Patents

Literature

40results about How to "Avoid aging and shedding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Vehicle media player device and vehicles

PendingCN109036128AAvoid aging and sheddingEffective conditioning of reflexesIdentification meansEngineeringOrganic polymer

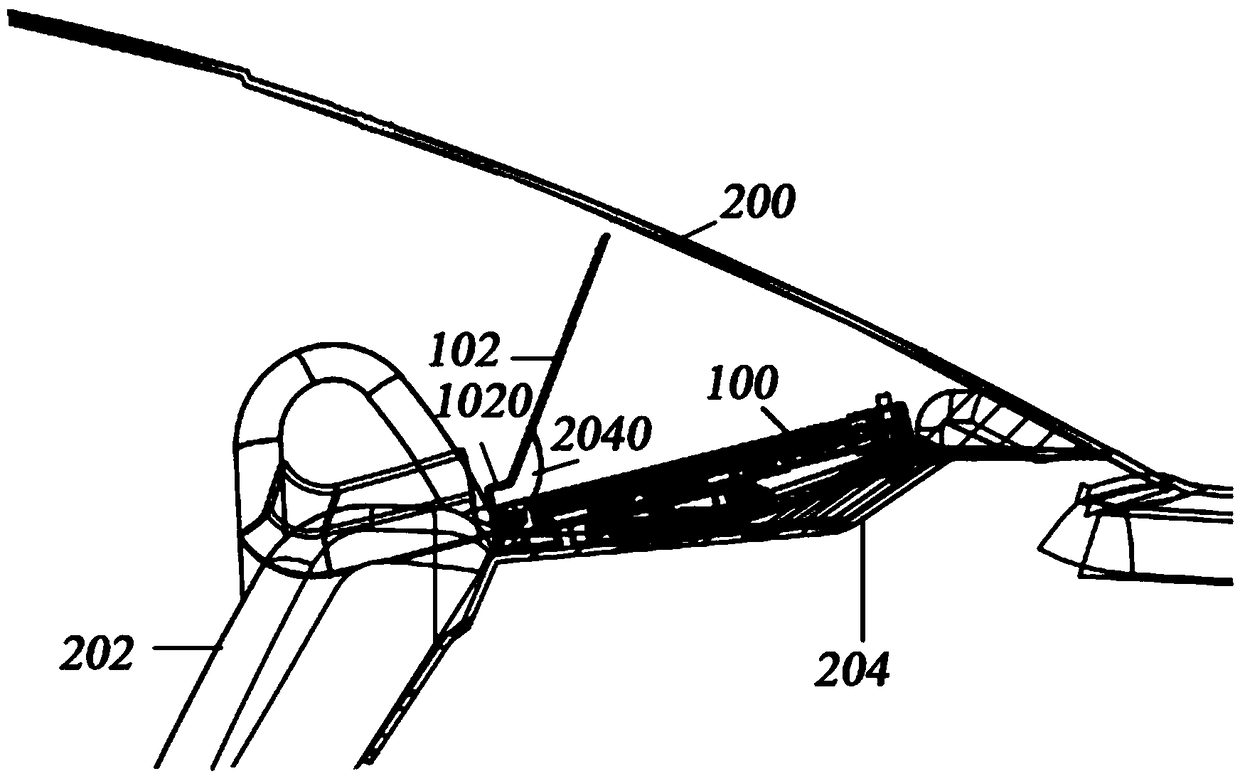

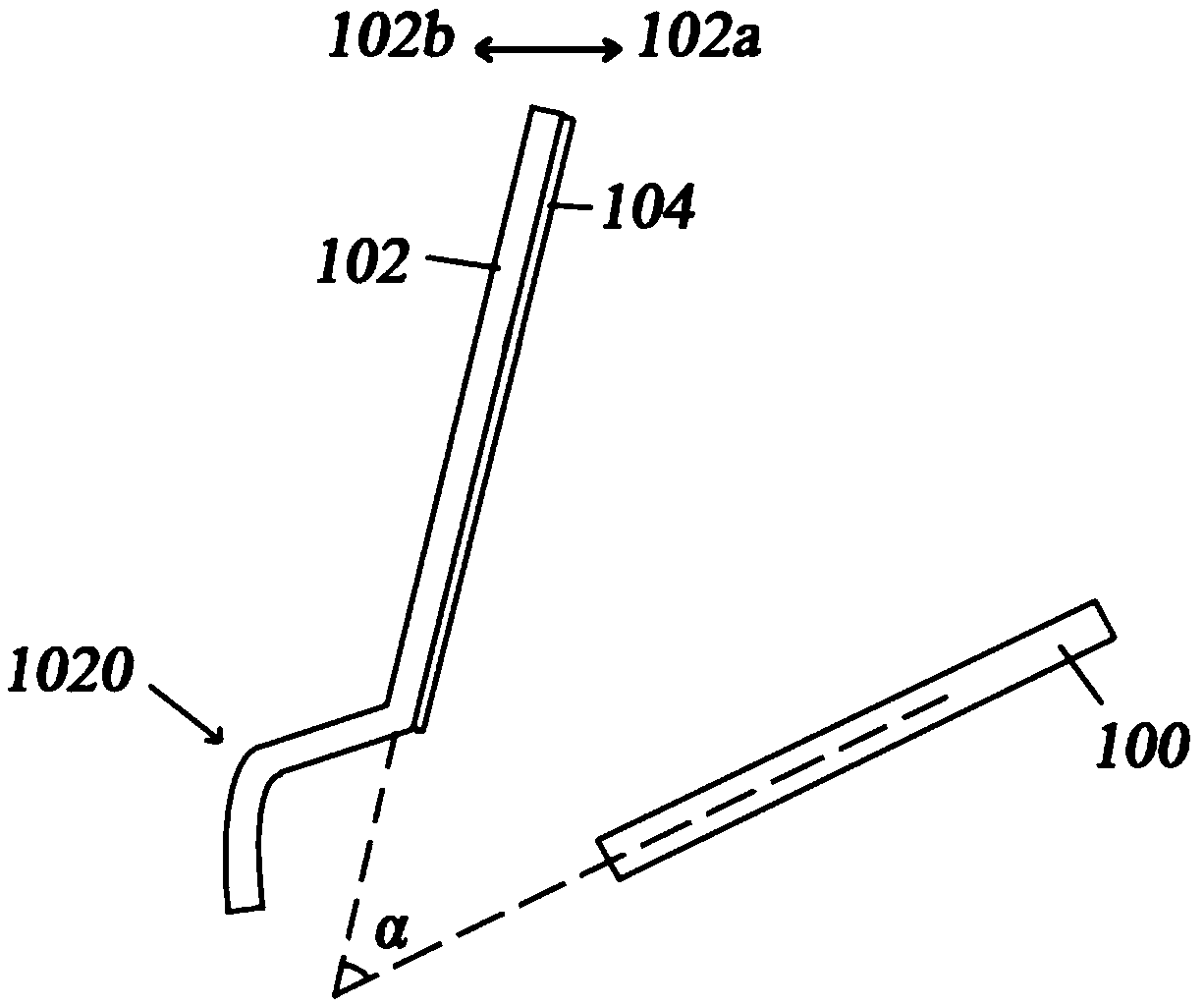

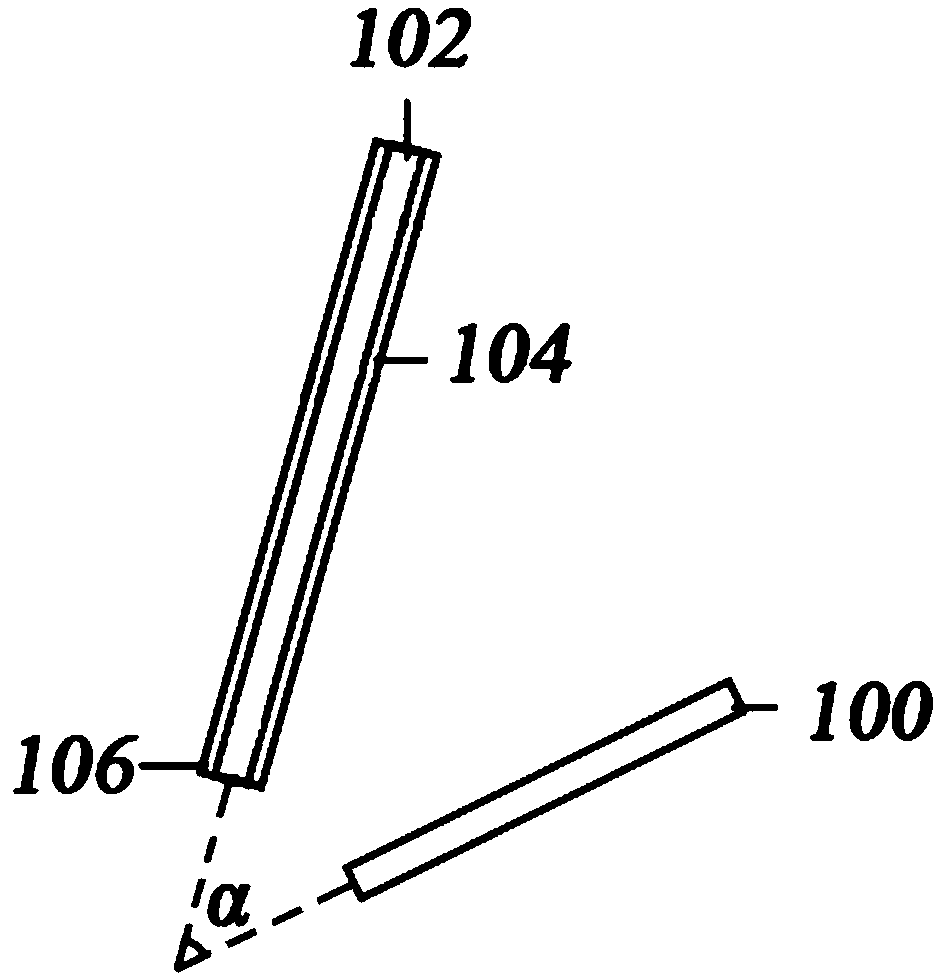

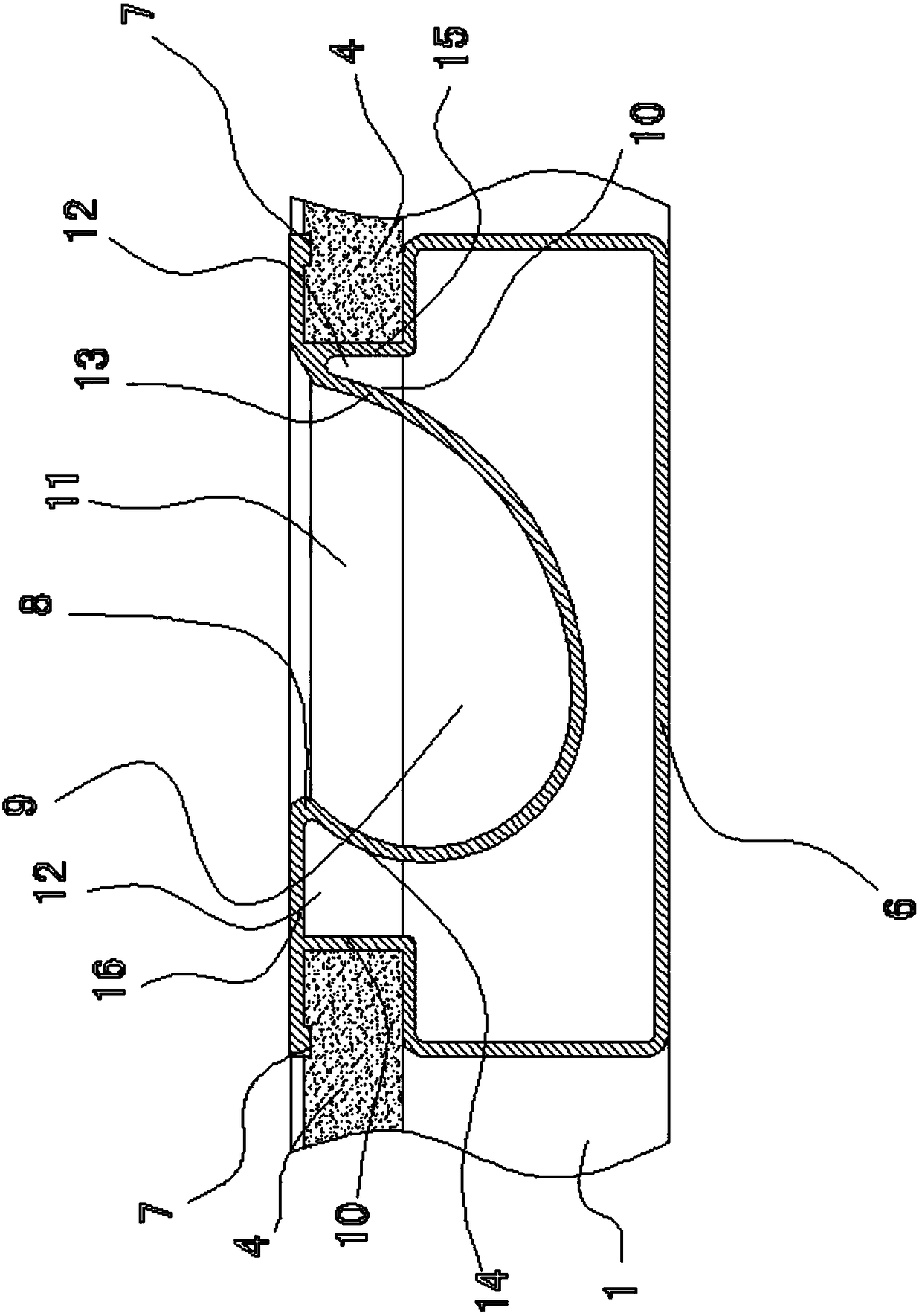

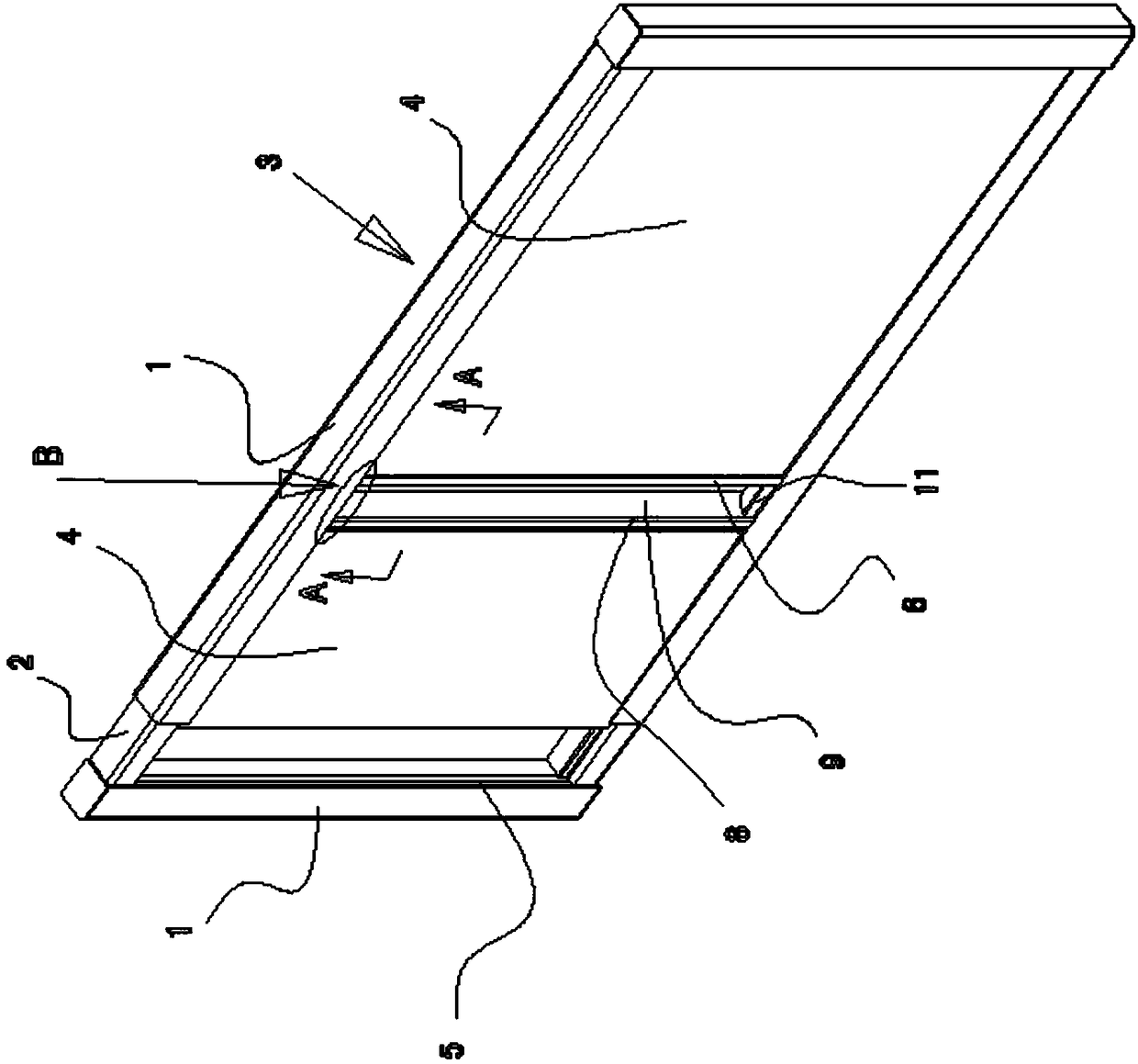

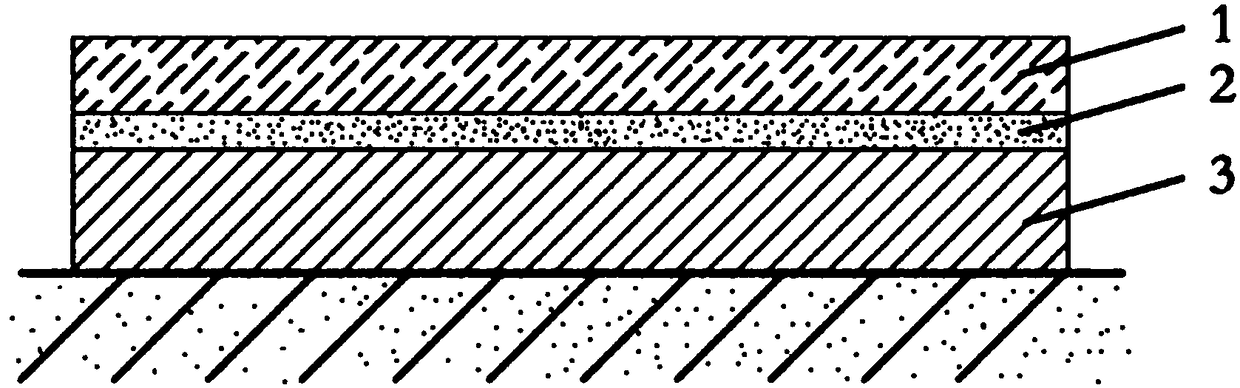

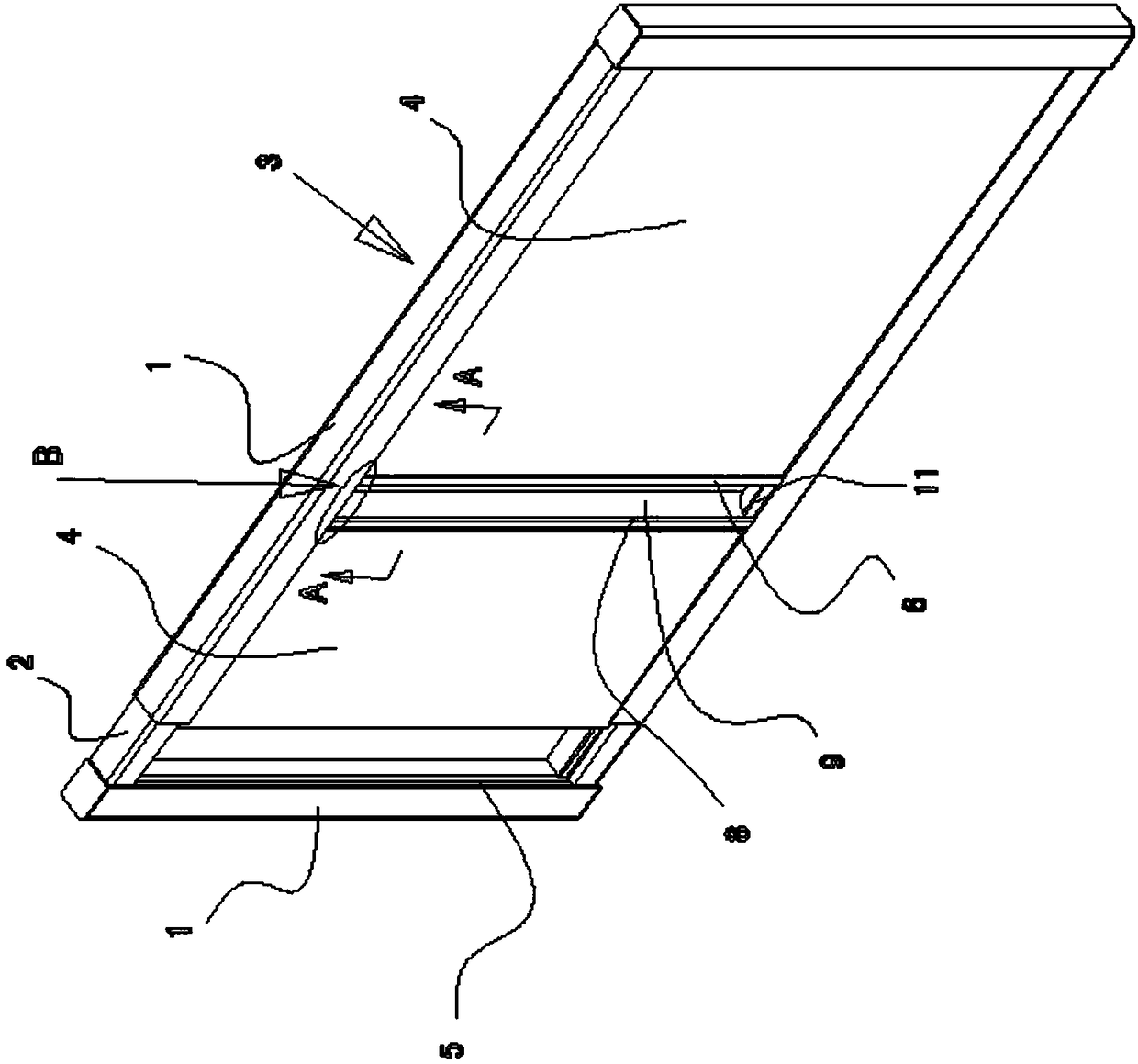

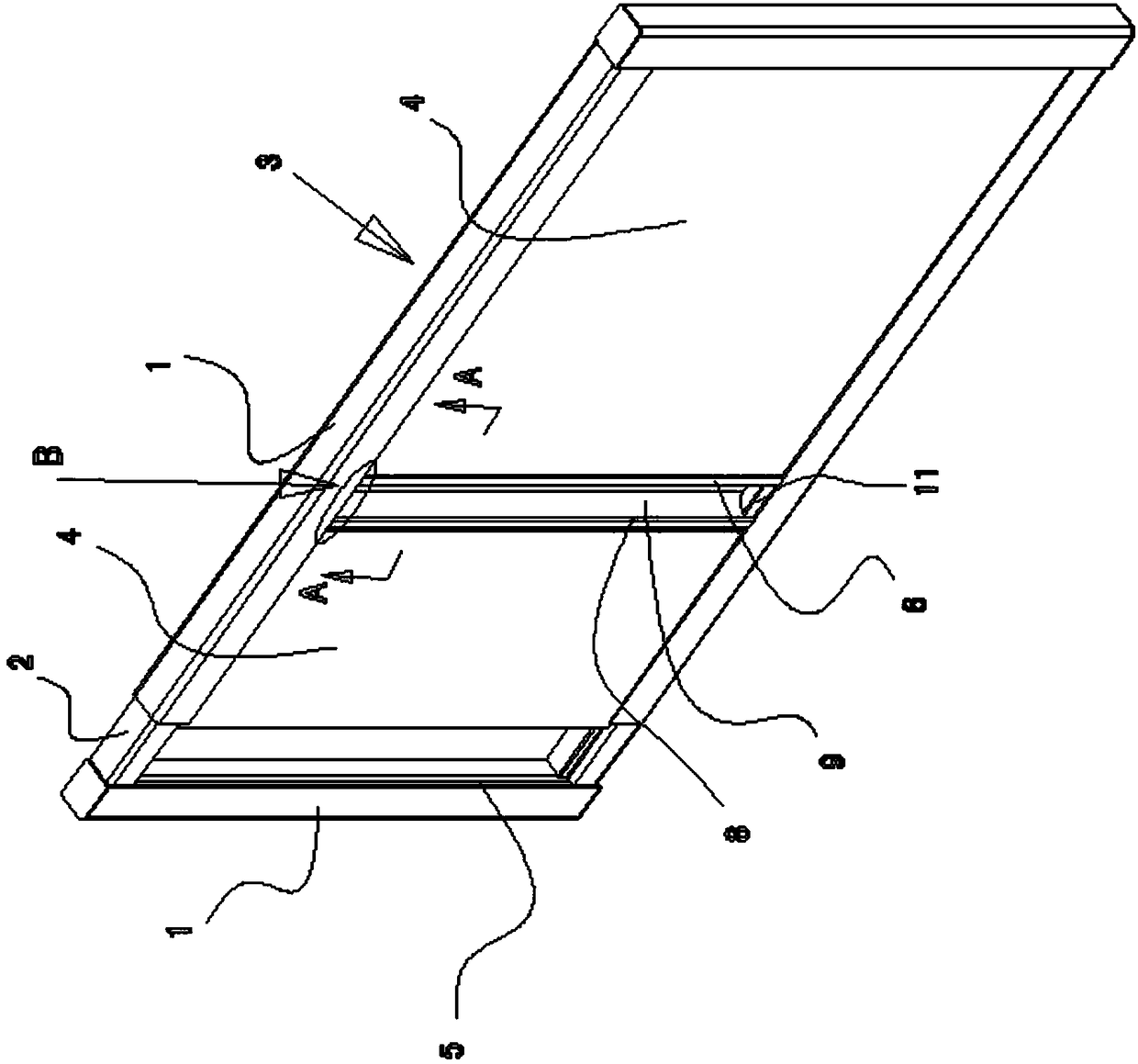

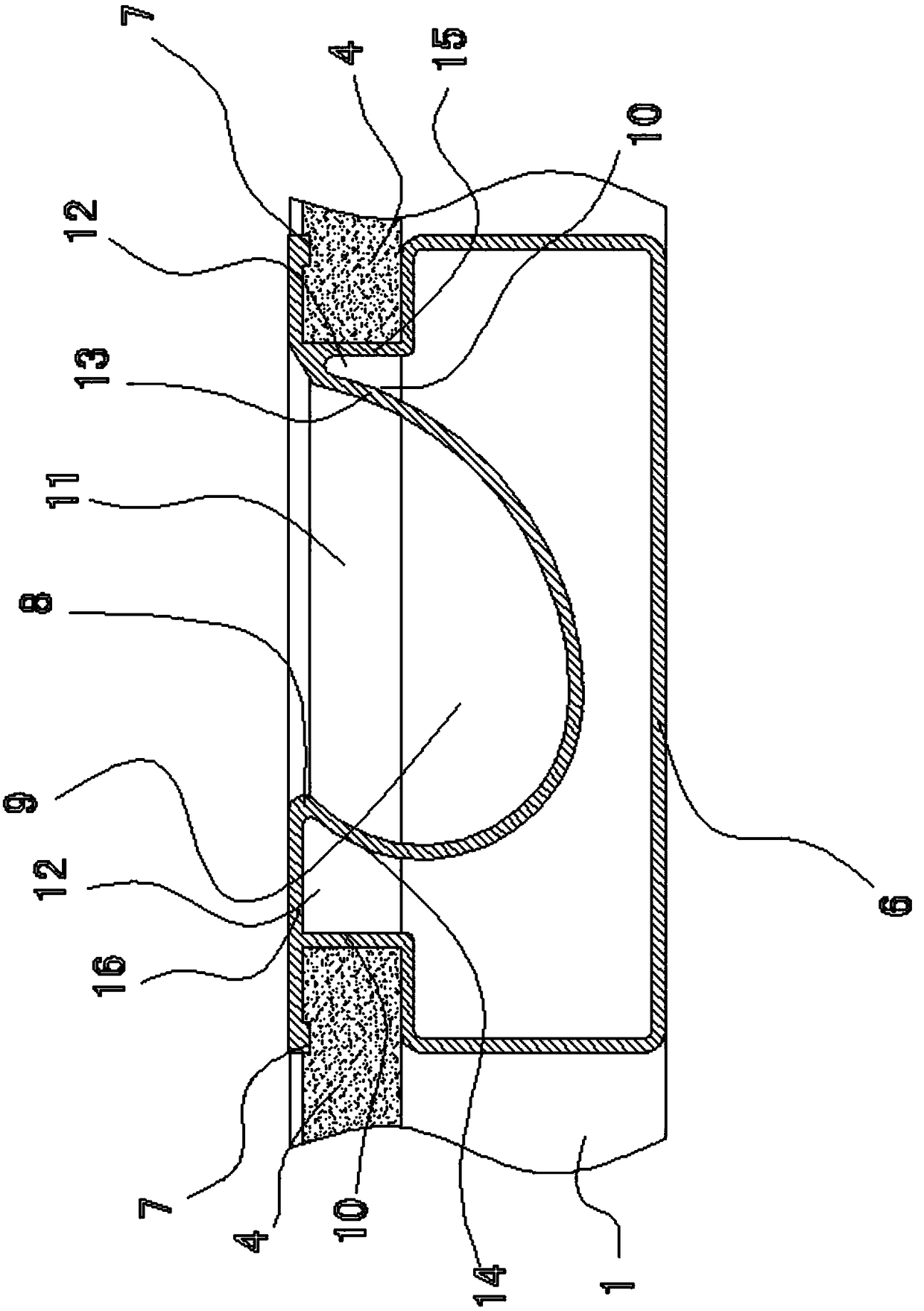

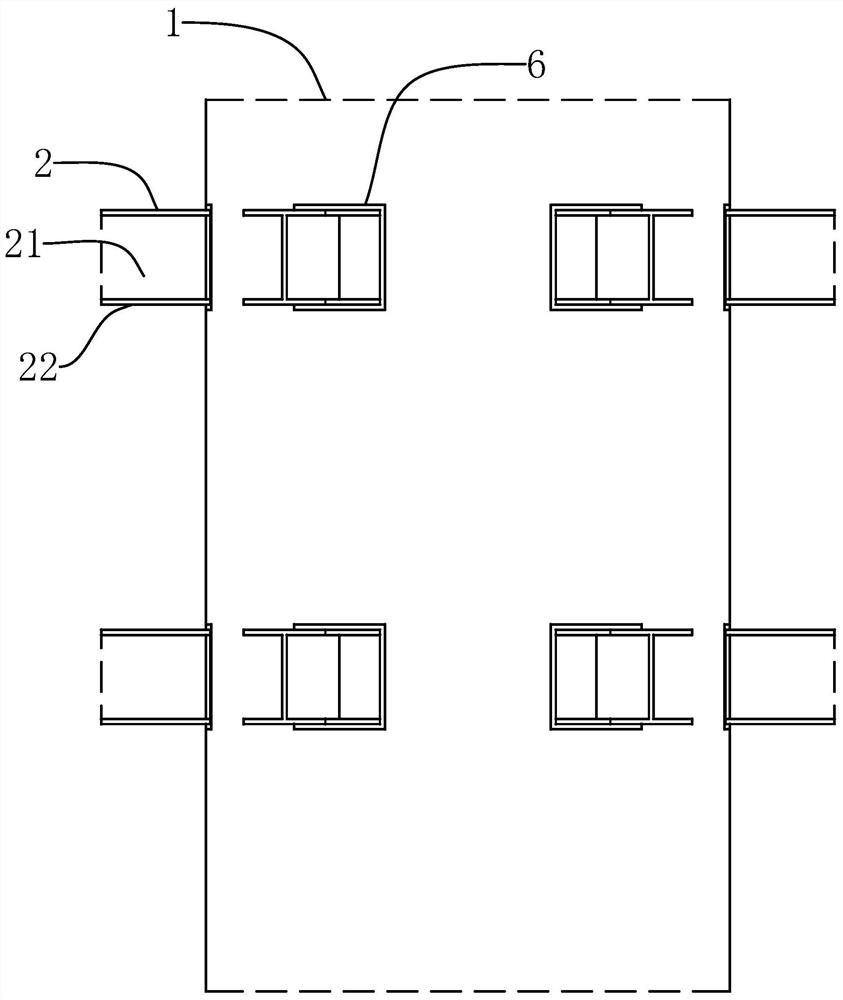

The invention provides a reflective vehicle media player device, which can effectively adjust the transparency and reflectivity of transparent panel, and optimize the imaging effect. The vehicle mediaplayer device includes a display screen; a transparent panel is arranged against the display screen, and the tilt angle between the transparent panel and the display screen is 20-70 degrees. The transparent panel is made of transparent organic polymer material. The first side of the transparent panel facing the display screen is provided with a semi-transparent and semi-reflective film.

Owner:SHANGHAI BIHU NETWORK TECH CO LTD

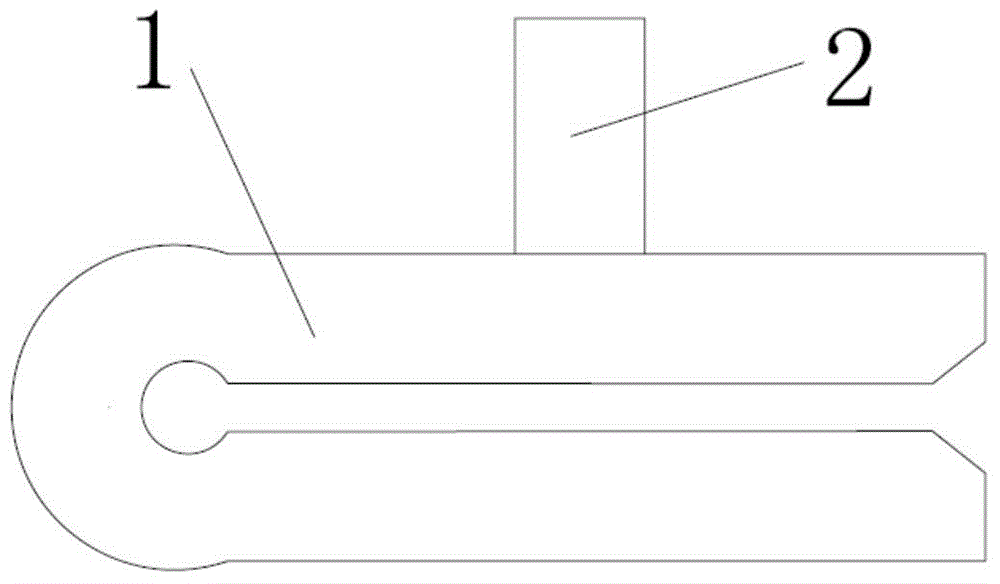

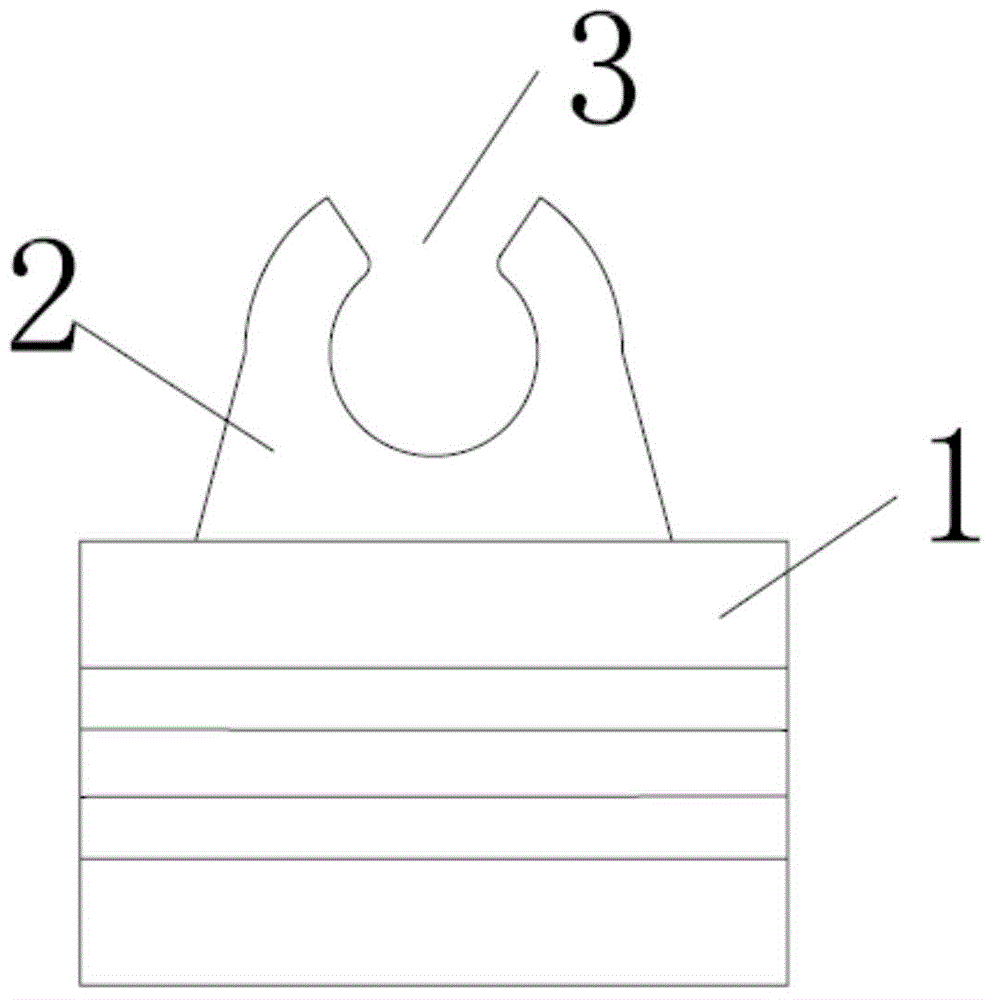

A fixing wire clamp for photovoltaic assembly connecting wires

InactiveCN104901615AAvoid wear and tearEliminate pull damagePhotovoltaicsPhotovoltaic energy generationPhotovoltaics

