Steel for carburizing

A technology of quality and chemical composition, applied in the field of carburizing steel, can solve the problems of reducing and failing to achieve surface C concentration, and achieve the effect of improving manufacturing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0112] Next, examples of the present invention will be described, but the conditions in the examples are examples of conditions adopted for confirming the practicability and effects of the present invention, and the present invention is not limited to the examples of conditions. The present invention can adopt various conditions as long as it does not deviate from the gist of the present invention and achieves the object of the present invention.

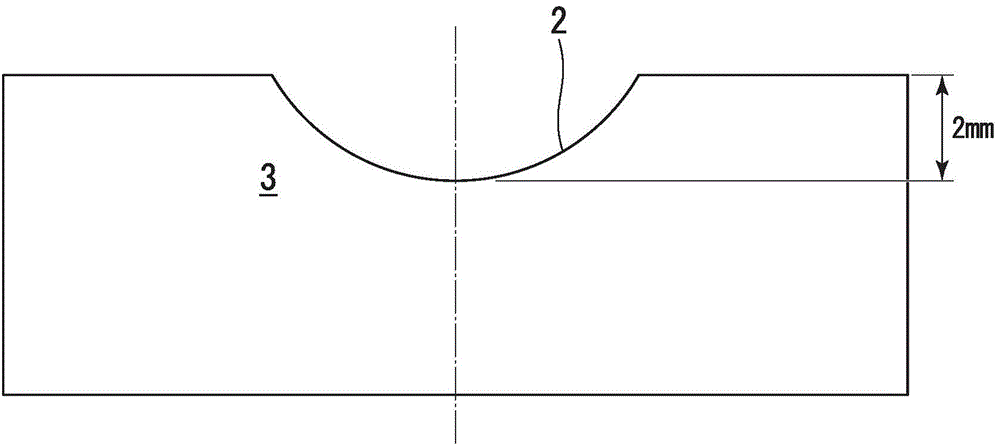

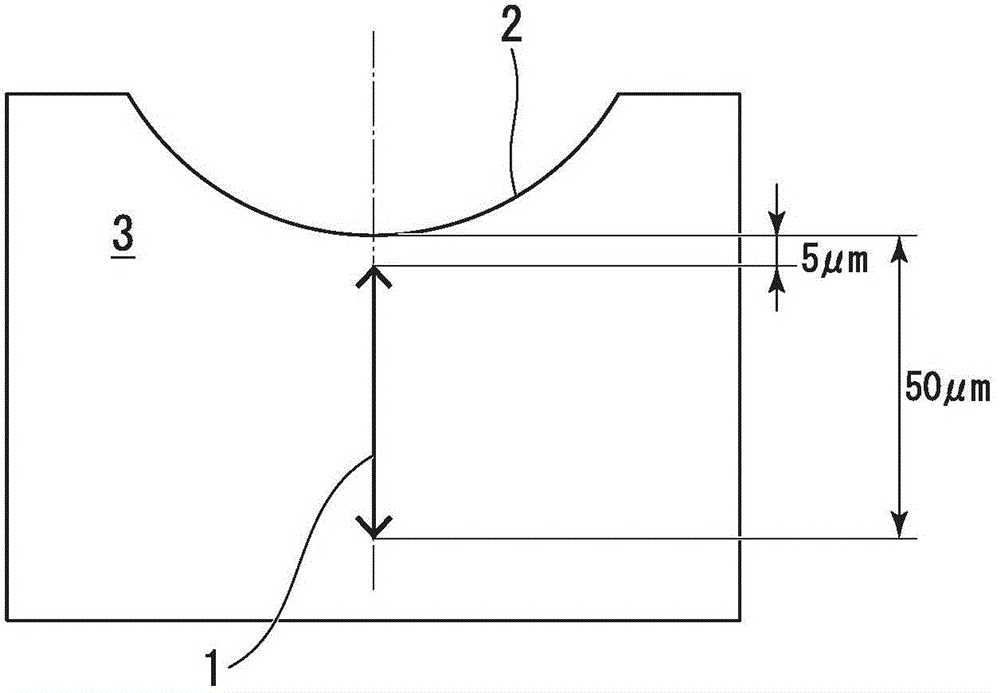

[0113] Soaking treatment is performed after forging and stretching various steel billets having the chemical compositions shown in Table 1-1 and Table 1-2 into a square bar shape with a cross-sectional dimension of 50 mm in length and 50 mm in width (50 mm × 50 mm) in the longitudinal direction. After normalizing (normalizing), it was further divided into four square rod shapes with cross-sectional dimensions of 25 mm in length and 25 mm in width. The obtained rods were collected along their central axis from the figure 2 Shown is...

