Tunnel arch prefabricated segment assembling construction method

A construction method and segment assembling technology, which is applied to tunnels, tunnel linings, shaft equipment, etc., and can solve problems such as insufficient thickness, falling blocks, and non-compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Below by embodiment and in conjunction with accompanying drawing, the present invention will be further described:

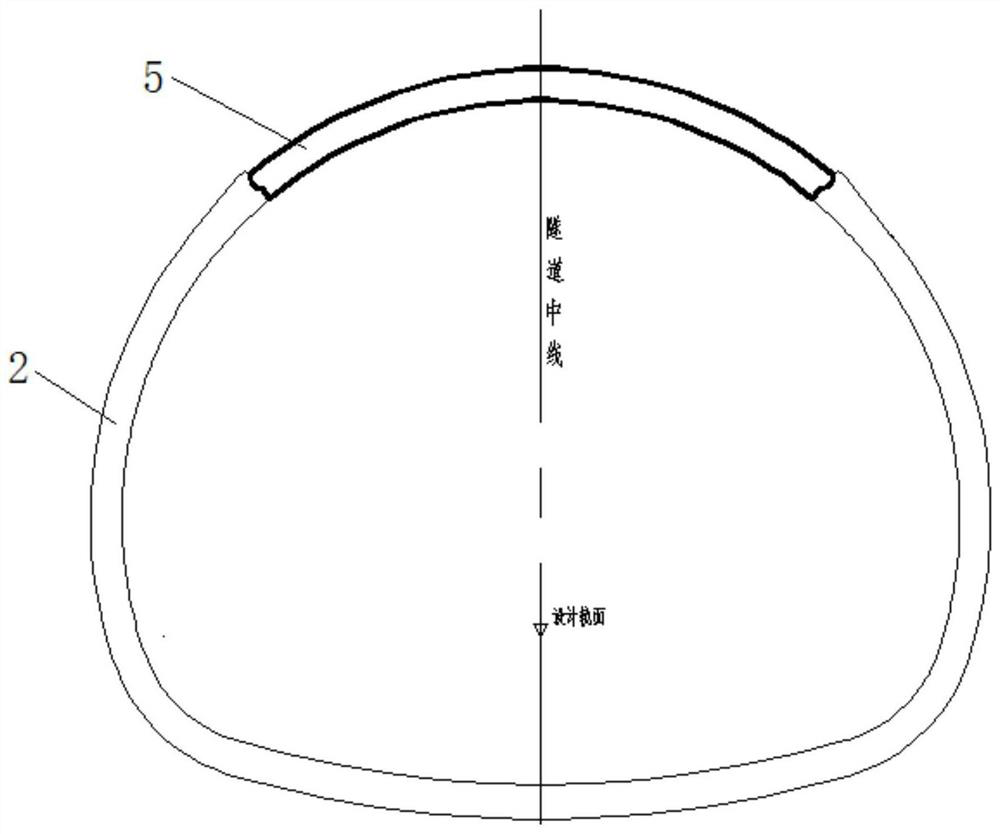

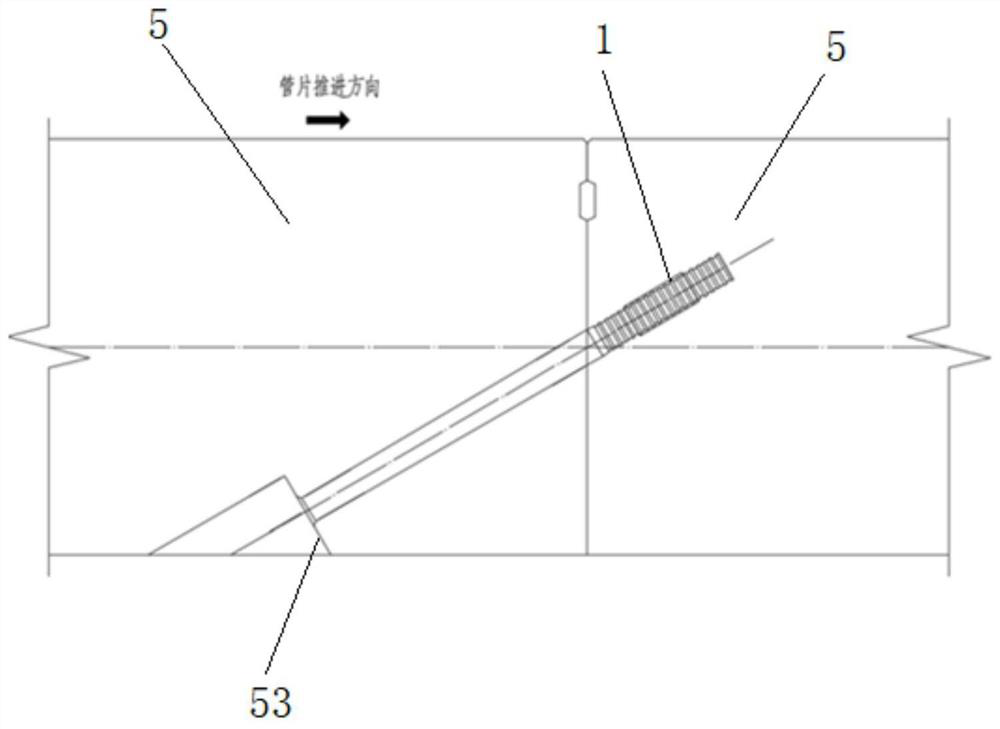

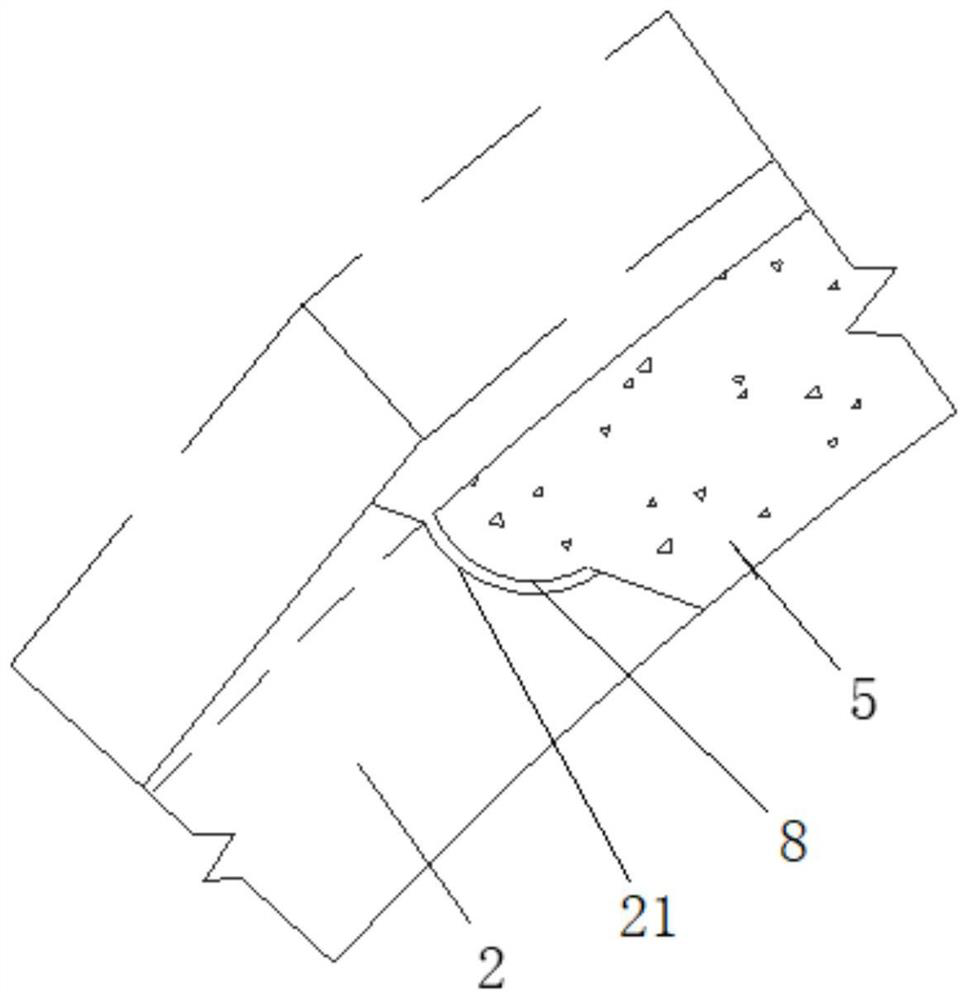

[0035] to combine figure 1 — Figure 7 As shown, a construction method for assembling prefabricated segments of a tunnel arch comprises the following steps:

[0036] Step A, performing arch prefabricated segment reinforcement cage binding construction in the prefabrication field outside the tunnel hole.

[0037] The prefabricated segment reinforcement cage in the arch is arc-shaped, and the chord length of the segment should at least cover the tunnel driving width. Preferably, the arch prefabricated segment 5 has a chord length of 8.6m and a width of 2m, and is used in a double-track railway tunnel.

[0038] The prefabricated segment reinforcement cage in the arch adopts the structural form of binding inner circumferential ribs, outer circumferential ribs, radial ribs, outer longitudinal ribs, and inner longitudinal ribs. Reinforcing bars 7 are provid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Chord length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com