Owner:袁欣

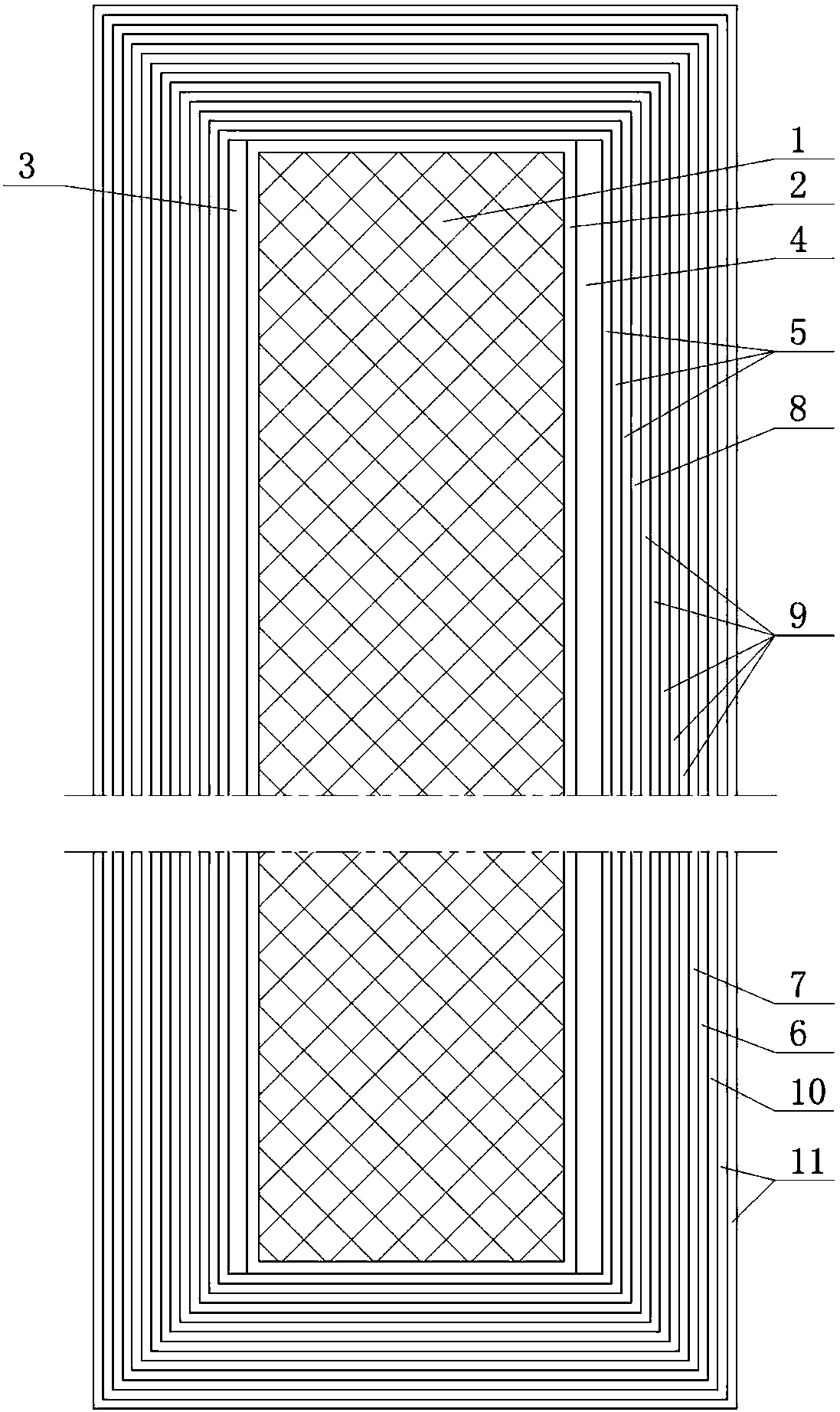

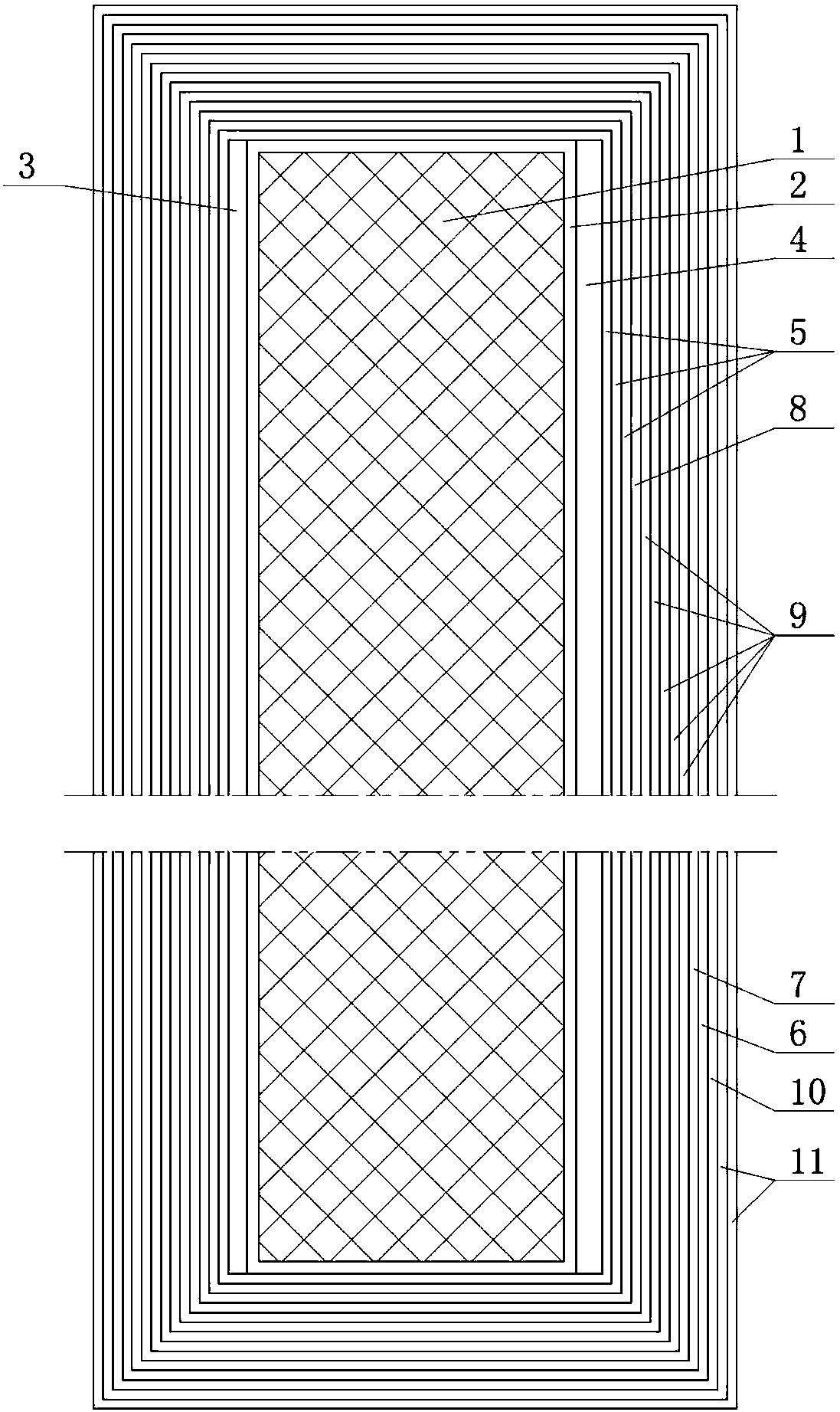

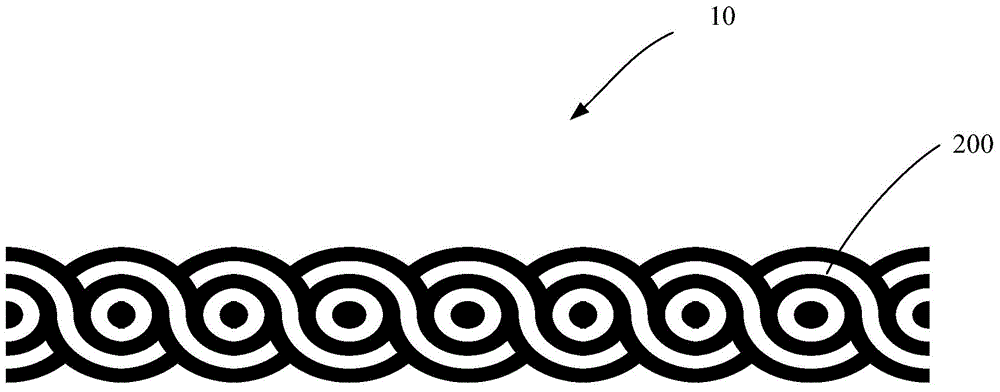

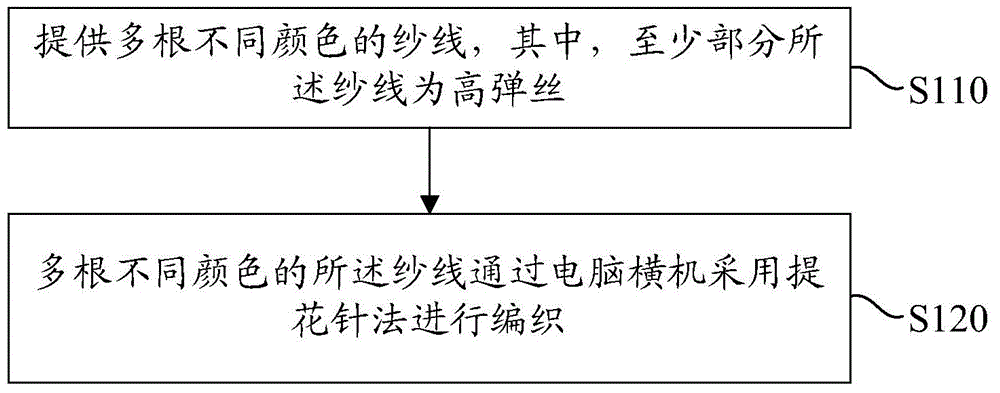

Method for weaving decorative picture and woven decorative picture

ActiveCN104141193ALong durationAvoid aging and sheddingWeft knittingSpecial ornamental structuresYarnSurface layer

The invention relates to a method for weaving a decorative picture and the woven decorative picture. The method for weaving the decorative picture comprises the steps that a plurality of pieces of yarn different in color are provided, at least two pieces of yarn are natural fiber yarn, and at least one piece of yarn is nylon fiber yarn; the pieces of yarn are arranged on a plurality of yarn mouths of a computerized flat knitting machine respectively, and each yarn mouth is provided with one piece of yarn; the yarn is woven by the computerized flat knitting machine through a jacquard weave needle method, the woven decorative picture comprises a body layer and at least one relief layer, and the relief layers are in weaving connection with the body layer and are on the different planes; each relief layer comprises a plurality of relief areas, and each relief area comprises an area where the same yarn is located on the surface layer of the woven decorative picture and appears continuously. The method for weaving the decorative picture is higher in efficiency, and the problem that pigment is aging and falls off in the traditional printing imaging mode is solved.

