Mud-water separation device and slurry mud-water separation method

A mud-water separation and mud technology, which is applied in the sedimentation tank and other directions, can solve the problem that manual mixing and mixing cannot achieve uniform mixing, etc., and achieve the effect of improving efficiency and increasing discharge volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

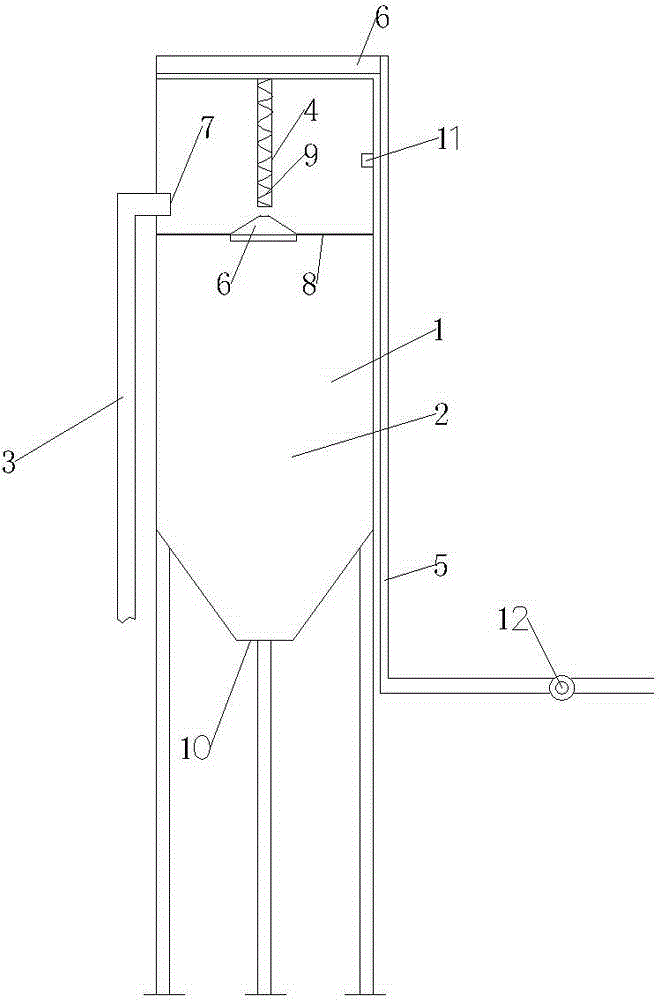

[0009] The accompanying drawings show the technical solution of the present invention and its embodiments, and the relevant details and working principles of the embodiments will be further described below in conjunction with the accompanying drawings.

[0010] refer to figure 1 As shown, the mud-water separation device provided by the present invention includes a main tank body 1, which has a cavity 2 in the main tank body 1, and the top of the main tank body 1 is connected with a drain pipe 3 leading to the cavity body 2, and the The upper end of the main tank body 1 is provided with a coiled pipe 13 that spirally surrounds. The coiled pipe 13 surrounds from the outside to the inside and connects downwards with the downlink pipe 4 at the center of the upper end of the main tank body 1. The outer end of the coiled pipe 13 is connected to the mud injection pipe. 5 conduction, the main tank body 1 is fixed with a downpipe 4 connected to the inner end of the coil 13, the end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com