Synchropoint identification method and system of synchronizer

An identification method and synchronizer technology, which can be applied to components with teeth, belts/chains/gears, mechanical equipment, etc., can solve the problem of inability to accurately obtain the position of the synchronizer, and achieve the effect of reducing impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

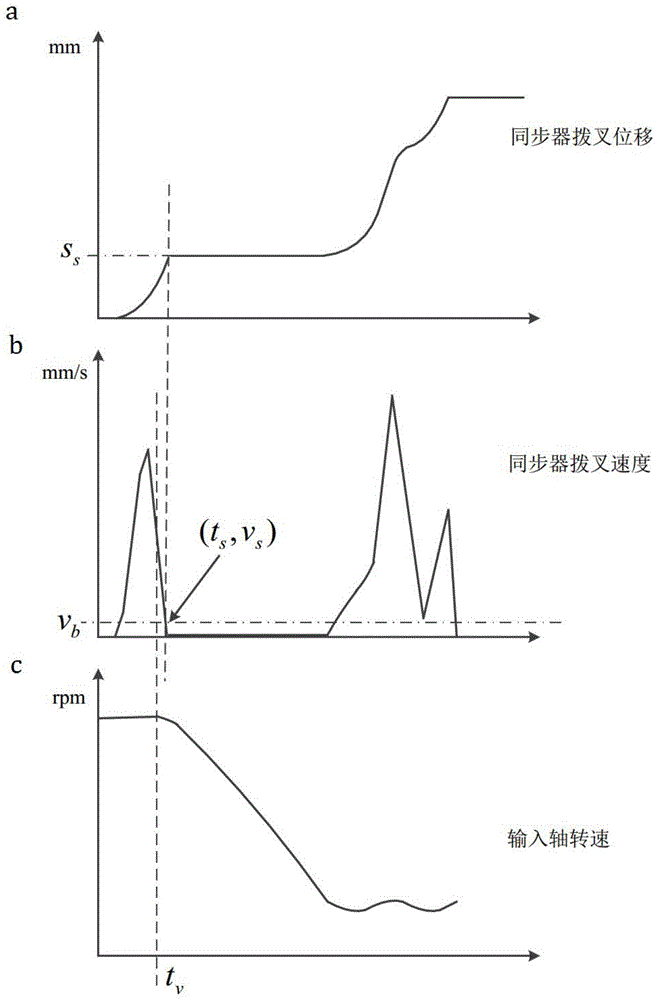

[0029] This embodiment proposes a method for identifying the synchronization point of the synchronizer. The method identifies the position of the synchronization point of the synchronizer according to the speed of the synchronizer fork and the rotational speed of the input shaft.

[0030] In this embodiment, the dual-clutch transmission is taken as an example, and the specific implementation steps are as follows:

[0031] 1) After the transmission control core issues a shift synchronization command, it starts to detect the displacement of the synchronizer fork;

[0032] 2) After the transmission control core issues a shift synchronization command, it starts to detect the input shaft speed;

[0033] 3) Calculate the axial velocity of the synchronizer fork according to the displacement of the synchronizer fork, and the calculation method is the difference method;

[0034] 4) When the detected rotational speed of the input shaft changes, record this moment as t v ;

[0035] 5)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com