Owner:邳州市城洁保洁有限公司

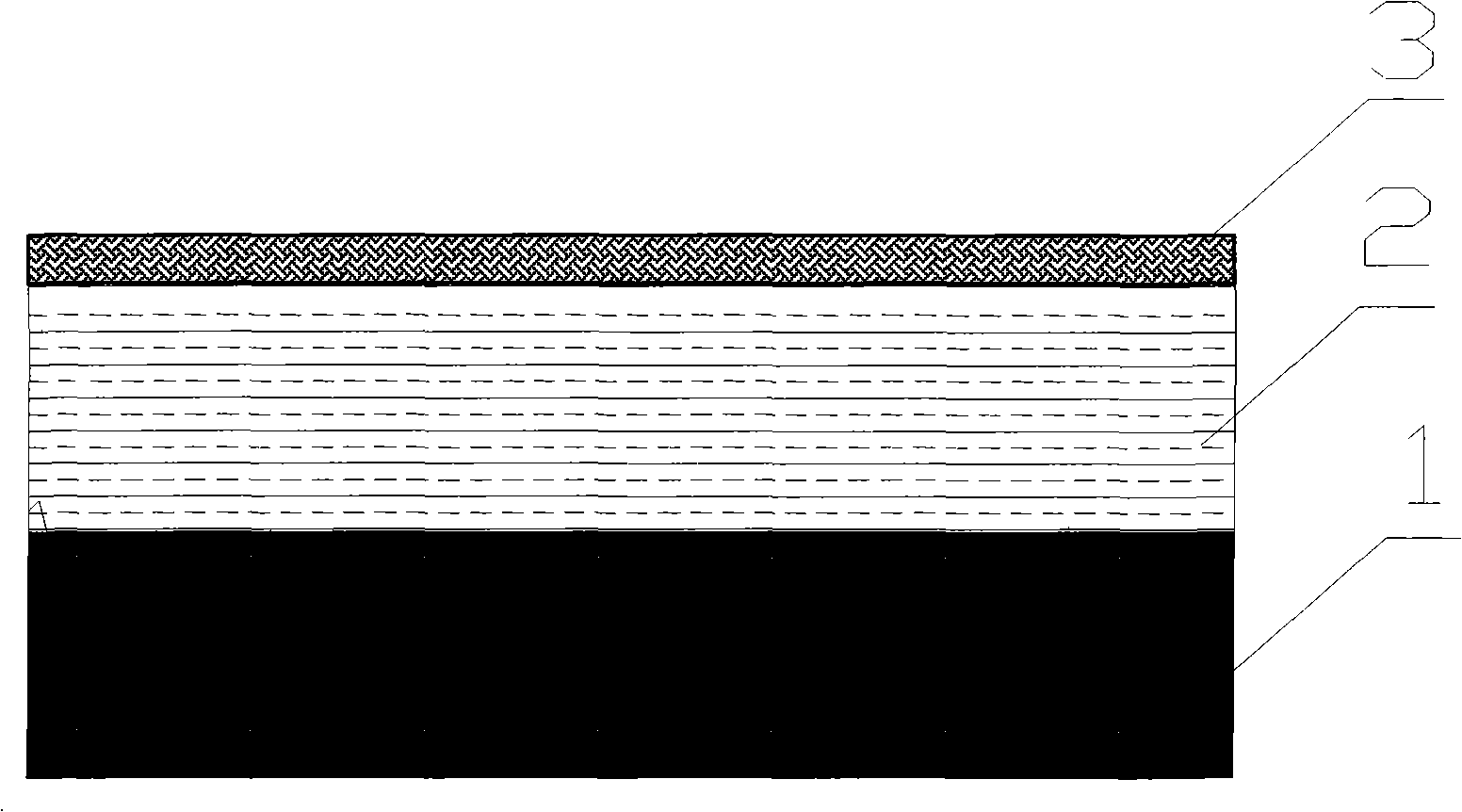

Flame retardant decorative sheet, manufacturing method of flame retardant decorative sheet and flame retardant material comprising flame retardant decorative sheet

InactiveCN108247786AImprove standardizationImprove aestheticsPlywood pressesWood treatment detailsAdhesiveEngineering

The invention provides a flame retardant decorative sheet and a manufacturing method of the flame retardant decorative sheet. The flame retardant decorative sheet comprises a board material assembly and a flame retardant adhesive layer which is at least attached to the surface of at least one side in the thickness direction of the board material assembly and formed by adhesive containing flame retardant adhesive. The board material assembly at least comprises a layer of wooden single board. The flame retardant adhesive contains water-soluble amino resin, dehydration catalyst, charring agent and assistant agent and contains water or not. The dehydration catalyst is one or more of ammonium polyphosphate, melamine orthophosphate and melamine pyrophosphate. The polymerization degree of the ammonium polyphosphate is 20 or above. The invention further provides a flame retardant material. The bonding performance of the flame retardant decorative sheet made by the adoption of the manufacturingmethod can meet the national standard requirement, and the flame retardant decorative sheet gives the flame retardant property to a base material and does not influence the mechanical property of thebase material. The formaldehyde emission is at the E1 grade or above, and the flame retardant decorative sheet is safe and environmentally friendly. Meanwhile, the nature texture of the wood is kept,and the decorative effect is good.

Owner:肖群伟

Impact-resistant polyurethane surface decoration material

InactiveCN108930378AStir wellImprove insulation effectCovering/liningsCoatingsCalcium silicateUV curing

The invention discloses an impact-resistant polyurethane surface decoration material. Two major processes are included, firstly, the primer line processing technological process comprises the specificsteps that (1) fixed-thickness sanding and dust removing are conducted, (2) seal coat is roller-painted on the back face and cured into a first UV seal coat layer, (3) a UV penetrant is roller-painted by two times, (4) infrared leveling is conducted, (5) UV putty is painted on the front face, UV is cured to generate a UV putty layer, (6) UV seal coat are roller-painted by three times and cured togenerate three second UV seal coat layers, and (7) fine sanding is conducted; and secondly, the finishing coat line roller-painting technological process comprises the specific steps that (1) dust removing is conducted, (2) UV glue is roller-painted to generate a first UV glue layer, and (3) UV finishing coat is painted by five times and cured to generate five UV finishing coat layers. Accordingto the impact-resistant polyurethane surface decoration material, strong penetration, rapid penetration and deep penetration of the UV curing penetrant and a fiber reinforced calcium silicate plate ora fiber cement plate are achieved, a film is formed through deep curing, the UV curing penetrant, the UV putty and the UV seal coat form a three-dimensional chemical netted crosslinking reaction, andthe problem of adhesive force of a decoration face layer and a base plate can be solved.

Owner:秦玲志

Preparation method of glass fiber reinforced plastic coating

InactiveCN109161312ASimple preparation processExtended service lifeFireproof paintsRadiation-absorbing paintsFire retardantAntioxidant

The invention discloses a preparation method of a glass fiber reinforced plastic coating. The glass reinforced plastic coating is prepared from the following raw materials in parts by mass: 80-120 parts of unsaturated polyester resin, 30-50 parts of a coloring agent, 1-5 parts of cyclohexanone peroxide, 1-10 parts of cobalt naphthenate, 2-6 parts of an antifoaming agent, 2-6 parts of a curing agent, 2-6 parts of an accelerator, 3-6 parts of a flame retardant, 3-6 parts of an ultraviolet absorber and 2-4 parts of an antioxidant. The preparation process provided by the invention is simple, environmentally-friendly and pollution-free; due to the addition of the flame retardant, the ultraviolet absorber and the antioxidant, a glass fiber reinforced plastic product is prevented from aging and falling off caused by the influence of the external environment; and the glass fiber reinforced plastic coating is more resistant to high temperature and more heat-insulating than the currently used glass fiber reinforced plastic coating, thereby greatly improving the service life of glass fiber reinforced plastic products.

