Pilot piston type stop valve adapted to perpendicular pipeline

A piston-type valve and piston-type technology, applied in the direction of lift valve, valve details, valve device, etc., can solve the problems of slow opening and closing speed of manual control, low degree of automation, and high operating energy consumption, so as to reduce energy consumption and save energy. Cost, effect of expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

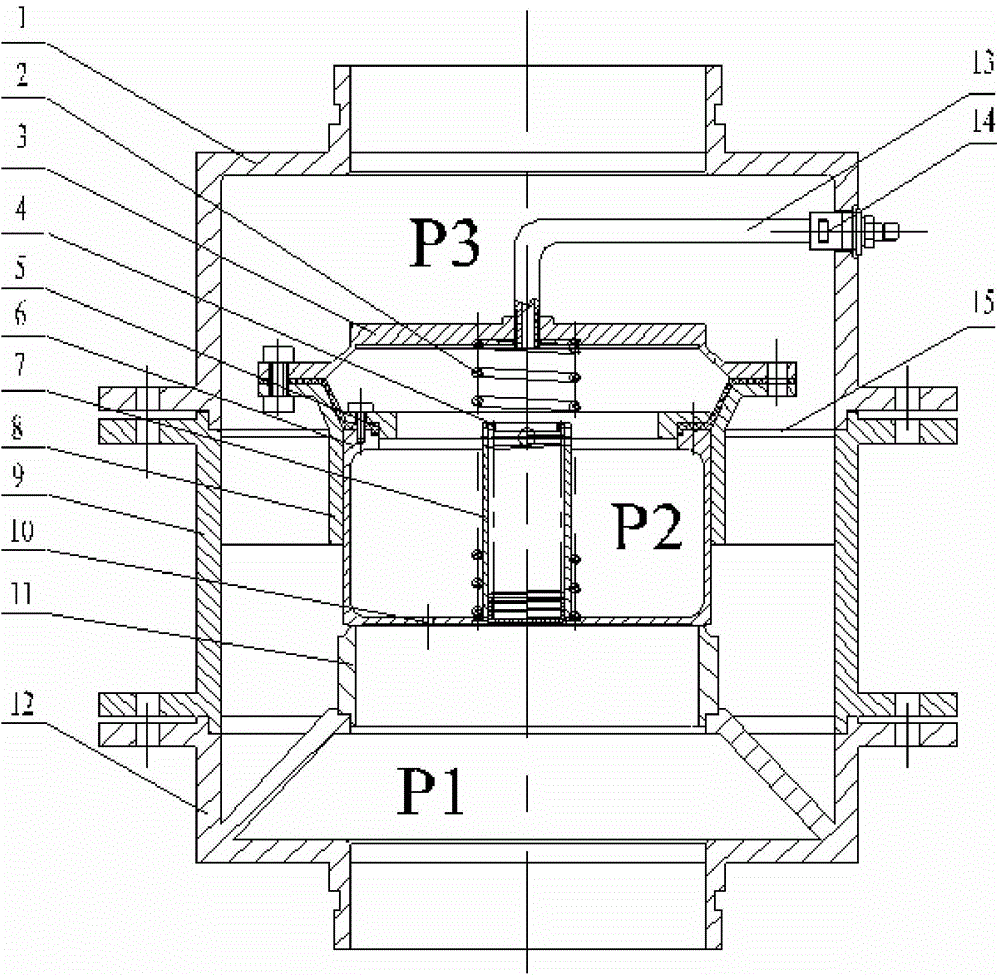

[0017] refer to figure 1 , the present invention includes a valve body upper cover 1, a valve body middle sleeve 9, a valve body lower cover 12, a piston valve core 6, a valve seat 11, a pilot valve 14 and a buffer sleeve 7, the valve body upper cover 1, the valve body The body middle sleeve 9 and the valve body lower cover 12 are connected sequentially from top to bottom, and a guide sleeve 8 is installed inside the valve body middle sleeve 9, and the guide sleeve 8 is connected with the piston valve core 6 through a rib plate 15, and the rib plate 15 Arranged radially and uniformly; the piston spool 6 is equipped with a spring 2 and a buffer sleeve 7, and the spring 2 is located at the upper end of the buffer sleeve 7; A piston-type spool cover 3 is installed on the upper part, and the piston-type spool cover 3 is connected with the pilot valve 14 through the pilot pipe 13; the bottom of the valve body lower cover 12 is provided with a water inlet, and the top of the valve b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com