Work-piece rotation mechanism for chuck double-station welding machine

A rotary mechanism, dual-station technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of high cost, low efficiency, coil process deviation, etc., and achieve the stability of the subsequent process and avoid deviation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The technical solutions of the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings of the present invention.

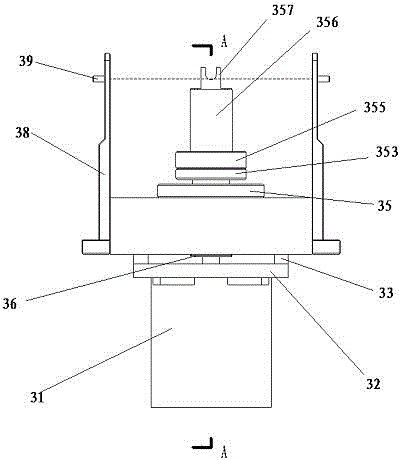

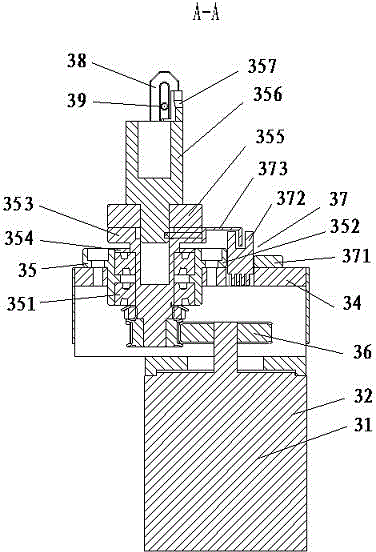

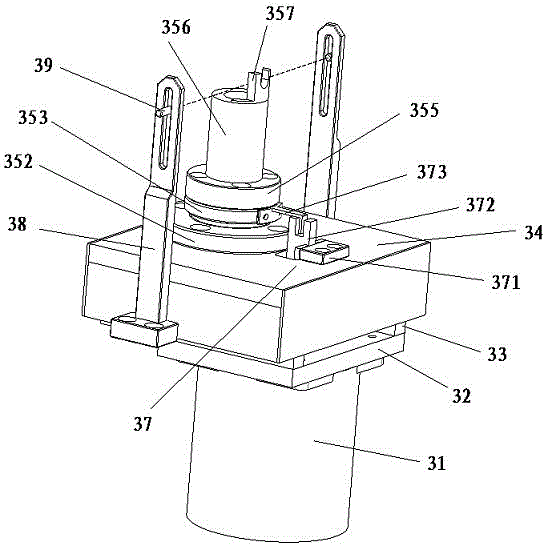

[0012] Such as Figure 1-Figure 3 As shown, a workpiece rotary mechanism of a chuck double-station welding machine, the workpiece rotary mechanism includes a rotary motor 31, a fixed plate 32 is installed on the rotary motor 31, and a vertical plate 33 is symmetrically arranged on the fixed plate 32. The vertical plate 33 is fixed with upper fixed plate 34, and slewing bearing group 35 is installed on the upper fixed plate 34, and slewing bearing group 35 is connected with rotary motor 31 by gear group 36, and slewing bearing group 35 comprises slewing bearing 351, and slewing bearing 351 is installed with Bearing holder 352, slewing bearing group 35 also comprises card shaft 353, and card shaft 353 passes bearing holder 352, slewing bearing 351 and is fixedly connected with gear grou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com