Owner:DE RUISEN NANTONG COMPOSITE MATERIAL CO LTD

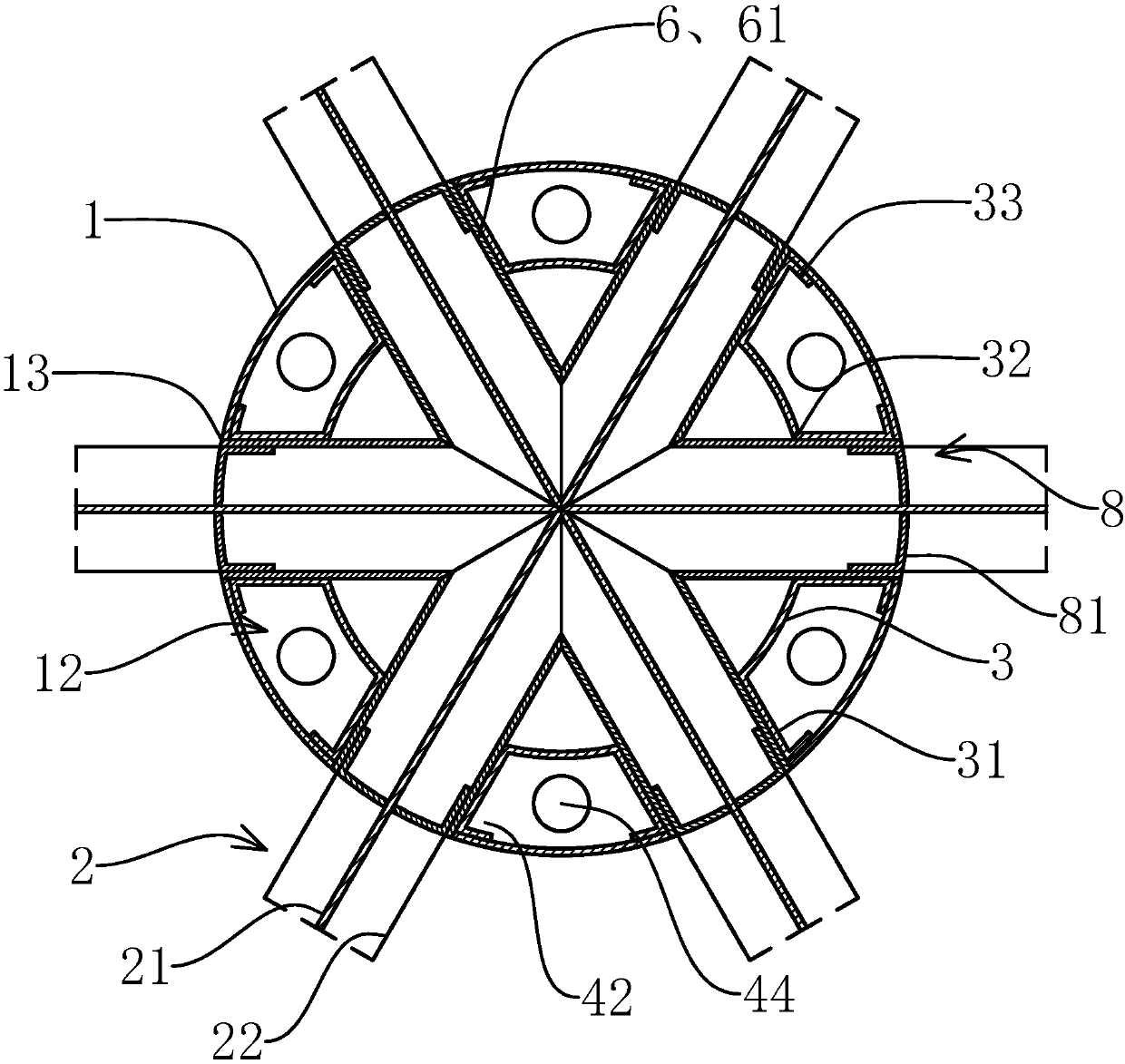

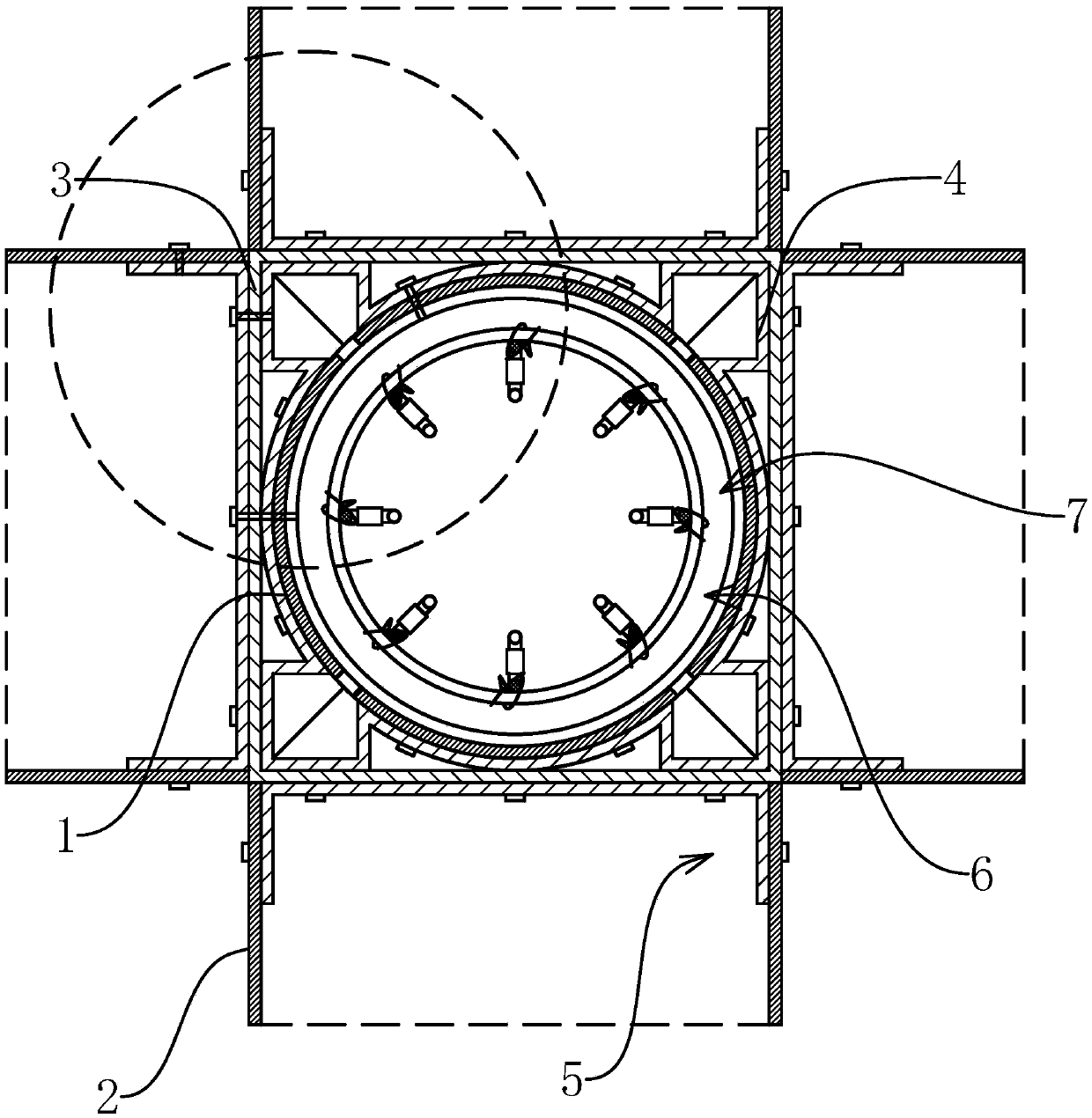

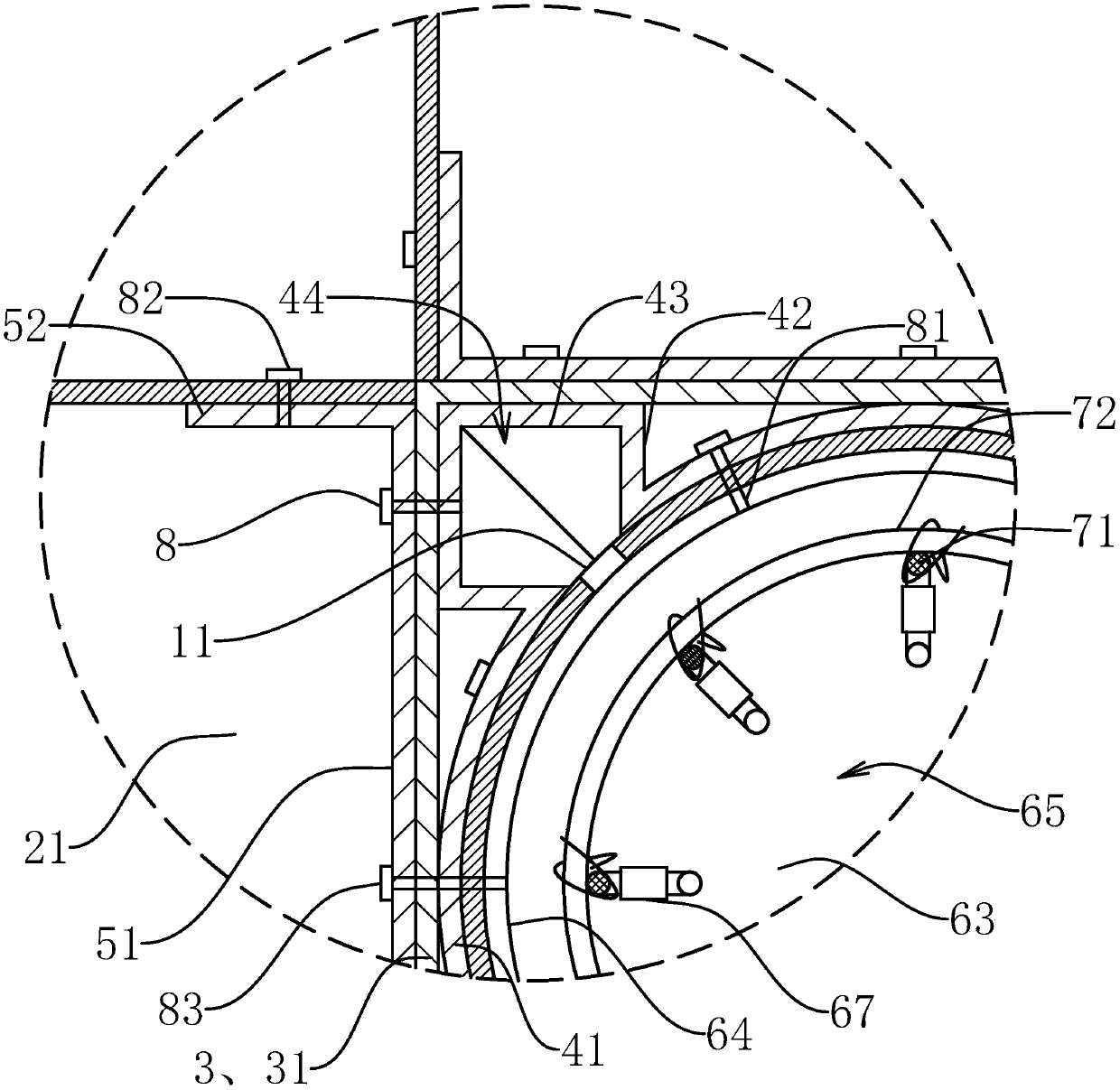

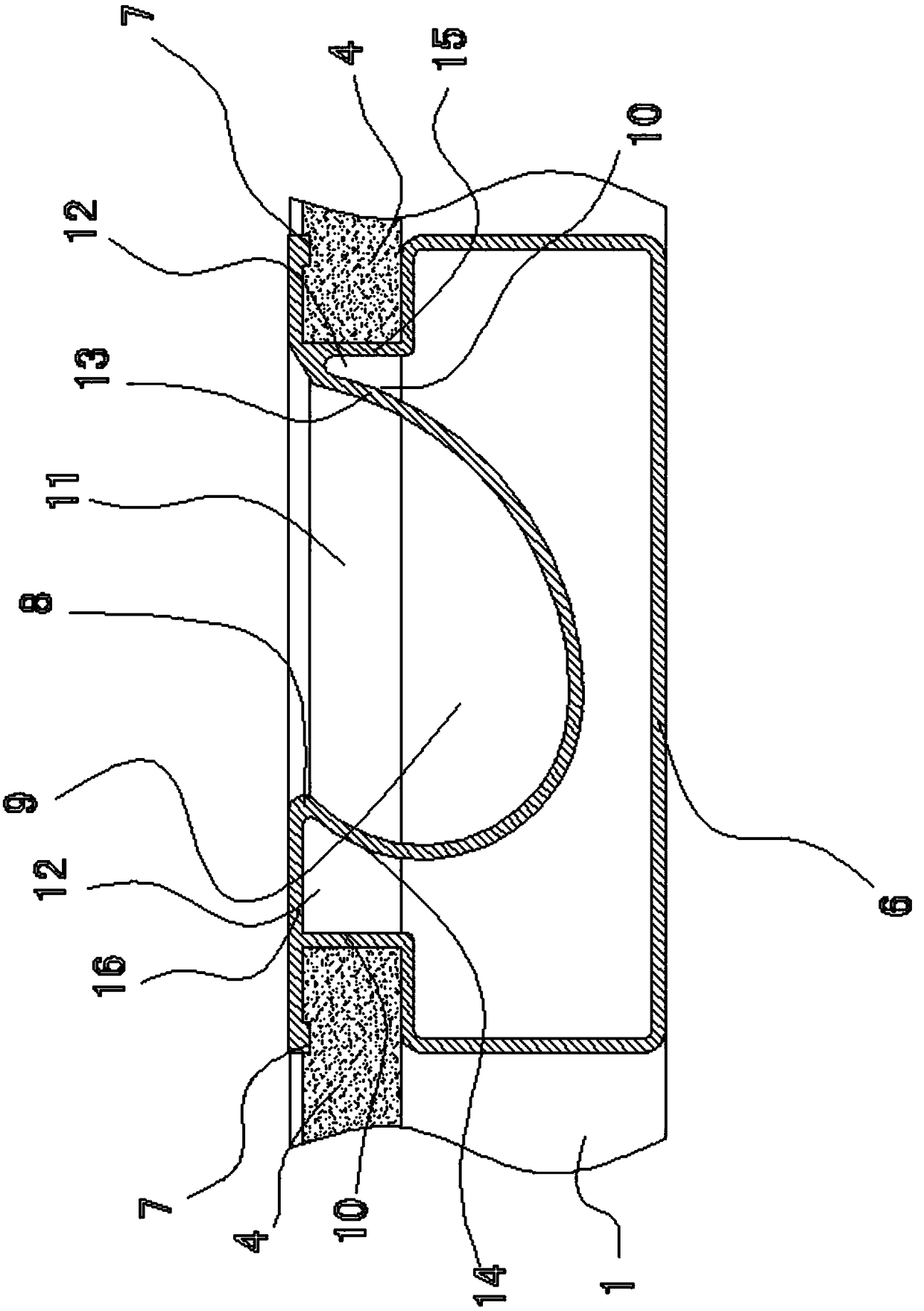

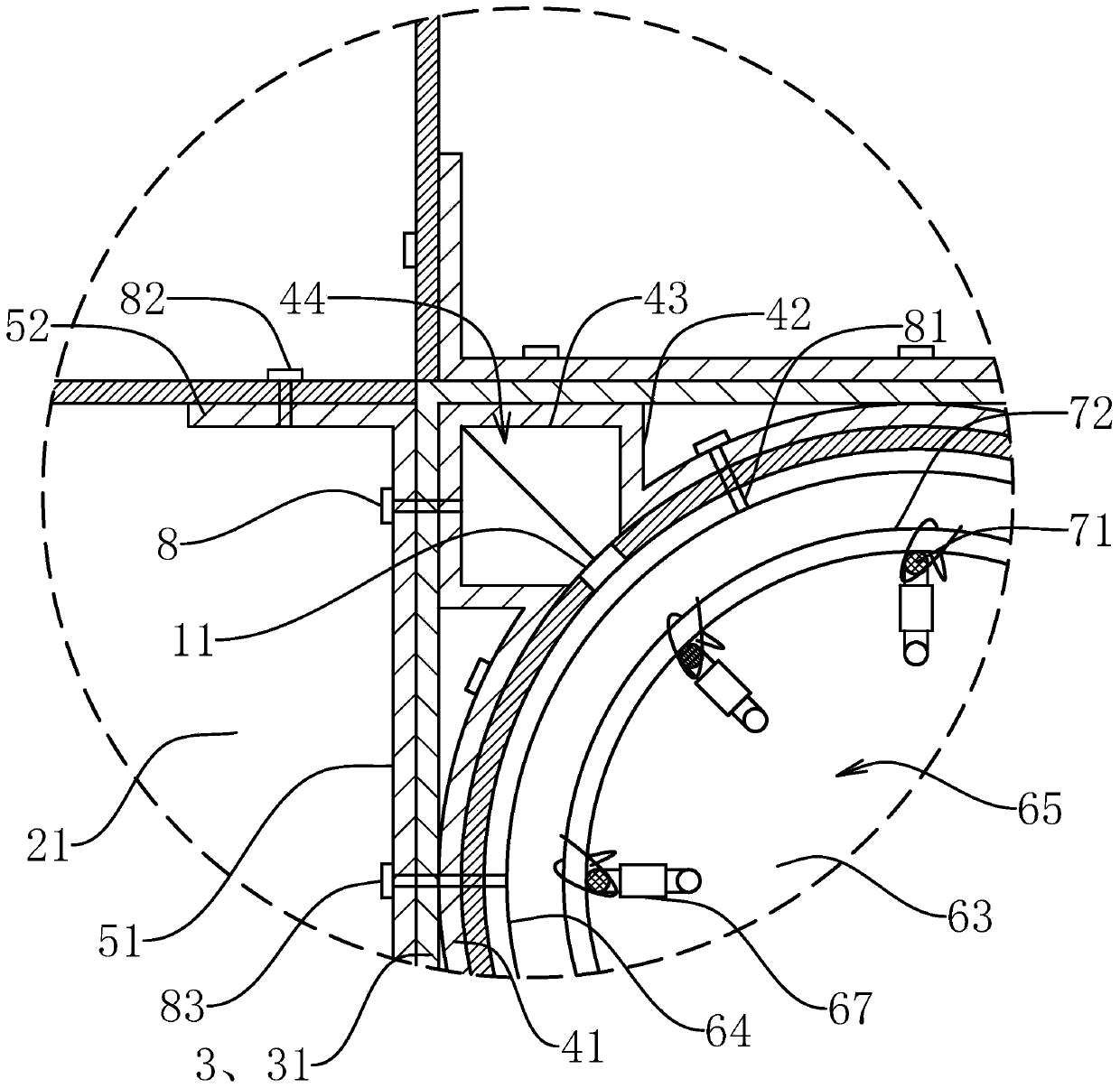

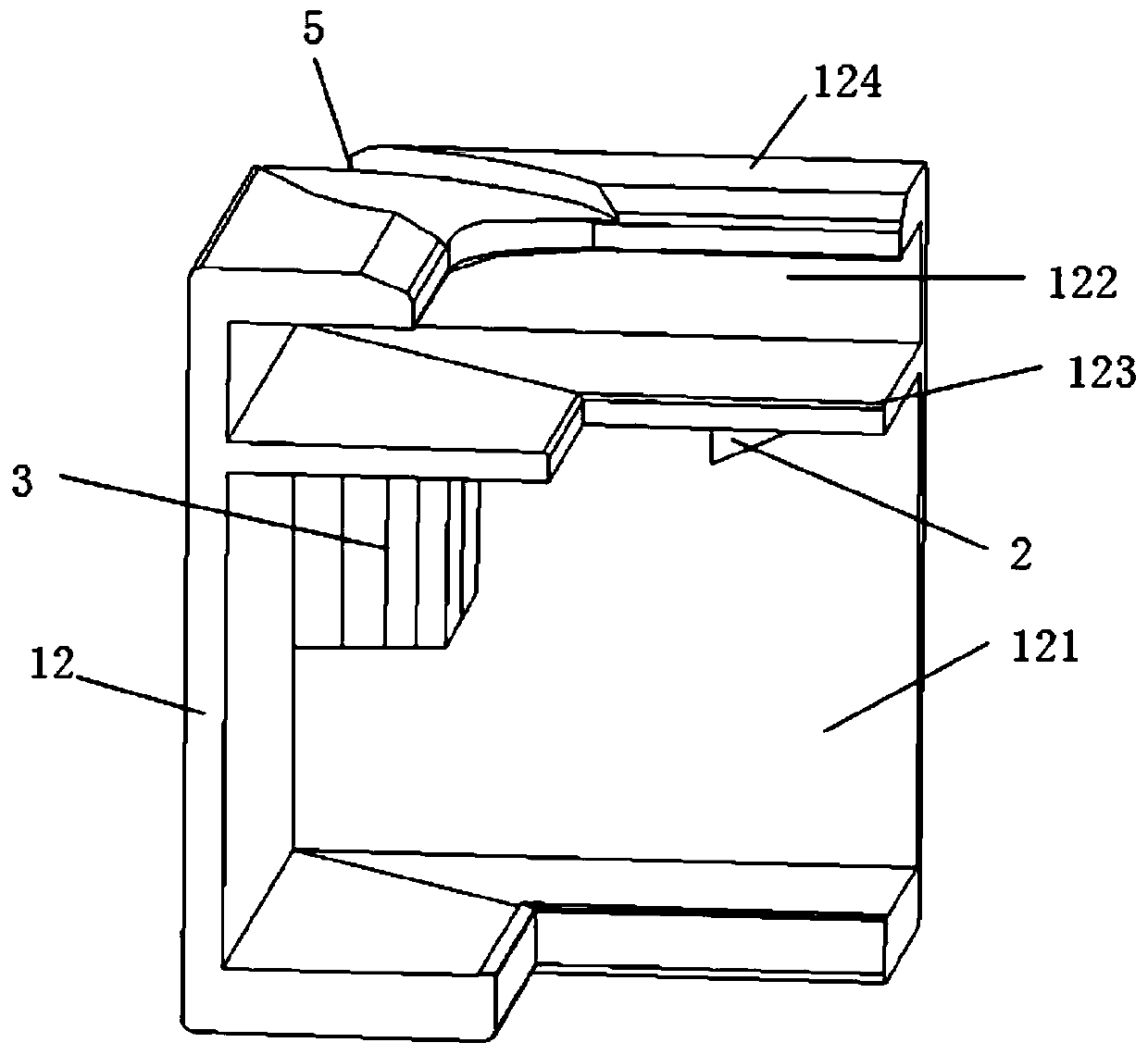

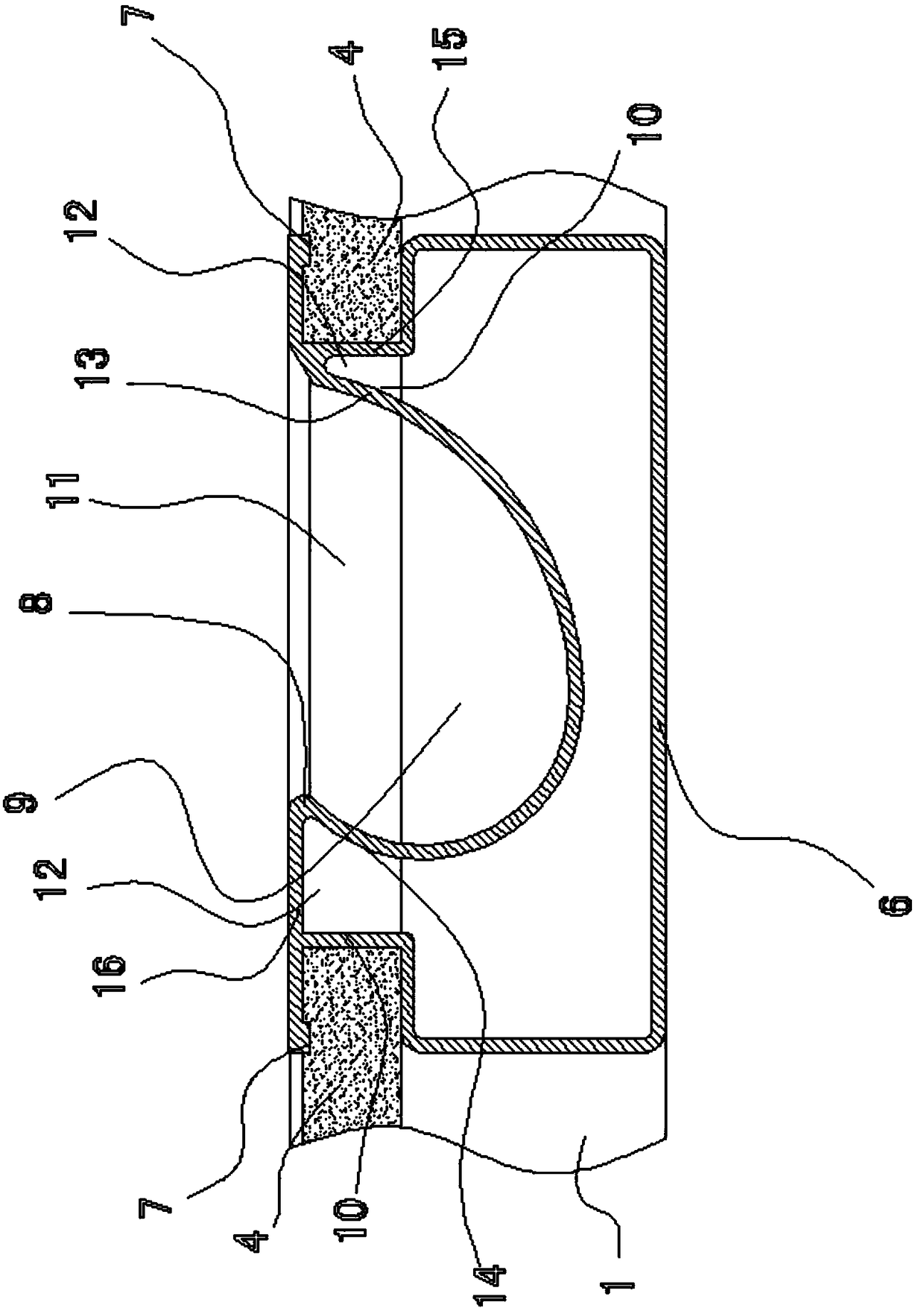

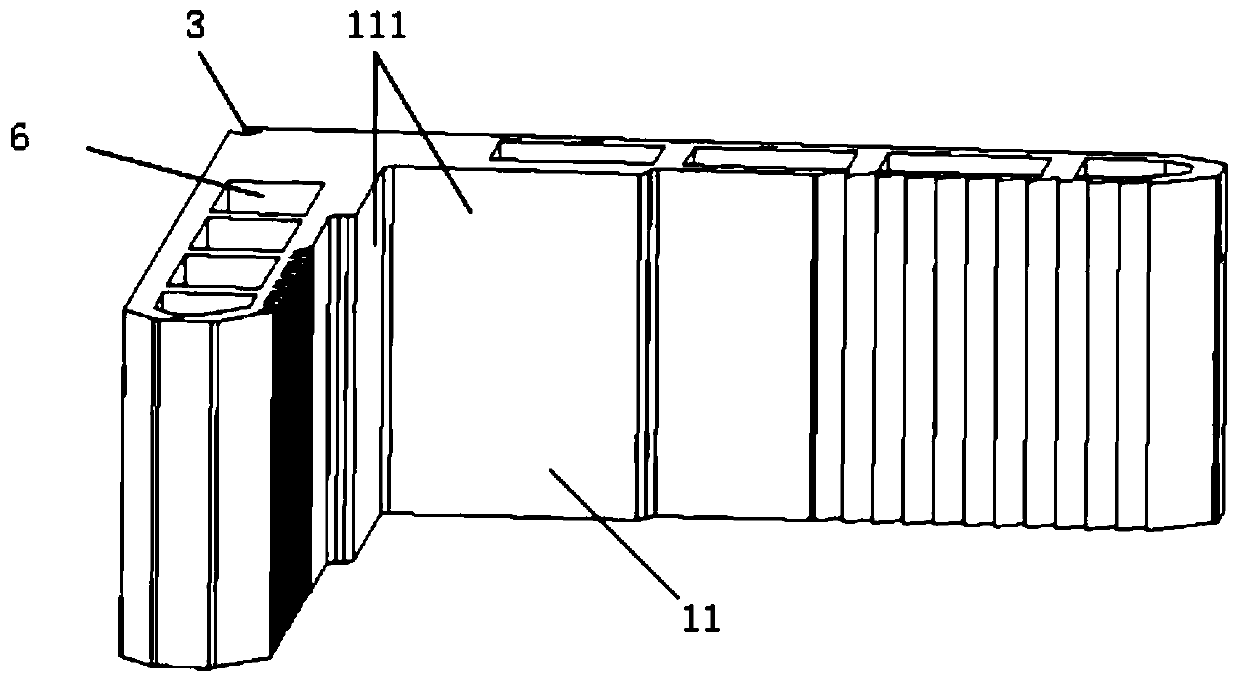

Stable beam-column connecting structure and mounting method thereof

ActiveCN109610653AEasy to installImprove vertical bearing capacityBuilding constructionsEngineeringUltimate tensile strength