reference example 29

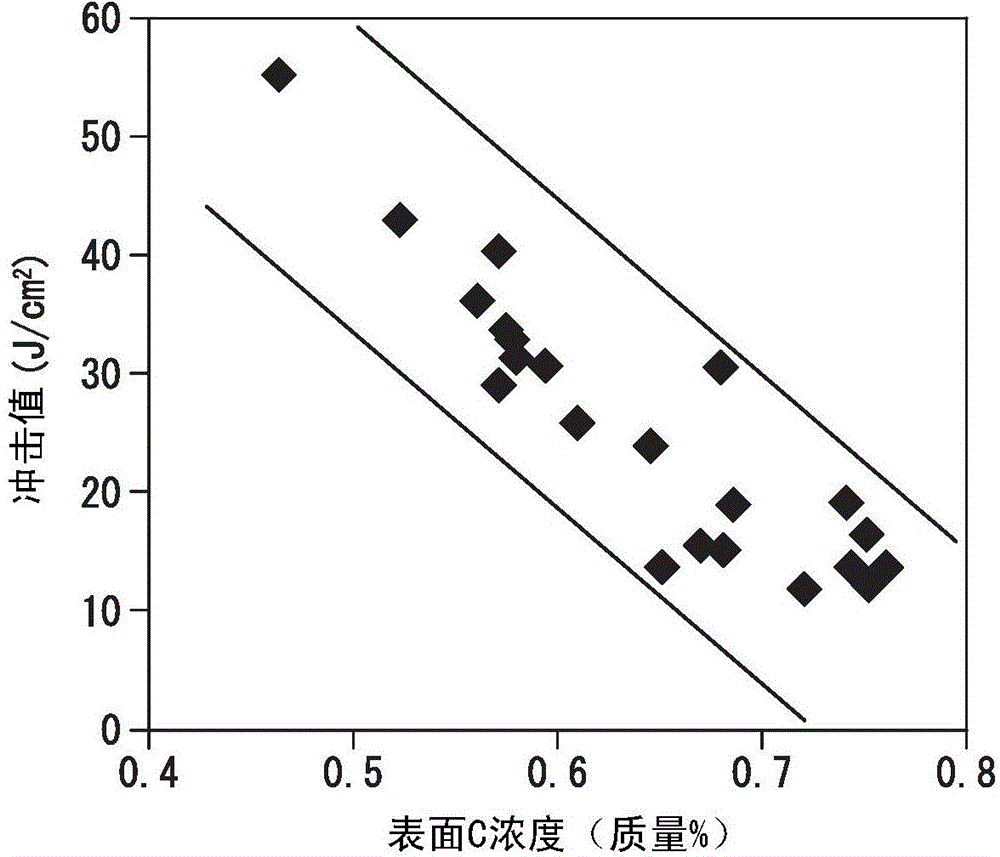

[0133] Reference Example 29 is the same steel as Comparative Example 26, but the carburizing conditions are different, and the carbon potential (carburizing treatment of 0.6) is set low, so it can be seen that the surface C concentration is low and a good impact value is obtained. However, setting the carbon potential low in actual production is not preferable since productivity decreases.

[0134] Table 1-1

[0135]

[0136] ※The symbol "-" in the table indicates that the element content is 0 or the amount regarded as an impurity.

[0137] Table 1-2

[0138]

[0139] ※The symbol "-" in the table indicates that the element content is 0 or the amount regarded as an impurity.

[0140] Table 2

[0141]

[0142] ※The carburizing conditions of Comparative Example 29 are different from other examples

[0143] Symbol Description

[0144] 1 Surface C concentration measurement area

[0145] 2 notches (notches)

[0146] 3 Charpy impact test piece (carburized material)

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com