A fixing wire clamp for photovoltaic assembly connecting wires

A technology for photovoltaic modules and connecting wires, which is applied in the field of fixing wire clips for connecting wires of photovoltaic modules, can solve the problems of the falling off environment of the cable ties, the improper fixing of the wires, and the missing, so as to improve the overall appearance and image, eliminate hidden troubles, Eliminate the effect of pulling damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

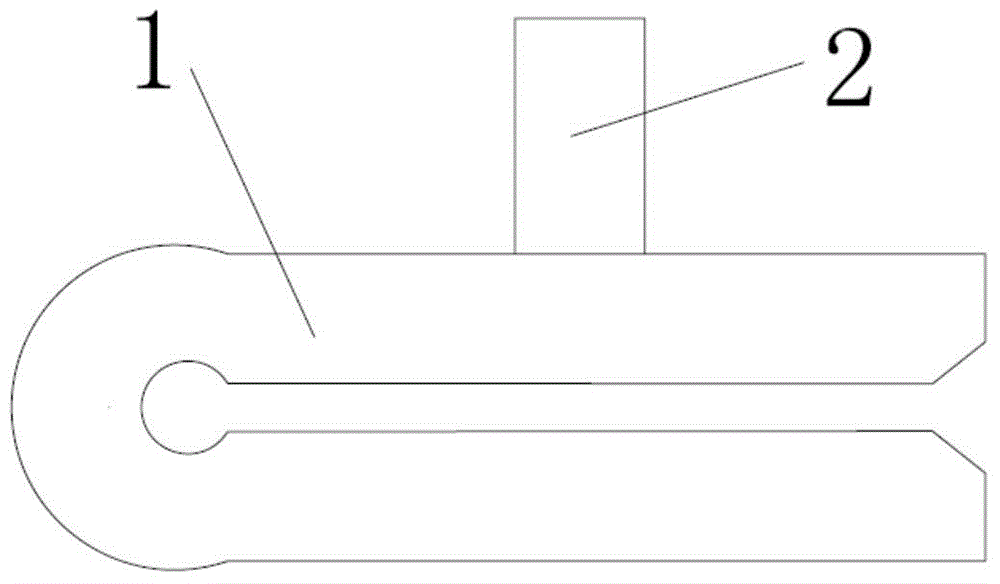

[0034] Such as figure 1 and figure 2 As shown, this embodiment proposes a fixing clip for connecting wires of photovoltaic modules, including a fixing clip seat 1 for clamping on the frame or bracket of the photovoltaic module, and a fixing wire ring 2 for fixing the connecting wires. Such as figure 1 As shown, the fixing clip seat 1 is a U-shaped clip seat, and the fixing wire ring 2 is a ring-shaped wire ring, and the fixing wire ring 2 is arranged on the outer surface of the fixing clip seat 1 .

[0035] Specifically, the fixing clip seat 1 and the fixing wire ring 2 of this embodiment are integrally formed, and a gap 3 for connecting wires to be inserted is provided on the fixing wire ring 2, and the fixing clip seat 1 is used to clamp the photovoltaic The inner side of the component is set as a jagged array surface or a dotted array surface (not shown in the figure), and an adhesive layer (not shown in the figure) can also be set on the inner side of the fixing clip se...

