Large-thrust high-speed electric cylinder

An electric cylinder, high thrust technology, applied in the direction of electric components, electrical components, electromechanical devices, etc., can solve the problems of difficult to reach more than 35 tons of thrust, high cost of use, poor practicability, etc., to improve stability, improve practicability, The effect of low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

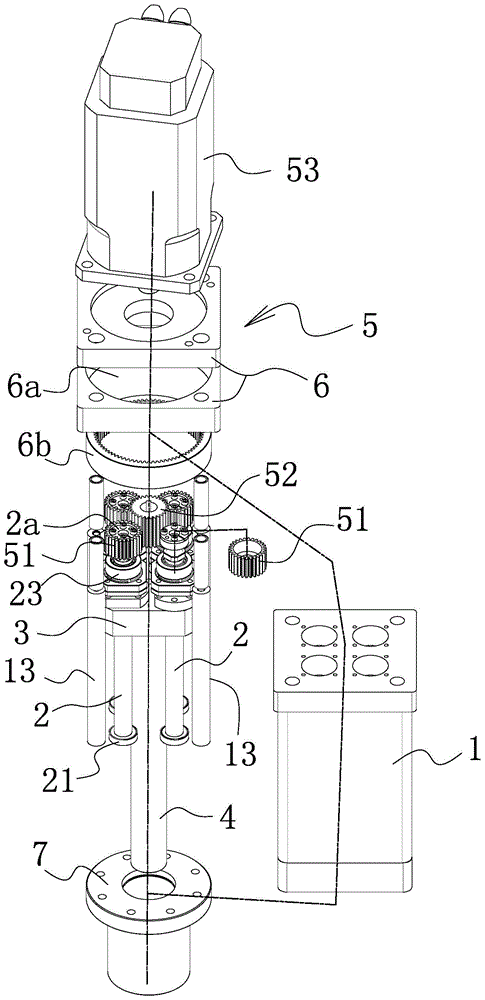

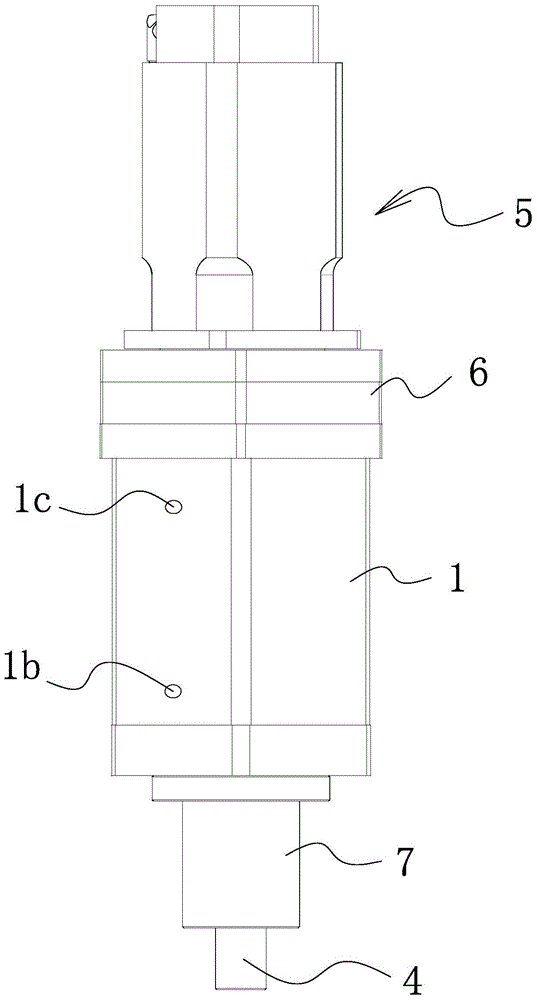

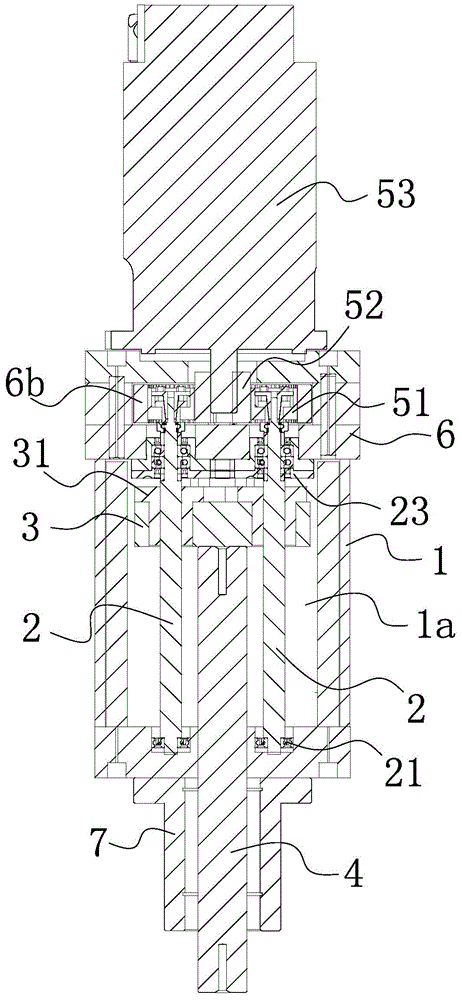

[0033] Such as figure 1 and Figure 3-4 As shown, the high-thrust high-speed electric cylinder includes a cylinder body 1 with a chamber 1a, on the cylinder body 1 there are at least two driving rods 2 respectively pierced in the chamber 1a and parallel to each other, and the driving rods 2 are evenly distributed And the two ends of each driving rod 2 are respectively pierced through the two ends of the cylinder body 1, and the driving rod 2 is connected with the cylinder body 1 in rotation. A positioning blind hole is provided inside one end of the cylinder body 1, and one end of the driving rod 2 is inserted into the positioning blind hole and a first fixing seat 21 is provided between the positioning blind hole and the driving rod 2, and at the other end of the cylinder body 1 Several positioning through holes are provided, and a second fixing seat is arranged in the positioning through holes, and the other end of the driving rod 2 extends to the outside of the cylinder bo...

Embodiment 2

[0044] Such as Figure 7 As shown, the structure and principle of this embodiment are basically the same as those of Embodiment 1, so we won’t repeat them here. The drive ring gear 54 is connected to the driving device 55 capable of driving the drive ring gear 54 to rotate. The driving device 55 here includes a multi-point meshing flexible transmission connected to the driving ring gear 54 . The structure of the multi-point meshing flexible transmission device is a prior art, so no further details will be given here.

[0045] By driving the rotation of the ring gear 54 to drive multiple planetary gears 51 to rotate simultaneously, the consistency of power output is ensured.

Embodiment 3

[0047] Such as Figure 8 As shown, the structure and principle of the present embodiment are basically the same as those of the second embodiment, and will not be described in detail here. The difference is that the drive device 55 includes a plurality of drive gears 55a that are meshed with the drive ring gear 54 respectively. , the drive gear 55a is connected to the driver 55b. The driver 55b is a drive motor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com