Electric power-assisting braking mechanism and control method thereof

A technology of electric power assist and braking mechanism, which is applied in the field of auto parts, can solve the problems that the braking system and the anti-theft system of the whole vehicle are associated and work together, single function, high cost, etc., so as to save parking manpower, expand functions, cost-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to help those skilled in the art to accurately understand the claimed subject matter of the present invention, the specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

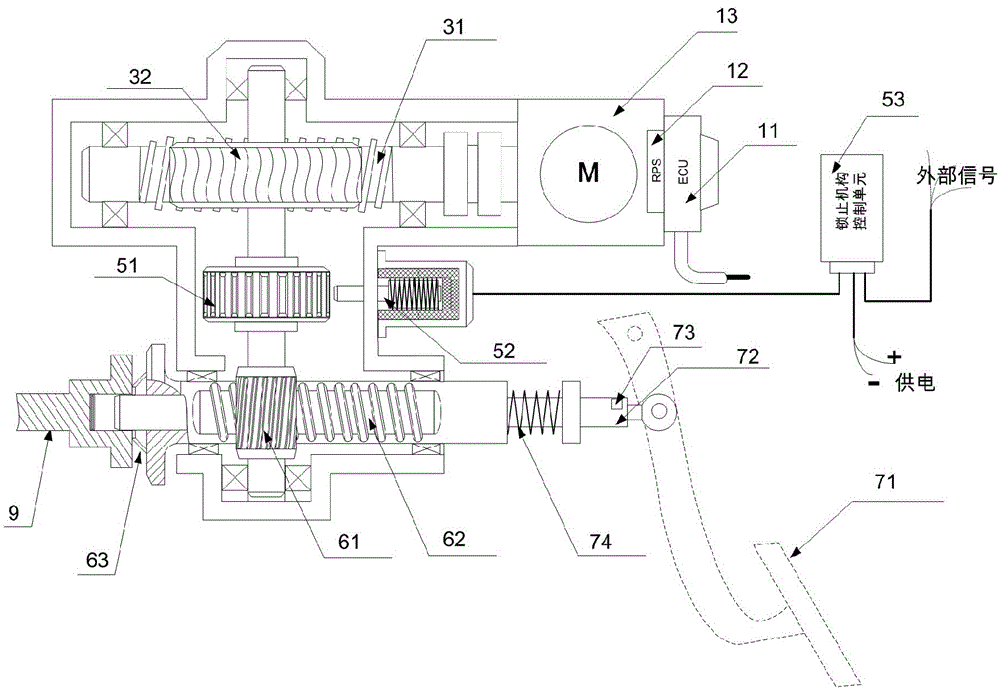

[0027] Such as figure 1 Shown is a schematic structural view of the electric power-assisted braking mechanism involved in the present invention. The electric power-assisted braking mechanism includes a housing 8 and a booster motor 1, a shaft coupling 2, a reduction mechanism 3, an intermediate shaft 4, a locking device 5, a brake booster mechanism 6 and a braking system connected sequentially inside the housing 8. Pedal assembly7. The output torque of the booster motor 1 is transmitted to the brake booster mechanism 6 through the coupling 2, the reduction mechanism 3, and the intermediate shaft 4, wherein the intermediate shaft 4 is provided with at least three gear pairs, including the first gear pair on one...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com