Injection molding frame veneer gluing method and device

A frame and skinning technology, applied in coating and other directions, can solve the problems of high manufacturing cost, inability to form corresponding patterns, complicated frame manufacturing process, etc., and achieve the effect of eliminating glue materials, beautiful appearance and improving production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

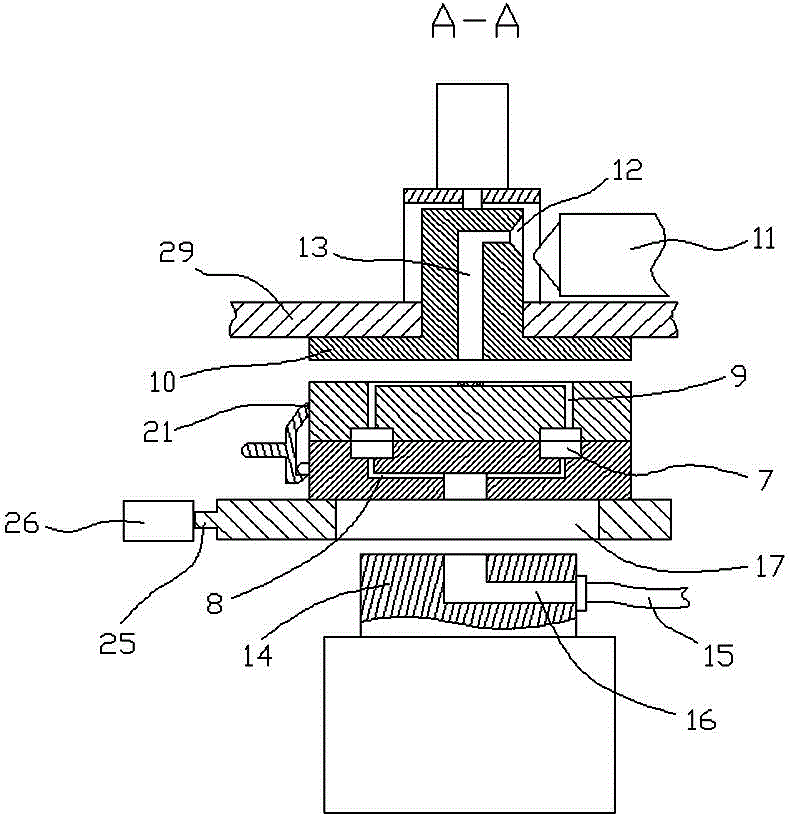

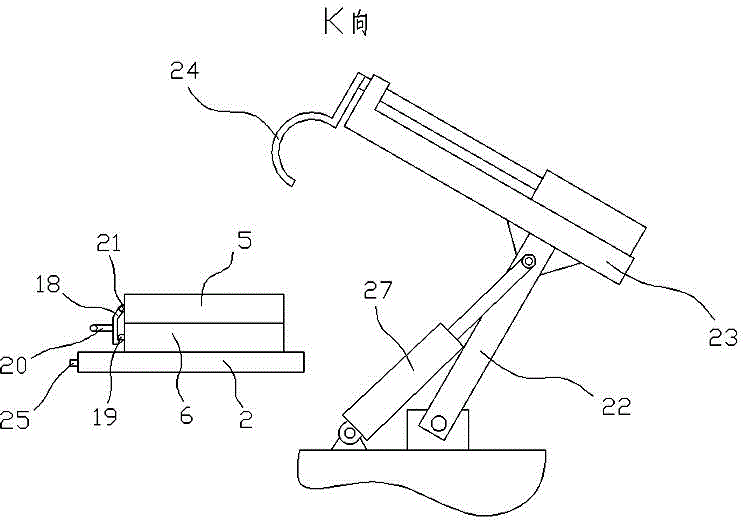

[0019] A skinning method for an injection molding frame, comprising an injection mold with an upper mold and a lower mold, a cavity for injection molding a frame is formed between the upper mold and the lower mold, and a hole leading to the bottom of the cavity is opened on the lower mold Air extraction holes, the upper mold is provided with a material injection hole leading to the top of the cavity; and the following steps are carried out: (1) Open the upper mold, and lay a layer of leather on the lower mold; (2) Close the upper mold; ( 3) Use air extraction equipment to pump air out of the air hole to make the leather fit the inner side of the cavity on the lower mold; (4) Inject molten injection molding material into the cavity through the injection hole; (5) Open the upper mold mold, take out the formed frame, and trim the excess leather fringe along the edge of the frame.

[0020] In this embodiment, the injection molding material is rubber or plastic, and the air extract...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com