Thin interbed carbonate rock bottom water reservoir CO2 huff and puff experimental test method

A technology of carbonate rock and testing method, which is applied in the direction of earthwork drilling, mining fluid, sustainable manufacturing/processing, etc. It can solve problems such as oil enrichment, uneven production of oil layers, and poor physical properties of thin layers, so as to achieve simple operation, principle reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

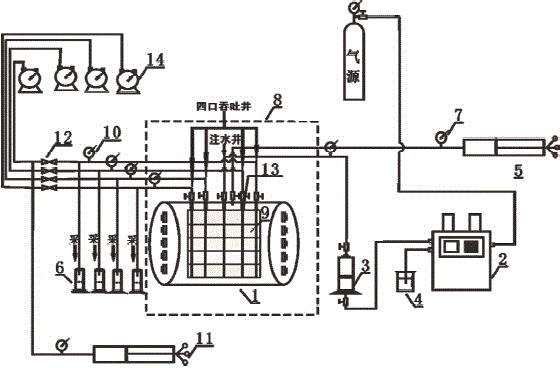

[0029] Further describe the present invention below in conjunction with accompanying drawing and example:

[0030] Such as figure 1 , figure 2 , image 3 Shown, the present invention a kind of thin interbedded carbonate rock bottom water reservoir CO 2 The throughput experimental test method comprises the following steps:

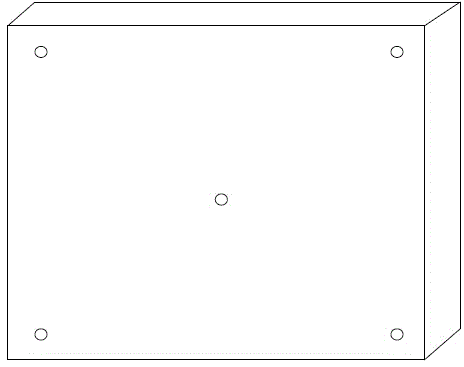

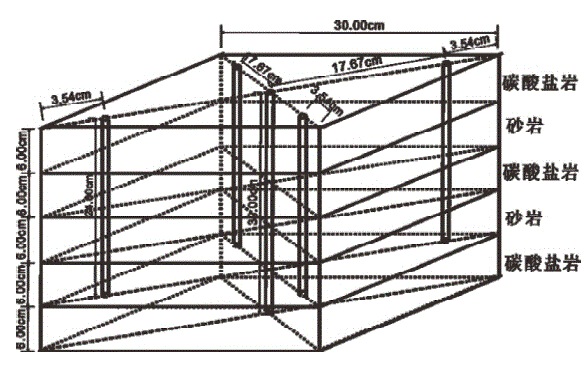

[0031] ①According to the carbonate rock cuttings and sandstone cuttings provided by the oil field, the cement was added to the carbonate rock and sandstone cuttings respectively according to multiple sample mixing ratios, and pressed under a certain pressure to form carbonate rock and sandstone oil Standard small cores are collected, and their physical parameters such as porosity and permeability are measured, and then the composition ratio of rock samples close to the porosity and permeability of oilfield reservoirs is selected, and the carbonate core particles are regenerated by artificial sintering. Cemented into three 30cm×30cm×6cm slab models, cem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com