Roller crusher

A technology of roller crusher and crushing roller, which is applied in the direction of grain processing, etc., to achieve the effects of compact construction method, cost reduction and construction simplification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

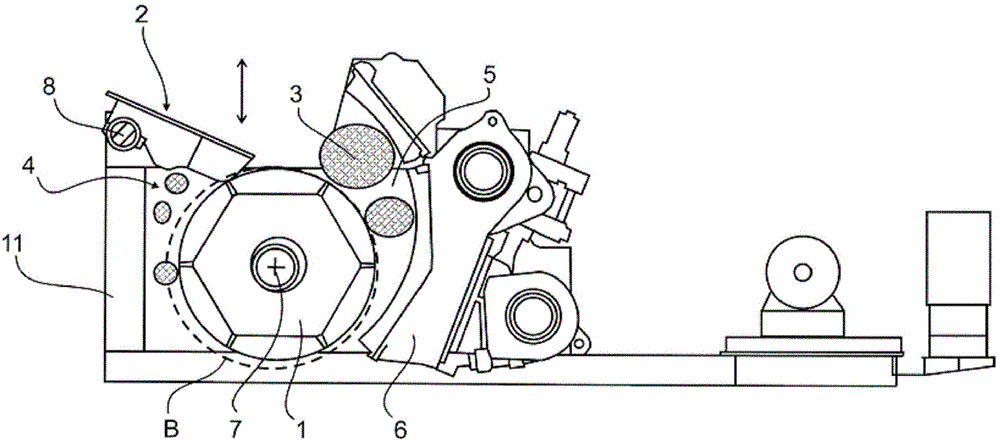

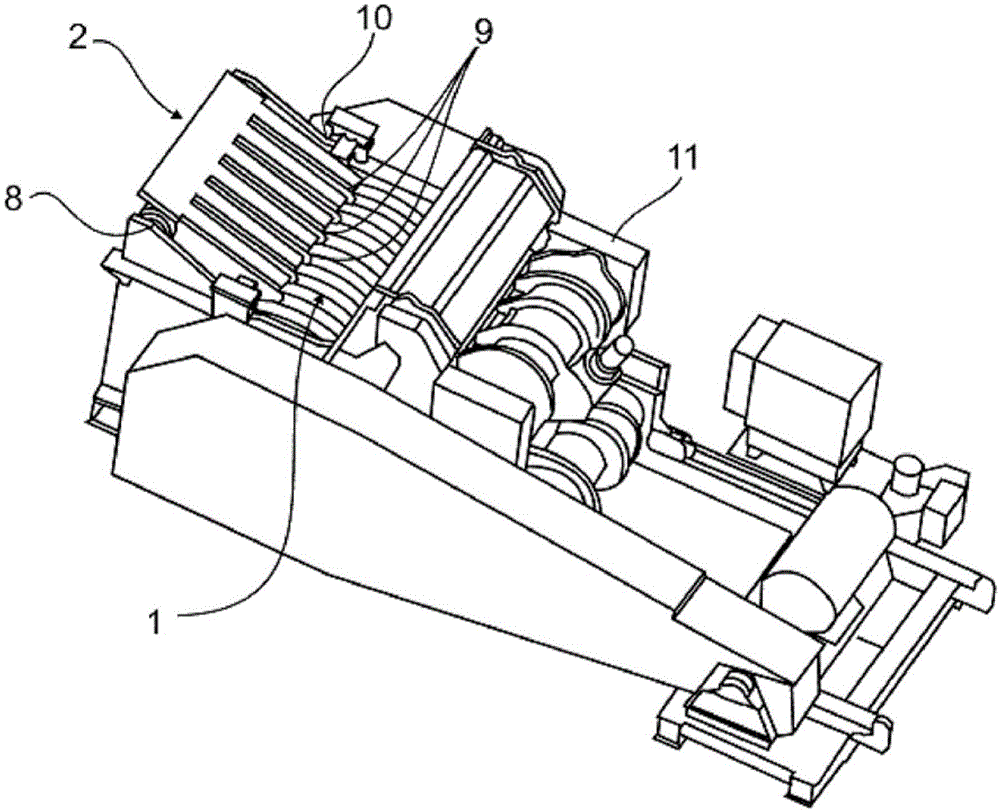

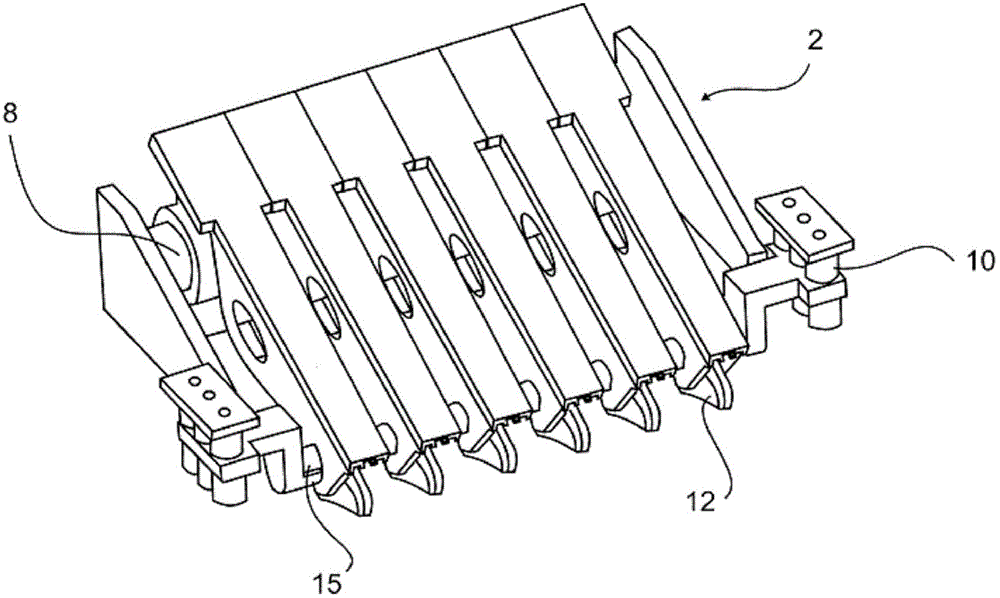

[0024] figure 1 The roll crusher is shown in longitudinal section, which is designed as an eccentric roll crusher. The roller crusher comprises a crushing roller 1 and a movable screening device 2 arranged such that it is inclined above the crushing roller 1 and provided for separating feed particles into coarse 3 and fine 4 particles. The fine particles 4 pass directly through the sieving space without further crushing, while the coarse particles 3 are fed into the roller gap 5 between the crushing roller 1 and the rocker arm 6 .

[0025] The exemplary embodiment relates to an eccentric roll crusher, wherein the crushing roll 1 is arranged eccentrically so as to be freely rotatable on a drive shaft 7 .

[0026]A circumscribed circle B is defined due to the eccentric movement of the crushing roller 1 , which reciprocates so as to oscillate in an eccentric manner. Due to the reciprocating movement, the spacing between the crushing roller 1 and the rocker 6 is also changed. W...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap