Efficient dust collection workshop

A workshop and dust technology, applied in the field of dust removal workshop, can solve the problems of external air pollution, flow, affecting the health of workshop workers, etc., and achieve the effect of ensuring respiratory health.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

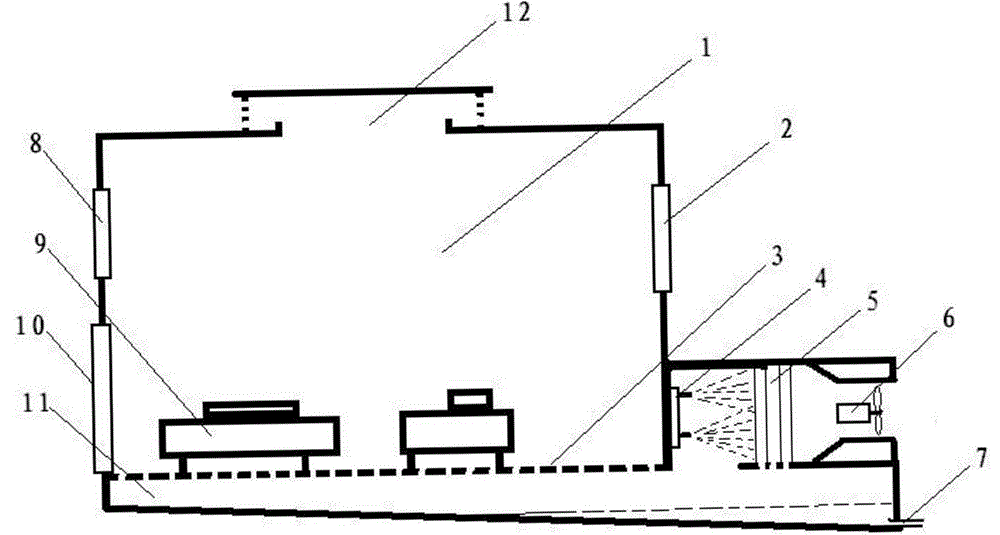

[0012] Below in conjunction with accompanying drawing, a kind of high-efficiency dedusting workshop will be further described for implementation.

[0013] figure 1 A schematic diagram showing the middle section structure of a high-efficiency dust removal workshop. figure 1 The workshop room 1 in the workshop, the ventilation channel 11 below and the dust removal device on the side of the workshop room constitute a high-efficiency dust removal workshop. The side of workshop room 1 is equipped with automatic door 10, glass window 2, preparation window 8. The automatic door 10 is conducive to being able to be opened and then automatically closed in time, and the glass window 2 and the spare window 8 are also in a closed state to ensure the top-down circulation condition of the air in the workshop room 1. There is a ventilation roof window 12 on the top of the workshop room, and the air supplement needed for air circulation in the workshop room 1 is obtained from this window. V...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com