Numerical-control mechanical corrugation expansion machine and corrugated pipe forming method thereof

A technology of mechanical expansion and forming mechanism, which is applied in the field of machinery, can solve the problems of complicated equipment, and the quality of the overlapping weld bead between the bellows and the connecting pipe cannot be guaranteed, and achieve low manufacturing cost, good working effect, and convenient installation and use. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

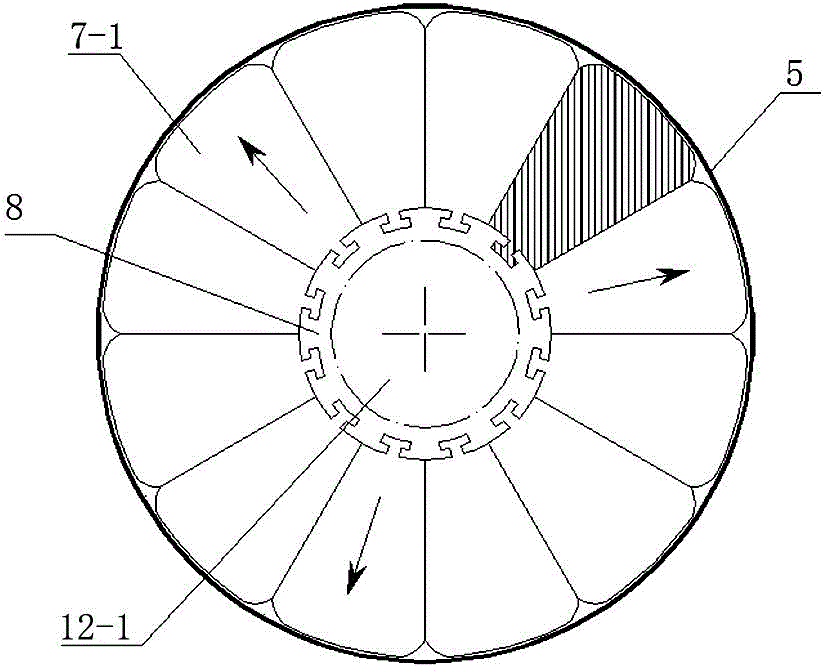

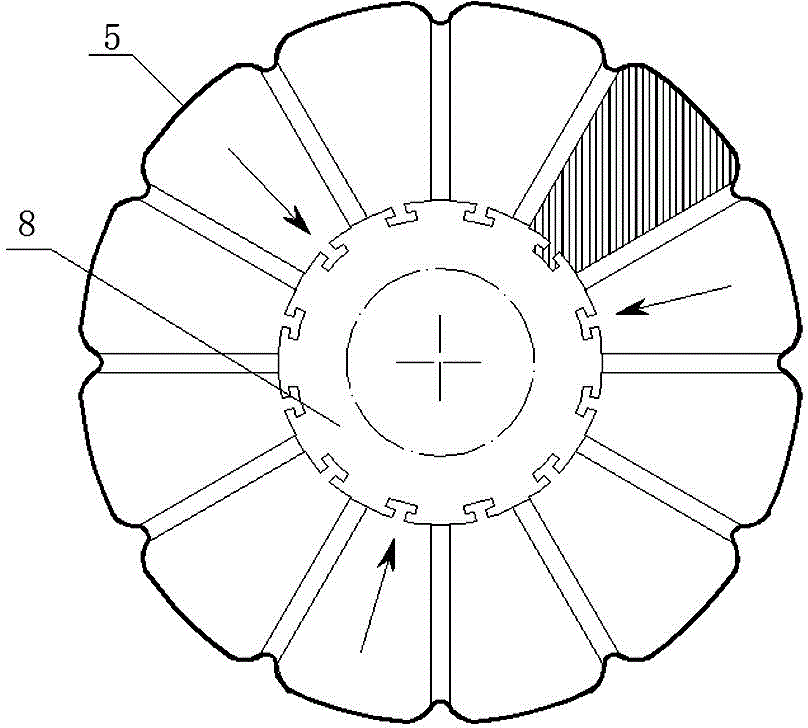

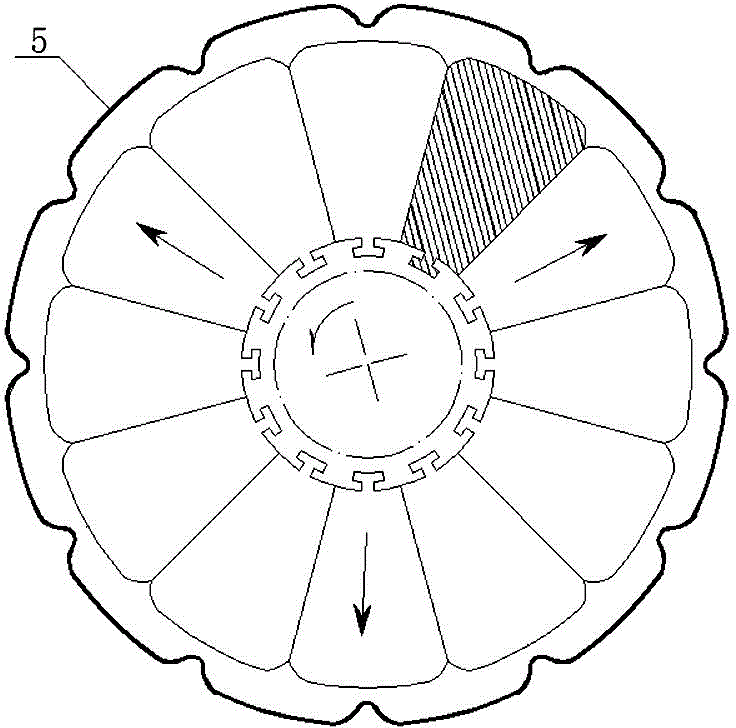

[0052]In order to clarify the technical scheme and technical effect of the present invention, the present invention will be further introduced below in conjunction with the accompanying drawings and specific embodiments.

[0053] A kind of numerical control mechanical expansion wave machine, such as Figure 1 to Figure 7 As shown, a die forming mechanism, a power mechanism and an electromechanical control system are provided. The die forming mechanism includes a circular bulging inner template 7 arranged laterally, and the circular bulging inner membrane plate 7 is composed of twelve The horizontal fan-shaped die unit 7-3 is formed, and during processing, the tube blank 5 to be processed is set on the periphery of the bulging inner template 7.

[0054] The mold forming mechanism is provided with a mold platen 9 above the bulging inner formwork 7, and a mold backing plate 10 is provided below the bulging inner formwork 7, and the bulging inner formwork 7 is located between the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com