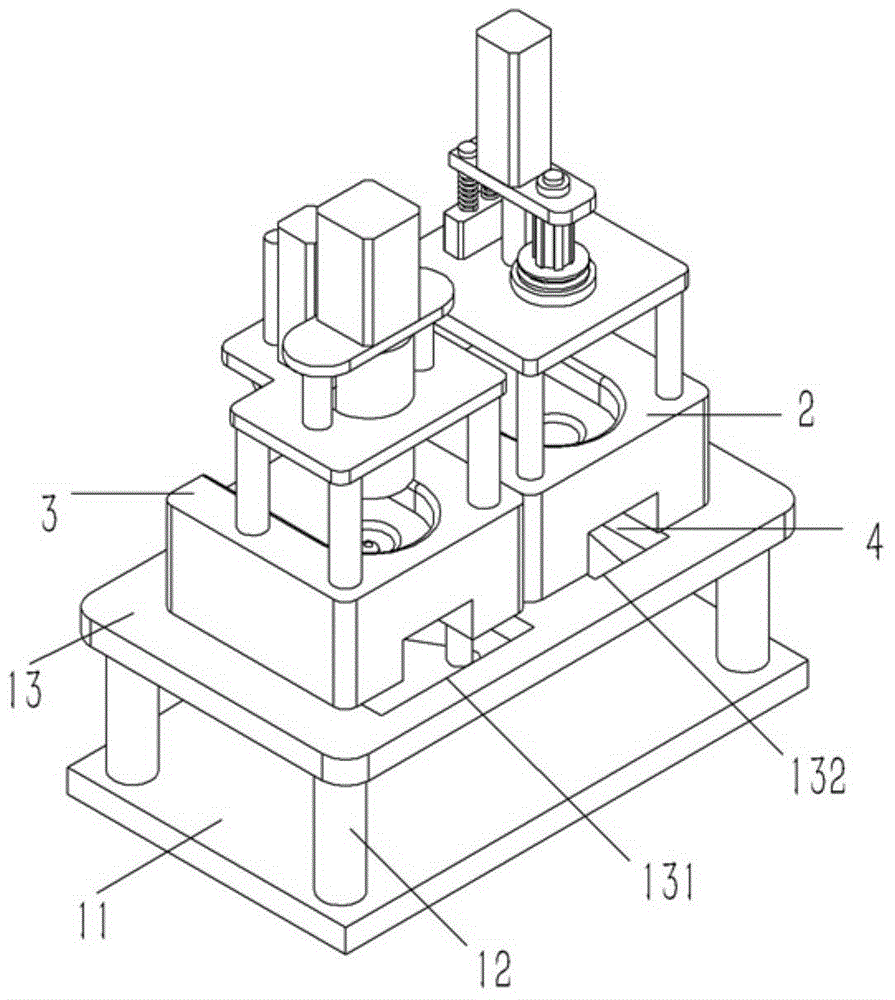

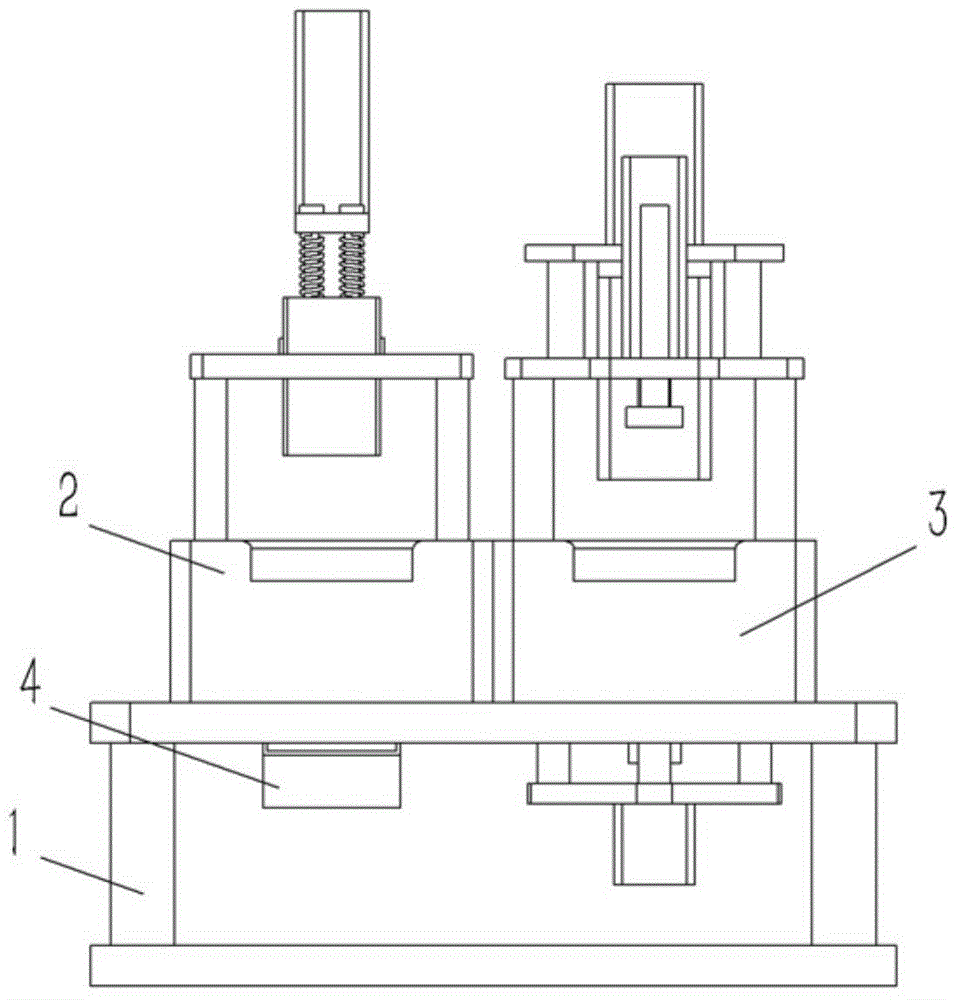

[0027] Example: see Figures 1 to 10 As shown, a production and processing device for preparing anti-static shoes includes a mounting base 1 on which a punching mechanism 2 and a press-fitting mechanism 3 are fixedly connected side by side;

[0028] The punching mechanism 2 includes a punching base 21, the top surface of the punching base 21 is formed with a first groove 211 for placing the heel, the bottom surface of the first placement groove 211 is formed with chip removal holes 212, and the first placement groove 211 The top surface of the perforated base 21 around is fixed with a perforated platform pillar 221, and the top of the perforated platform pillar 221 is fixed with a perforated platform 22, and the front end of the perforated platform 22 is plugged with a positioning briquetting block 23, and the rear end is plugged. There is a spline shaft 24, and a pulley 25 is inserted on the spline shaft 24. The pulley 25 is hinged on the drilling platform 22. The top end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com