Cleaning device for steel sheet pile cleaning machine and application method of device

A cleaning device and a technology for steel sheet piles, which are applied to cleaning methods using tools, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of high labor intensity, waste of water resources, low production efficiency, etc., and reduce labor intensity. , to ensure the tightness, the effect of saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below in conjunction with the accompanying drawings, but it should be pointed out that the implementation of the present invention is not limited to the following embodiments.

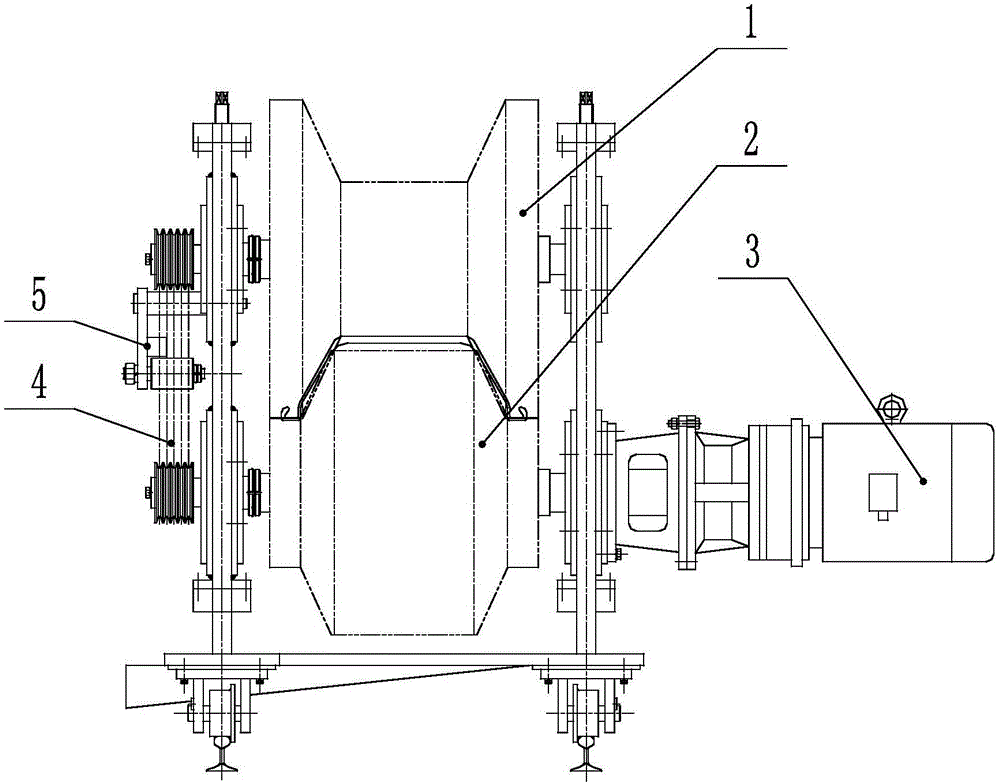

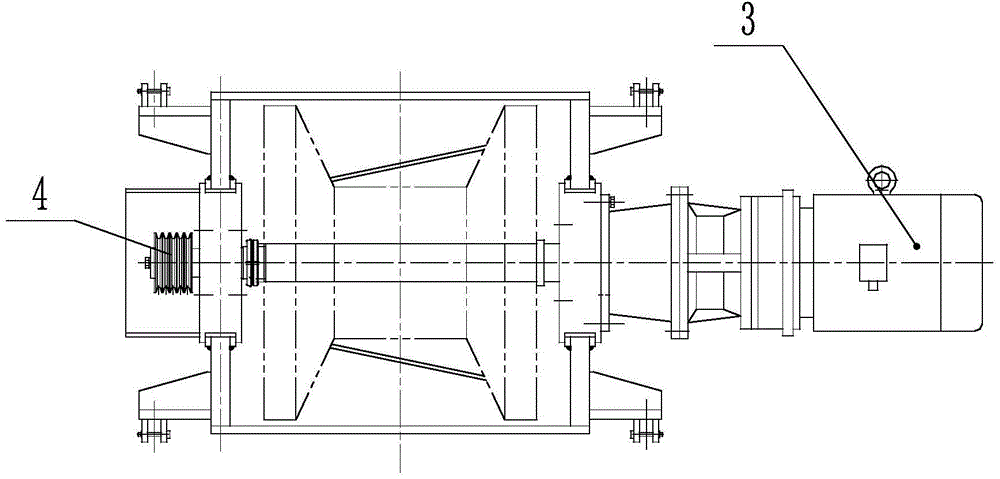

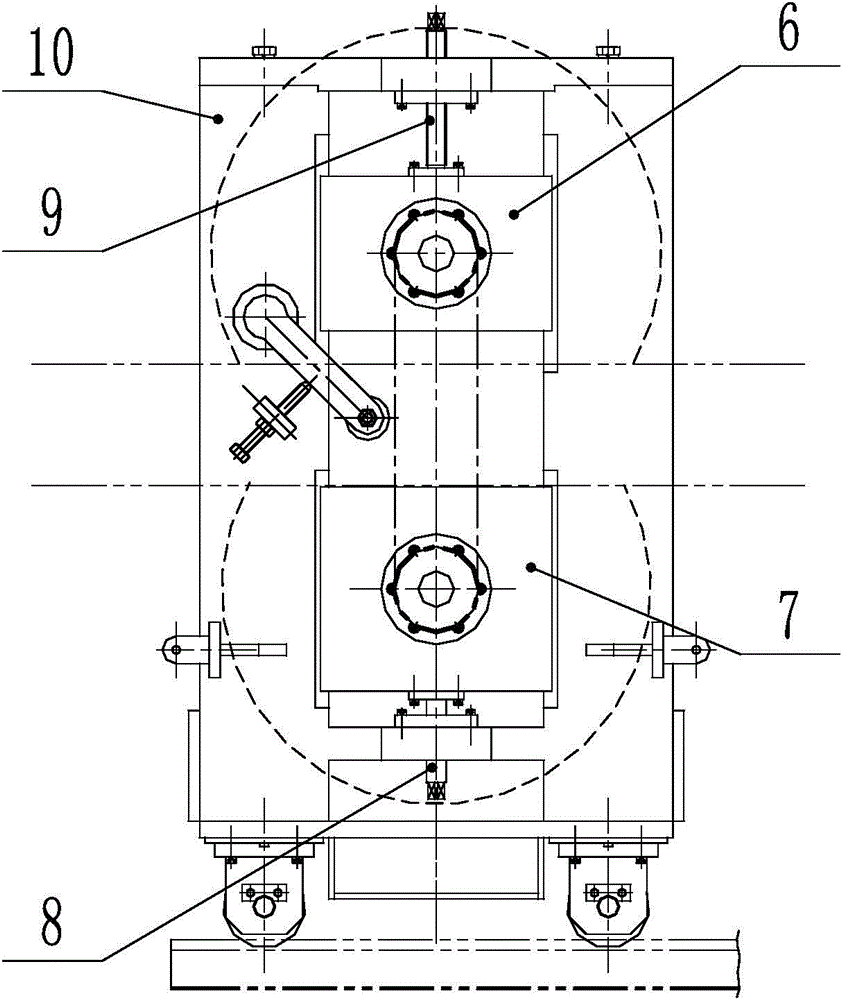

[0027] See Figure 1-Figure 8 , the cleaning device for the steel sheet pile clearing machine, including the upper roller brush 1, the lower roller brush 2, the deceleration motor 3, the upper slider 6, the lower slider 7, the frame 10, the belt transmission mechanism 4, the adjustment mechanism, the deceleration The motor 3 drives the upper and lower roller brushes 1 and 2 to rotate through the belt transmission mechanism 4, the upper roller brush 1 and the lower roller brush are fixedly connected to the frame 10 through the upper and lower sliders 6 and 7 respectively, and the upper and lower sliders 6, The distance between 7 is adjusted by the adjustment mechanism, and then the adjustment of the distance between the upper and lower rolling bru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com