Halomonas axialensis and application thereof in degrading of decabromodiphenyl ether

A technology of decabromodiphenyl ether and Halomonas, which is applied in the direction of bacteria, microorganism-based methods, biochemical equipment and methods, etc., can solve the problem of less aerobic degradation of decabromodiphenyl ether, and broaden the degradation pathway Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

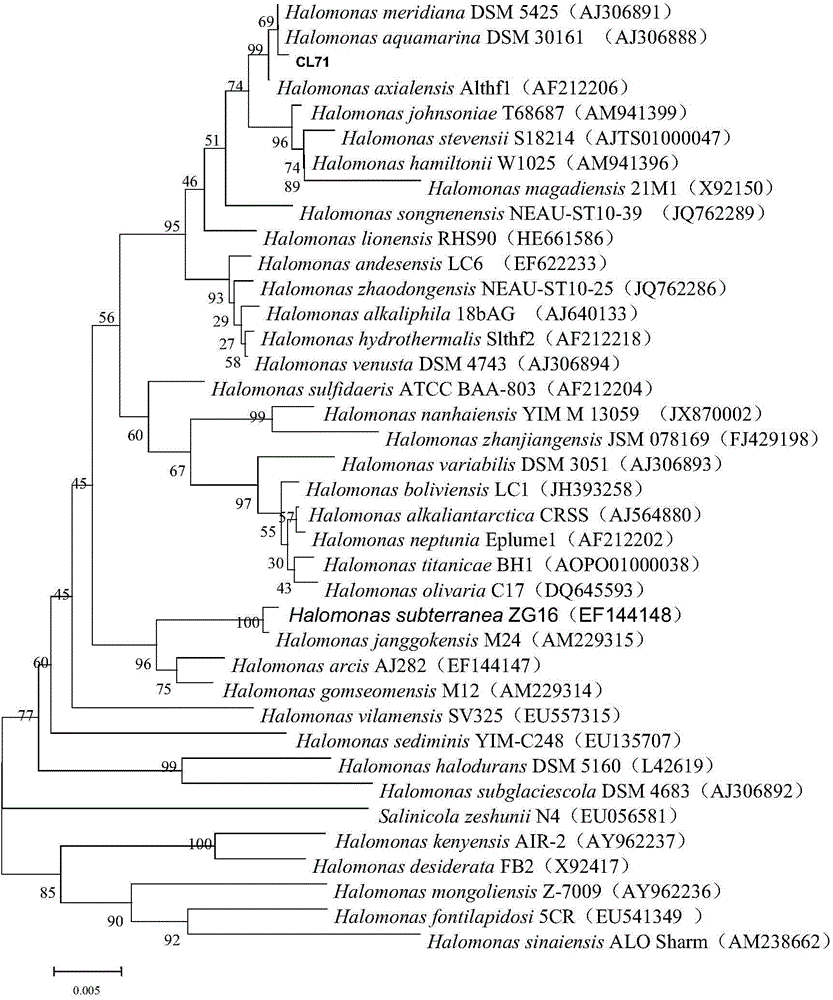

[0024] 1. Isolation and identification of Halomonas axialensis SWIR-CL71

[0025] 1. Enrichment, isolation and purification of Halomonas axialensis SWIR-CL71

[0026] Medium:

[0027] Artificial Seawater Medium (MMC): Each liter of medium contains 24g of NaCl, NH 4 NO 3 1g, KCl 0.7g, KH 2 PO 4 2.0g, Na 2 HPO 4 3.0g, pH 7.4, MgSO 4 7g (added after sterilization).

[0028] Trace element salt solution: every liter of trace element salt solution contains 2mg of CaCl, FeCl 3 ·6H 2 O 50mg, CuSO 4 0.5mg, MnCl 2 ·.H 2 O 0.5mg, ZnSO 4 ·.7H 2 O 10 mg.

[0029] Marine bacteria agar 2216 medium and marine bacteria broth 2216 medium were purchased from BD Medical Instruments (Shanghai) Co., Ltd.

[0030] Decabromodiphenyl ether mother liquor: the organic solvent is dichloromethane, and the concentration of decabromodiphenyl ether is 1 g / L.

[0031] The axial seamount Halomonas (Halomonas axialensis) SWIR-CL71 of the present invention is obtained from the surface sedim...

Embodiment 2

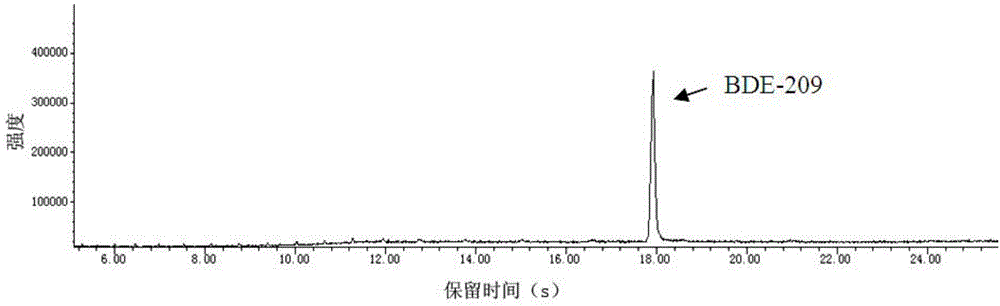

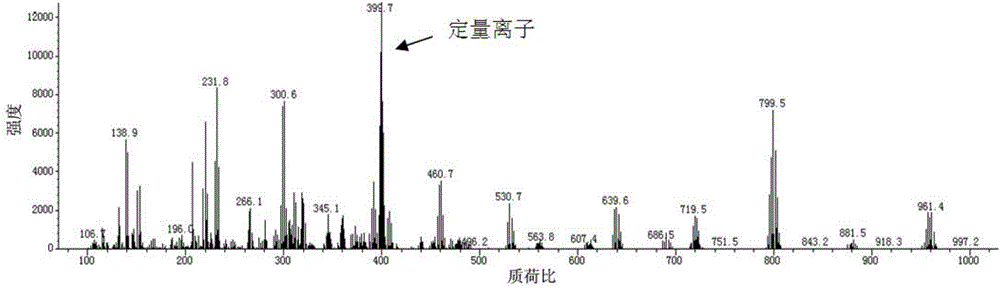

[0043] Degradation analysis of decabromodiphenyl ether by Halomonas axialensis SWIR-CL71:

[0044] Artificial Seawater Medium (MMC): Each liter of medium contains 24g of NaCl, NH 4 NO 3 1g, KCl 0.7g, KH 2 PO 4 2.0g, Na 2 HPO 4 3.0g, pH 7.4, MgSO 4 7g (added after sterilization).

[0045] Trace element salt solution: every liter of trace element salt solution contains 2mg of CaCl, FeCl 3 ·6H 2 O 50mg, CuSO 4 0.5mg, MnCl 2 ·.H 2 O 0.5mg, ZnSO 4 ·.7H 2 O 10 mg.

[0046] Enrichment medium EM (Enrichment Medium): marine bacteria broth 2216 medium.

[0047] Decabromodiphenyl ether degradation medium: 100mL MMC medium + trace elements.

[0048] Proliferation culture of Halomonas axialensis (Halomonas axialensis) SWIR-CL71: Under sterile conditions, inoculate the strain of Halomonas axialensis into a sterilized 1L medium containing 500mL seawater broth culture (2216) Place in a conical flask in a constant temperature shaker at 28°C, 160rpm, and incubate for 48h. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com