Embodiment 2

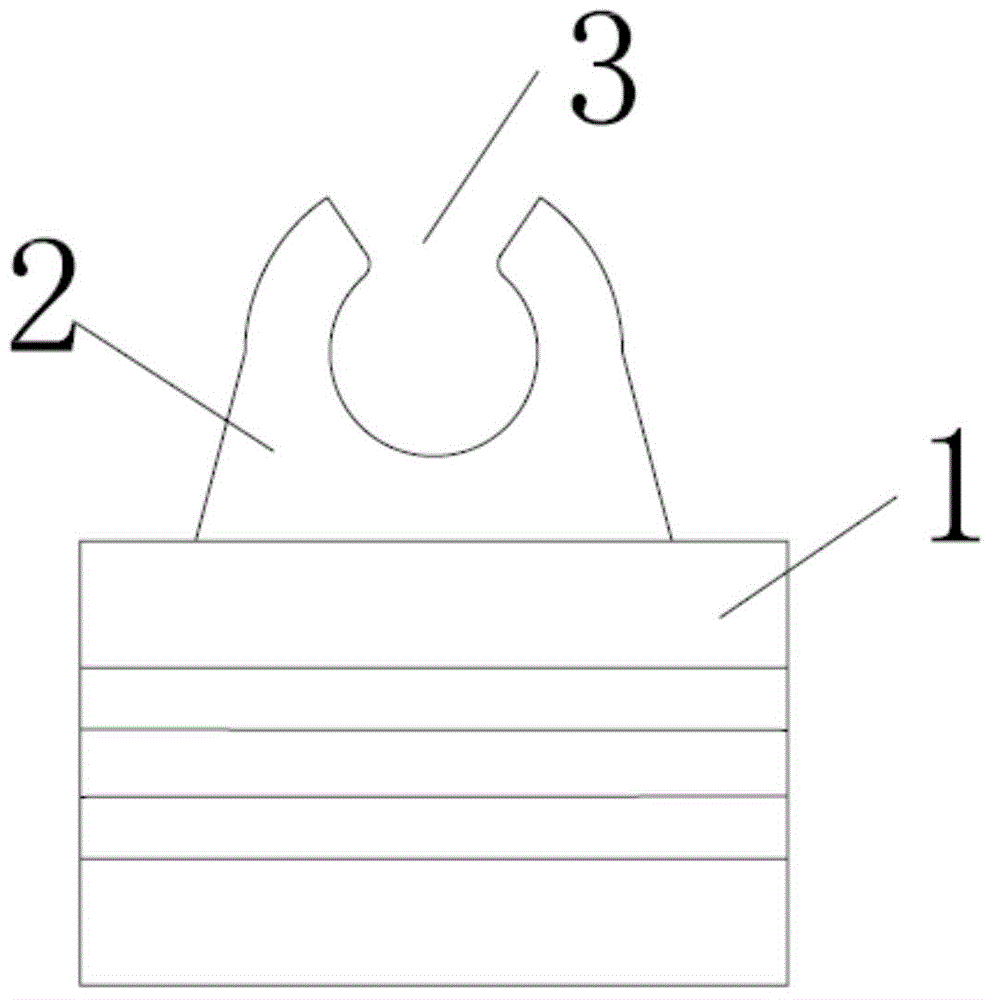

[0041] image 3 It is a front view of the structure of the fixing clip for the photovoltaic module connection wire of the second embodiment, Figure 4 It is the right view of the structure of the fixing clamp for connecting wires of the photovoltaic module in the second embodiment. Such as figure 2 and image 3 As shown, this embodiment proposes another fixed clip for connecting wires of photovoltaic modules. The only difference from the first embodiment is that this embodiment is provided with a The fixed wire ring 2, and the fixed wire ring 2 of this embodiment is a closed ring, no gap is opened on the fixed wire ring 2, and the fixed wire ring 2 is directly inserted into the connecting wire to realize the connection with the connecting wire .

[0042] In other embodiments, there can also be three, four or more fixing wire loops 2 , which are arranged at any position on the outer surface of the fixing clamp seat 1 .

Embodiment 3

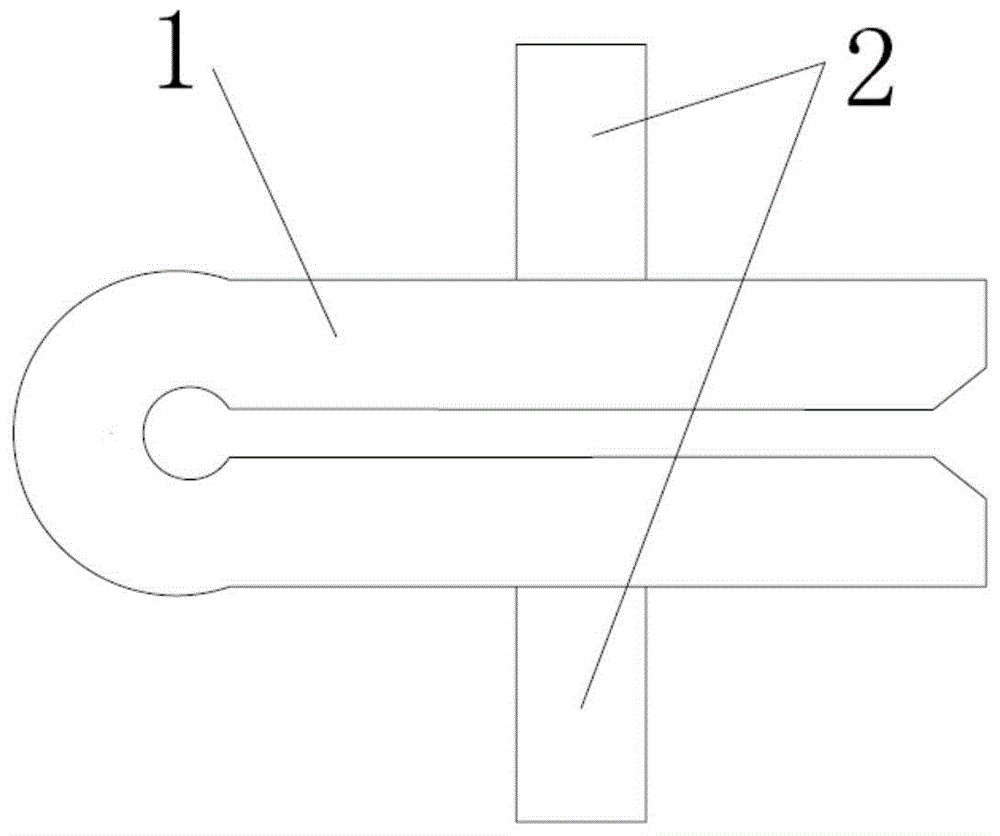

[0044] Figure 5 It is a schematic diagram of the structure connection of the fixed clip for connecting wires of the photovoltaic module in the third embodiment. Such as Figure 5 As shown, this embodiment proposes yet another fixed wire clamp for connecting wires of photovoltaic modules, which differs from Embodiment 1 only in that the fixed clip seat 1 and the fixed wire ring 2 of this embodiment are separately formed. , and a connecting pin 4 is protruded on an outer surface of the fixing clip seat 1, and a through hole 5 is opened at the corresponding position of the fixing wire ring 2, and the through hole 5 of the fixing wire ring 2 is rotatably sleeved on the fixing clip On the connecting pin 4 of the seat 1, it can be rotated 360 degrees and is arranged on the outer surface of the clamp seat 1.

[0045]Of course, in other embodiments, the fixed wire ring can also be rotatably arranged in other specific ways, or it can be engaged at a fixed position at a different ang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com