Assembly type lining monitoring and measuring component embedding arrangement method

A layout method and component technology, which can be applied in shaft lining, tunnel lining, mining equipment, etc., and can solve problems such as different construction techniques

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Below by embodiment and in conjunction with accompanying drawing, the present invention will be further described:

[0032] A method for embedding and arranging assembled lining monitoring and measuring components, comprising the following steps:

[0033] Step A: Carry out the construction of the prefabricated segments of the arch in the prefabrication field outside the tunnel, and at the same time, carry out the cast-in-place construction of the left and right side walls in the tunnel.

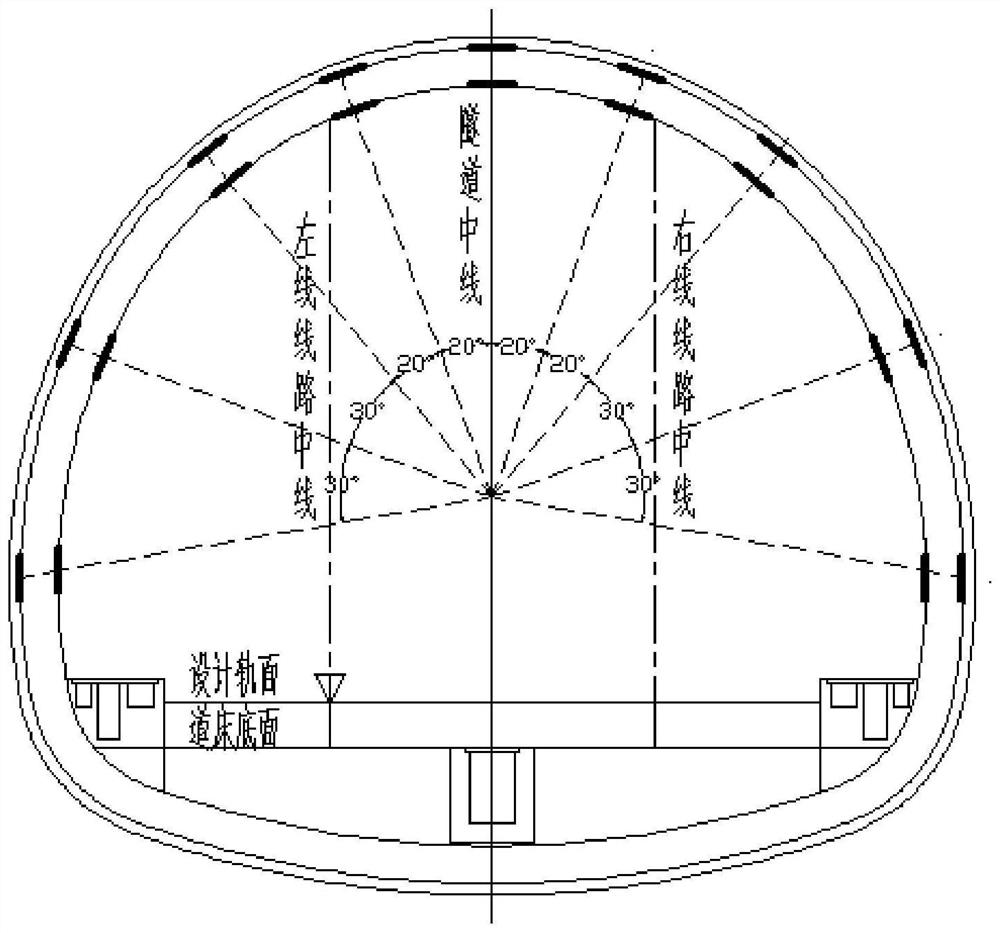

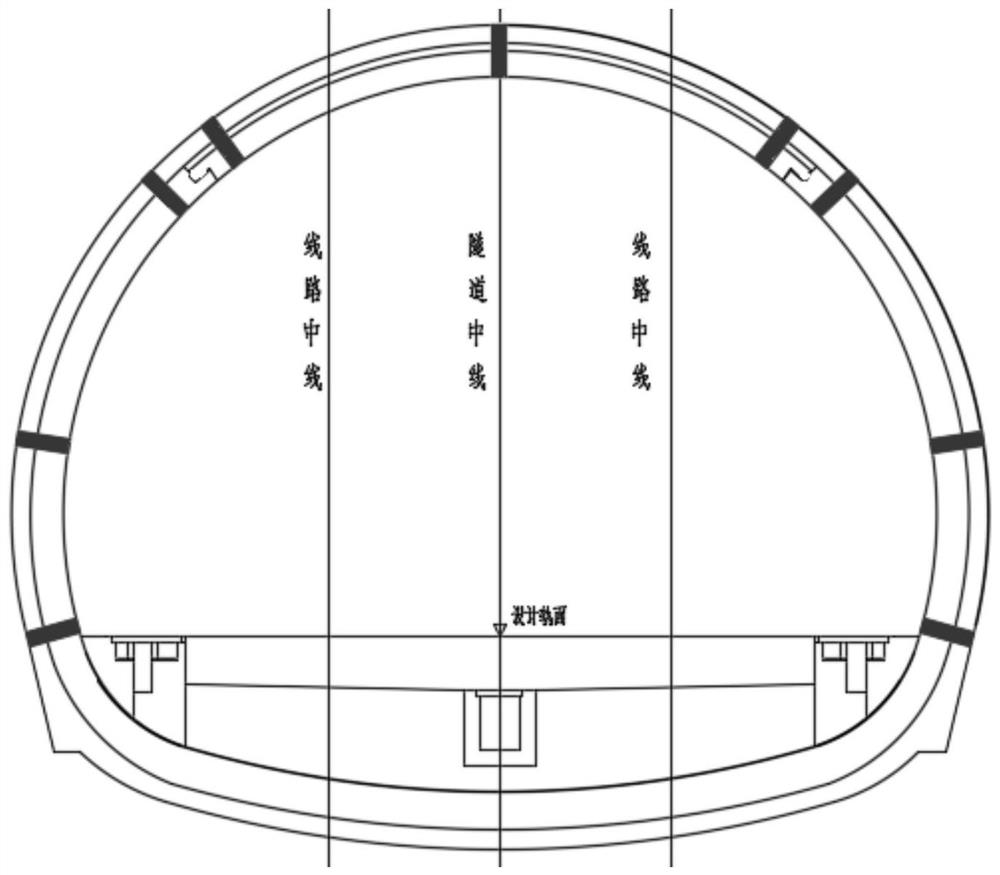

[0034] When tying up the prefabricated segment reinforcement cages in the arch and side wall reinforcement cages, arrange nine monitoring points on each measurement section. Among them, a monitoring point is arranged in the middle of the vault, a monitoring point is arranged symmetrically on both sides of each lining joint, a monitoring point is arranged in the middle of each side wall, and a monitoring point is arranged in the corner of each side wall, for example image 3 shown. Ea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com