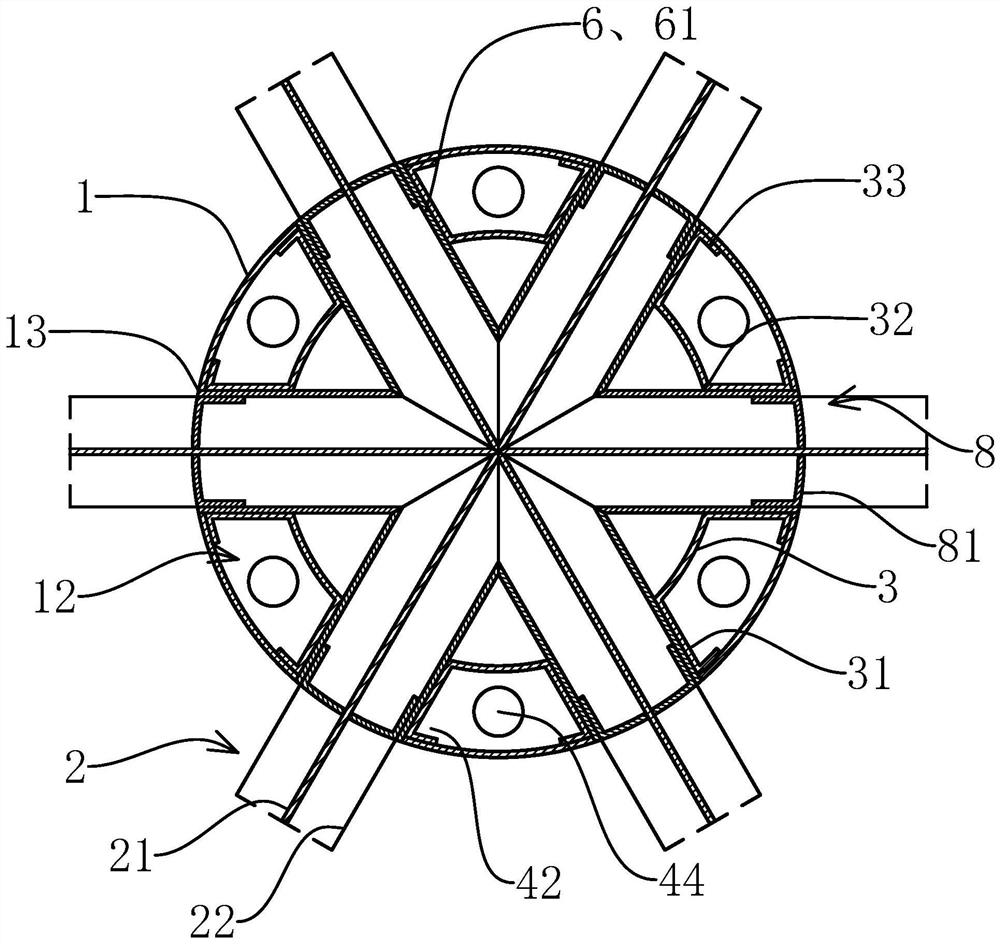

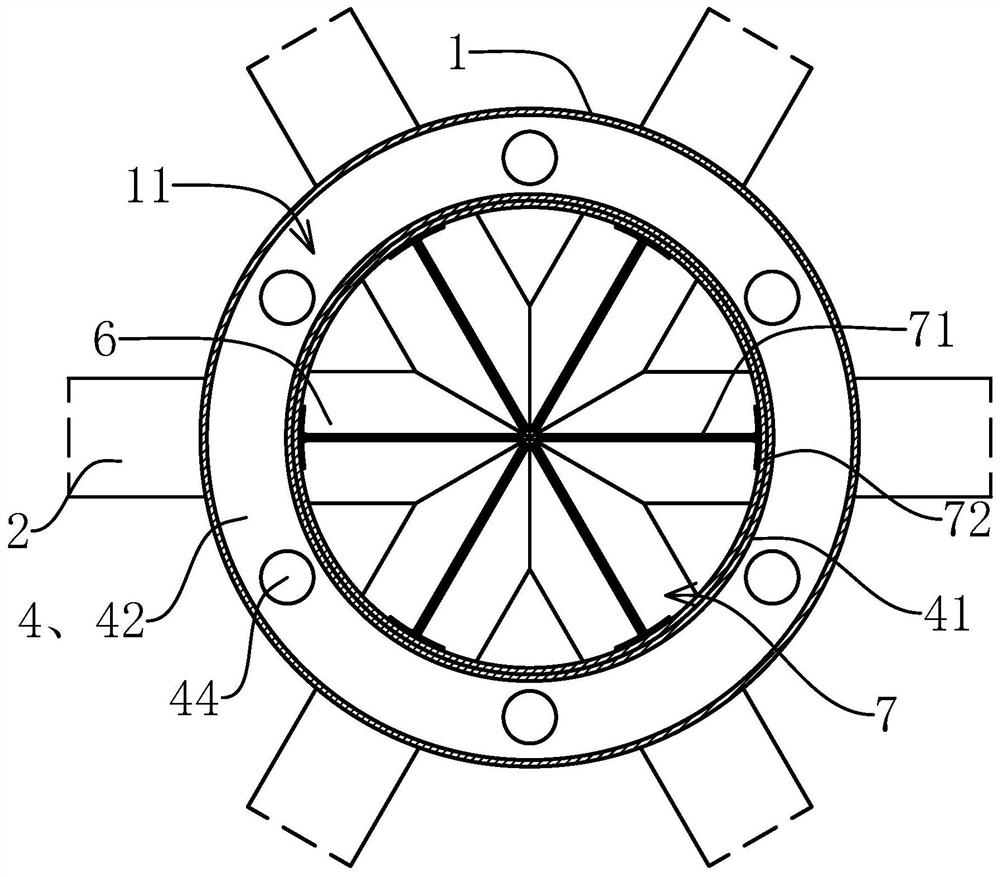

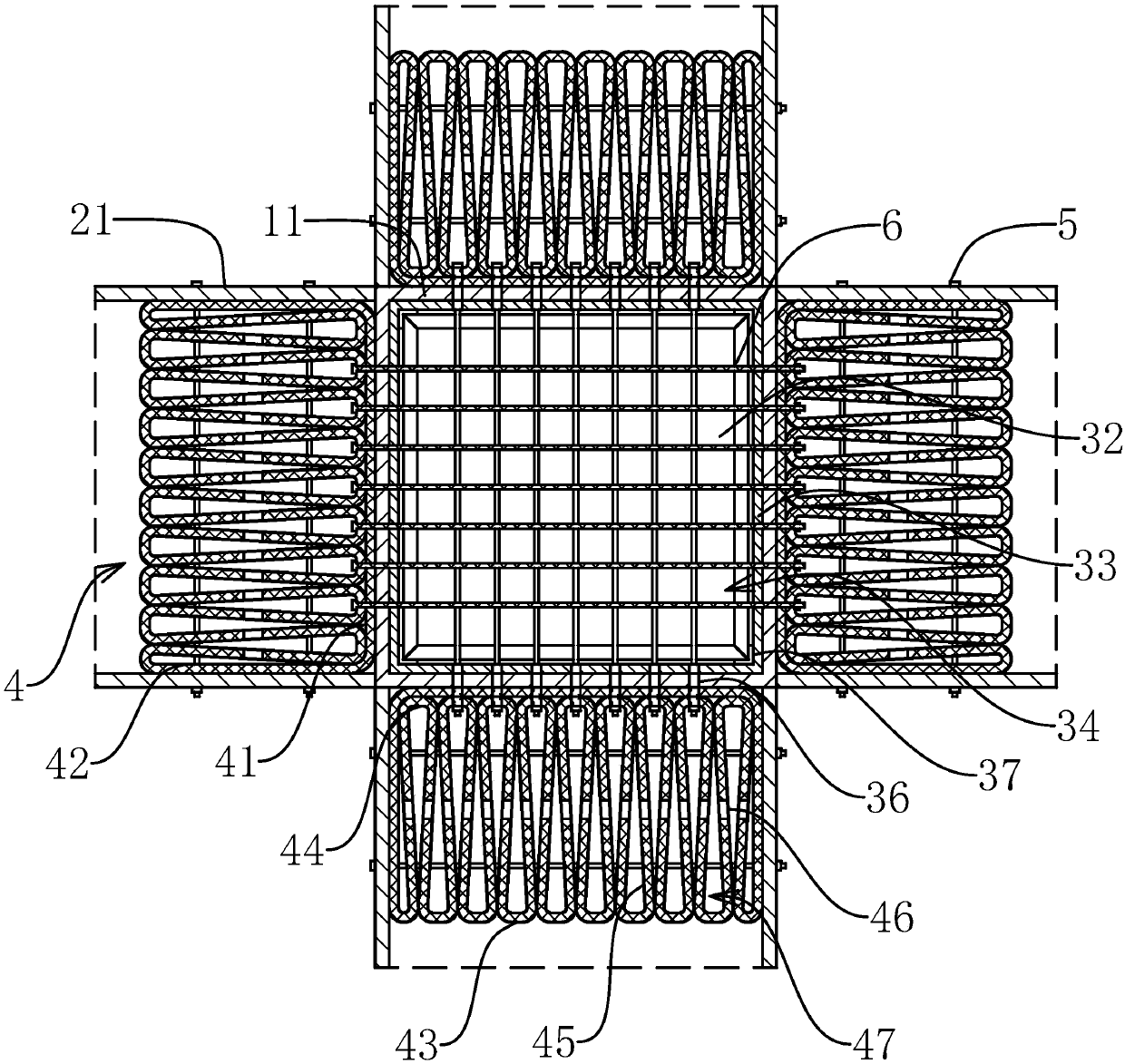

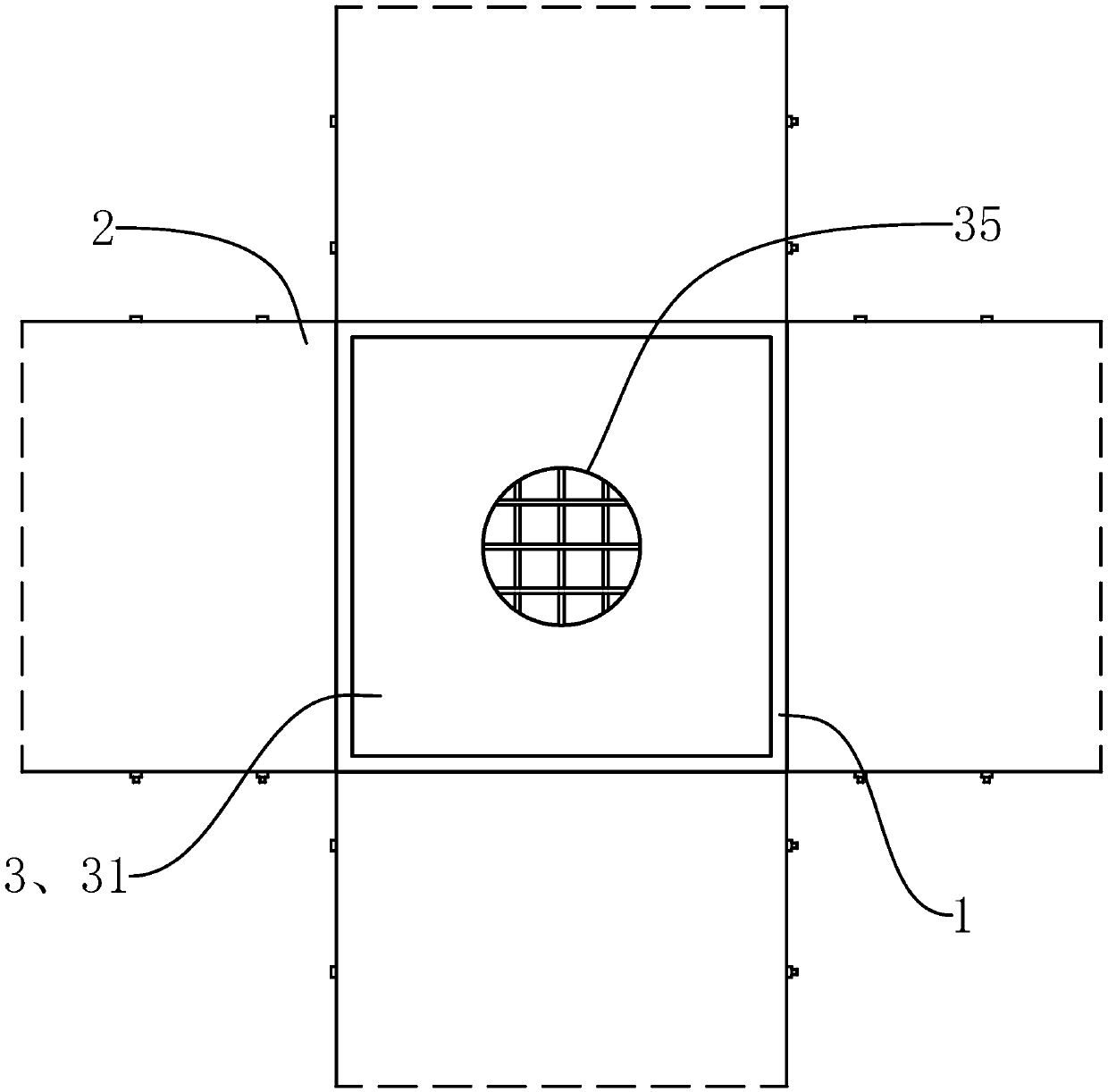

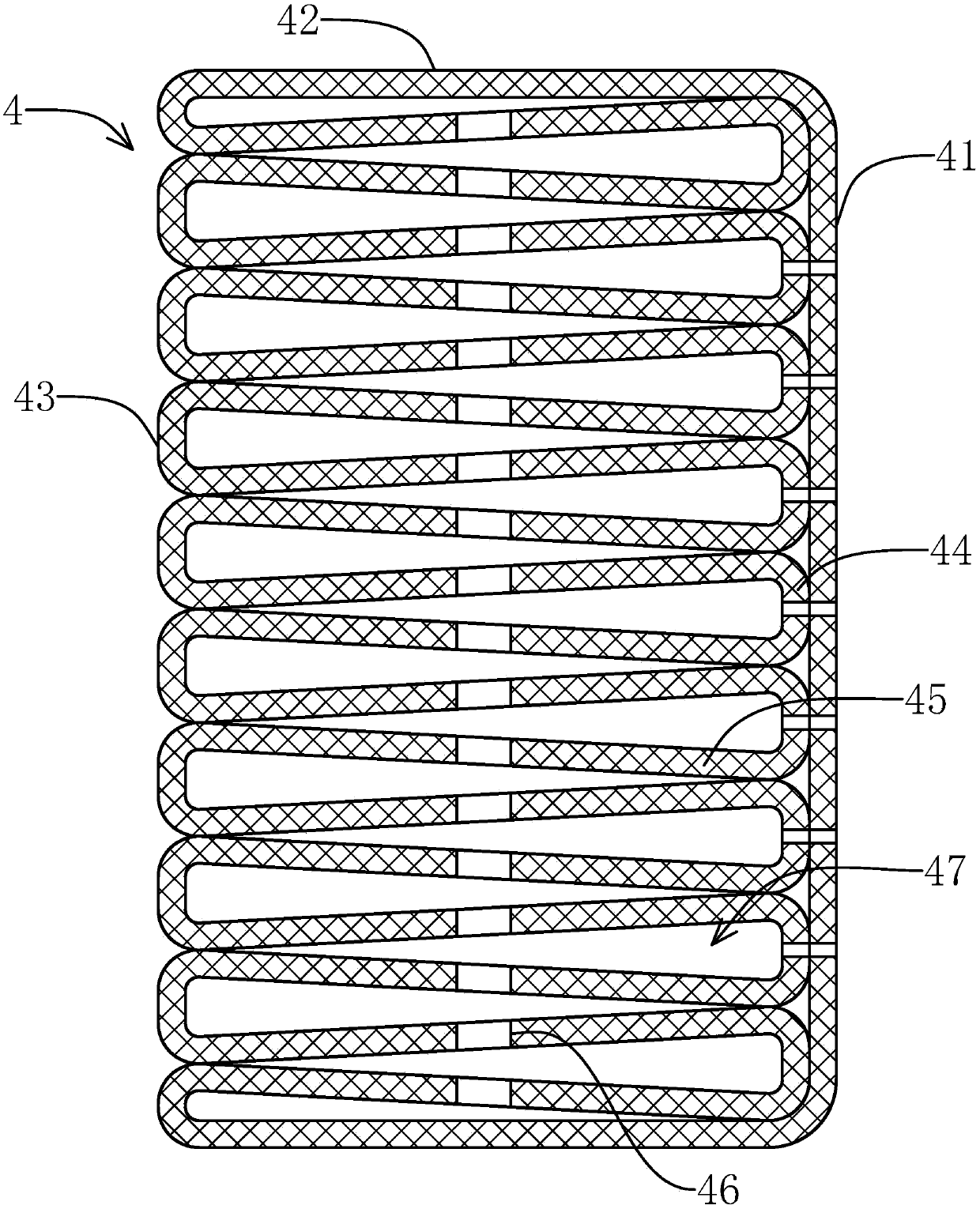

The invention provides a stable beam-column connecting structure and a mounting method thereof, and belongs to the field of steel structures. The problem that the existing beam-column connecting strength is low is solved. The stable beam-column connecting structure comprises a column body and bema bodies, the column body is internally provided with a hollow circular tube center tube, a plurality of connecting joints are arranged on the column body and the center tube, each connecting joint comprises two connecting pieces sleeving the center tube, and each connecting piece comprises a circular-sleeve-shaped connecting sleeve sleeving the outer side of the center tube in a matched mode, and further comprises an inner connecting plate and an outer connecting plate, the inner edges of the inner connecting plates and the inner edges of the outer connecting plates are fixed to the outer walls of the two ends of the connecting sleeve correspondingly, the outer edges of the inner connecting plates and the outer edges of the outer connecting plates are connected with the inner wall of the column body, a circular-ring-shaped main grouting cavity which is coaxial with the column body is formed by the connecting pieces and the column body in a defined mode, the column body is provided with a plurality of outer supporting holes, and an inner supporting hole is formed in the center tube; andthe stable beam-column connecting structure further comprises reinforcing seats located in the center tube, and the reinforcing seat is arranged between the every two adjacent connecting joints. According to the stable beam-column connecting structure, the beam-column connecting strength and stability can be improved.

