Disassembly and assembly pincers of engine valve lock

A technology for engine valves and locks, applied in pliers, hand-held tools, manufacturing tools, etc., can solve the problems of high cost, increased equipment cost, complex structure, etc., and achieve the effects of low production cost, quick disassembly and assembly, and accurate positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

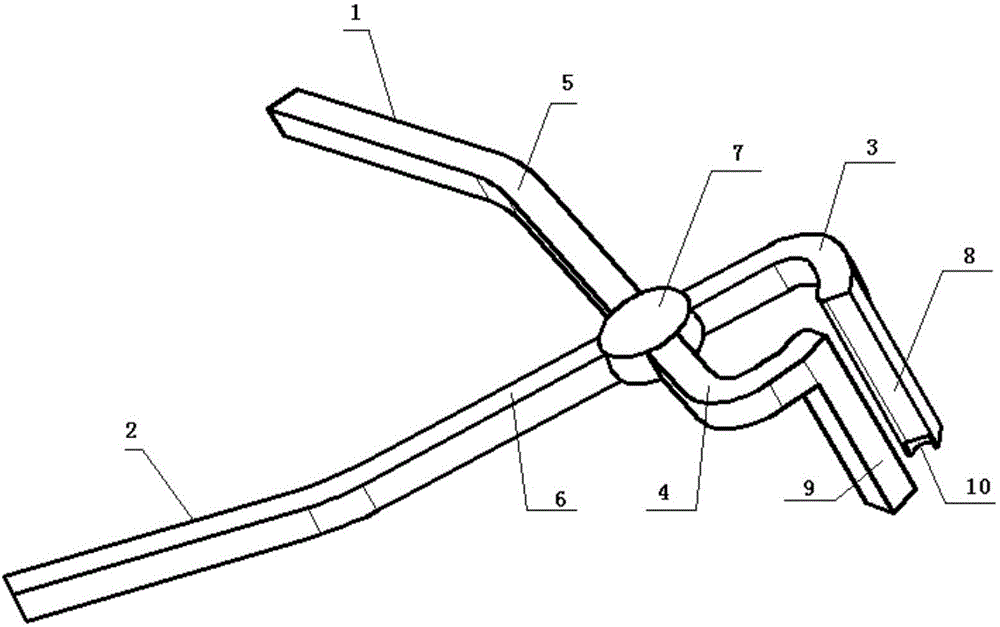

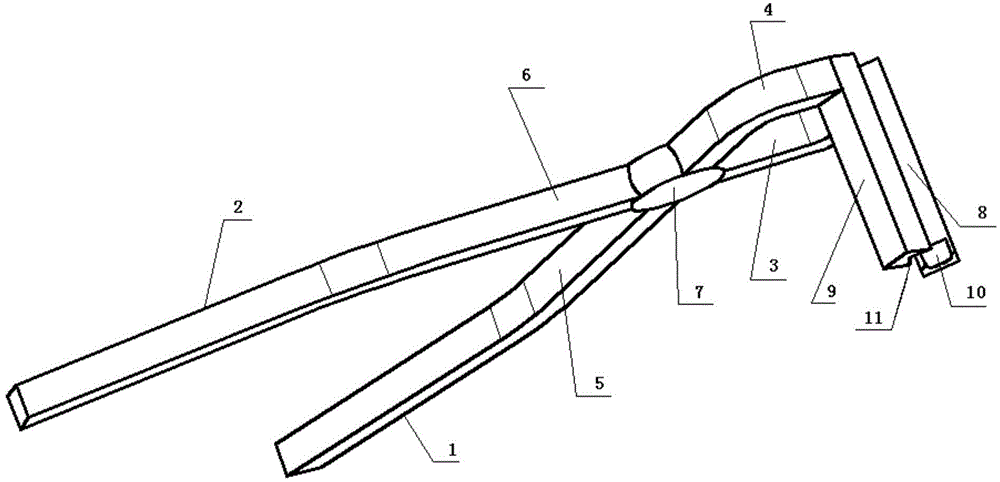

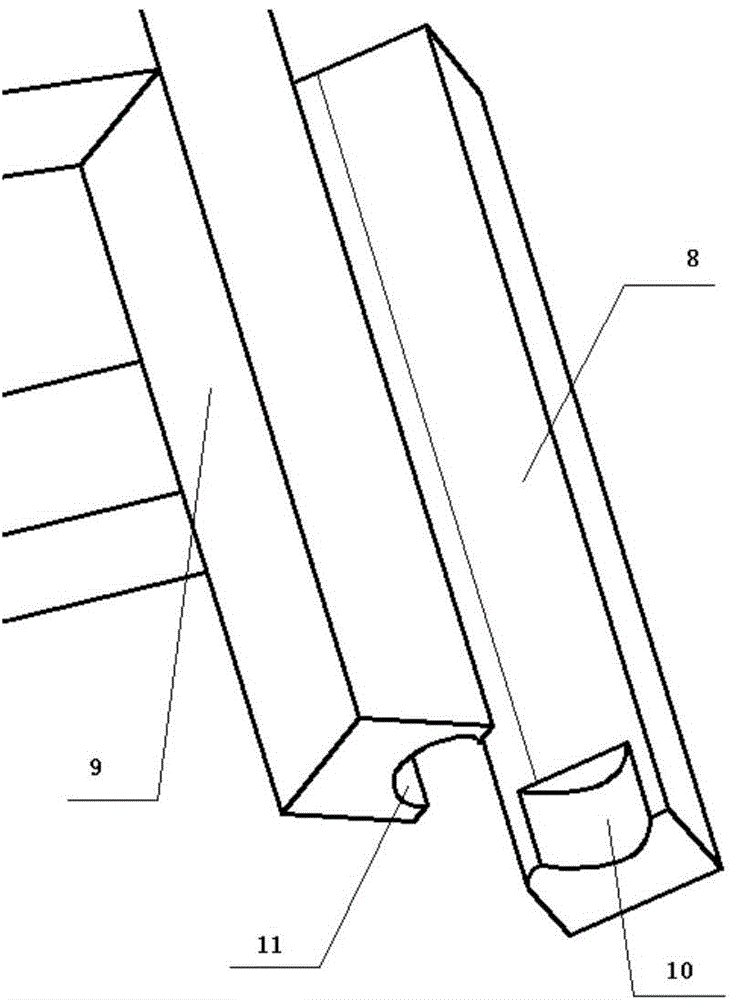

[0027] Such as Figure 1-3 Shown, a kind of pliers for removing and installing the engine valve lock plate comprises a first pliers handle 1, a second pliers handle 2, a movable fulcrum 7, a first vertical arm 8 and a second vertical arm 9; the first pliers handle 1, The second pliers handle 2 is arranged crosswise, and the movable fulcrum 7 is set at the intersection of the first pliers handle 1 and the second pliers handle 2; the first vertical arm 8 and the second vertical arm 9 are respectively arranged on the first pliers handle 1 and the second pliers handle The ends of the handle 2 are vertically connected to the first handle 1 and the second handle 2 respectively; the first handle 1 includes the first long rod 5 and the first short rod 3, and the second handle 2 includes the second Long rod 6 and the second short rod 4; The connecting points of the first long rod 5 and the first short rod 3, the second long rod 6 and the second short rod 4 are all located in the movabl...

Embodiment 2

[0038] It is basically the same as the embodiment 1, except that the length ratio of the first short rod 3 and the second short rod 4 to the first long rod 5 and the second long rod 6 is 1:5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com