Fracturing fluid for enhanced oil recovery

A fracturing fluid and recovery factor technology, applied in the field of fracturing fluids, can solve the problems of long swelling time, difficult to satisfy, many types and large amounts of additives, etc., and achieves the advantages of reducing the construction period of a single well, short swelling time, and simplifying the preparation process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

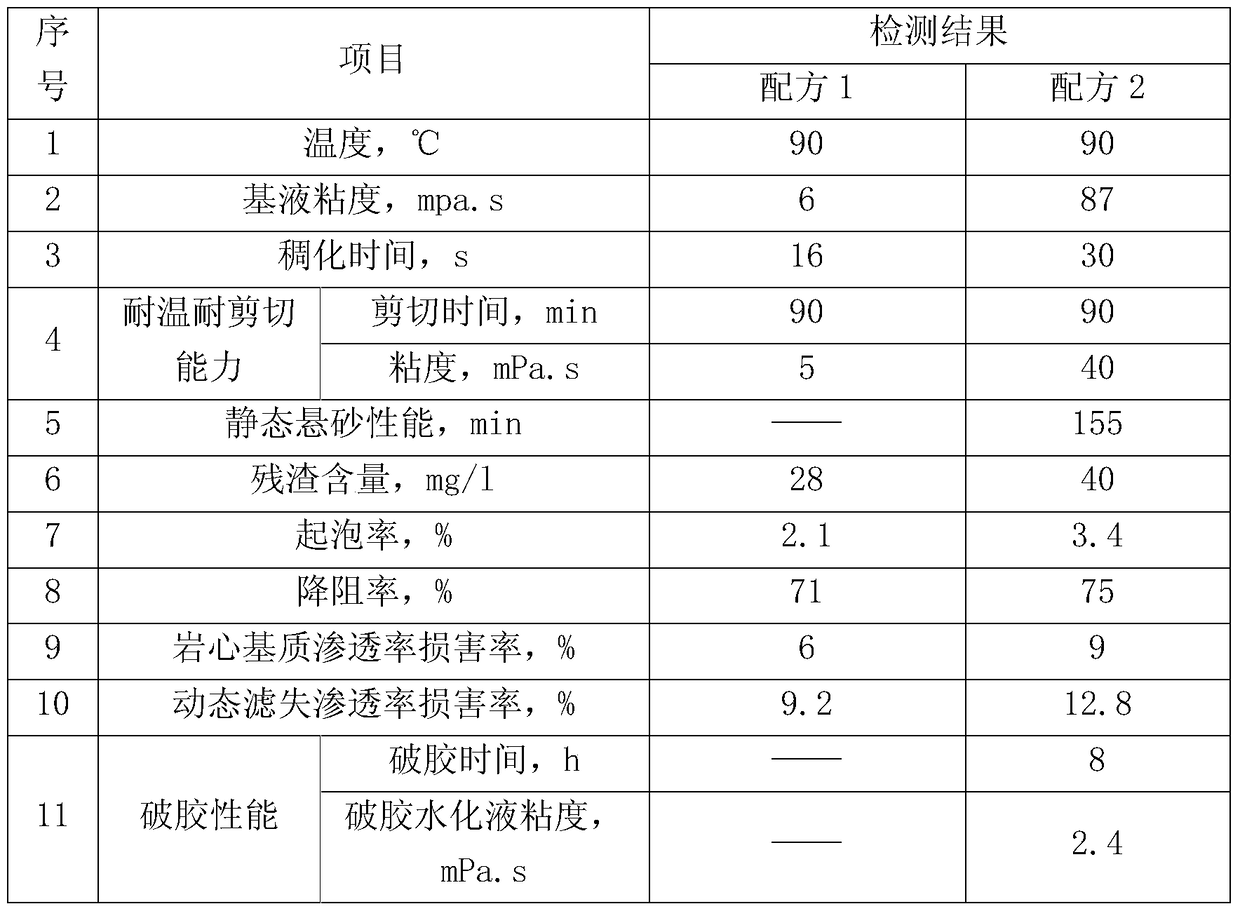

Embodiment 1

[0028] Weigh 0.75g of thickener, 0.1g of alkyl polyglycoside, and 0.15g of potassium persulfate into 499g of water for preparation, and stir at 400r / min for 3min to obtain the fracturing fluid system.

Embodiment 2

[0030] Weigh 4g of thickener, 0.5g of alkyl polyglycoside, and 0.2g of capsule breaker into 495.3g of water for preparation, and stir for 3min at 400r / min to obtain the fracturing fluid system.

Embodiment 3

[0032] Weigh 5g of thickener, 0.75g of alkyl polyglycoside, 0.25g of potassium persulfate, and 0.08g of ammonium persulfate into 493.92g of water, and stir at 400r / min for 3min to obtain the fracturing fluid system.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com