Ceramic composite coating

A ceramic composite and ceramic coating technology, which is applied in the direction of ceramic layered products, layered products, flat products, etc., can solve the problems of easy adhesion of plastic films, quality problems of plastic films, etc., to prevent aging and falling off, and to prevent adhesion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

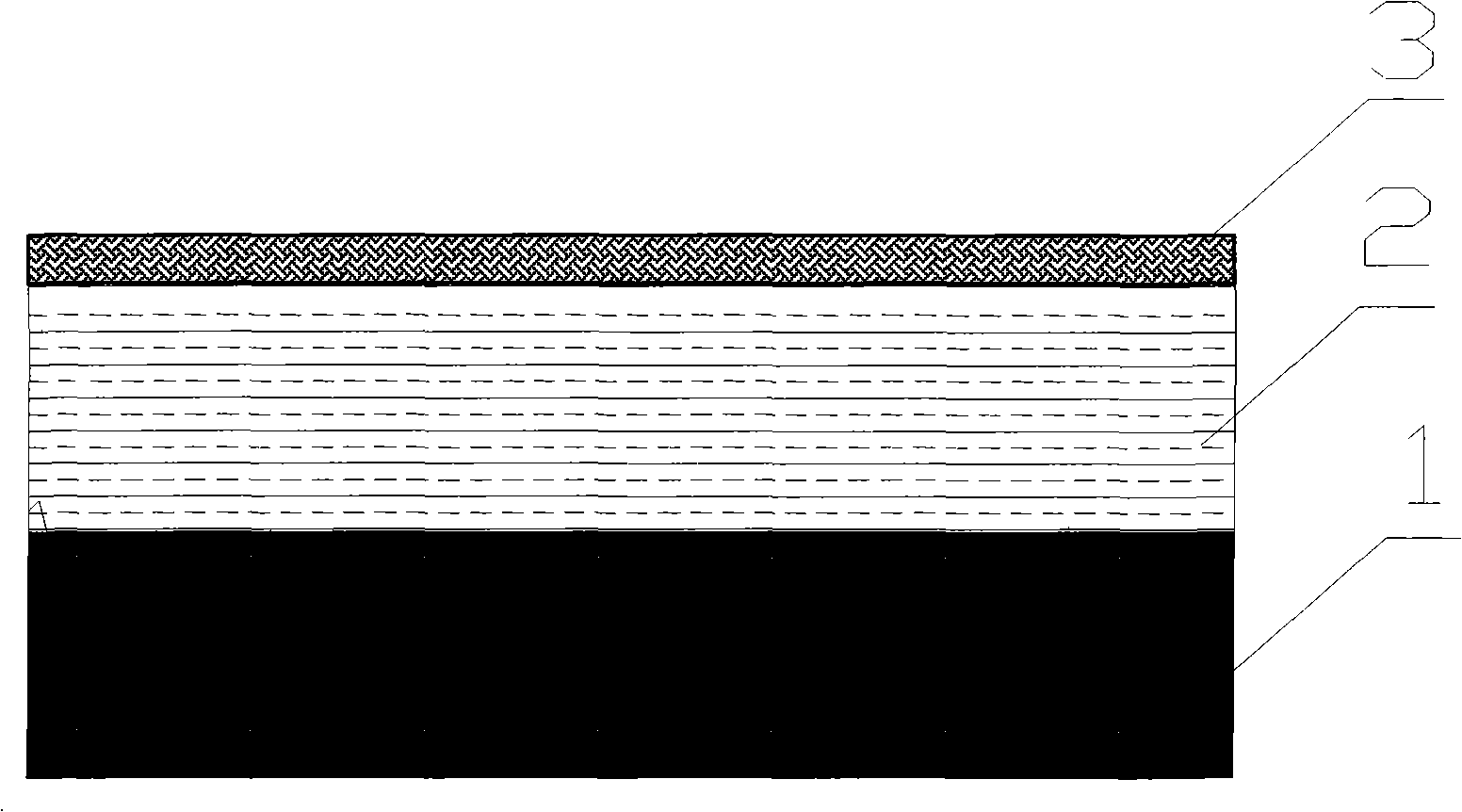

[0012] Example figure 1 Shown is first to use a kind of ceramic composite coating of the present invention, wherein the insulating ceramic bottom layer 2 is directly coated on the metal roller core 1 surface as the bottom layer of insulating high-voltage corona, and will additionally be coated with a layer of anti-sticking on it Schematic diagram of the structure of the polymer coating 3.

[0013] The porosity of the insulating ceramic bottom layer 2 of the ceramic composite coating is lower than 2%, and the thickness is greater than 0.5 mm; the thickness of the anti-adhesive polymer top layer 3 of the ceramic composite coating is less than 0.05 mm.

[0014] Compared with the traditional technology, a ceramic composite coating of the present invention, the surface of the metal roller core 1 must be thoroughly cleaned before coating, and the insulating ceramic bottom layer 2 can use thermal spraying, physical evaporation, and chemical evaporation coating methods . Coated on t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com