Garbage incinerator and garage disposal method

A waste incinerator and waste technology, which is applied in the combustion method, incinerator, combustion type, etc., can solve the problems of low treatment efficiency, low treatment efficiency, insufficient incineration, etc., and achieves continuous feeding operation and convenient feeding. Volume, easy to adjust the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

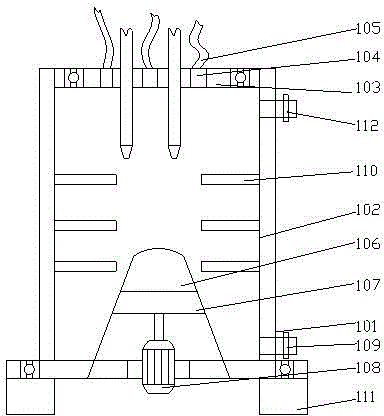

[0029] Such as figure 1 As shown, a garbage incinerator includes a furnace body 101 and a furnace lining 102 arranged on the inner wall of the furnace body 101;

[0030] A material distribution tray 103 is arranged on the upper end surface of the furnace body 101, and the described material distribution tray 103 is connected with the upper end surface of the furnace body 101 through a bearing, and a flame nozzle is arranged on the described material distribution tray 103;

[0031] At least 6 star valves 104 are arranged on the material distribution tray 103, and the star valves 104 are respectively connected with feeding pipes 105 for feeding;

[0032] A material distribution cone 106 is arranged in the middle of the furnace body 101, a ring gear 107 is fixedly connected to the outer wall of the furnace body 101 below the material distribution cone 106, and a driving motor 108 is arranged at the bottom of the furnace body 101. , the drive motor 108 drives the ring gear 107 to...

Embodiment 2

[0038] The present invention also discloses a kind of garbage incinerator garbage treatment method on the basis of embodiment 1, comprises the following steps:

[0039] S1: Open the star valve, add garbage to be processed into the furnace body 101 through at least 6 feeding pipes 105, and the garbage to be processed enters the furnace body 101 through the distribution tray 103, and the garbage stock in the furnace body 101 reaches the maximum value , close the star valve to close the body of furnace 101, start the drive motor 108, and drive the body of furnace 101 to rotate, and the garbage will fall in a scattered state under the centrifugal force of the material dividing plate 110 and the body of furnace 101 rotating;

[0040] S2: Burn the garbage in the furnace body, use the burner nozzle to burn the garbage in the furnace body 101, stop driving the motor 108 after the garbage is fully burned, and output the garbage from the material output port to the furnace body 101;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com