High-speed stranding machine splitter

A technology of a stranding machine and a wire splitter is applied in the field of stranding machines, which can solve the problems of different laying distances of copper strands and uneven distribution of copper wires, so as to improve the efficiency, reduce mutual wear and reduce the amount of wear. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

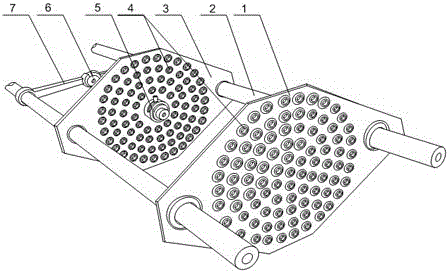

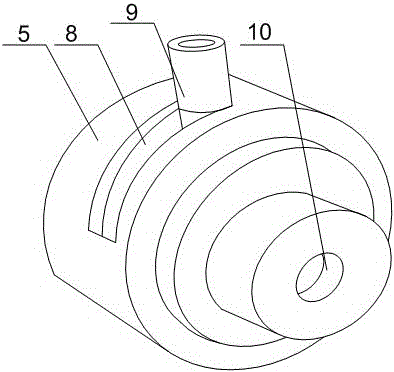

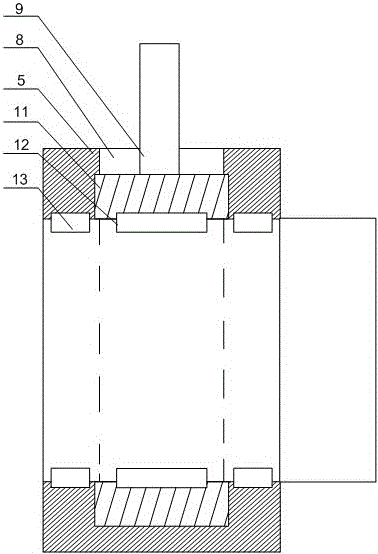

[0022] like Figure 1 ~ Figure 3 As shown, this embodiment includes a bracket 2 and a distribution board 1 and a reserved board 3 which are sequentially fixed on the bracket 2 along the direction of copper wire entry, and a plurality of Wire hole 4, a wire feeder 5 is fixed at the axis of the reserved plate 3, two connecting rods 7 are slidably arranged on the bracket 2, and the movable ends of the two connecting rods 7 pass through the adjusting ring 6 Connected to each other, a wire inlet hole is provided in the adjustment ring 6, and an inner conical surface is set on the top of the wire inlet hole, and a plurality of balls are arranged on the bottom of the wire inlet hole; The adjusting ring 11 with the same inner diameter has an arc-shaped groove 8 on the outer wall of the wire feeder 5, and the push rod 9 passes through the arc-shaped groove 8 to connect with the adjusting ring 11. On the inner wall of the adjusting ring 11, a plurality of The short rollers 12 are provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com