Device for preparation of dual-porosity transparent gas bearing rock mass and preparation method

A technology of double porosity and inflatable device, applied in the preparation of test samples, etc., can solve the problems of no gas, large difference in rock mass, no double porosity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention is described further below:

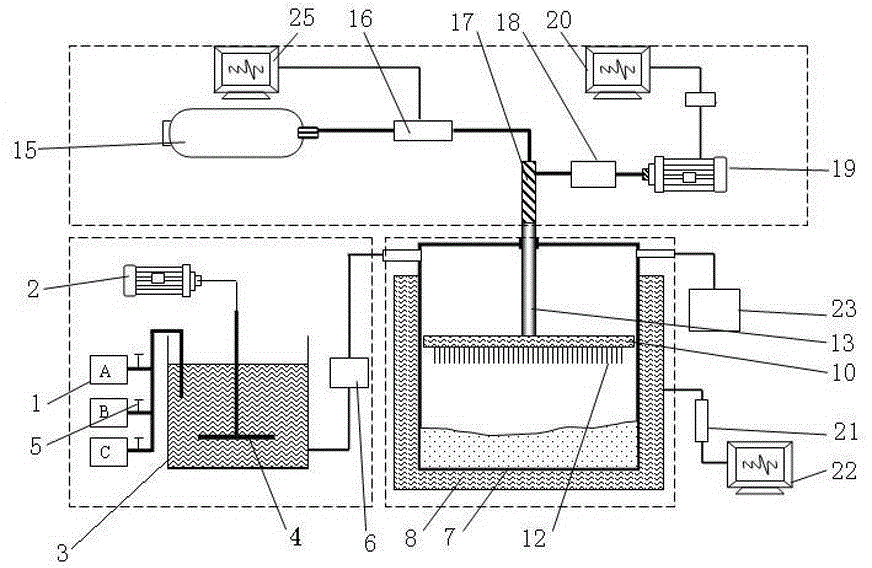

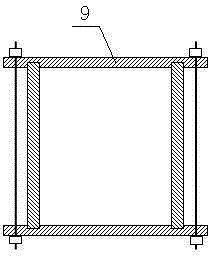

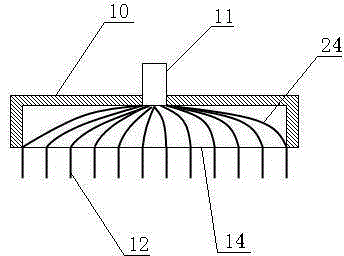

[0025] Such as figure 1 As shown, the device for preparing a double-porosity transparent gas-bearing rock mass includes a core preparation device, an inflatable device in the rock body, a gas delivery control system, a motion control system, a vacuum pumping device, and a temperature control system. The gas delivery control system passes the gas The transmission pipe is connected to the inflatable device in the rock body, the motion control system is connected to the sliding smooth rod 13 through the rotating screw 17, the inflatable device in the rock body is placed in the rock mass forming mold 7, the vacuum pumping device is connected to the rock mass forming mold 7, and the temperature control system is connected to Water bath box 8; motion control system is made up of rotary screw rod 17, gearbox 18, transmission motor 19, motion console, motor control system 20 connections, and motor control system 20 is installe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com