Construction method for assembling lining grouting reinforcement cavity based on mining method tunnel construction

A technology for tunnel construction and grouting reinforcement, which is applied in the direction of tunnel lining, tunnel, shaft lining, etc., and can solve the problems of prefabricated segments and side wall voids, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below by embodiment and in conjunction with accompanying drawing, the present invention will be further described:

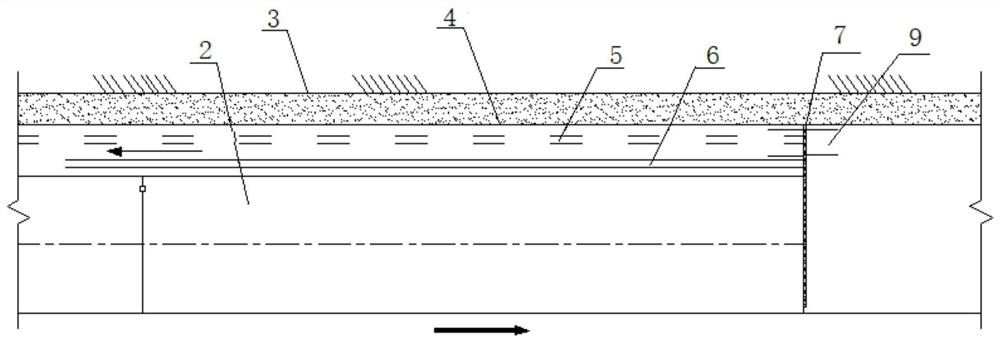

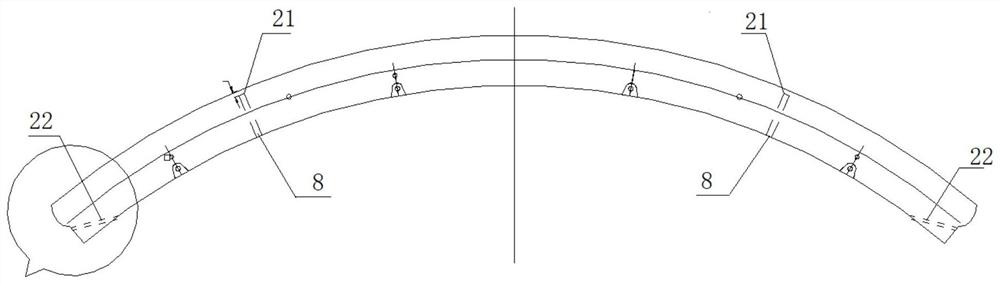

[0027] according to figure 1 — Figure 4 As shown, a construction method for the assembled lining grouting reinforcement cavity based on the mining method tunnel construction, including the following steps:

[0028] Step A. Preliminary work preparation: The side wall 1 is poured on site, and the prefabricated segments 2 are prefabricated outside the tunnel and then transported to the tunnel for group installation along the longitudinal direction.

[0029] When the prefabricated segments 2 are constructed in groups, it is best to use 5 prefabricated segments 2 as a group for the first time, then 6 prefabricated segments 2 as a group, and the last group as 7 prefabricated segments 2 Install and backfill grouting.

[0030] The prefabricated segment 2 is provided with two radial grouting holes 21 whose outer wall does not penetrate, and the two radial grou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com