Commutator segment manufacturing method

A manufacturing method and commutator piece technology, applied in commutator manufacturing, metal processing equipment, etc., can solve the problems of high production cost, bending of the back of the piece body, low utilization rate of copper materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

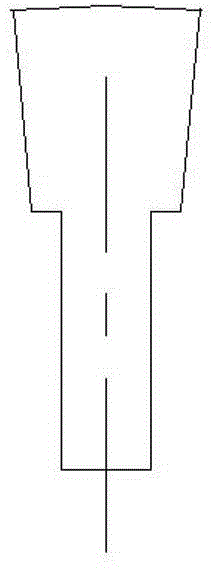

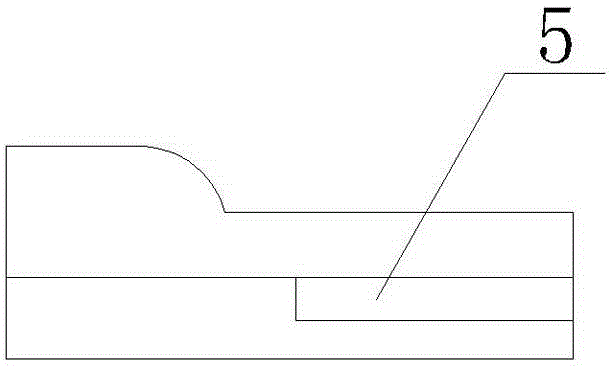

[0022] See Figure 9 and Figure 10 The commutator piece workpiece made by the present invention consists of a sheet body 2 and a step 1 arranged on the top of the sheet body 2. The step 1 and the sheet body 2 are L-shaped, and the left and right sides of the sheet body 2 are provided with a sheet along the height direction of the sheet body. Groove 3, left and right sides 14, inner side 12 of sheet body, left and right sides 13, outer side 11 of the step. The manufacturing method of the commutator segment of the present invention comprises the following steps: a. copper wire rod drawing process, drawing out the section bar that is equivalent to sheet body shape but does not have sheet groove, see figure 1 and figure 2 ; b. Fixed-length cutting process, the profile is cut to the required length, see figure 1 and figure 2 ; c. The first cold heading process, see image 3 , Figure 4 and Figure 11 , in the cavity of the first cold heading die A, the head of the profile...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com