Owner:台州航权机械科技有限公司

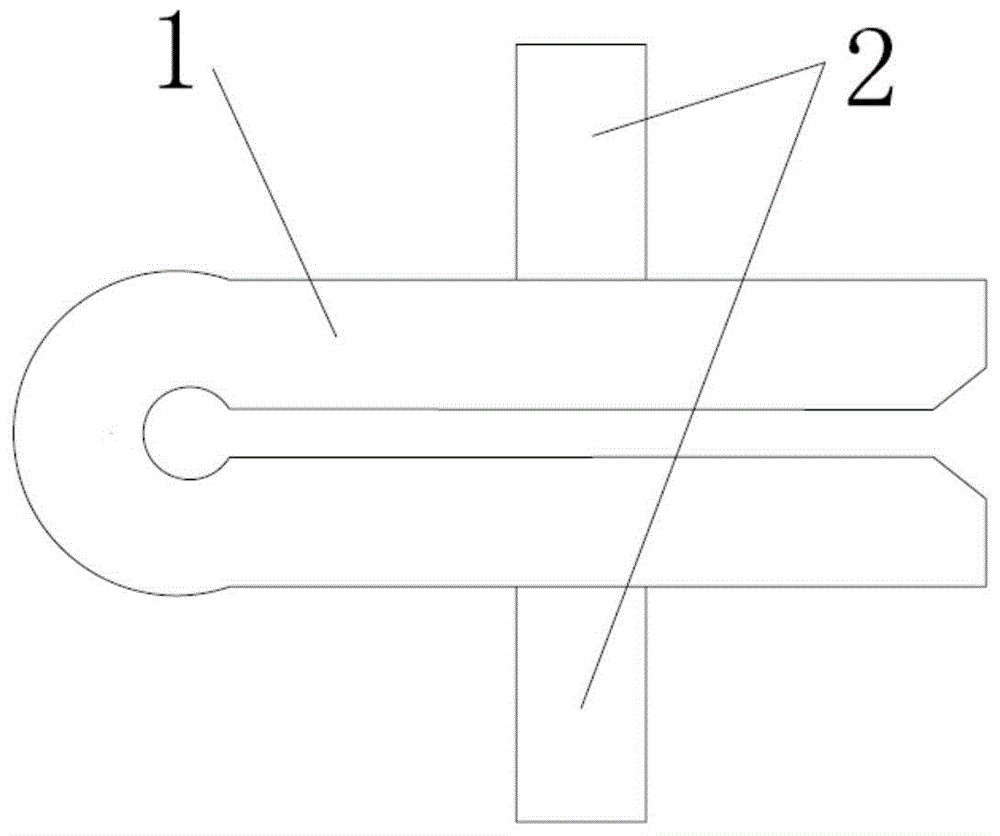

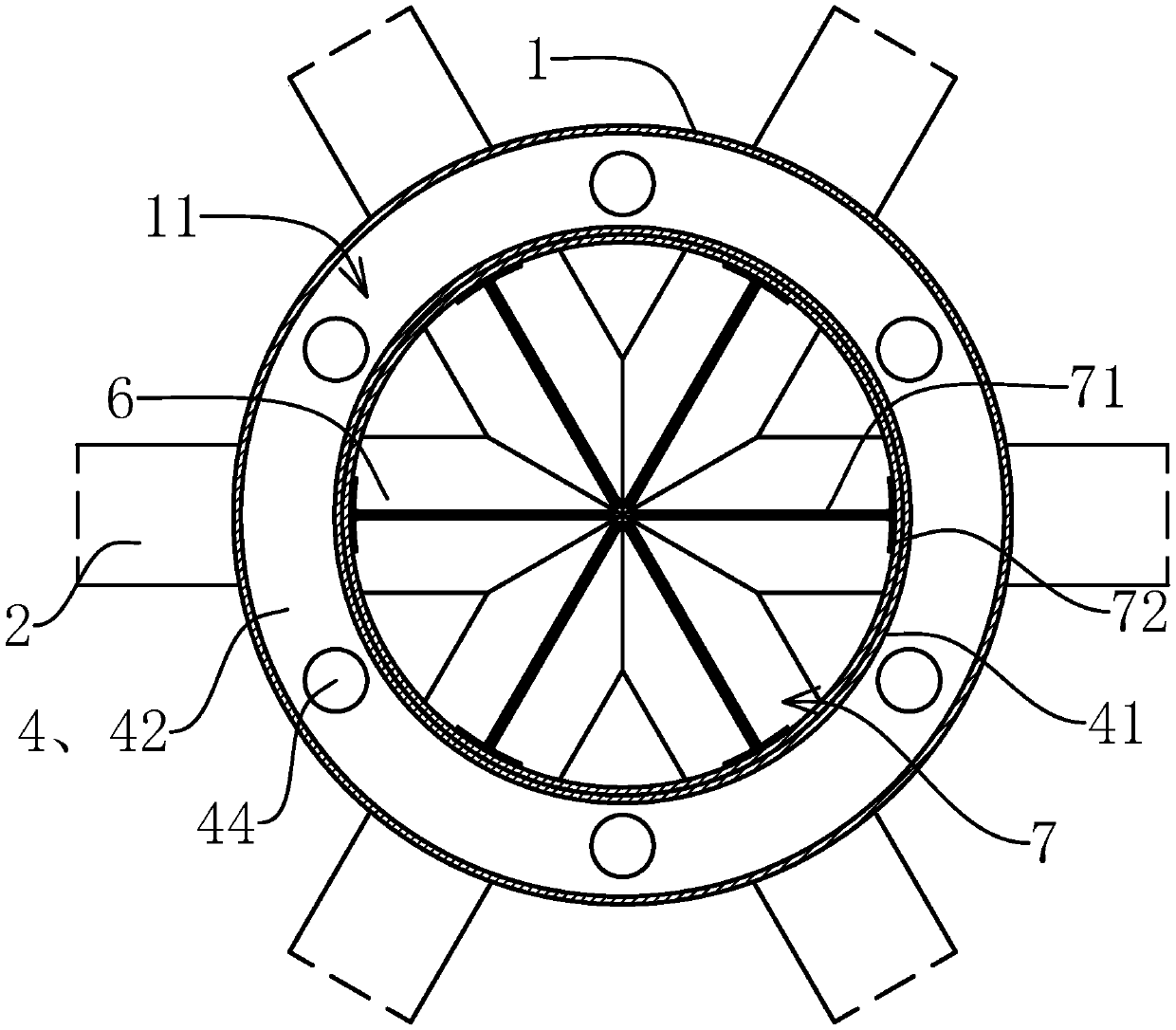

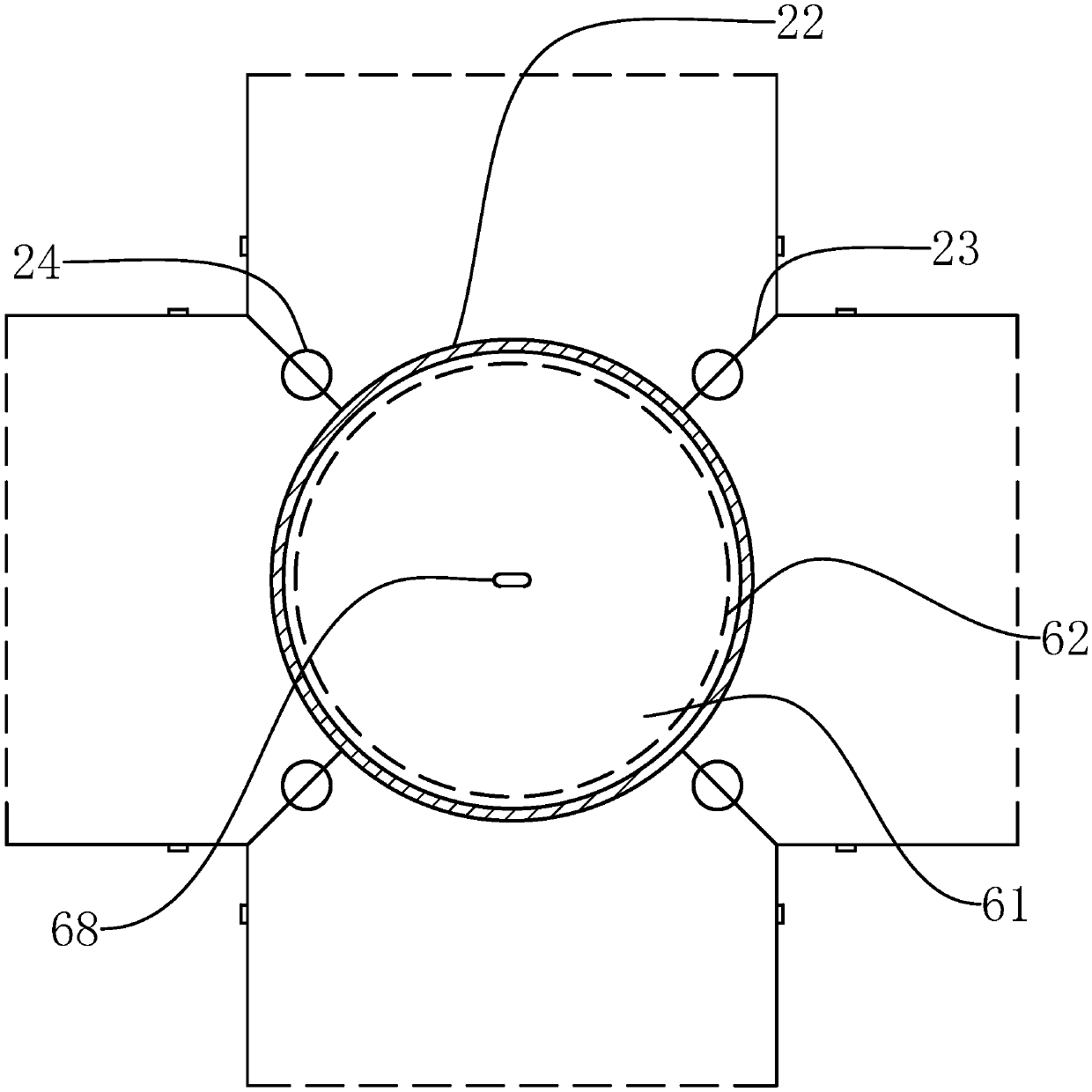

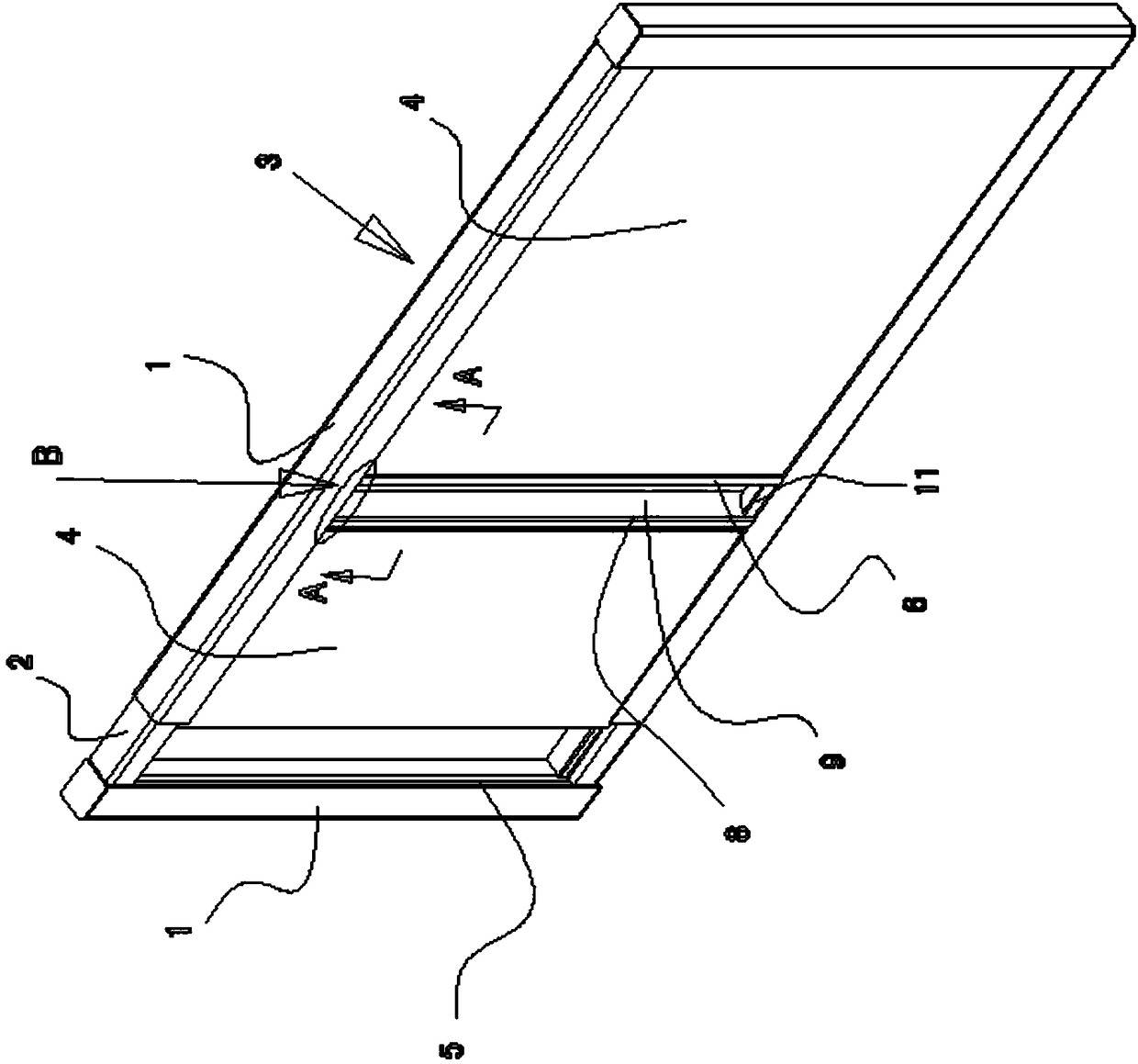

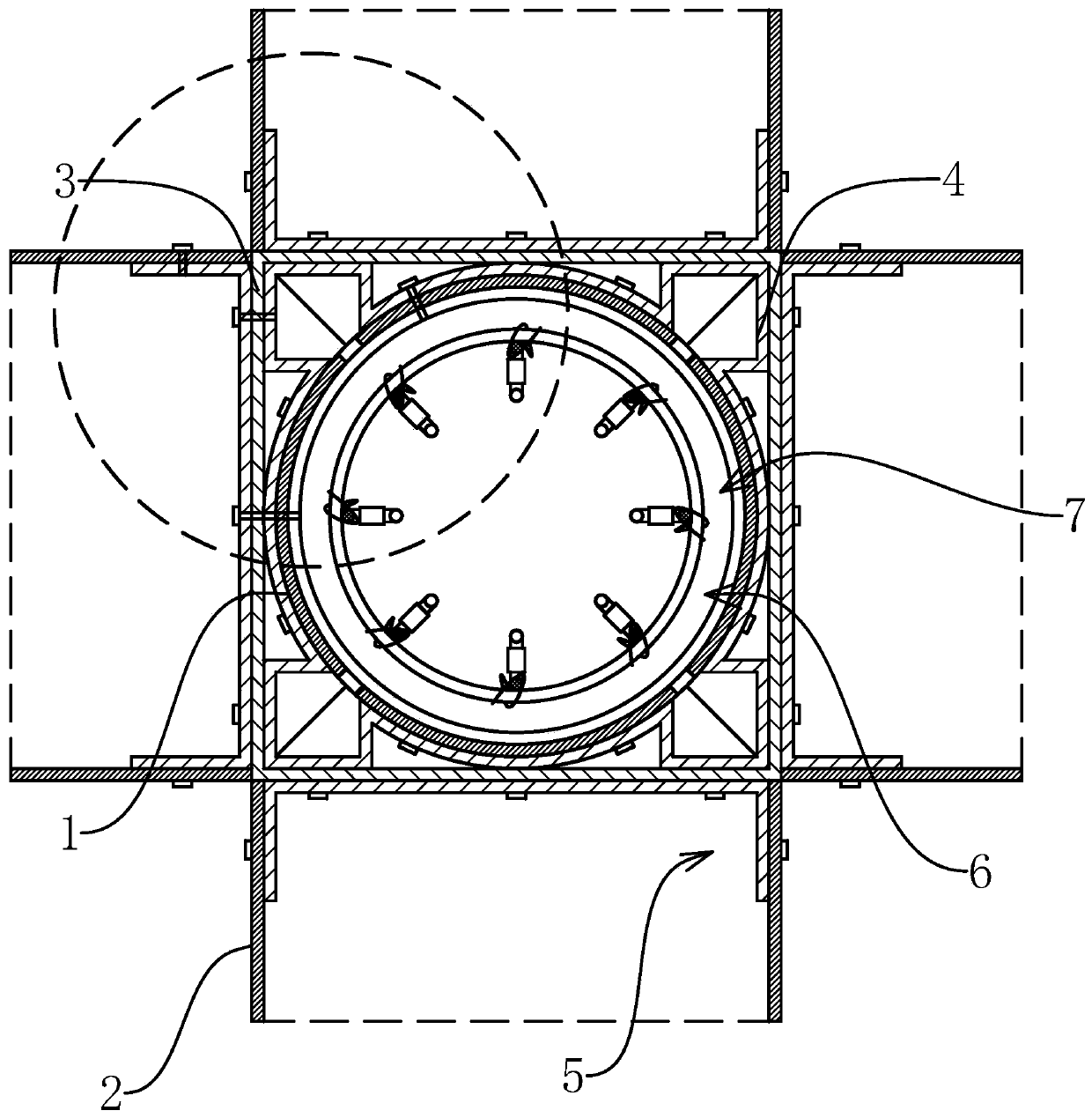

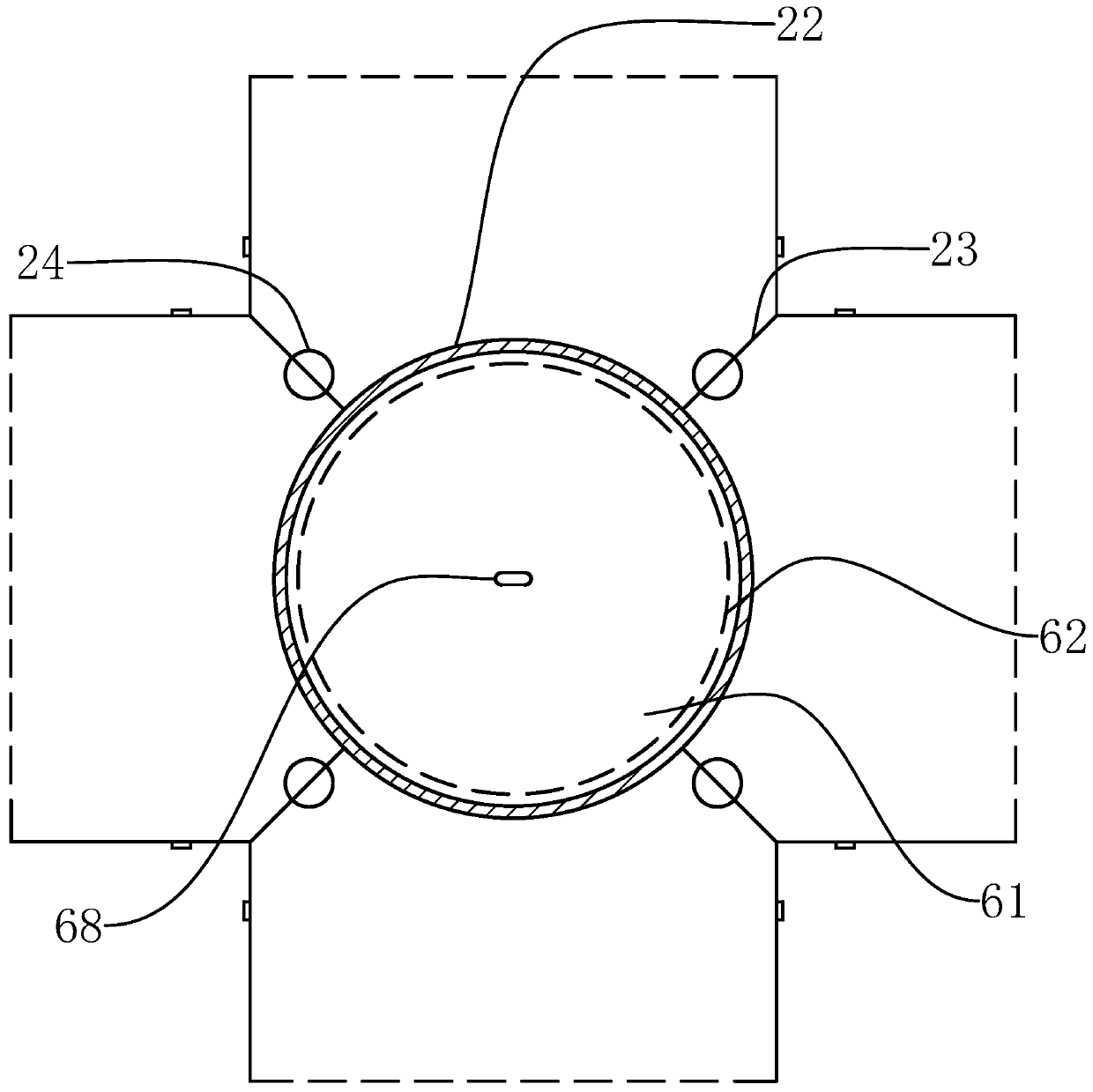

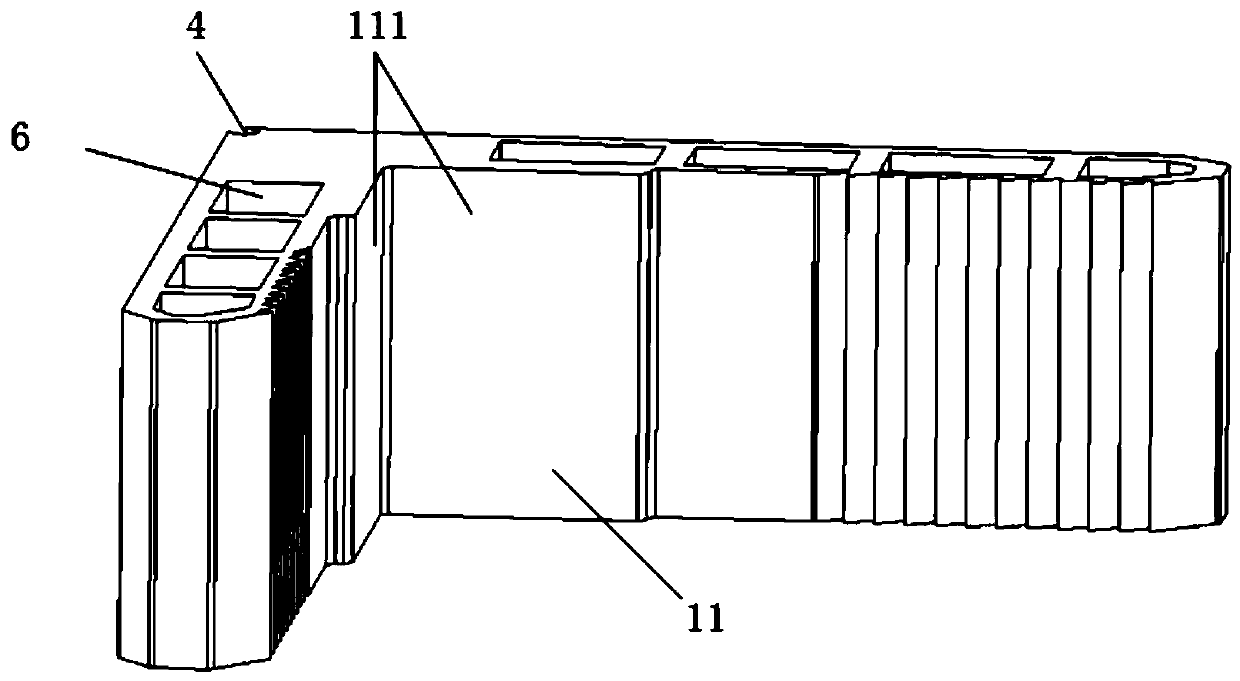

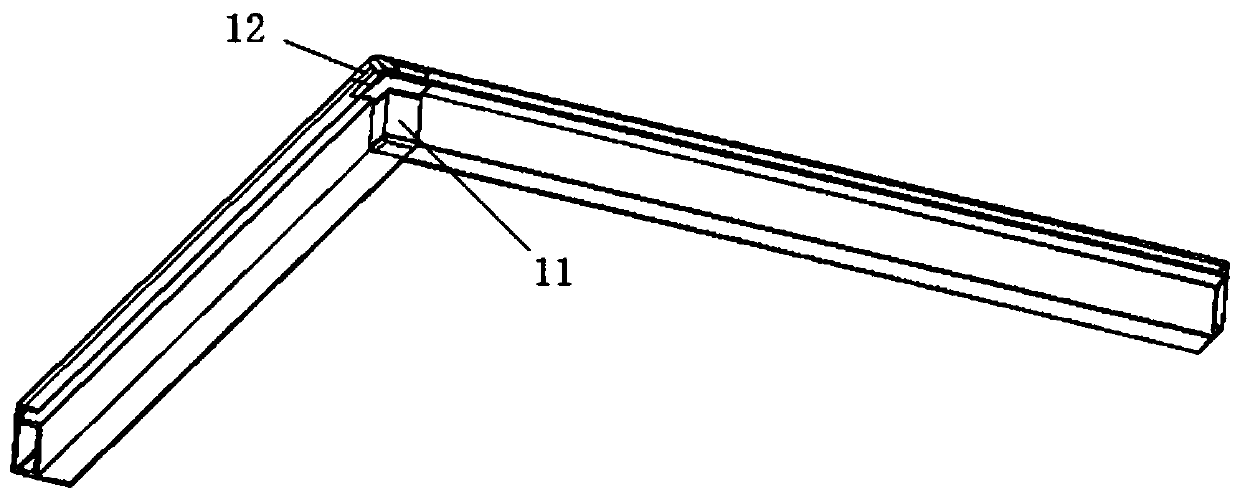

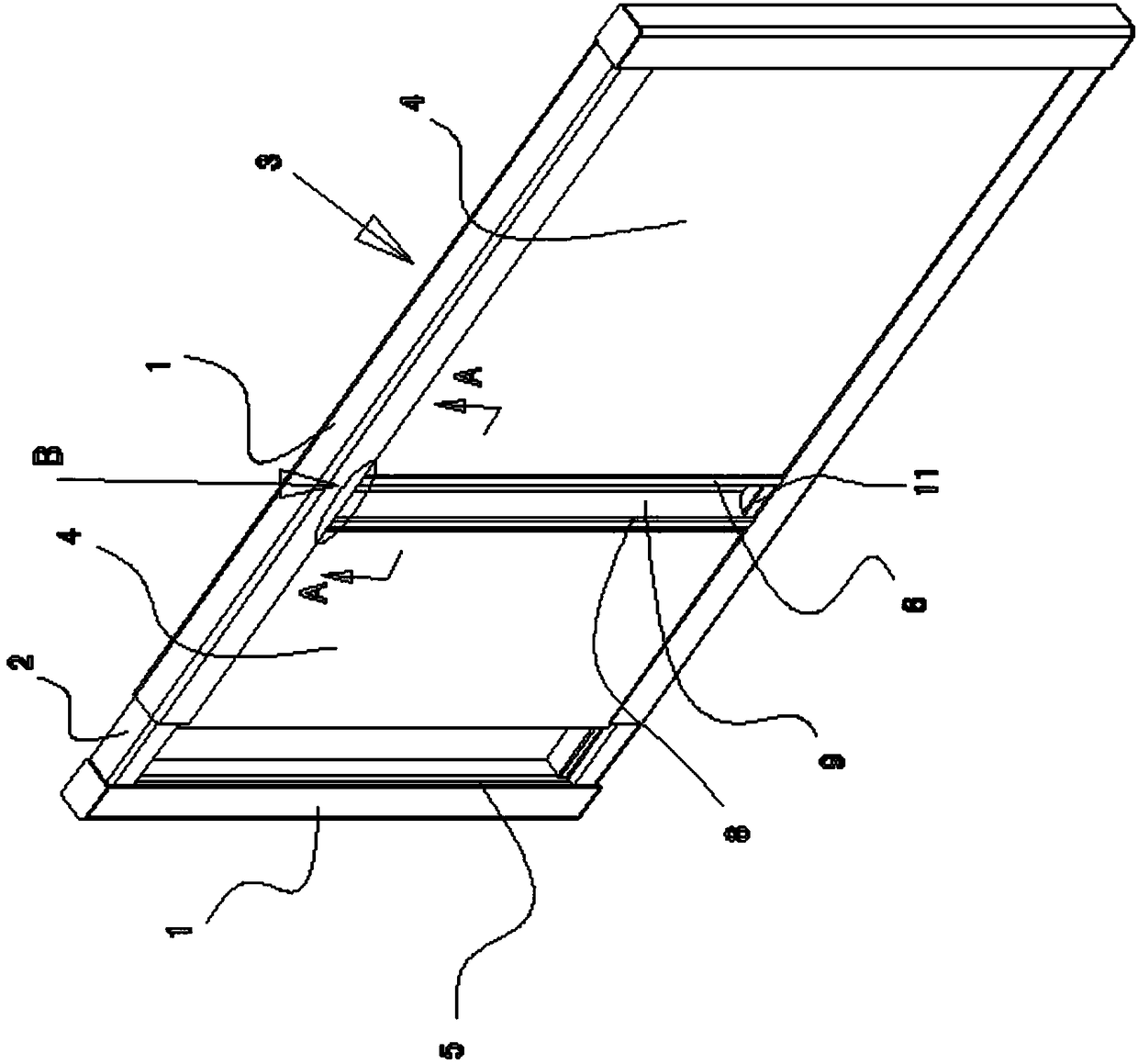

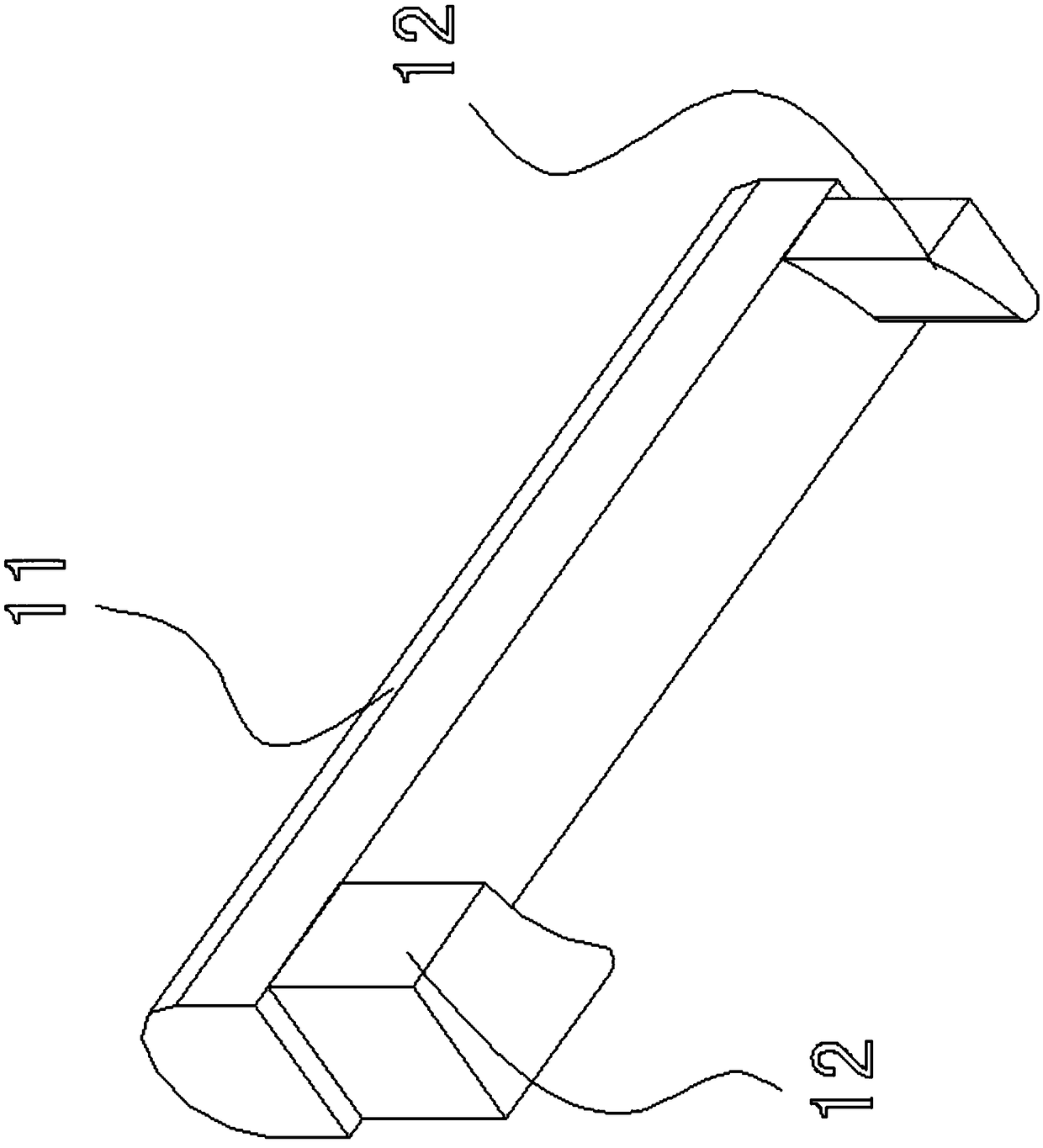

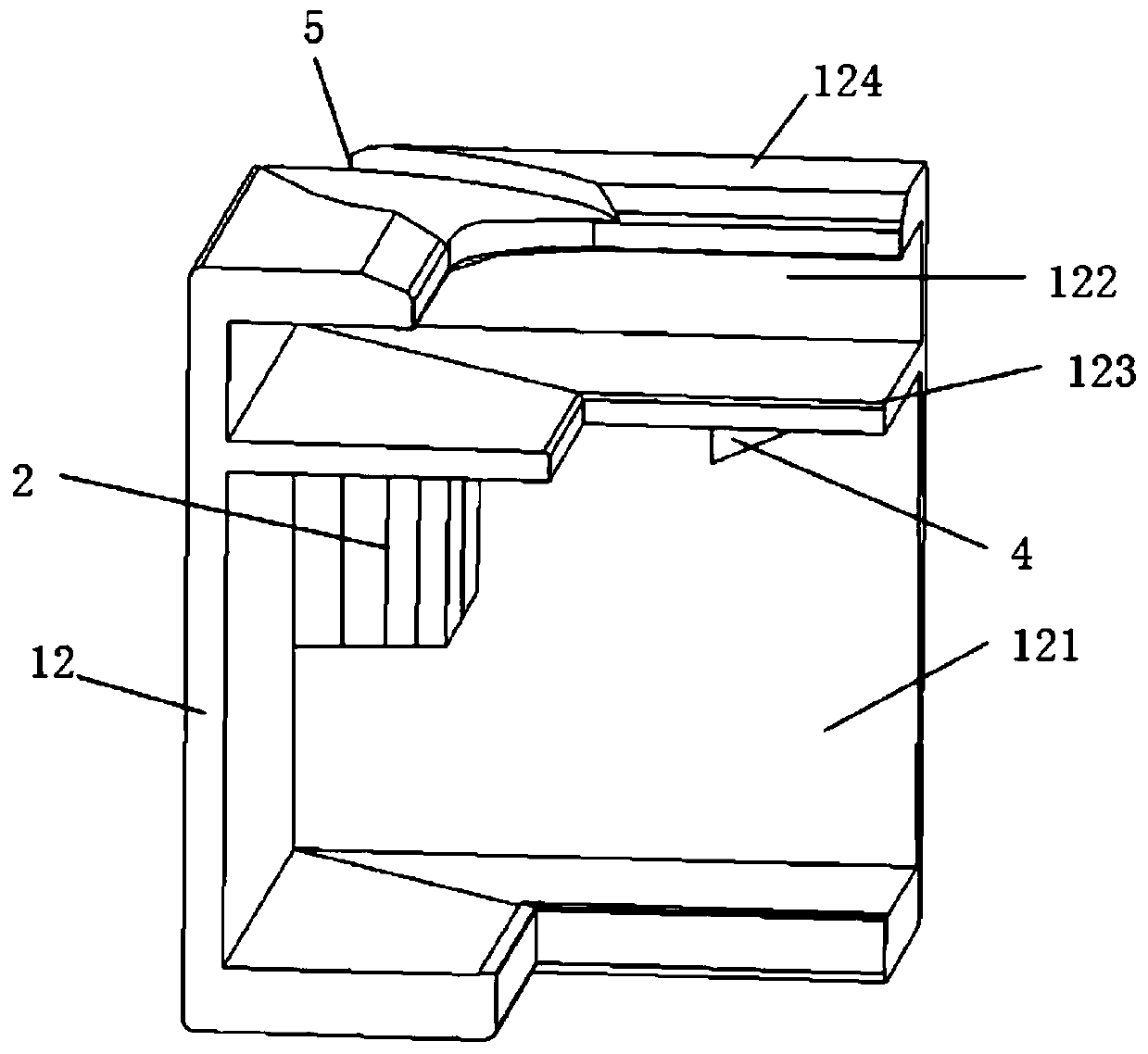

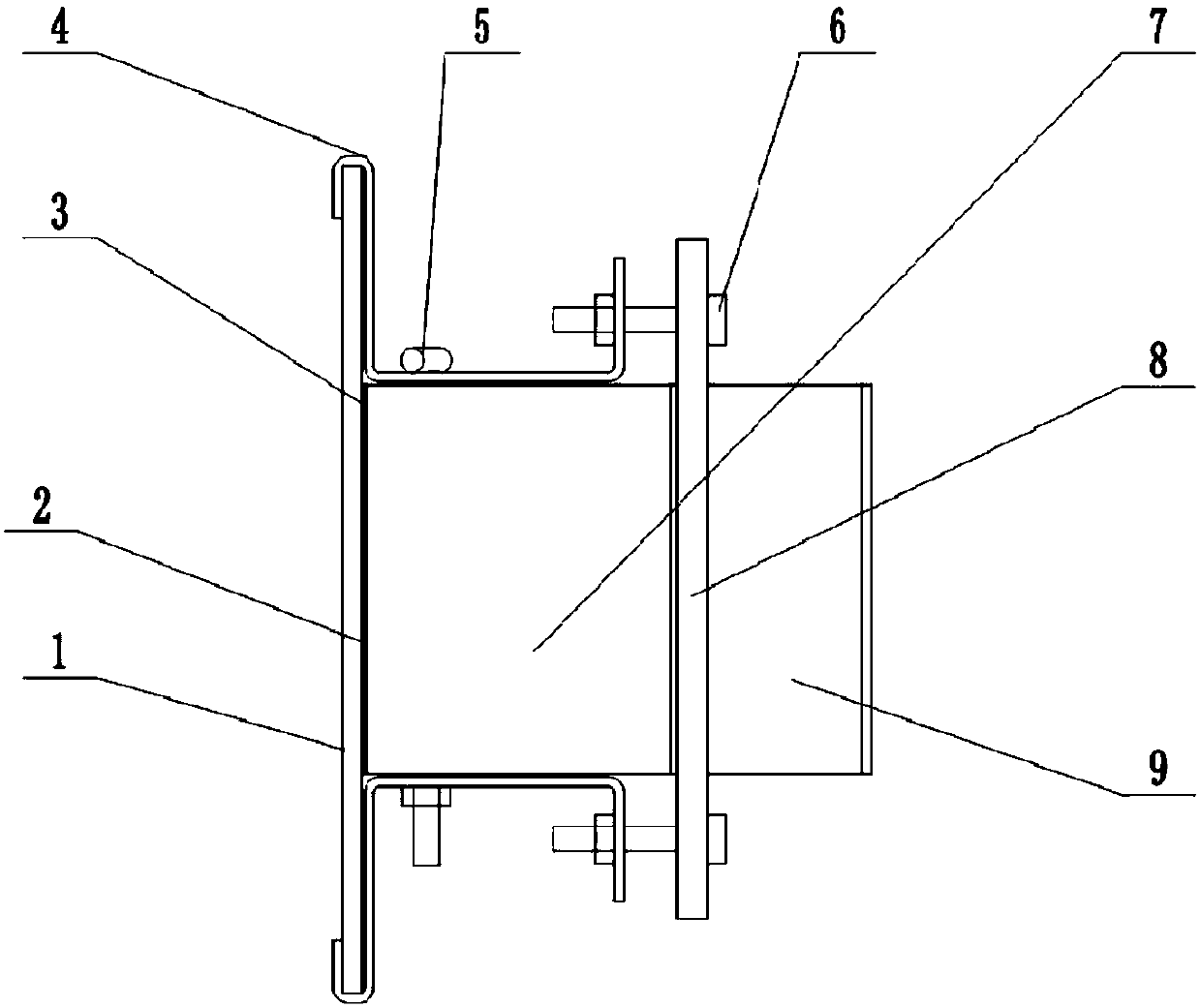

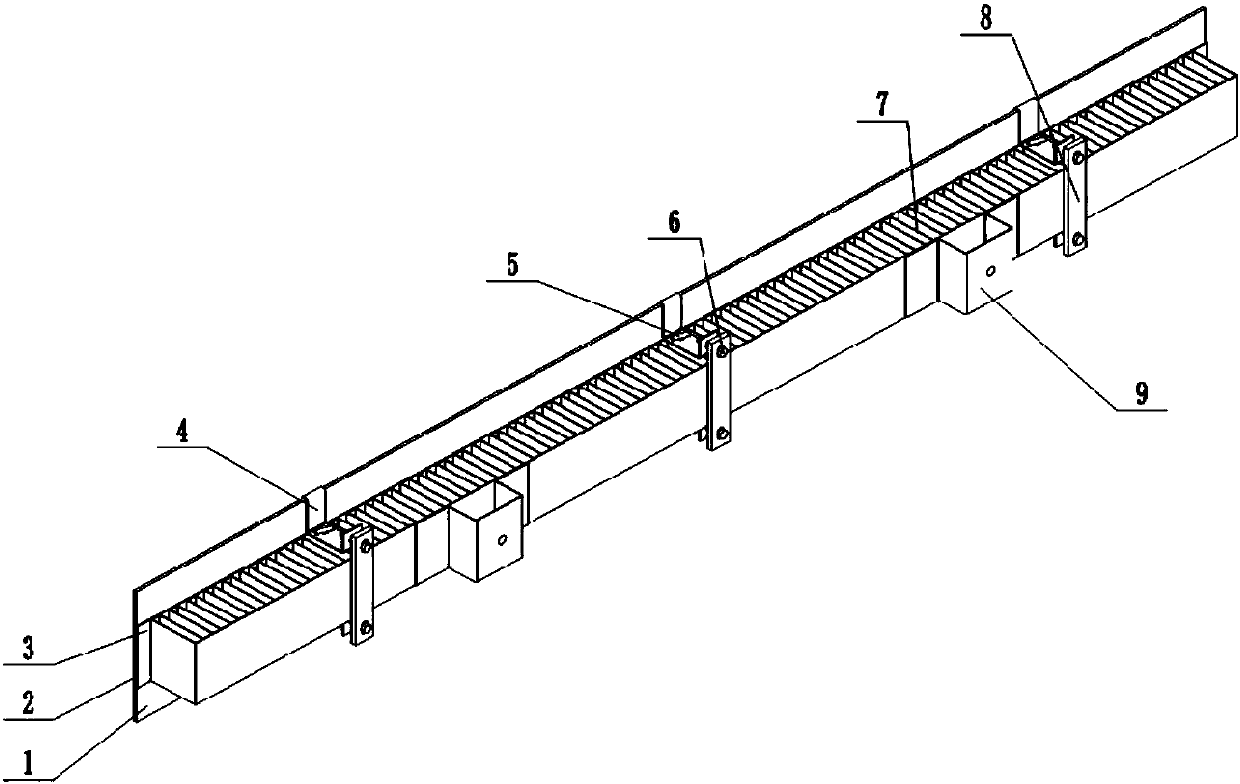

Beam-column joint structure and mounting method thereof

ActiveCN109610652AImprove connection stabilityImprove connection strengthBuilding constructionsEngineeringBeam column

The invention provides a beam-column joint structure and a mounting method thereof, and belongs to the field of steel structures. The problem that the existing beam-column connecting strength is low is solved. The beam-column joint structure comprises a column body and four beam bodies, the column body is a circular tube, and the beam bodies are square tubes; the beam-column joint structure further comprises square tube connecting tubes, the connecting tubes sleeve the outer side of the column body and are connected with the column body through connecting pieces, each connecting tube comprisesfour connecting plates, the connecting pieces are formed in an integrated bending mode and each comprises four internal-connecting plates and four corner connection pieces, and each corner connectionpiece comprises two connection plates and two external-connecting plates; the beam-column joint structure further comprises four steel channel connecting seats, and each connecting seat comprises a bottom plate and two side plates; the beam-column joint structure further comprises a pouring seat located in the column body, the pouring seat comprises an upper baffle and a lower baffle, the upper baffle and the lower baffle are connected through a reinforcement cage, and an upper connecting ring and a lower connecting ring are fixed to the bottom face of the upper baffle and the top face of thelower baffle correspondingly; and the four beam bodies sleeve the four connecting seats in a matched mode. According to the beam-column joint structure, the beam-column connecting strength and stability can be improved.

Owner:台州航权机械科技有限公司

Manufacturing method of outer wall heat-preservation decorating plate with vacuum heat-insulation function

InactiveCN108222397AImprove standardizationImprove aestheticsCovering/liningsFlooringCalcium silicateLacquer

The invention discloses a manufacturing method of an outer wall heat-preservation decorating plate with a vacuum heat-insulation function and further provides a flame-retardant material. The manufacturing method comprises two procedures, namely the primer line processing technical procedure and the finishing coat line roller-coating technical procedure. The primer line processing technical procedure comprises the specific steps that 1, constant-thickness sanding and dust removing are conducted; 2, roller-coating of back surface seal coat is conducted, and the back surface seal coat is cured into a first UV seal coat layer; 3, roller-coating of ultraviolet (UV) penetrating agents is conducted for two times; 4, infrared leveling is conducted; 5, the front surface is coated with UV putty, andUV curing is conducted to generate a UV putty layer; 6, roller-coating of the UV seal coat is conducted for three times, and the UV seal coat is cured to generate three second UV seal coat layers; and 7, fine sanding is conducted. The finishing coat line roller-coating technical procedure comprises the specific steps that 1, dust removing is conducted; 2, roller-coating of UV glue is conducted togenerate a first UV glue layer; and 3, UV finishing coat is smeared for five times and cured to generate five UV finishing coat layers. According to the manufacturing method of the outer wall heat-preservation decorating plate with the vacuum heat-insulation function, strong, rapid and deep permeation of UV curing penetrating agents and a fiber-reinforced calcium silicate plate or a fiber cementplate can be achieved, deep curing film-forming is achieved, the UV curing penetrating agents, the UV putty and the UV seal coat form a stereo chemical net-shaped cross-linking reaction, and the adhesive force problem of a decorating face layer and a base plate can be solved. The gluing property of the flame-retardant decorating plate prepared through the manufacturing method meets the national standard requirement, and a base material has the flame-retardant property; the mechanical property of the base material is not affected, the formaldehyde emission is also in the grade E1 or above, andthus safety and environmental protection are achieved; and meanwhile, the natural texture of wood is kept, and the decorating effect is good.

Owner:李石燕

Outer wall heat-insulating decoration plate structure

InactiveCN108252470AEliminate hot and cold bridge phenomenonImproving the thermal insulation and decoration structure of the external wallCovering/liningsCalcium silicateKeel

The invention relates to a decoration structure, in particular to an outer wall heat-insulating decoration plate structure for a building outer wall, a vehicle-ship outer wall and the like, and further provides a fire retardant material. The outer wall heat-insulating decoration plate structure comprises a base layer wall body, a keel, fixing screws and a heat-insulating decoration plate, the heat-insulating decoration plate is attached to the base layer wall body, and the other side of the heat-insulating decoration plate is fixedly connected with the keel. The outer wall heat-insulating decoration plate structure is an environment-friendly heat-insulating decoration composite plate which has excellent performance of high pressure resistance, non-water-absorbing performance, damp proofing, airtighness, small weight, corrosion resistance, long service life, low heat conduction coefficient and the like. According to the outer wall heat-insulating decoration plate structure, the problemsof strong, rapid and deep permeation of an ultraviolet photocuring permeating agent and a fiber reinforced calcium silicate plate or a fiber cement plate can be solved, the deep layer is solidified into films and can form a three-dimensional chemical net-shaped cross-linking reaction with UV putty and UV closed paint, and the problem of adhesive force of a decoration face layer and a base plate can be solved. The bonding performance of a fire retardant decoration plate prepared through the method meets the national standard requirement, and a base material has fire retardant performance; themechanical performance of the base material is not affected, the releasing quantity of formaldehyde reaches the grade E1 or above, and safety and environment protection are achieved; and meanwhile, the natural texture of woods is kept, and the decoration effect is good.

Owner:肖群伟

External wall fireproof flame-retardant composite heat-insulating decorative plate and preparation method thereof

InactiveCN108612279AIncrease packing densityHigh tensile strengthCovering/liningsSynthetic resin layered productsThermal insulationPolystyrene

The invention relates to an external wall fireproof flame-retardant composite heat-insulating decorative plate, comprising a water-soluble non-combustible ceramic protective layer, an organic-inorganic composite toughening layer and a flame-retardant thermal insulation layer. The organic-inorganic composite toughening layer is flame-retardant thermal insulation type polymer mortar, and has the following components: a cementitious material S, ceramic microbeads, hydroxyethyl methylcellulose, redispersible latex powders, limestone powders and modified expandable graphite. Components of the flame-retardant thermal insulation layer are: modified expandable polystyrene and modified expandable graphite. The flame-retardant heat-insulating plate is mounted on a wall surface by bonding and anchoring. Bonding performance of the flame-retardant decorative plate prepared by the method of the invention meets requirements of national standards and flame retardant properties are given to a base material. Furthermore, mechanical properties of the base material would not be influenced, and formaldehyde emission is above an E1 level, the decorative plate is safe and environmental-friendly. At the same time, natural texture of timber is maintained and decorative effect is good.

