Drilling waste collection and lifting device for drilling

A technology for transferring devices and waste, applied in the direction of earthwork drilling, wellbore/well parts, etc., which can solve the problems of uncontinuous operation, easy damage of motor, easy adhesion of drilling cuttings, etc., and achieves compact structure, convenient use, and avoids Effect of cuttings adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention is not limited by the following examples, and specific implementation methods can be determined according to the technical solutions of the present invention and actual conditions.

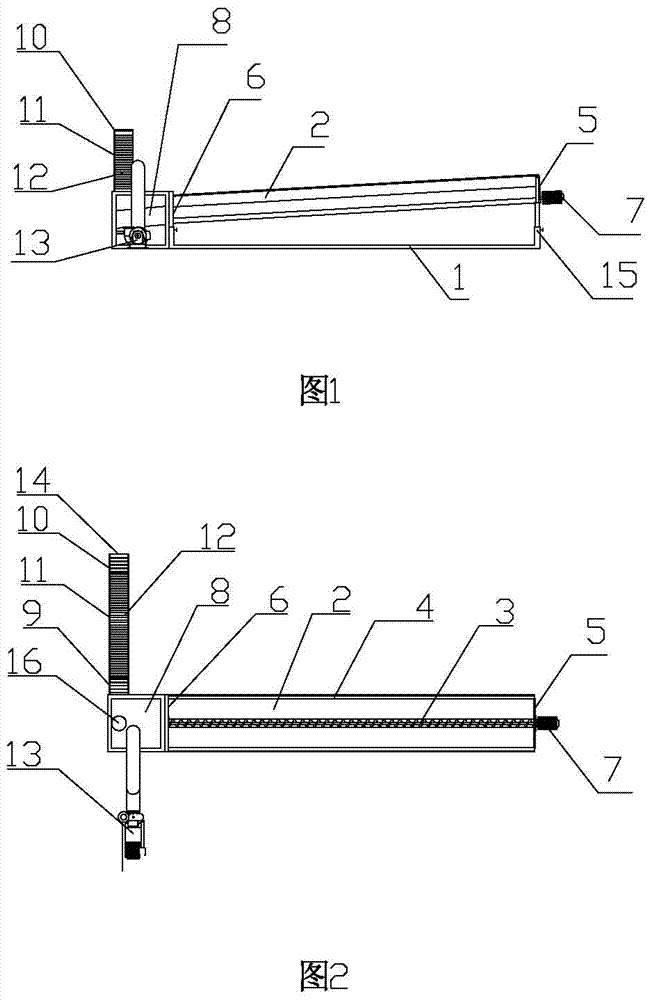

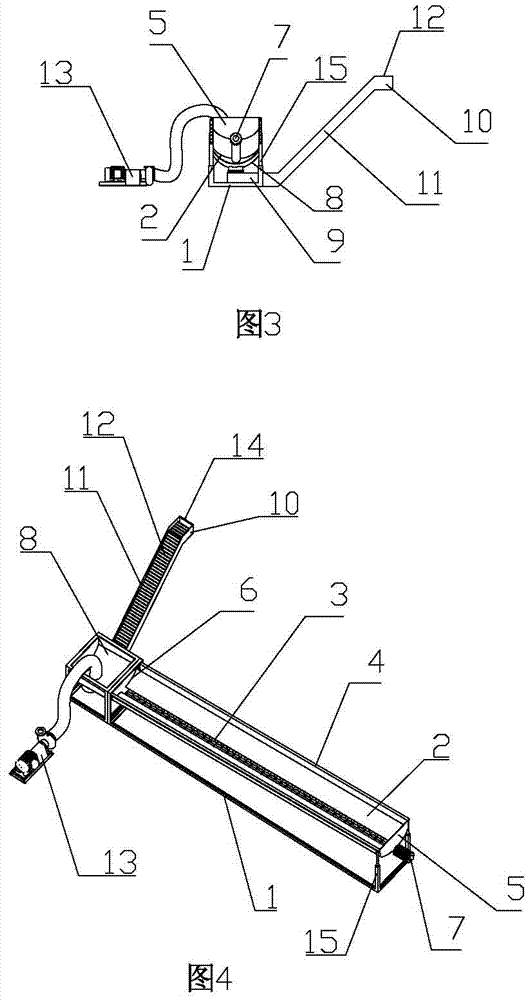

[0025] In the present invention, for the convenience of description, the description of the relative positional relationship of each component is described according to the layout of Figure 1 of the specification, such as: the positional relationship of front, rear, top, bottom, left, right, etc. It is determined according to the layout direction of the drawings in the description.

[0026] Below in conjunction with embodiment and accompanying drawing, the present invention will be further described:

[0027] As shown in accompanying drawings 1, 2, 3, and 4, the lifting and transferring device for collecting waste while drilling includes a collection component and a lifting and transferring component. The propeller 3 and the collection and cleaning pipe 4, the bottom ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com