Nitrogen adjustment mechanism for chuck double-station welding machine

An adjustment mechanism and dual-station technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve problems such as low efficiency, high cost, coil process deviation, etc., to avoid deviation and follow-up process stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] The technical solutions of the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings of the present invention.

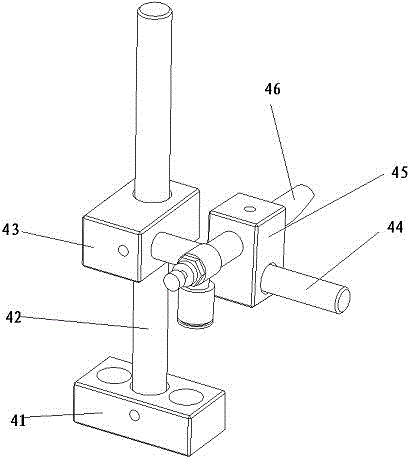

[0008] like figure 1 As shown, a nitrogen adjustment mechanism of a chuck double-station welding machine, the nitrogen adjustment mechanism includes a vertical guide rod fixing block 41 fixed to the bottom plate of the upper frame, the vertical guide rod fixing block 41 is equipped with a vertical guide rod 42, and the vertical guide rod The bar 42 is provided with a transverse guide rod fixing block 43, a transverse guide rod 44 is installed on the transverse guide rod fixing block 43, a nitrogen pipe fixing block 45 is installed on the transverse guide rod 44, and a nitrogen nozzle is installed on the nitrogen passenger fixing block 45 46.

[0009] The nitrogen adjustment mechanism of the chuck double-station welding machine of the present invention can adjust the nitrogen accordin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com