Oil nozzle

A technology of fuel injectors and nozzles, which is applied in the direction of engine components, delivery pipes/joints, engine lubrication, etc., and can solve the problems that lubricating oil cannot be sprayed to the preset position, wasting lubricating oil and compressed air, and reducing the lubricating effect , to achieve the effect of saving compressed air, preventing oil dripping and improving the utilization rate of lubricating oil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings.

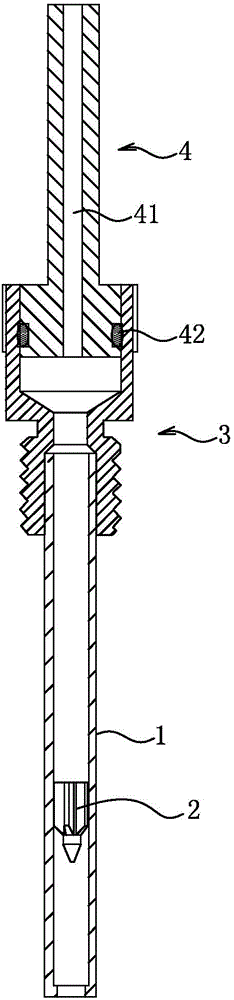

[0021] Figure 2-7 A fuel injector according to an embodiment of the invention is shown schematically.

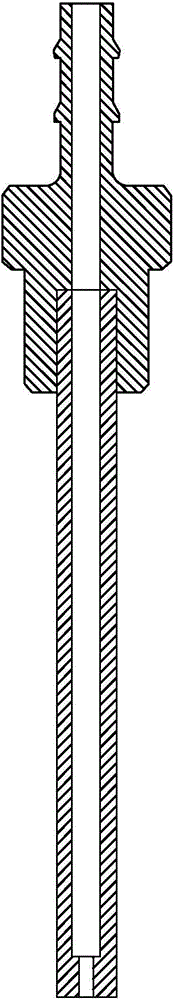

[0022] Such as figure 2 As shown, the fuel injector of this embodiment includes a nozzle 1 , a guide body 2 and a sleeve body 3 , the end of the nozzle tube 1 is connected to the sleeve body 3 , and the guide body 2 is located in the nozzle tube 1 .

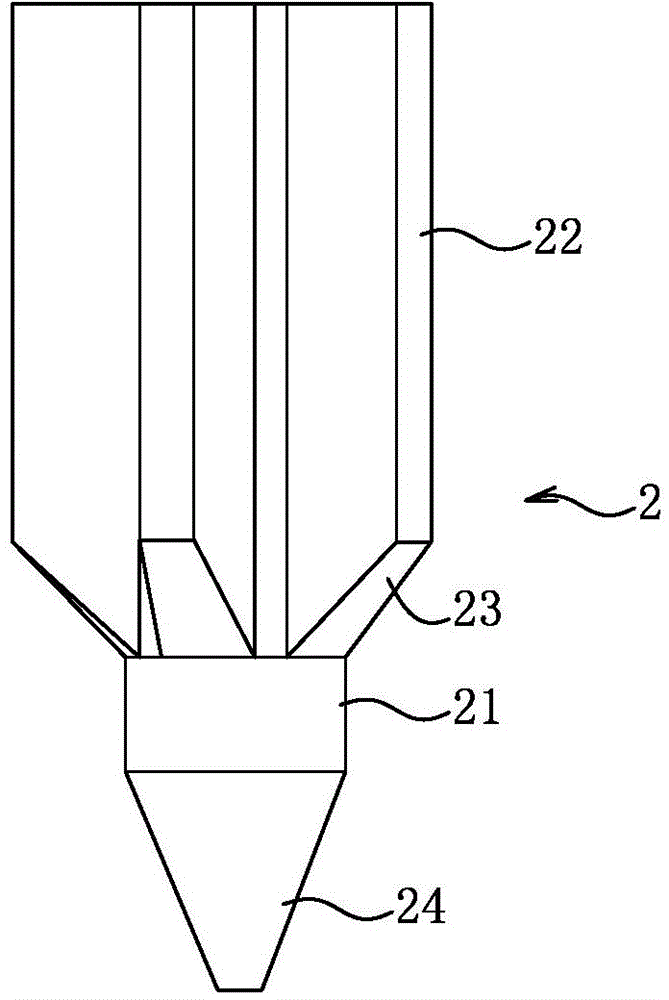

[0023] Such as image 3 and Figure 4 As shown, the guide body 2 includes a central cylinder 21 and a plurality of guide vanes 22 , and the plurality of guide vanes 22 are axially arranged on the outer surface of the central cylinder 21 . The central cylinder 21 and the deflector 22 are of an integral structure. An inclined surface 23 is provided on the end of the deflector 22 close to the outlet of the nozzle 1 . A plurality of guide vanes 22 are evenly distributed on the outer surface of the central ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com