The Method of Retrofitting the Tank Body Structure by Adopting Different Direction Double-layer Prestressed Steel Corbels

A technology for prestressed steel and structural transformation, applied in applications, artificial waterways, buildings, etc., to achieve the effect of saving investment and simple and easy technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

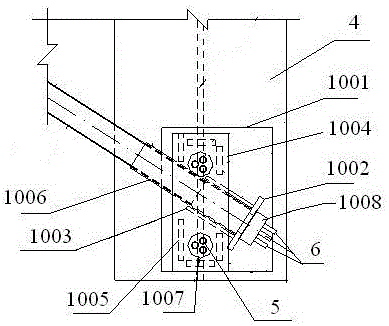

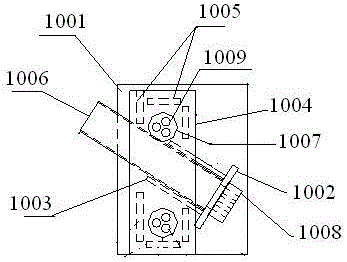

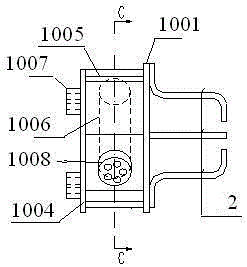

[0031] Excavate corbel arrangement joints, arrange unbonded prestressed anchor cables 5 horizontally, arrange connecting anchor reinforcement 2, support channel body 3 outer formwork, tension adjustment and anchor sealing, pour high-performance freeze-thaw resistant self-compacting fine stone early-strength concrete 4. Among them, the anchor bar 2 is fixedly connected with the pre-embedded limit steel plate 1001 of the opposite direction double-layer prestressed steel structure corbel 1, and the two ends of the unbonded prestressed anchor cable 5 are respectively connected to the opposite direction double-layer prestressed steel structure corbel Through the connection, the cable 6 is fixed and anchored to the corbel of the double-layer prestressed steel structure in different directions, and the high-performance freeze-thaw resistant self-compacting fine stone early-strength concrete 4 is located outside the corbel of the double-layer prestressed steel structure in different dir...

Embodiment 2

[0044] Excavate corbel arrangement joints, arrange unbonded prestressed anchor cables 5 horizontally, arrange connecting anchor reinforcement 2, support channel body 3 outer formwork, tension adjustment and anchor sealing, pour high-performance freeze-thaw resistant self-compacting fine stone early-strength concrete 4. Among them, the anchor bar 2 is fixedly connected with the pre-embedded limit steel plate 1001 of the opposite direction double-layer prestressed steel structure corbel 1, and the two ends of the unbonded prestressed anchor cable 5 are respectively connected to the opposite direction double-layer prestressed steel structure corbel Through the connection, the cable 6 is fixed and anchored to the corbel of the double-layer prestressed steel structure in different directions, and the high-performance freeze-thaw resistant self-compacting fine stone early-strength concrete 4 is located outside the corbel of the double-layer prestressed steel structure in different dir...

Embodiment 3

[0060]Excavate corbel arrangement joints, arrange unbonded prestressed anchor cables 5 horizontally, arrange connecting anchor reinforcement 2, support channel body 3 outer formwork, tension adjustment and anchor sealing, pour high-performance freeze-thaw resistant self-compacting fine stone early-strength concrete 4. Among them, the anchor bar 2 is fixedly connected with the pre-embedded limit steel plate 1001 of the opposite direction double-layer prestressed steel structure corbel 1, and the two ends of the unbonded prestressed anchor cable 5 are respectively connected to the opposite direction double-layer prestressed steel structure corbel Through the connection, the cable 6 is fixed and anchored to the corbel of the double-layer prestressed steel structure in different directions, and the high-performance freeze-thaw resistant self-compacting fine stone early-strength concrete 4 is located outside the corbel of the double-layer prestressed steel structure in different dire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com