Owner:肖群伟

Outer wall heat-preservation decorative board structure

InactiveCN108729610AEliminate hot and cold bridge phenomenonImproving the thermal insulation and decoration structure of the external wallCovering/liningsPretreated surfacesEnvironmental resistanceCalcium silicate

The invention relates to a decorative structure, in particular to an outer wall heat-preservation decorative board structure used for outer walls of buildings, outer walls of cars and ships and the like. The outer wall heat-preservation decorative board structure comprises a base wall body, keels, fixing screws and heat-preservation decorative boards, the heat-preservation decorative boards are bonded to the base wall body, and the keels are fixedly connected to the other faces of the heat-preservation decorative boards; the outer wall heat-preservation decorative board structure is an environment-friendly heat-preservation composite board which has excellent performance such as great pressure resistance, a good water insulation effect, good moisture resistance, high air impermeability, light weight, excellent corrosion resistance, a long service life and low heat conductivity coefficients. The outer wall heat-preservation decorative board structure can solve the problems of high permeability, rapid permeability and deep permeability of ultraviolet-curable permeating agents and fiber-reinforced calcium silicate boards or fiber cement boards, is deeply solidified into membranes, undergoes a stereoscopic chemical network cross-linking reaction with UV putty and UV sealing paint and can solve the problem of an adhesion force of decorative surface layer and base plates. A flame-retardant material is also provided. The gluing performance of a flame-retardant decorative board prepared by a method meets the requirements of national standards, and a substrate has flame-retardant performance; furthermore, the mechanical performance of the substrate is not influenced, the emission amount of formaldehyde is also above the E1 level, and safety and environmental protection are achieved. At the same time, the natural texture of wood materials is maintained, and the decorative effect is good.

Owner:肖挺超

Production process for novel UV decorative plate

InactiveCN109107849AProduct quality is stableGood insulation performanceCovering/liningsPretreated surfacesChemical networkLacquer

The invention discloses a production process for a novel UV decorative plate. The production process includes two flows. Specific steps of each of the flows are as follows: I. a process flow of primerline processing: namely a step of (1) flatly sanding by using a sanding machine and removing dust, (2) roller painting back seal coat and solidifying into a first UV seal coat layer, (3) roller painting an UV penetrant twice, (4) performing infrared levelling, (5) front coating UV putty and performing UV curing to form an UV putty layer, (6) roller painting UV seal coat three times and respectively curing to form three layers of second UV seal coat layers, and (7) performing fine sanding; and II. a process flow of roller painting finish paint lines: namely a step of (1) removing the dust, (2)roller painting UV glue to form a first UV glue layer, and (3) painting UV finish coat five times and curing to form five layers of UV finish coat layers. The production process can solve problems that strong penetration, rapid penetration, deep penetration and deep curing into film of UV curing penetrants and fiber-reinforced calcium silicate boards or fiber cement boards, and a three-dimensional chemical network cross-linking reaction with the UV putty and the UV seal coat is formed, and can solve the problem of adhesion of a decorative surface layer and a substrate.

Owner:刘宇鹏

Energy-saving thermal insulation anti-seismic integrated wallboard

InactiveCN108240086AImprove standardizationImprove aestheticsCovering/liningsFlooringCalcium silicateInsulation layer

The invention discloses an energy-saving thermal insulation anti-seismic integrated wallboard. A decorative board is a multi-layer composite board, a surface layer is a fluorocarbon paint, a middle layer is a calcium silicate board, an inner layer is an insulation layer, and the insulation layer is sandwiched by a thin plate. The thin plate is an environment-friendly thermal insulation decorativecomposite board with high compression resistance, no water absorption, moisture resistance, air resistance, light weight, corrosion resistance, long service life and low thermal conductivity and the like. An uv-curable penetrating agent and a fiber reinforced calcium silicate board or a fiber cement with strong penetration, rapid infiltration, deep penetration, deep curing film can be solved, anda three-dimensional chemical network crosslinking reaction can be formed with an UV putty, an UV sealing paint. The adhesion problem of a decorative surface layer and the base plate can also be solved. The invention also provides a flame retardant material. Adhesion properties of an anti-flaming decorative board prepared by the method of the composite exterior decorative panels meet the requirements of the national standard and gives the base material the flame-retardant property; moreover, mechanical properties of the base material can not be influenced, and the formaldehyde emission is alsoabove E1 level, is safe and environmentally-friendly. At the same time, the natural texture of wood is kept, and decorative effect is good.

Owner:周金妹

Ceramic composite coating

InactiveCN101306594AAvoid aging and sheddingAvoid stickingCeramic layered productsFlat articlesCeramic compositeCorona discharge

The invention relates to a coat which coats the surface of a roller core of a plastic filming-drawing mechanism corona-discharge roller made of metal or other materials. The coat coats the surface of the roller core of the plastic filming-drawing mechanism corona-discharge roller; therefore, the high-voltage corona can be borne on one hand, and a plastic film is prevented from bonding to the surface of adiabatic ceramic materials on the other hand. Compared with the ceramic coat which adopts the traditional technique, the ceramic composite coat of the invention can prevent the plastic film from bonding to the surface of the adiabatic ceramic materials.

Owner:郑效慈

Method for preparing graphene composite anti-attrition metal material by adopting SLM technology

PendingCN113814415AImprove wear resistanceIncreased durabilityAdditive manufacturing apparatusIncreasing energy efficiencyMetallic materialsWaste product

The invention discloses a method for preparing a graphene composite anti-attrition metal material through an SLM technology. The method comprises the following steps that alloy powder with the particle size ranging from 20 micrometers to 50 micrometers is selected for later use; graphene is ground into powder, and then large particles are removed; alloy powder and graphene powder are added into the mixed powder to be mixed, and blended powder is formed; a program file and forming process parameters of SLM equipment are determined; and the blended powder is evenly spread on a working platform of the SLM equipment, selective melting is started through the SLM equipment according to the program file and the forming process parameters imported into the SLM equipment, after each layer of blended powder is subjected to selective melting, the next layer of blended powder is laid, selective melting continues, and the process is repeated till the anti-attrition metal material is stacked and formed. The anti-attrition metal material is formed at a time, the process is simplified, meanwhile, the yield of the material is increased, and waste products such as cracks of the material in the machining process are avoided.

Owner:SPECIAL EQUIP SAFETY SUPERVISION INSPECTION INST OF JIANGSU PROVINCE

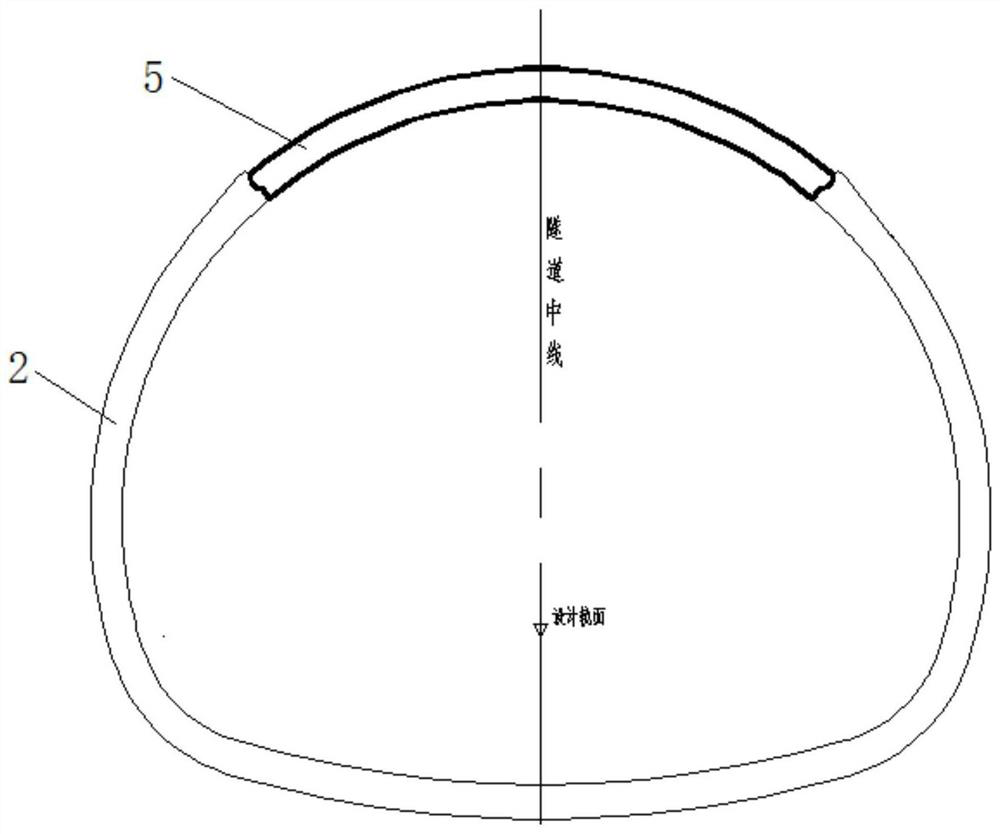

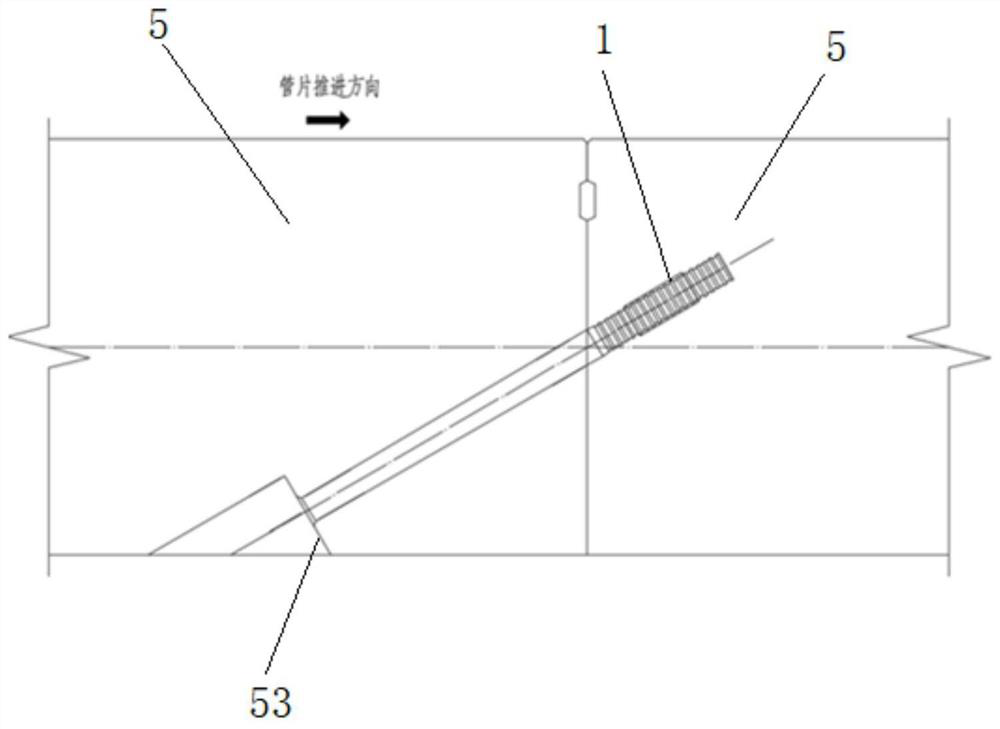

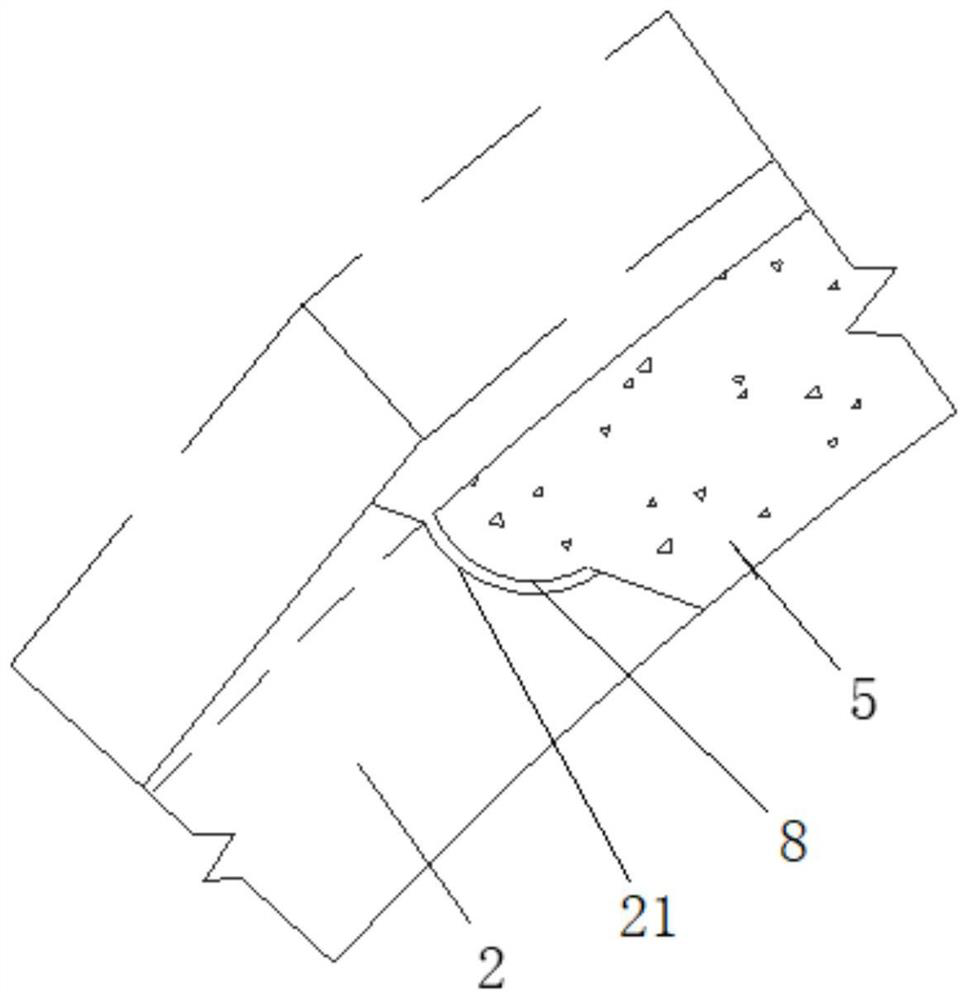

Tunnel arch prefabricated segment assembling construction method

PendingCN113374504AAvoid the risk of falling off and collapsingFast constructionUnderground chambersTunnel liningArchitectural engineeringLap joint

