3D (three dimensional) printer and materials vessel thereof, and manufacturing method of materials vessel

A technology of a 3D printer and a manufacturing method, which is applied in the field of 3D printing and can solve problems such as short life, complicated processing technology, and difficulty in ensuring the bottom of the trough is flat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

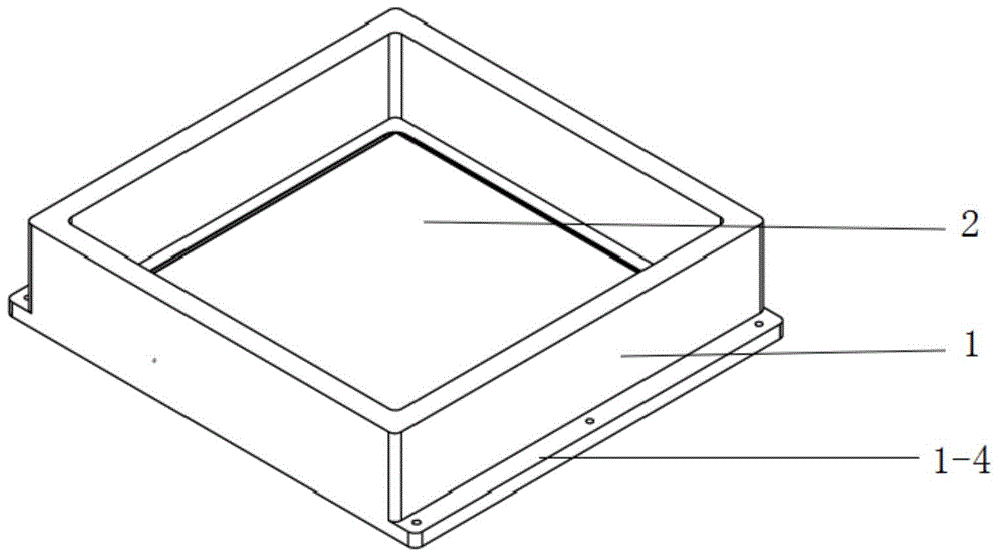

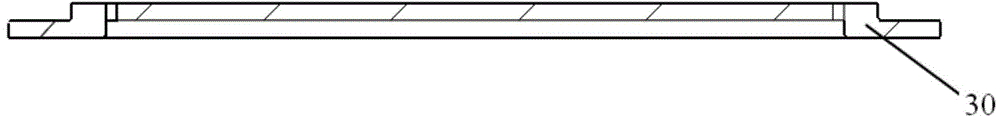

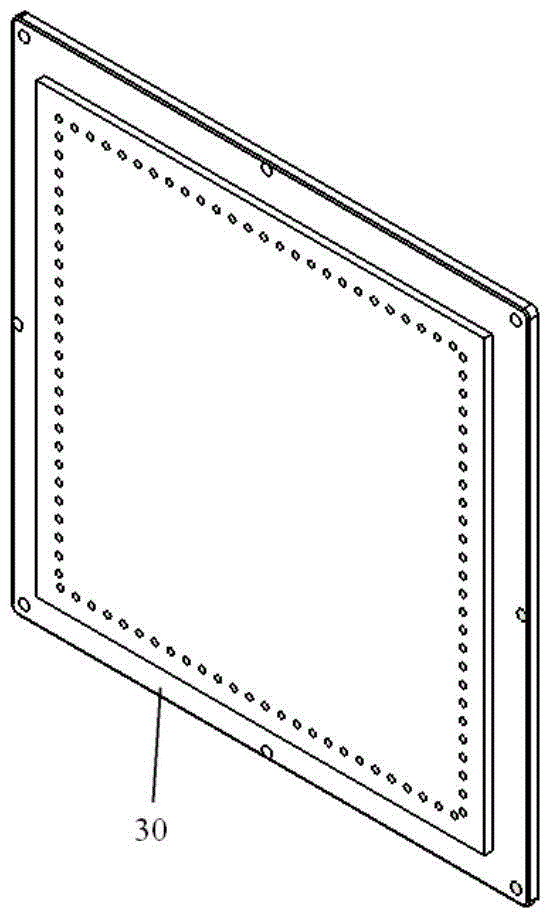

[0040] like figure 1 , Figure 2a and Figure 2b As shown, the present invention provides a trough for a 3D printer, which includes: a tank frame 1 with open ends at both ends, a non-stick film 2 and a platform base 30, and one side of the open end of the tank frame 1 is fixed on a cover covered with On the platform base 30 of the non-stick film 2 , a ventilation hole 3 - 1 is provided in the area of the platform base 30 restricted by the inner wall of the bezel 1 . Wherein, the non-stick film 2 covers the upper surface of the platform base 30 , although it is closely attached, it is not really pasted together, and a certain range of separation can occur.

[0041] The non-stick film 2 is a semi-breathable flexible film, which is chemically inert to the printing material and is non-sticky. It will not react with the printing material and can prevent the printing layer from sticking to the bottom of the trough. The non-stick film 2 can be used as a Fluoride products or othe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com