The invention discloses a tunnel arch prefabricated segment assembling construction method. The method comprises the steps that A, arch prefabricated segment reinforcement cage binding construction is conducted on a prefabrication yard outside a tunnel hole; B, arch prefabricated segments are poured and formed; C, after the arch prefabricated segments are prefabricated, grouped mounting is conducted in the mode that jacking is conducted firstly and then longitudinal sliding is conducted; and D, every 5-6 arch prefabricated segments form a group, after one group is mounted, arch back grouting and arch prefabricated segment and side wall joint grouting are conducted, and all bolts in bolt sinking tables are dismounted after grouting is completed. The tunnel arch prefabricated segment assembling construction method is applied to tunnel assembling type lining construction, the effect that arch prefabricated segment construction is safe and stable is ensured, and accurate lap joint with a cast-in-place side wall can be achieved.

Owner:中铁隧道集团一处有限公司 +2

A beam-column joint structure and its installation method

ActiveCN109610652BImprove connection stabilityImprove connection strengthBuilding constructionsEngineeringRebar

The invention provides a beam-column joint structure and a mounting method thereof, and belongs to the field of steel structures. The problem that the existing beam-column connecting strength is low is solved. The beam-column joint structure comprises a column body and four beam bodies, the column body is a circular tube, and the beam bodies are square tubes; the beam-column joint structure further comprises square tube connecting tubes, the connecting tubes sleeve the outer side of the column body and are connected with the column body through connecting pieces, each connecting tube comprisesfour connecting plates, the connecting pieces are formed in an integrated bending mode and each comprises four internal-connecting plates and four corner connection pieces, and each corner connectionpiece comprises two connection plates and two external-connecting plates; the beam-column joint structure further comprises four steel channel connecting seats, and each connecting seat comprises a bottom plate and two side plates; the beam-column joint structure further comprises a pouring seat located in the column body, the pouring seat comprises an upper baffle and a lower baffle, the upper baffle and the lower baffle are connected through a reinforcement cage, and an upper connecting ring and a lower connecting ring are fixed to the bottom face of the upper baffle and the top face of thelower baffle correspondingly; and the four beam bodies sleeve the four connecting seats in a matched mode. According to the beam-column joint structure, the beam-column connecting strength and stability can be improved.

Owner:湖北嘉美宜居绿色建筑材料有限公司

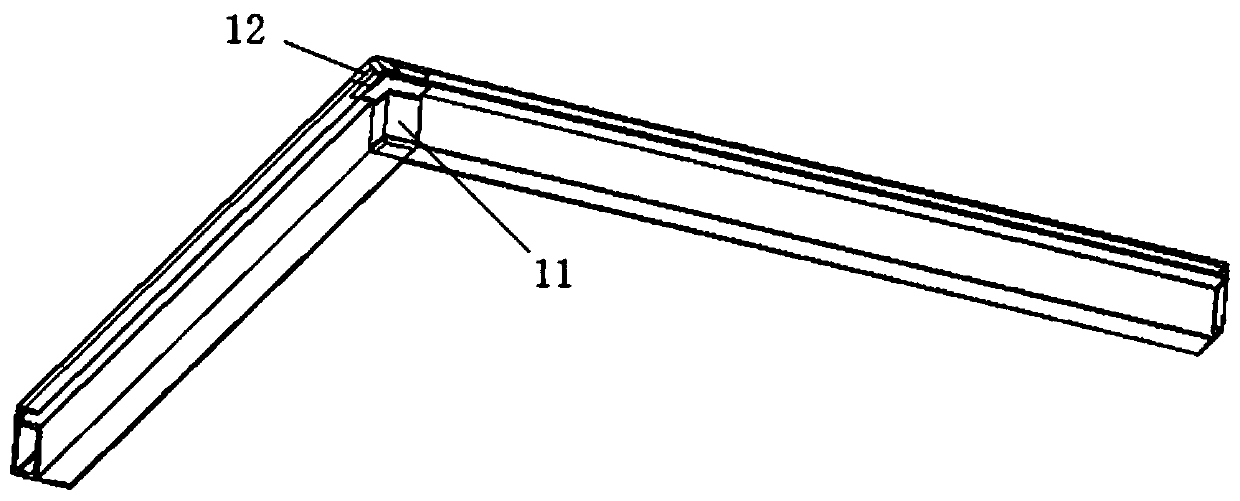

Corner piece for photovoltaic module

PendingCN110562598AEasy to get stuckFastening integration with high strengthClosuresEngineeringMechanical engineering

Owner:PERLIGHT SOLAR

Exterior wall heat-preservation decorative plate structure

InactiveCN108252467AEliminate hot and cold bridge phenomenonImproving the thermal insulation and decoration structure of the external wallCovering/liningsFlooringCalcium silicateKeel

The invention relates to a decorative structure, in particular to an exterior wall heat-preservation decorative plate structure used for exterior walls of buildings, external walls of vehicles and ships, and the like. The exterior wall heat-preservation decorative plate structure comprises a basic layer wall, a keel, a fixing screw and a heat-preservation decorative plate; the heat-preservation decorative plate is attached to the basic layer wall, and the other face of the heat-preservation decorative plate is fixedly connected with the keel. An environment-friendly heat-preservation decorative composite plate has the excellent properties that the compression resistance is high, the non-water-absorbent, moistureproof, airtight, lightweight and corrosion resistant effects are achieved, theservice life is long, and the heat conductivity is low. According to the environment-friendly heat-preservation decorative composite plate, the problems of high penetration, quick penetration and deep-layer penetration of an ultraviolet light curing penetrant and a fiber-reinforced calcium silicate plate or a fiber cement plate can be solved, the environment-friendly heat-preservation decorative composite plate is deeply cured into a film, the environment-friendly heat-preservation decorative composite plate, UV putty and UV sealed paint form a three-dimensional chemical network crosslinking reaction, and the problem of adhesive force of a decorative face layer and a base plate can be solved. The invention further provides a flame-retardant material. The gluing property of the flame-retardant decorative plate prepared through the method can meet the national standard requirement, and a flame-retardant property is given to a basic material; the mechanical property of the basic materialis not affected, the formaldehyde releasing amount is also the E1 level or above, and the safe and environment-friendly effects are achieved; and meanwhile, the natural texture of wood is kept, and the decorative effect is good.

Owner:秦春玉

Wiring method capable of protecting connectors of two sections of household wires against short circuits

InactiveCN107994356AAvoid electric shockAvoid aging and sheddingLine/current collector detailsConnections effected by permanent deformationCopperElectric shock

The invention provides a wiring method capable of protecting connectors of two sections of household wires against short circuits. The method includes the steps that two electric wires in one sectionof wire I are sheared into a long electric wire and a short electric wire, insulating skins on connectors of the two electric wires are peeled off, and the front end of a copper core of the short electric wire does not make contact with the tail end of a copper core of the long electric wire; two electric wires in the other section of wire II are sheared into a long electric wire and a short electric wire, insulating skins on connectors of the two electric wires are peeled off, and the front end of a copper core of the short electric wire does not make contact with the tail end of a copper core of the long electric wire; when the connectors of the two sections of wires are wound, the copper core of the short electric wire in the wire I and the copper core of the long electric wire in the wire II are wound; the copper core of the long electric wire in the wire I and the copper core of the short electric wire in the wire II are wound; thus the two connectors do not make contact with eachother; insulating tape is wound around the two connectors; the two connectors are fixedly sleeved with two insulating plastic sleeves respectively. By means of the wiring method, the short circuits of the connectors of the two sections of wires are avoided, and the danger of electric shocks is avoided.

Owner:王嘉伟

Polyvinyl chloride synthetic wood imitating material and preparing method thereof

InactiveCN109129753AImprove standardizationImprove aestheticsPressure wood treatmentWood treatment detailsWood veneerPolyvinyl chloride

The invention provides a polyvinyl chloride synthetic wood imitating material and a preparing method thereof. The polyvinyl chloride synthetic wood imitating material comprises a panel assembly and aninflaming retarding gluing agent layer, wherein the inflaming retarding gluing agent layer is at least attached to the surface of at least one side in the thickness direction of the panel assembly and is formed by a gluing agent containing an inflaming retarding gluing agent. The panel assembly at least comprises a layer of wood veneer. The inflaming retarding gluing agent contains water-solubleamino resin, a dehydrated catalyst, a carbon forming agent and an assistant agent and contains or does not contain water. The dehydrated catalyst is selected from one or more of ammonium polyphosphate, melamine orthophosphate and melamine pyrophosphate. The polymerization degree of the ammonium polyphosphate is 20 or above. The invention further provides an inflaming retarding material. The gluingperformance of the polyvinyl chloride synthetic wood imitating material prepared through the method meets the national standard requirement, and a base material is endowed with the inflaming retarding performance. In addition, the mechanical performance of the base material is not influenced, formaldehyde emission reaches the E1 level or above, and safety and environment friendliness are achieved; and meanwhile, the nature texture of the wood is kept, and the decoration effect is good.

Owner:秦春玉

A stable beam-column connection structure and installation method thereof

ActiveCN109610653BEasy to installImprove vertical bearing capacityBuilding constructionsUltimate tensile strengthMechanical engineering

The invention provides a stable beam-column connecting structure and a mounting method thereof, and belongs to the field of steel structures. The problem that the existing beam-column connecting strength is low is solved. The stable beam-column connecting structure comprises a column body and bema bodies, the column body is internally provided with a hollow circular tube center tube, a plurality of connecting joints are arranged on the column body and the center tube, each connecting joint comprises two connecting pieces sleeving the center tube, and each connecting piece comprises a circular-sleeve-shaped connecting sleeve sleeving the outer side of the center tube in a matched mode, and further comprises an inner connecting plate and an outer connecting plate, the inner edges of the inner connecting plates and the inner edges of the outer connecting plates are fixed to the outer walls of the two ends of the connecting sleeve correspondingly, the outer edges of the inner connecting plates and the outer edges of the outer connecting plates are connected with the inner wall of the column body, a circular-ring-shaped main grouting cavity which is coaxial with the column body is formed by the connecting pieces and the column body in a defined mode, the column body is provided with a plurality of outer supporting holes, and an inner supporting hole is formed in the center tube; andthe stable beam-column connecting structure further comprises reinforcing seats located in the center tube, and the reinforcing seat is arranged between the every two adjacent connecting joints. According to the stable beam-column connecting structure, the beam-column connecting strength and stability can be improved.

Owner:台州航权机械科技有限公司

Compact type square pipe beam column node structure and installing method thereof

InactiveCN108678162AImprove stabilityFirmly connectedBuilding constructionsUltimate tensile strengthThreaded rod

The invention provides a compact type square pipe beam column node structure and an installing method thereof, belongs to the field of steel structures and solves the problem of low connecting strength of an existing beam column. The compact type square pipe beam column node structure comprises a column body, beam bodies, a node, a plurality of external threaded rods and a plurality of internal threaded rods, wherein the column body comprises four column plates; the beam body comprises four beam plates; the node is located on the column body and comprises a grouting box located at the inner side of the column body and connecting seats located at the inner sides of the end parts of the beam bodies; four connecting seats located on four beam bodies are respectively fixed to the outer side surfaces of the four column plates; the connecting seats are formed through integrated bending of long-stripped rectangular platy steel plates; the external threaded rods and the internal threaded rodsare respectively located in external pouring cavities and internal pouring cavities. The compact type square pipe beam column node structure provided by the invention is capable of improving the connecting strength and the stability of the beam column.

Owner:XINCHANG SICHUANG DESIGN CONSULTING CO LTD

Knitted decorative painting and knitting method thereof

InactiveCN104141194AImprove efficiencyAvoid pigment aging and peeling offWeft knittingSpecial ornamental structuresPolyamideYarn

The invention discloses a knitted decorative painting and a knitting method thereof. The knitted decorative painting is formed by the way that a plurality of yarns with different colors are knitted by a computerized flat knitting machine. Patterns are formed on the front face of the knitted decorative painting through the computerized flat knitting machine in a jacquard needle method, and at least one part of yarns is polyamide yarns. The knitting method of the knitted decorative painting includes the following steps that the yarns with different colors are provided, at least one part of yarns is the polyamide yarns, and the yarns with different colors are knitted through the computerized flat knitting machine in the jacquard needle method. The knitted decorative painting is formed in a knitted mode through the computerized flat knitting machine, compared with a hand knitting mode, the efficiency is higher, the patterns of the knitted decorative painting are obtained through the yarns with different colors in a jacquard weave mode, the colors and braided fabric are integrated, the problem that the colors age and fade in a traditional printing and drawing imaging mode is solved, the technical means is innovated based on an original jacquard weave, the jacquard weave effect from two colors to sixteen colors is achieved, the painting has multiple colors, and the effect holding time is long.

Owner:SHENZHEN MI HILL IND

Advanced aluminum alloy heat-resisting grease metallic baking paint and processing method thereof

InactiveCN109439131AAvoid aging and sheddingIncreased resistance to high temperature andCoatingsChemical industryMetallic materials

The invention discloses advanced aluminum alloy heat-resisting grease metallic baking paint, made from, by weight, 10-20 parts of aluminum alloy particular powder, 15-30 parts of calcium-based heat-resisting grease, 5-10 parts of a thickener, 10-20 parts of polyethylene glycol modified amino resin, 5-10 parts of a pH neutralizer, 1-5 parts of a leveling agent, 1-5 parts of a polysiloxane defoamingagent, 1-5 parts of an emulsifier, and 1-5 parts of color paste. The calcium-based heat-resisting grease is made with calcium-soap thickened medium-viscosity petroleum from the reaction of 10-20 parts of natural fatty acids and 5-10 parts of calcium hydroxide. The invention relates to the technical field of chemical industry. The advanced aluminum alloy heat-resisting grease metallic baking paintand a processing method thereof have the advantages that the problem is well solved that existing baking paint has low resistance to high temperature and poor in impact resistance, the paint herein is well applicable to outdoor environments with strong sunlight and proneness to scratch and collision, the aging and peeling problem of the baking paint due to long-term stay in a high-temperature environment is avoided, and the high temperature resistance and impact resistance of the baking paint are improved by using the aluminum alloy metallic material.

Owner:湖北三雷德化工有限公司

Magnesian inorganic decorative integral plate

InactiveCN108252465AEasy to fixEasy to set upCovering/liningsFlooringNational standardMechanical property

The invention provides a magnesian inorganic decorative integral plate. The magnesian inorganic decorative integral plate comprises a frame body and a glass panel. A pipe-shaped handle aluminum alloyprofile is arranged on the magnesian inorganic decorative integral plate, and inlaid grooves are formed in the pipe-shaped handle aluminum alloy profile; a notch with a lintel is formed in the handlealuminum alloy profile, and two glass panels are inlaid on the two frame-shaped inlaid grooves of the frame body; a groove is formed in the pipe-shaped handle aluminum alloy profile, and an inlaid block is arranged on the pipe-shaped handle aluminum alloy profile; and inlaid feet are arranged on the inlaid block, and the inlaid block is inlaid in the inlaid grooves on the two sides of the frame body. Compared with the prior art, the magnesia inorganic decorative integral plate has the advantages that planes can form a plurality of decorative areas, and the position of a handle combined with analuminum alloy frame can adapt to the practical use. The invention further provides a flame retardant material. The adhesive property of a flame-retardant decorative plate prepared by the method canmeet the national standard, and the base material flame-retardant property can be achieved; the mechanical property of the base material is not affected, the release amount of formaldehyde is above E1level, and safety and environmental protection are achieved; and at the same time, the natural texture of wood is kept, and the decorative effect is good.

Owner:肖群伟

Angle bracket part for photovoltaic module

PendingCN110562599AEasy to get stuckFastening integration with high strengthClosuresEngineeringUltimate tensile strength

Owner:PERLIGHT SOLAR

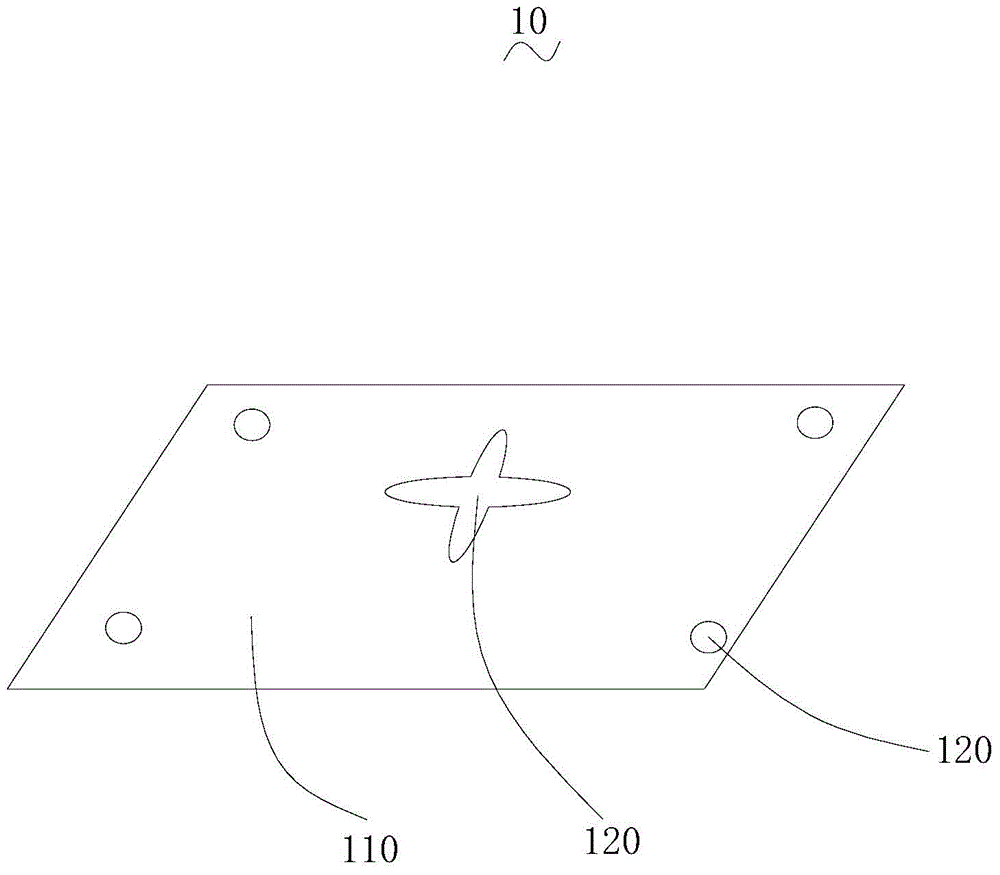

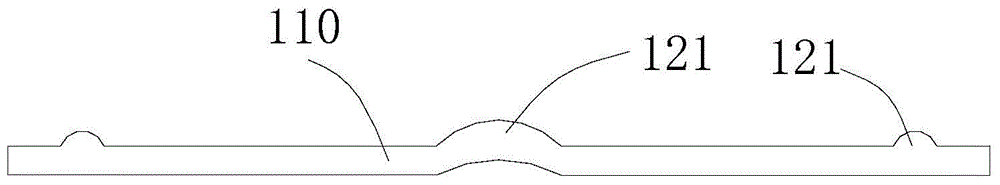

Low power condensation photovoltaic cell assembly

PendingCN108123676AAvoid aging and sheddingImprove reliabilityPhotovoltaicsPhotovoltaic energy generationCell assemblySilica gel

The invention discloses a low power condensation photovoltaic cell assembly, which comprises a silicon cell slice, a glass plate and a heat radiator, wherein the silicon cell slice and the glass plateare laminated and connected; a layer of heat conduction silica gel pad is laid on the back surface of the silicon cell slice; the heat radiator is tightly laminated and connected with the silicon cell slice through the heat conduction silica gel pad. The glass plate and the silicon cell slice are fixed through adopting a bolt tensioning mode, the structure reliability is enhanced, the phenomena of aging and shedding as a result of silica gel bonding can be avoided, the heat conduction silica gel pad enhances the heat conduction effects, the mounting is convenient, tedious steps such as required air drying in the case of silica gel bonding can be avoided, and the mounting efficiency is improved.

Owner:SHANGHAI SOLAR ENERGY S&T

Wiring method of two segments of leads on electric vehicle

InactiveCN108011274AAvoid aging and sheddingAvoid short circuitLine/current collector detailsConnection insulationElectric vehicleElectric wire

A wiring method of two segments of leads on an electric vehicle is disclosed. The wiring method is characterized in that insulation outer skins of joints of two electric wires are peeled so as to expose conductive wire cores; the conductive wire cores of the two electric wires are winded; the two joints are wrapped with an insulation tape; two insulated plastic casing pipes with 1cm to 5cm lengthssleeve the two joints; two ends of the insulated plastic casing pipes are contacted with lead insulation outer skins of two sides; and a fire source is used to heat two sides of the insulated plasticcasing pipes, and then the two sides of the insulated plastic casing pipes are pressed on the lead insulation outer skins so that the insulated plastic casing pipes and the lead insulation outer skins are stuck together. In the invention, the insulated plastic casing pipes fixedly sleeve the joints so that the insulation tape wrapping the joints is prevented from aging and falling off and a shortcircuit phenomenon caused by aging and falling off of the insulation tape at the joints is avoided.

Owner:王嘉伟

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com